Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Marshalling his troops - Pitchcare

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

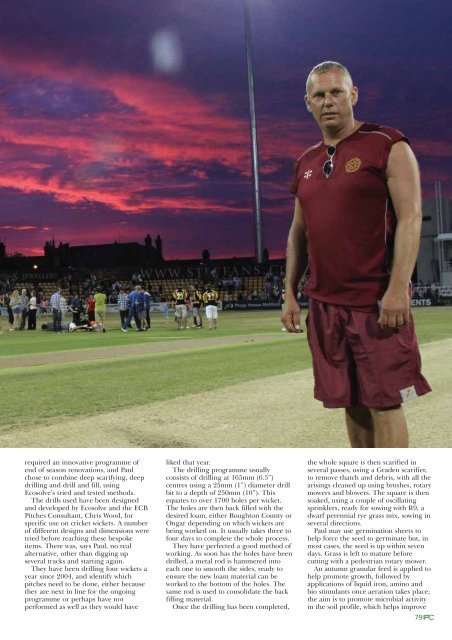

equired an innovative programme of<br />

end of season renovations, and Paul<br />

chose to combine deep scarifying, deep<br />

drilling and drill and fill, using<br />

Ecosolve’s tried and tested methods.<br />

The drills used have been designed<br />

and developed by Ecosolve and the ECB<br />

Pitches Consultant, Chris Wood, for<br />

specific use on cricket wickets. A number<br />

of different designs and dimensions were<br />

tried before reaching these bespoke<br />

items. There was, says Paul, no real<br />

alternative, other than digging up<br />

several tracks and starting again.<br />

They have been drilling four wickets a<br />

year since 2004, and identify which<br />

pitches need to be done, either because<br />

they are next in line for the ongoing<br />

programme or perhaps have not<br />

performed as well as they would have<br />

liked that year.<br />

The drilling programme usually<br />

consists of drilling at 165mm (6.5”)<br />

centres using a 25mm (1”) diameter drill<br />

bit to a depth of 250mm (10”). T<strong>his</strong><br />

equates to over 1700 holes per wicket.<br />

The holes are then back filled with the<br />

desired loam, either Boughton County or<br />

Ongar depending on which wickets are<br />

being worked on. It usually takes three to<br />

four days to complete the whole process.<br />

They have perfected a good method of<br />

working. As soon has the holes have been<br />

drilled, a metal rod is hammered into<br />

each one to smooth the sides, ready to<br />

ensure the new loam material can be<br />

worked to the bottom of the holes. The<br />

same rod is used to consolidate the back<br />

filling material.<br />

Once the drilling has been completed,<br />

the whole square is then scarified in<br />

several passes, using a Graden scarifier,<br />

to remove thatch and debris, with all the<br />

arisings cleaned up using brushes, rotary<br />

mowers and blowers. The square is then<br />

soaked, using a couple of oscillating<br />

sprinklers, ready for sowing with R9, a<br />

dwarf perennial rye grass mix, sowing in<br />

several directions.<br />

Paul may use germination sheets to<br />

help force the seed to germinate but, in<br />

most cases, the seed is up within seven<br />

days. Grass is left to mature before<br />

cutting with a pedestrian rotary mower.<br />

An autumn granular feed is applied to<br />

help promote growth, followed by<br />

applications of liquid iron, amino and<br />

bio stimulants once aeration takes place;<br />

the aim is to promote microbial activity<br />

in the soil profile, which helps improve<br />

79