Spur gears steel, milled - Nozag AG

Spur gears steel, milled - Nozag AG

Spur gears steel, milled - Nozag AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20.5<br />

Mounting and further machining for spur <strong>gears</strong><br />

Recommendations for mounting and further machining<br />

Choice of spur <strong>gears</strong><br />

If a low noise spur gear drive is needed, then the toothing should posses a high overlap rate, this means the pinion should have at least 25<br />

teeth. Pinions with down to 10 teeth can be used by manual operation or drives with low circumferential speed.<br />

Quality<br />

The quality of toothing to the spur <strong>gears</strong> in our catalog is 8f to DIN 3962/3963/3967.<br />

Material<br />

Standard spur <strong>gears</strong> are available in different materials; the material is shown on the data sheets in this catalog. <strong>Spur</strong> <strong>gears</strong> made of ETG100<br />

can be carbonitrided for higher requirements. <strong>Spur</strong> <strong>gears</strong> made of heat treatable <strong>steel</strong> C45; tensile strength 60 kp/mm 2 in non treated state.<br />

For higher strength, the toothing can be flame- or induction- hardened.<br />

Hardening temperature: 820 - 860°C quenching medium: oil Tempering temperature: 560–670°C<br />

Machining<br />

All standard spur <strong>gears</strong> are on stock with a bore tolerance of H7, except <strong>gears</strong> made of plastic. If further machining is needed in the bore or<br />

hub, then it is advisable to clamp on the external diameter.<br />

Mounting advice<br />

The centre distances are standardised to DIN 3964. The following guidelines apply for standard spur <strong>gears</strong>:<br />

+/- 0,03 for centre distances up to 40 mm,<br />

+/- 0.04 « « up to 100 mm,<br />

+/- 0,05 « « up to 250 mm,<br />

+/- 0,07 for larger distances<br />

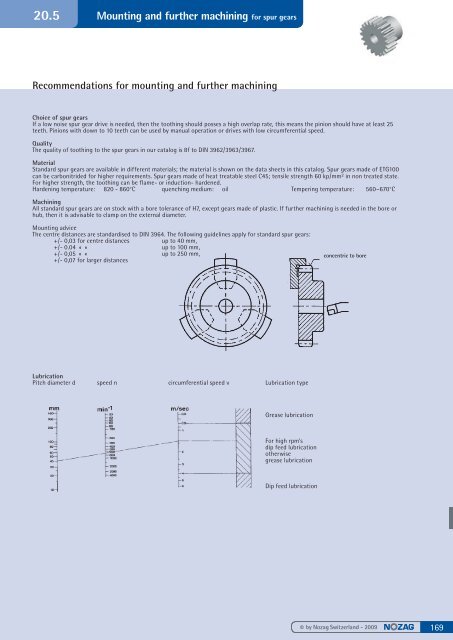

Lubrication<br />

Pitch diameter d speed n circumferential speed v Lubrication type<br />

Grease lubrication<br />

For high rpm’s<br />

dip feed lubrication<br />

otherwise<br />

grease lubrication<br />

Dip feed lubrication<br />

concentric to bore<br />

© by <strong>Nozag</strong> Switzerland - 2009 © 169<br />

by <strong>Nozag</strong> Switzerland - 2009 169