ECOLOGICAL LONG-LASTING ATTRACTIVE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TEChNICAL dATA ShEET<br />

1. Introduction<br />

1.1 General<br />

With the development of the DAUERHOLZ process, it has been possible<br />

for the first time to modify indigenous wood in such a way that it exceeds<br />

all other standard indigenous woods and even many tropical woods as<br />

regards durability and dimensional stability in outdoor applications without<br />

making any compromises in terms of strength. Full impregnation of<br />

wood with non-toxic wax through to the core ensures very good hydrophobicity<br />

(water-repellent impregnation) of the material. Combined with<br />

the low equilibrium moisture content of DAUERHOLZ, the basis of life for<br />

wood-destroying organisms (fungi, insects) is thereby eliminated.<br />

1.2 The DAUERHOLZ manufacturing process<br />

The basic material for the production of DAUERHOLZ is sawn timber from<br />

native woods, especially Scotch pine. In accordance with a preconditioning<br />

process exactly co-ordinated to the patented DAUERHOLZ process<br />

followed by drying, the wood is impregnated with a liquid wax inside<br />

an autoclave. This is followed by a defined post-conditioning process for<br />

formulating the equilibrium moisture content and consistent wax distribution<br />

inside the wood. The treated wood then runs through the usual<br />

processing steps such as sawing, planing and profiling.<br />

2. DAUERHOLZ features<br />

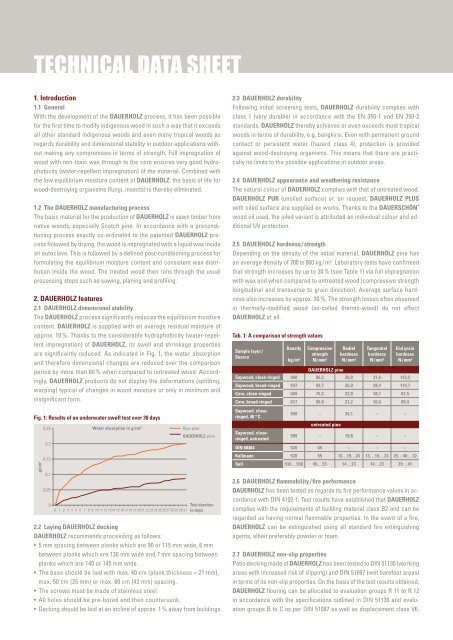

2.1 DAUERHOLZ dimensional stability<br />

The DAUERHOLZ process significantly reduces the equilibrium moisture<br />

content. DAUERHOLZ is supplied with an average residual moisture of<br />

approx. 10 %. Thanks to the considerable hydrophobicity (water-repellent<br />

impregnation) of DAUERHOLZ, its swell and shrinkage properties<br />

are significantly reduced. As indicated in Fig. 1, the water absorption<br />

and therefore dimensional changes are reduced over the comparison<br />

period by more than 60 % when compared to untreated wood. Accordingly,<br />

DAUERHOLZ products do not display the deformations (splitting,<br />

warping) typical of changes in wood moisture or only in minimum and<br />

insignificant form.<br />

Fig. 1: Results of an underwater swell test over 30 days<br />

g/cm 3<br />

0,25<br />

0,2<br />

0,15<br />

0,1<br />

0,05<br />

0<br />

Water absorption in g/cm³<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31<br />

Raw pine<br />

DAUERHOLZ-pine<br />

Test duration<br />

in days<br />

2.2 Laying DAUERHOLZ decking<br />

DAUERHOLZ recommends proceeding as follows:<br />

• 5 mm spacing between planks which are 90 or 115 mm wide, 6 mm<br />

between planks which are 130 mm wide and 7 mm spacing between<br />

planks which are 140 or 145 mm wide.<br />

• The base should be laid with max. 40 cm (plank thickness = 21 mm),<br />

max. 50 cm (25 mm) or max. 80 cm (42 mm) spacing.<br />

• The screws must be made of stainless steel.<br />

• All holes should be pre-bored and then countersunk.<br />

• Decking should be laid at an incline of approx. 1% away from buildings<br />

2.3 DAUERHOLZ durability<br />

Following initial screening tests, DAUERHOLZ durability complies with<br />

class 1 (very durable) in accordance with the EN 350-1 and EN 350-2<br />

standards. DAUERHOLZ thereby achieves or even exceeds most tropical<br />

woods in terms of durability, e.g. bangkirai. Even with permanent ground<br />

contact or persistent water (hazard class 4), protection is provided<br />

against wood-destroying organisms. This means that there are practically<br />

no limits to the possible applications in outdoor areas.<br />

2.4 DAUERHOLZ appearance and weathering resistance<br />

The natural colour of DAUERHOLZ complies with that of untreated wood.<br />

DAUERHOLZ PUR (unoiled surface) or, on request, DAUERHOLZ PLUS<br />

with oiled surface are supplied ex works. Thanks to the DAUERSCHÖN +<br />

wood oil used, the oiled variant is attributed an individual colour and additional<br />

UV protection.<br />

2.5 DAUERHOLZ hardness / strength<br />

Depending on the density of the initial material, DAUERHOLZ pine has<br />

an average density of 700 to 800 kg / m³. Laboratory tests have confirmed<br />

that strength increases by up to 30 % (see Table 1) via full impregnation<br />

with wax and when compared to untreated wood (compressive strength<br />

longitudinal and transverse to grain direction). Average surface hardness<br />

also increases by approx. 30 %. The strength losses often observed<br />

in thermally-modified wood (so-called thermo-wood) do not affect<br />

DAUERHOLZ at all.<br />

Tab. 1: A comparison of strength values<br />

Sample layer /<br />

Source<br />

Density<br />

kg / m³<br />

Compressive<br />

strength<br />

N / mm²<br />

Radial<br />

hardness<br />

N / mm²<br />

Tangential<br />

hardness<br />

N / mm²<br />

End grain<br />

hardness<br />

N / mm²<br />

Sapwood, close-ringed 960<br />

DAUERHOLZ pine<br />

86,2 39,8 31,6 143,5<br />

Sapwood, broad-ringed 937 69,7 35,0 28,4 114,7<br />

Core, close-ringed 669 75,2 22,8 18,7 87,5<br />

Core, broad-ringed 617 56,8 21,2 16,6 80,4<br />

Sapwood, closeringed,<br />

40 ° C<br />

Sapwood, closeringed,<br />

untreated<br />

949 – 34,1 – –<br />

untreated pine<br />

509 – 19,8 – –<br />

DIN 68364 520 45 – – –<br />

Kollmann 520 55 13…19…24 13…19…24 25…40…72<br />

Sell 510…550 45…55 14…23 14…23 39…41<br />

2.6 DAUERHOLZ flammability / fire performance<br />

DAUERHOLZ has been tested as regards its fire performance values in accordance<br />

with DIN 4102-1. Test results have established that DAUERHOLZ<br />

complies with the requirements of building material class B2 and can be<br />

regarded as having normal flammable properties. In the event of a fire,<br />

DAUERHOLZ can be extinguished using all standard fire extinguishing<br />

agents, albeit preferably powder or foam.<br />

2.7 DAUERHOLZ non-slip properties<br />

Patio decking made of DAUERHOLZ has been tested to DIN 51130 (working<br />

areas with increased risk of slipping) and DIN 51097 (wet barefoot areas)<br />

in terms of its non-slip properties. On the basis of the test results obtained,<br />

DAUERHOLZ flooring can be allocated to evaluation groups R 11 to R 12<br />

in accordance with the specifications outlined in DIN 51130 and evaluation<br />

groups B to C as per DIN 51097 as well as displacement class V6.