Deepwater development The ultimate frontier - Total.com

Deepwater development The ultimate frontier - Total.com

Deepwater development The ultimate frontier - Total.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

18<br />

DeePWaTer DeVeloPmenT<br />

s<br />

1<br />

2<br />

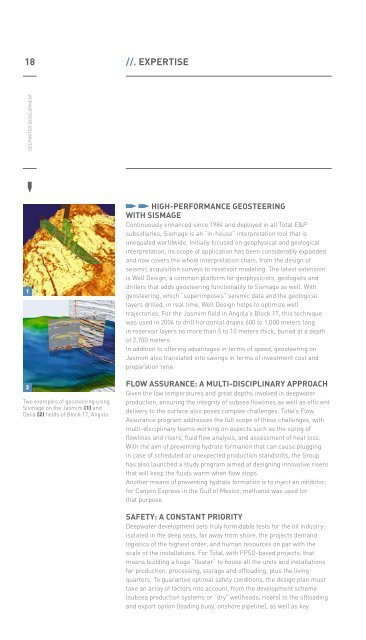

Two examples of geosteering using<br />

Sismage on the Jasmim (1) and<br />

Dalia (2) fields of Block 17, angola.<br />

//. exPertise<br />

hiGh-PerfOrMaNCe GeOsteeriNG<br />

With sisMaGe<br />

Continuously enhanced since 1984 and deployed in all <strong>Total</strong> e&P<br />

subsidiaries, Sismage is an “in-house” interpretation tool that is<br />

unequaled worldwide. initially focused on geophysical and geological<br />

interpretation, its scope of application has been considerably expanded<br />

and now covers the whole interpretation chain, from the design of<br />

seismic acquisition surveys to reservoir modeling. <strong>The</strong> latest extension<br />

is Well Design, a <strong>com</strong>mon platform for geophysicists, geologists and<br />

drillers that adds geosteering functionality to Sismage as well. With<br />

geosteering, which “superimposes” seismic data and the geological<br />

layers drilled, in real time, Well Design helps to optimize well<br />

trajectories. for the Jasmim field in angola’s Block 17, this technique<br />

was used in 2004 to drill horizontal drains 600 to 1,000 meters long<br />

in reservoir layers no more than 5 to 10 meters thick, buried at a depth<br />

of 2,700 meters.<br />

in addition to offering advantages in terms of speed, geosteering on<br />

Jasmim also translated into savings in terms of investment cost and<br />

preparation time.<br />

fLOW assuraNCe: a MuLti-disCiPLiNary aPPrOaCh<br />

Given the low temperatures and great depths involved in deepwater<br />

production, ensuring the integrity of subsea flowlines as well as efficient<br />

delivery to the surface also poses <strong>com</strong>plex challenges. <strong>Total</strong>’s flow<br />

assurance program addresses the full scope of these challenges, with<br />

multi-disciplinary teams working on aspects such as the sizing of<br />

flowlines and risers, fluid flow analysis, and assessment of heat loss.<br />

With the aim of preventing hydrate formation that can cause plugging<br />

in case of scheduled or unexpected production standstills, the Group<br />

has also launched a study program aimed at designing innovative risers<br />

that will keep the fluids warm when flow stops.<br />

another means of preventing hydrate formation is to inject an inhibitor:<br />

for Canyon express in the Gulf of mexico, methanol was used for<br />

that purpose.<br />

safety: a CONstaNt PriOrity<br />

<strong>Deepwater</strong> <strong>development</strong> sets truly formidable tests for the oil industry:<br />

isolated in the deep seas, far away from shore, the projects demand<br />

logistics of the highest order, and human resources on par with the<br />

scale of the installations. for <strong>Total</strong>, with fPSo-based projects, that<br />

means building a huge “floater” to house all the units and installations<br />

for production, processing, storage and offloading, plus the living<br />

quarters. To guarantee optimal safety conditions, the design plan must<br />

take an array of factors into account, from the <strong>development</strong> scheme<br />

(subsea production systems or “dry” wellheads, risers) to the offloading<br />

and export option (loading buoy, onshore pipeline), as well as key