Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

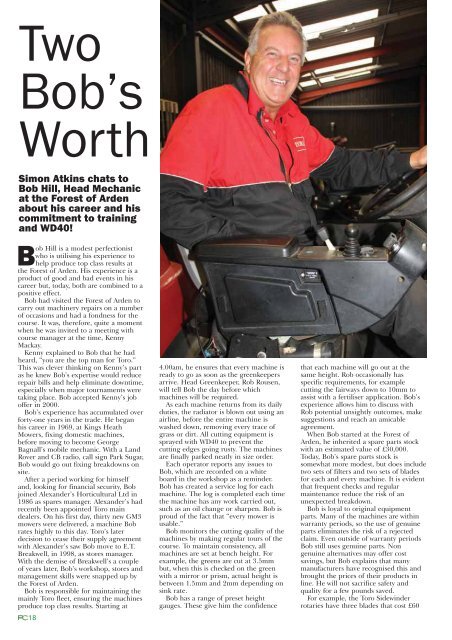

Two<br />

Bob’s<br />

Worth<br />

Simon Atkins chats to<br />

Bob Hill, Head Mechanic<br />

at the Forest of Arden<br />

about <strong>his</strong> career and <strong>his</strong><br />

commitment to training<br />

and WD40!<br />

Bob Hill is a modest perfectionist<br />

who is utilising <strong>his</strong> experience to<br />

help produce top class results at<br />

the Forest of Arden. His experience is a<br />

product of good and bad events in <strong>his</strong><br />

career but, today, both are combined to a<br />

positive effect.<br />

Bob had visited the Forest of Arden to<br />

carry out machinery repairs on a number<br />

of occasions and had a fondness for the<br />

course. It was, therefore, quite a moment<br />

when he was invited to a meeting with<br />

course manager at the time, Kenny<br />

Mackay.<br />

Kenny explained to Bob that he had<br />

heard, “you are the top man for Toro.”<br />

T<strong>his</strong> was clever thinking on Kenny’s part<br />

as he knew Bob’s expertise would reduce<br />

repair bills and help eliminate downtime,<br />

especially when major tournaments were<br />

taking place. Bob accepted Kenny’s job<br />

offer in 2000.<br />

Bob’s experience has accumulated over<br />

forty-one years in the trade. He began<br />

<strong>his</strong> career in 1969, at Kings Heath<br />

Mowers, fixing domestic machines,<br />

before moving to become George<br />

Bagnall’s mobile mechanic. With a Land<br />

Rover and CB radio, call sign Park Sugar,<br />

Bob would go out fixing breakdowns on<br />

site.<br />

After a period working for himself<br />

and, looking for financial security, Bob<br />

joined Alexander’s Horticultural Ltd in<br />

1986 as spares manager. Alexander’s had<br />

recently been appointed Toro main<br />

dealers. On <strong>his</strong> first day, thirty new GM3<br />

mowers were delivered, a machine Bob<br />

rates highly to t<strong>his</strong> day. Toro’s later<br />

decision to cease their supply agreement<br />

with Alexander’s saw Bob move to E.T.<br />

Breakwell, in 1998, as stores manager.<br />

With the demise of Breakwell’s a couple<br />

of years later, Bob’s workshop, stores and<br />

management skills were snapped up by<br />

the Forest of Arden.<br />

Bob is responsible for maintaining the<br />

mainly Toro fleet, ensuring the machines<br />

produce top class results. Starting at<br />

18<br />

4.00am, he ensures that every machine is<br />

ready to go as soon as the greenkeepers<br />

arrive. Head Greenkeeper, Rob Rousen,<br />

will tell Bob the day before which<br />

machines will be required.<br />

As each machine returns from its daily<br />

duties, the radiator is blown out using an<br />

airline, before the entire machine is<br />

washed down, removing every trace of<br />

grass or dirt. All cutting equipment is<br />

sprayed with WD40 to prevent the<br />

cutting edges going rusty. The machines<br />

are finally parked neatly in size order.<br />

Each operator reports any issues to<br />

Bob, which are recorded on a white<br />

board in the workshop as a reminder.<br />

Bob has created a service log for each<br />

machine. The log is completed each time<br />

the machine has any work carried out,<br />

such as an oil change or sharpen. Bob is<br />

proud of the fact that “every mower is<br />

usable.”<br />

Bob monitors the cutting quality of the<br />

machines by making regular tours of the<br />

course. To maintain consistency, all<br />

machines are set at bench height. For<br />

example, the greens are cut at 3.5mm<br />

but, when t<strong>his</strong> is checked on the green<br />

with a mirror or prism, actual height is<br />

between 1.5mm and 2mm depending on<br />

sink rate.<br />

Bob has a range of preset height<br />

gauges. These give him the confidence<br />

that each machine will go out at the<br />

same height. Rob occasionally has<br />

specific requirements, for example<br />

cutting the fairways down to 10mm to<br />

assist with a fertiliser application. Bob’s<br />

experience allows him to discuss with<br />

Rob potential unsightly outcomes, make<br />

suggestions and reach an amicable<br />

agreement.<br />

When Bob started at the Forest of<br />

Arden, he inherited a spare parts stock<br />

with an estimated value of £30,000.<br />

Today, Bob’s spare parts stock is<br />

somewhat more modest, but does include<br />

two sets of filters and two sets of blades<br />

for each and every machine. It is evident<br />

that frequent checks and regular<br />

maintenance reduce the risk of an<br />

unexpected breakdown.<br />

Bob is loyal to original equipment<br />

parts. Many of the machines are within<br />

warranty periods, so the use of genuine<br />

parts eliminates the risk of a rejected<br />

claim. Even outside of warranty periods<br />

Bob still uses genuine parts. Non<br />

genuine alternatives may offer cost<br />

savings, but Bob explains that many<br />

manufacturers have recognised t<strong>his</strong> and<br />

brought the prices of their products in<br />

line. He will not sacrifice safety and<br />

quality for a few pounds saved.<br />

For example, the Toro Sidewinder<br />

rotaries have three blades that cost £60