OPTIMUM COLLIERIES INVESTMENT - Optimum Coal

OPTIMUM COLLIERIES INVESTMENT - Optimum Coal

OPTIMUM COLLIERIES INVESTMENT - Optimum Coal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

<strong>OPTIMUM</strong> COAL INVESTS IN SUSTAINABILITY<br />

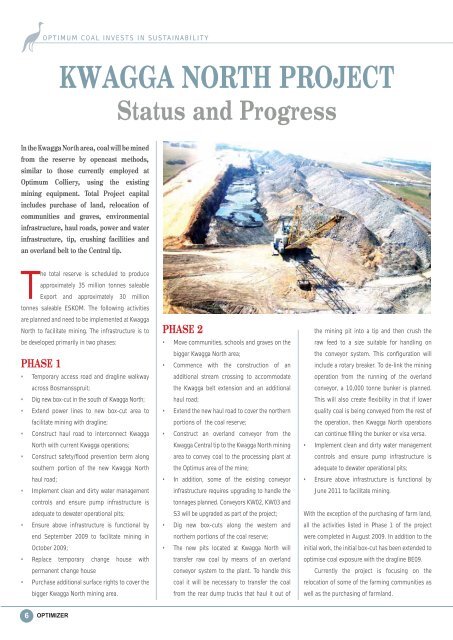

In the Kwagga North area, coal will be mined<br />

from the reserve by opencast methods,<br />

similar to those currently employed at<br />

<strong>Optimum</strong> Colliery, using the existing<br />

mining equipment. Total Project capital<br />

includes purchase of land, relocation of<br />

communities and graves, environmental<br />

infrastructure, haul roads, power and water<br />

infrastructure, tip, crushing facilities and<br />

an overland belt to the Central tip.<br />

The total reserve is scheduled to produce<br />

approximately 35 million tonnes saleable<br />

Export and approximately 30 million<br />

tonnes saleable ESKOM. The following activities<br />

are planned and need to be implemented at Kwagga<br />

North to facilitate mining. The infrastructure is to<br />

be developed primarily in two phases:<br />

PHASE 1<br />

• Temporary access road and dragline walkway<br />

across Bosmansspruit;<br />

• Dig new box-cut in the south of Kwagga North;<br />

• Extend power lines to new box-cut area to<br />

facilitate mining with dragline;<br />

• Construct haul road to interconnect Kwagga<br />

North with current Kwagga operations;<br />

• Construct safety/fl ood prevention berm along<br />

southern portion of the new Kwagga North<br />

haul road;<br />

• Implement clean and dirty water management<br />

controls and ensure pump infrastructure is<br />

adequate to dewater operational pits;<br />

• Ensure above infrastructure is functional by<br />

end September 2009 to facilitate mining in<br />

October 2009;<br />

• Replace temporary change house with<br />

•<br />

permanent change house<br />

Purchase additional surface rights to cover the<br />

bigger Kwagga North mining area.<br />

OPTIMIZER<br />

KWAGGA NORTH PROJECT<br />

Status and Progress<br />

PHASE 2<br />

• Move communities, schools and graves on the<br />

bigger Kwagga North area;<br />

• Commence with the construction of an<br />

additional stream crossing to accommodate<br />

the Kwagga belt extension and an additional<br />

haul road;<br />

• Extend the new haul road to cover the northern<br />

portions of the coal reserve;<br />

• Construct an overland conveyor from the<br />

Kwagga Central tip to the Kwagga North mining<br />

area to convey coal to the processing plant at<br />

the Optimus area of the mine;<br />

• In addition, some of the existing conveyor<br />

infrastructure requires upgrading to handle the<br />

tonnages planned. Conveyors KW02, KW03 and<br />

S3 will be upgraded as part of the project;<br />

• Dig new box-cuts along the western and<br />

northern portions of the coal reserve;<br />

• The new pits located at Kwagga North will<br />

transfer raw coal by means of an overland<br />

conveyor system to the plant. To handle this<br />

coal it will be necessary to transfer the coal<br />

from the rear dump trucks that haul it out of<br />

the mining pit into a tip and then crush the<br />

raw feed to a size suitable for handling on<br />

the conveyor system. This confi guration will<br />

include a rotary breaker. To de-link the mining<br />

operation from the running of the overland<br />

conveyor, a 10,000 tonne bunker is planned.<br />

This will also create fl exibility in that if lower<br />

quality coal is being conveyed from the rest of<br />

the operation, then Kwagga North operations<br />

can continue fi lling the bunker or visa versa.<br />

• Implement clean and dirty water management<br />

controls and ensure pump infrastructure is<br />

adequate to dewater operational pits;<br />

• Ensure above infrastructure is functional by<br />

June 2011 to facilitate mining.<br />

With the exception of the purchasing of farm land,<br />

all the activities listed in Phase 1 of the project<br />

were completed in August 2009. In addition to the<br />

initial work, the initial box-cut has been extended to<br />

optimise coal exposure with the dragline BE09.<br />

Currently the project is focusing on the<br />

relocation of some of the farming communities as<br />

well as the purchasing of farmland.