Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

Group 3 - Rear Axle - Copyright © jholst.net, all rights reserved.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

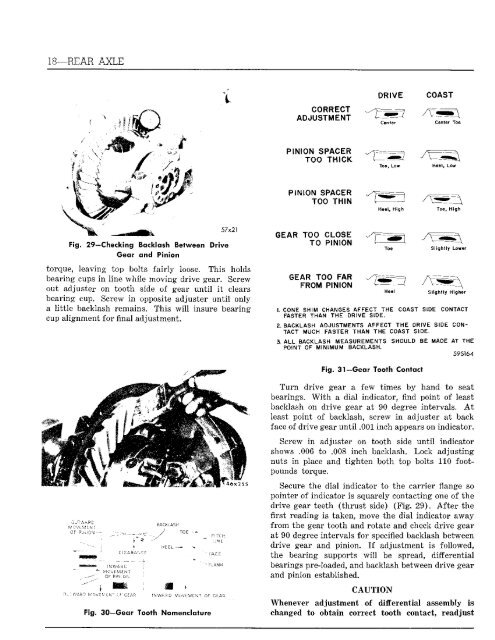

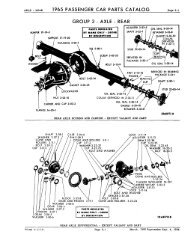

18—REAR AXLE<br />

Fig. 29—Checking Backlash Between Drive<br />

Gear and Pinion<br />

57x21<br />

torque, leaving top bolts fairly loose. This holds<br />

bearing cups in line while moving drive gear. Screw<br />

out adjuster on tooth side of gear until it clears<br />

bearing cup. Screw in opposite adjuster until only<br />

a little backlash remains. This will insure bearing<br />

cup alignment for final adjustment.<br />

C'JT'vVAPC<br />

OF PlhiGX-<br />

OF PSN.ON<br />

OUT WAS T W 07I.V ZK"<br />

CIEARAVCE<br />

• FACE<br />

- FLAN*<br />

'AWA3D MOVEMENT OF Gc.AR<br />

Fig. 30—Gear Tooth Nomenclature<br />

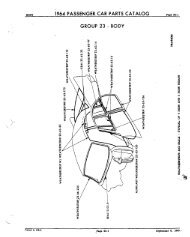

CORRECT<br />

ADJUSTMENT<br />

PINION SPACER<br />

TOO THICK<br />

PINION SPACER<br />

TOO THIN<br />

GEAR TOO CLOSE<br />

TO PINION<br />

GEAR TOO FAR<br />

FROM PINION<br />

DRIVE COAST<br />

Center<br />

Toe. Low<br />

Heel, High<br />

Heel<br />

Center Toe<br />

Toe, High<br />

Slightly Lower<br />

Slightly Higher<br />

1. CONE SHIM CHANGES AFFECT THE COAST SIDE CONTACT<br />

FASTER THAN THE DRIVE SIDE.<br />

2. BACKLASH ADJUSTMENTS AFFECT THE ORIVE SIDE CON<br />

TACT MUCH FASTER THAN THE COAST SIDE.<br />

3. ALL BACKLASH MEASUREMENTS SHOULD BE MADE AT THE<br />

POINT OF MINIMUM BACKLASH.<br />

59S164<br />

Fig 31—Gear Tooth Contact<br />

Turn drive gear a few times by hand to seat<br />

bearings. With a dial indicator, find point of least<br />

backlash on drive gear at 90 degree intervals. At<br />

least point of backlash, screw in adjuster at back<br />

face of drive gear until .001 inch appears on indicator.<br />

Screw in adjuster on tooth side until indicator<br />

shows .006 to .008 inch backlash. Lock adjusting<br />

nuts in place and tighten both top bolts 110 footpounds<br />

torque.<br />

Secure the dial indicator to the carrier flange so<br />

pointer of indicator is squarely contacting one of the<br />

drive gear teeth (thrust side) (Fig, 29). After the<br />

first reading is taken, move the dial indicator away<br />

from the gear tooth and rotate and check drive gear<br />

at 90 degree intervals for specified backlash between<br />

drive gear and pinion. If adjustment is followed,<br />

the bearing supports will be spread, differential<br />

bearings pre-loaded, and backlash between drive gear<br />

and pinion established.<br />

CAUTION<br />

Whenever adjustment of differential assembly is<br />

changed to obtain correct tooth contact, readjust