- Page 1 and 2:

STANDARD PROGRAM www.nozag.ch

- Page 3 and 4:

Overview of further product range 1

- Page 5 and 6:

Contents 1. Spur gears 005 2. Inter

- Page 7 and 8:

1. Spur gears Natural size, scale =

- Page 9 and 10:

1.1 Spur gears steel, milled Up to

- Page 11 and 12:

1.1 Up to Ø 65mm made of High stre

- Page 13 and 14:

1.1 Up to Ø 65mm made of High stre

- Page 15 and 16:

1.1 Up to Ø 65mm made of High stre

- Page 17 and 18:

1.1 Spur gears steel, milled Up to

- Page 19 and 20:

1.1 Up to Ø 65mm made of High stre

- Page 21 and 22:

1.1 Spur gears steel, milled Up to

- Page 23 and 24:

1.1 Up to Ø 65mm made of High stre

- Page 25 and 26:

1.1 Made of heat-treatable steel C4

- Page 27 and 28:

1.3 Made of case hardened steel 16M

- Page 29 and 30:

1.3 Made of case hardening steel 16

- Page 31 and 32:

1.4 Made of brass MS58 - straight t

- Page 33 and 34:

1.5 Made of Plastic PA 12 G, core i

- Page 35 and 36:

1.5 Made of plastic POM - straight

- Page 37 and 38:

1.5 Made of plastic POM - straight

- Page 39 and 40:

1.5 Made of plastic Hostaform C inj

- Page 41 and 42:

1.5 Made of plastic Hostaform C inj

- Page 43 and 44:

1.5 Made of laminated fabric PF CC

- Page 45 and 46:

2.1 Up to Ø 65mm made of high stre

- Page 47 and 48:

3.1 Up to Ø 65mm made of high stre

- Page 49 and 50:

3.1 Up to Ø 65mm made of high stre

- Page 51 and 52:

3.1 Up to Ø 65mm made of high stre

- Page 53 and 54:

3.2 Made of steel 42CrMo4, 1.7227 -

- Page 55 and 56:

3.3 Made of brass MS58 - straight t

- Page 57 and 58:

3.4 Made of plastic Hostaform C inj

- Page 59 and 60:

4.2 Made of brass CuSn12Pb, one sta

- Page 61 and 62:

4.2 Made of brass CuSn12Pb, one sta

- Page 63 and 64:

5.1 Worms, right-handed made of ste

- Page 65 and 66:

5.1 Worms, right-handed made of ste

- Page 67 and 68:

5.1 Worms, right-handed made of ste

- Page 69 and 70:

5.2 Worm gear units for high capaci

- Page 71 and 72:

6.0 Racks Standard racks or from dr

- Page 73 and 74:

6.1 Made of steel C45 or St37, stra

- Page 75 and 76:

6.3 Made of high quality, specially

- Page 77 and 78:

6.5 Made of high strength special s

- Page 79 and 80:

6.7 Made of stainless steel 1.4305,

- Page 81 and 82:

7.1 Made of case hardening steel 16

- Page 83 and 84:

8.1 Trapezoid threaded screws Made

- Page 85 and 86:

8.2 Trapezoid threaded nuts Flange

- Page 87 and 88:

8.2 Hexagonal steel nuts Trapezoid

- Page 89 and 90:

8.2 Safety nut MSZ-..-SIFA Part No.

- Page 91 and 92:

9. Splined shafts and sleeves Splin

- Page 93 and 94:

10. Product range Chains Standard >

- Page 95 and 96:

10. Chains D Z Chains (Delta-Z) ®

- Page 97 and 98:

© by Nozag Switzerland - 2009 095

- Page 99 and 100:

10. Full size scale = 1:1 03-1 04-1

- Page 101 and 102:

10.1 European design according to I

- Page 103 and 104:

10.2 European design according to I

- Page 105 and 106:

10.3 European design according to I

- Page 107 and 108:

10.5 European design according to I

- Page 109 and 110:

10.7 Light series LL and heavy seri

- Page 111 and 112:

10.8 For Roller chains according to

- Page 113 and 114:

10.10 p p 1 l 1 End connection link

- Page 115 and 116:

11. Chain mounting accessories Chai

- Page 117 and 118:

12.1 Sprockets Made of steel C43, c

- Page 119 and 120:

12.1 Sprockets Made of steel C43, c

- Page 121 and 122:

12.1 Sprockets Made of steel C43, c

- Page 123 and 124: 12 .1 Sprockets Made of steel C43,

- Page 125 and 126: 12.1 Sprockets Made of steel C43, c

- Page 127 and 128: 12.1 Sprockets Made of steel C43, c

- Page 129 and 130: 12.1 Sprockets Made of steel C43, c

- Page 131 and 132: 12.1 Sprockets Made of steel C43, c

- Page 133 and 134: 12.1 da da dad d B1 B 1 Sprockets M

- Page 135 and 136: 12.1 Sprockets Made of steel C43, c

- Page 137 and 138: 12.1 Sprockets Made of steel C43, c

- Page 139 and 140: 11.1 Sprockets Made of steel C43, c

- Page 141 and 142: 12.3 Made of plastic injection moul

- Page 143 and 144: 13. For spur gears and plate wheels

- Page 145: 15. With maintenance free rubber sp

- Page 148 and 149: 17. With / without pilot hole a d 1

- Page 150 and 151: 18. Friction Coupling 148 A C H Eig

- Page 152 and 153: 19. 150 Hardened and ground precisi

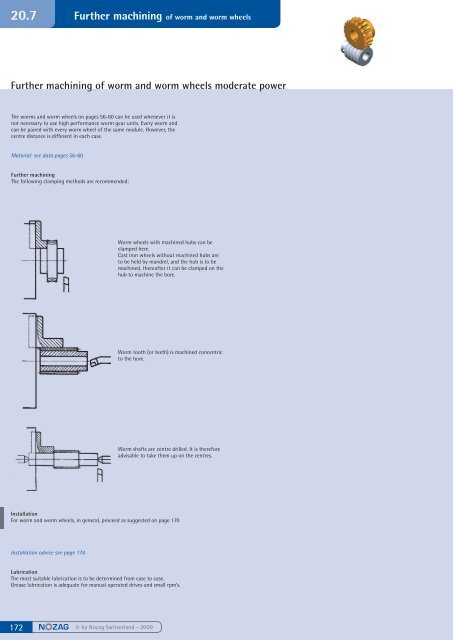

- Page 154 and 155: 20. Calculations Spur gears charts

- Page 156 and 157: 20.1 Calculations 1. Introduction T

- Page 158 and 159: 20.2 Load chartes Spur gears Sg....

- Page 160 and 161: 20.2 Load chart Spur gears Sg......

- Page 162 and 163: 20.2 Load chart Spur gears PGST....

- Page 164 and 165: 22.3 20.3 Load chart Bevel gears St

- Page 166 and 167: 20.4 Load table 164 Load charts for

- Page 168 and 169: 20.4 Load table * At maximum root s

- Page 170 and 171: 20.4 Load table * At maximum root s

- Page 172 and 173: 20.6 170 Mounting advice for bevel

- Page 176 and 177: 20.8 174 Installation advice worm g

- Page 178 and 179: 21. 176 Technical data for trapezoi

- Page 180 and 181: 21. 178 Technical data for trapezoi

- Page 182 and 183: 22. 180 Factors f 1 and f 2 Depende

- Page 184 and 185: 22. 182 z 2 - z 1 (z 2 - z 1 ) 2 2

- Page 186 and 187: 22. 8. Chain length 184 x = number

- Page 188 and 189: 22. For the mounting of chain drive

- Page 190 and 191: 22. Shorten by 1 link Note to order

- Page 192 and 193: 23. 190 General terms and condition

- Page 194 and 195: 25. 192 Documentation GETRIEBEMOTOR

- Page 196: Subsidiaries Representations > > >