Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

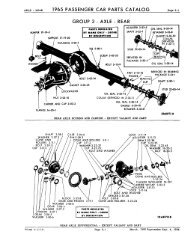

12—REAR AXLE<br />

GAUGE BLOC<br />

SP-528<br />

\<br />

SLEEVE<br />

SP-1370<br />

SLEEVE<br />

SP-V582<br />

\<br />

WRENCH<br />

SCREW<br />

SPACER SP-137:<br />

SPACER SP-2921<br />

CROSS BORS<br />

TUBE SP-561<br />

J<br />

MAIN<br />

BODY<br />

SP-526<br />

CENTRALIZING<br />

WASHER SP-534<br />

SPACER -SPACER<br />

,,SP-1730 SP-539<br />

SLEEVE SP-2920<br />

\<br />

COMPRESSION<br />

SLEEVE SP-535<br />

COMPRESSION<br />

NUT SP-533<br />

PINION LOCATING SPACER SP-2919 57x438<br />

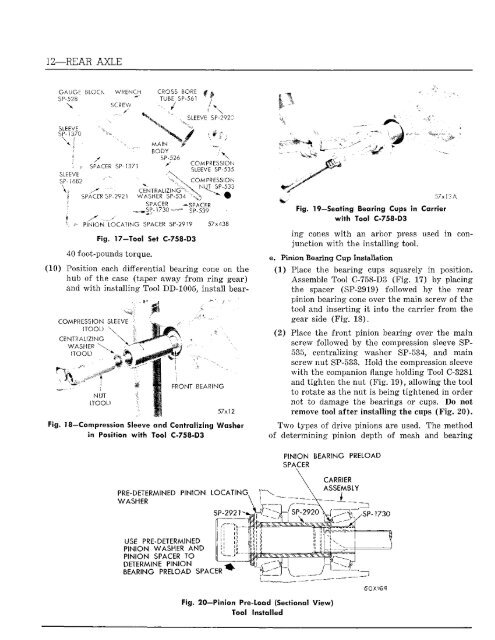

Fig. 17-Tool Set C-758-D3<br />

40 foot-pounds torque.<br />

(10) Position each differential bearing cone on the<br />

hub of the case (taper away from ring gear)<br />

and with inst<strong>all</strong>ing Tool DD-1005, inst<strong>all</strong> bear-<br />

COMPRESSION SLEEVE<br />

(TOOL) \<br />

CENTRALIZING \<br />

WASHER \<br />

(TOOL)<br />

m<br />

NUT<br />

(TOOL)<br />

X<br />

FRONT BEARING<br />

57x12<br />

Fig. 18—Compression Sleeve < 3ntralizing Washer<br />

in Position with 1 -758-D3<br />

PRE-DETERMINED PINION LOCATING,<br />

WASHER<br />

USE PRE-DETERMINED<br />

PINION WASHER AND<br />

PINION SPACER TO<br />

DETERMINE PINION<br />

BEARING PRELOAD SPACER<br />

SP-2921<br />

57x!3A<br />

Fig. 19—Seating Bearing Cups in Carrier<br />

with Tool C-758-D3<br />

ing cones with an arbor press used in conjunction<br />

with the Inst<strong>all</strong>ing tool.<br />

e. Pinion Bearing Cup Inst<strong>all</strong>ation<br />

(1) Place the bearing cups squarely in position.<br />

Assemble Tool C-758-D3 (Fig. 17) by placing<br />

the spacer (SP-2919) followed by the rear<br />

pinion bearing cone over the main screw of the<br />

tool and inserting it into the carrier from the<br />

gear side (Fig. 18).<br />

(2) Place the front pinion bearing over the main<br />

screw followed by the compression sleeve SP-<br />

535, centralizing washer SP-534, and main<br />

screw nut SP-533. Hold the compression sleeve<br />

with the companion flange holding Tool C-3281<br />

and tighten the nut (Fig. 19), <strong>all</strong>owing the tool<br />

to rotate as the nut is being tightened in order<br />

not to damage the bearings or cups. Do not<br />

remove tool after inst<strong>all</strong>ing the cups (Fig. 20).<br />

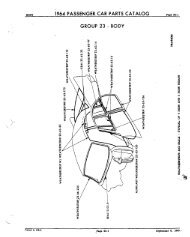

Two types of drive pinions are used. The method<br />

of determining pinion depth of mesh and bearing<br />

PINION BEARING PRELOAD<br />

SPACER<br />

Fig. 20—Pinion Pre-load (Sectional View)<br />

Tool Inst<strong>all</strong>ed<br />

CARRIER<br />

ASSEMBLY<br />

SP-1730<br />

(50X163