Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

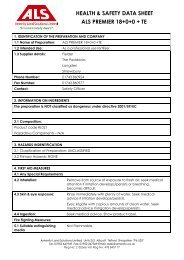

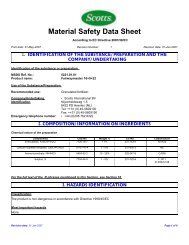

A more modest stock of parts Various bench marks for height of cut<br />

per genuine set. Bob believes fitting<br />

genuine blades ensures the machine<br />

performs correctly and, being correctly<br />

balanced, eliminates vibration. When the<br />

blades become worn they will be replaced<br />

with a new set.<br />

Bob explained that if the blades are<br />

sharpened, and a piece of metal becomes<br />

detached hitting a person and/or<br />

damaging the machine, the mechanic is<br />

responsible. Bob reminded me of the<br />

phrase, “where there is blame there is a<br />

claim.”<br />

Bob identifies the parts he requires<br />

online and is also able to check stock and<br />

price. If required, he can receive parts<br />

ordered before 2.00pm by 9.00am the<br />

next morning. He has a shortlist of<br />

suppliers that includes Abbey Mowers,<br />

Turner Groundscare, Crown Oils, and<br />

Pearmans. He restricts the number of<br />

suppliers used to help reduce the<br />

amount of administration required.<br />

All Toro machines at the Forest of<br />

Arden are replaced as part of a rolling<br />

five year programme but, even as they<br />

approach replacement, it is difficult to<br />

see the difference between new and old<br />

due to the care they receive.<br />

The other machinery is replaced<br />

following an annual consultation between<br />

Rob and Bob. Both offer their thoughts<br />

and reasoned arguments before deciding<br />

on their final choices.<br />

Indeed, t<strong>his</strong> year, Bob was adamant the<br />

sprayer should be replaced and has even<br />

sacrificed a new grinder for <strong>his</strong> workshop<br />

to secure the purchase. However,<br />

recognition of the value of the workshop<br />

is supported by the investment in a new<br />

two post ramp, able to lift three and four<br />

wheel machines, and a new heating<br />

system to keep him warm in the winter<br />

months!.<br />

Bob is passionate about Toro<br />

machinery. He believes they are the<br />

forerunners as the machines are tested<br />

for longer. However, when quizzed as to<br />

<strong>his</strong> favourite machine Bob replied “Each<br />

manufacturer has its own top products.<br />

Toro has golf equipment and John Deere<br />

has tractors.”<br />

Bob remains a little sceptical about<br />

hybrid and electric machines “You have<br />

still got an engine and hydraulics,” he<br />

said. “And battery technology, at t<strong>his</strong><br />

point in time, is still in its early stages.<br />

Some mowers are claimed to be able to<br />

cut 18 greens on a charge but, if you are<br />

double cutting, then you have 36<br />

greens.” It was to be proven if the cost<br />

comparisons between a standard<br />

machine and a hybrid machine would<br />

stack up, he says.<br />

Bob is also a solver of problems. To<br />

protect the sprayer booms and assist the<br />

operator, Bob designed and fitted a self<br />

levelling system when operators of the<br />

5410s were finding that the boxes were<br />

jumping off. He came up with a hook to<br />

restrain the boxes. His ideas and<br />

solutions for Toro machines are passed to<br />

Clive Pinnock of Lely UK, who he has<br />

known through the service side from the<br />

1980s. Once approved, these solutions<br />

are communicated to dealers throughout<br />

the UK.<br />

One of Bob’s worst experiences was an<br />

accident at work, in which <strong>his</strong> right hand<br />

was crushed between a loader ram and<br />

the loader boom. Perhaps a case of<br />

shutting the door once the horse has<br />

bolted, he has since strictly coordinated a<br />

health and safety programme. All<br />

grounds staff using any mechanical<br />

equipment receive an induction on how<br />

to operate each machine safely.<br />

Each operator has their own machine<br />

All machines are thoroughly cleaned ... ... and parked up neatly!<br />

safety log, which is similar to a driving<br />

licence, and only allows them to use a<br />

machine once it has been signed off.<br />

Every day, except Thursdays, when a full<br />

health and safety meeting is held, short<br />

refresher or tool box talks are given by<br />

Bob to ensure safety awareness is in the<br />

front of their minds. Through <strong>his</strong> own<br />

hard lesson Bob now instils putting your<br />

own safety first. He says, if in doubt, stop<br />

and complete a risk assessment and, if<br />

you are still unsure, ask!<br />

During the winter Bob runs lectures on<br />

machinery maintenance. Time spent<br />

explaining how to use, set up and service<br />

a machine can add considerably to its<br />

working life and save costly call outs to<br />

simple fixes. His training is designed to<br />

be ‘hands-on’ practical, so participants<br />

enjoy the course and leave with a sense<br />

of achievement. Bob recognises that<br />

there is a lack of knowledge within the<br />

industry and tries to encourage new<br />

mechanics to <strong>his</strong> courses.<br />

Marriott’s Spirit to Serve philosophy<br />

recognises ‘people are the most<br />

important asset’, and Bob Hill is one<br />

such asset. Whilst any championship<br />

course with 36 holes could justify its own<br />

mechanic, I have seen that the role of a<br />

mechanic can<br />

encompass so<br />

much more. In<br />

fact, you could<br />

say that Bob<br />

Hill is worth a<br />

couple of Bobs!<br />

Simon Atkins<br />

joined <strong>Pitchcare</strong><br />

as part of <strong>his</strong><br />

Guild of<br />

Agricultural<br />

Journalists/John<br />

Deere Training<br />

Award 2010<br />

19