Spatial Analyzer - VMT GmbH

Spatial Analyzer - VMT GmbH

Spatial Analyzer - VMT GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

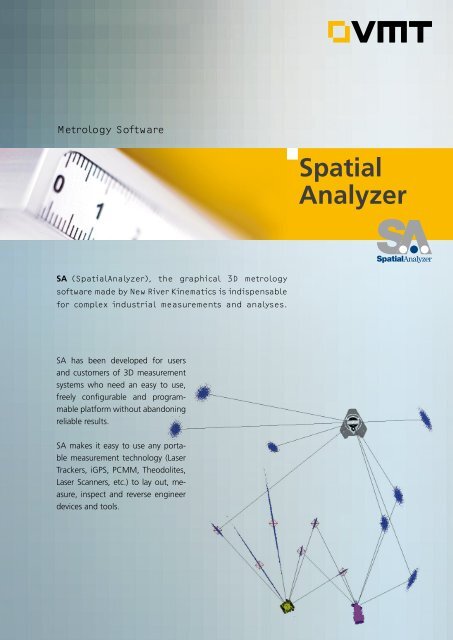

Metrology Software<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>), the graphical 3D metrology<br />

software made by New River Kinematics is indispensable<br />

for complex industrial measurements and analyses.<br />

SA has been developed for users<br />

and customers of 3D measurement<br />

systems who need an easy to use,<br />

freely configurable and program-<br />

mable platform without abandoning<br />

reliable results.<br />

SA makes it easy to use any porta-<br />

ble measurement technology (Laser<br />

Trackers, iGPS, PCMM, Theodolites,<br />

Laser Scanners, etc.) to lay out, me-<br />

asure, inspect and reverse engineer<br />

devices and tools.<br />

<strong>Spatial</strong><br />

<strong>Analyzer</strong>

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Product Description<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>) is a traceable, graphical 3D metrology soft-<br />

ware platform that can communicate simultaneously with virtually<br />

all of the different types of 3D measurement systems, which makes<br />

complex analyses very simple.<br />

SA offers a complete suite of meticulously<br />

tested and user-friendly alignment and<br />

transformation tools and a wide variety of<br />

advanced technologies for analysis, precision<br />

and computation, including GD+T.<br />

SA provides an integrated, easy to use interface<br />

for each of the portable measurement<br />

technologies – e.g. for all types of<br />

Laser Trackers (Leica, Faro, SMX and API).<br />

The open system architecture makes it<br />

simple to connect all of the instrument interfaces<br />

with TCP/IP.<br />

To guarantee your quality assurance<br />

SA offers:<br />

› Maintenance of essential data<br />

› Storage of original observations<br />

› Measurement traceability<br />

SA‘s graphical user interface enables you<br />

to open CAD models (e.g. CATIA), convert<br />

them and then perform all of the neces-<br />

sary measurements and analysis right there<br />

in the production facility.<br />

Sharing results is easy because precision<br />

analysis and reporting formats are compat-<br />

ible with web browsers.<br />

With SA sophisticated applications can be<br />

implemented in every industry with large<br />

scale production.<br />

SA delivers solutions that completely integrate<br />

portable measurement systems with<br />

3D real time inspections, assemblies and<br />

reverse engineering.

) ) )<br />

All instrument interfaces communicate<br />

with the SA via an internal<br />

TCP/IP network<br />

) ) )<br />

) ) )<br />

) ) )<br />

Instrument interface connections<br />

will be handled by standard specifications<br />

(TCP/IP, NetBEUI, USB,<br />

RS 3 )<br />

SA collects the measurement<br />

data, controls the instruments<br />

and performs the analyses and<br />

reporting<br />

Each computer in the network can<br />

be used as a REMOTE MONITOR for<br />

observing a work session<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Industrial Measurement<br />

3

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Module Overview<br />

SA’s modular design allows you to easily integrate what‘s<br />

necessary and leave out what’s not.<br />

SA Base<br />

Primary functionality for<br />

measurement, construction<br />

and analysis<br />

› Basic module for traceable<br />

metrology<br />

› User friendly graphical interface<br />

› ASCII import and export<br />

function<br />

› Advanced technologies for<br />

analysis, precision and computation<br />

› Multitude of tools for edit,<br />

visualization, construct and<br />

analysis<br />

› Measurement planning using<br />

simulations with the expected<br />

precision<br />

› Integrated, user specific reporting<br />

with MS Office, HTML, AVI-<br />

Movies, Callouts …<br />

› Work with several different<br />

instruments simultaneously<br />

SA Relationship Fitting<br />

A completely new type of<br />

feature based, spatial<br />

transformation capability<br />

› Transformations are calculated<br />

based on individually weighted rela-<br />

tionships. All objects can be involved<br />

in several different relationships.<br />

› Classic optimization:<br />

Point to Point<br />

Point to Surface<br />

› Relationship optimization:<br />

Points to Objects<br />

Objects to Objects<br />

Point Group to Point Group<br />

Point Clouds to Objects<br />

Point Groups to Objects<br />

Frame to Frame<br />

…<br />

› Perfect for Measurement against<br />

CAD and Coordinate Comparison<br />

› Relationship transformations<br />

reduce preparation, set up and<br />

working time to a minimum<br />

SA Standard CAD Exchange<br />

Module for the exchange of<br />

standard CAD formats<br />

› IGES › STEP › VDA › SAT › etc.<br />

SA USMN<br />

Unified <strong>Spatial</strong> Metrology Network<br />

(USMN) brings answers to<br />

your measurement uncertainty<br />

issues in an easy to use and<br />

understandable environment<br />

› Different weighting for observation<br />

points and instruments<br />

› Weighted solution<br />

› Considers Instrument uncertainties<br />

› DOF freely definable<br />

› Using Scale Bars<br />

› Calculate point uncertainties<br />

› Simulation of measuring tasks

SA Trans Track<br />

Extended capability for meas-<br />

urement synchronization and<br />

6D operations in real time<br />

› Trans Track uses the data from various<br />

measurement systems to track for<br />

example an assembly in real time<br />

› Assembly automation<br />

› 6D control and analysis in real time<br />

› Applications (e.g. 6D machine control,<br />

measurement synchronization with<br />

multiple systems)<br />

SA GD+T with Feature Check<br />

Perfect solution for the high<br />

demands on Geometric Dimen-<br />

sioning and Tolerancing<br />

› Well developed toolbar for construction,<br />

checking and editing for Geometric<br />

Dimensioning and Tolerancing (GD+T)<br />

› Manual and guided Inspection mode<br />

› User friendly interface for quick and<br />

easy inspection<br />

› GD+T direct importing<br />

SA Measurement Plan<br />

Advanced programming language<br />

for automated measurement,<br />

analysis, reporting and archival<br />

processes<br />

› Easy to manage script programming<br />

controlled by the user interface<br />

› Automated with logical conjunctions<br />

and loops<br />

› Access to all standard SA functions<br />

› Data exchange with third party<br />

programs<br />

› Script editor for step-by-step imple-<br />

mentation, control and editing<br />

› Once a plan is generated, it can be used<br />

with any other SA instrument interface<br />

SA Reverse Design<br />

Complete solution for analysis<br />

and parameter recognition of<br />

extended point clouds<br />

› Comprehensive reverse design<br />

process<br />

› Quick triangle alignment<br />

› Feature extraction from point clouds<br />

(surfaces, regular geometries, STL,<br />

etc.)<br />

› Feature-based alignment to CAD<br />

data<br />

› Programmable data collection,<br />

thinning, filtering and feature<br />

extraction<br />

Additional Modules:<br />

Direct Import Modules<br />

Direct way to import native files<br />

› Catia V (includes GD+T)<br />

› Catia V<br />

› Catia CGR<br />

› ProEngineer<br />

› SolidWorks<br />

› UniGraphics<br />

Robot Calibration<br />

Universal Robot Calibration.<br />

Optimized performed for<br />

customized solutions.<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Industrial Measurement

6<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Instrument Interfaces<br />

Separate applications responsible for connecting, configuring,<br />

controlling and collecting all available data from the instruments.<br />

The interface connects to the instrument and establishes a net-<br />

work session with SA. Since the connection with SA is a network<br />

session (TCP/IP) any number of interfaces can run simultaneously<br />

and from any computer on the network. Same Interface for the<br />

same type of instruments.<br />

Convenient interfaces to over 80<br />

different instruments:<br />

› Theodolite, Total Station (e.g. Leica, Sokkia, Zeiss)<br />

› PCMM (e.g. CimCore, Faro, Krypton, Metris)<br />

› Laser Tracker (e.g. API, Faro, Leica)<br />

› Scanner and other similar instruments<br />

(e.g. Metris, Metronor, iGPS)<br />

› Videogrammetry (e.g. Aicon, Krypton, Metronor)<br />

› Auxiliary instruments (e.g. Nivel20, Weather<br />

Stations, One Axis Laser, Temperature Sensors)<br />

› Open interface for integrating your own<br />

equipment and special instruments<br />

Example Instrument Interface<br />

– Laser Tracker:<br />

› Common interface for all Laser Trackers<br />

› Initialize instrument<br />

› Full ADM —> Auto-Measure and locate<br />

› Configurable measurement profiles<br />

› 3D measurements up to 1000 Hz<br />

› Integrated OP-checks and system status<br />

› Target and reflector database<br />

› ADM Offset compensation<br />

› Weather Station recording and compensation<br />

› Level tracking and compensation<br />

› Automated with SA Measurement Plan<br />

› Quick Select

SA Viewer: Free test version<br />

<strong>Spatial</strong><strong>Analyzer</strong>’s free viewer allows you to open, visualize and analyse the SA files.<br />

With the free SA viewer, you and your customers can view the results together with<br />

the original data and analyse them, using the versatile SA tools and the 3D graphical<br />

environment.<br />

› Work with the original files<br />

› Use all of the analysis and simulation tools<br />

› View the results in a 3D graphical environment<br />

SA (<strong>Spatial</strong><strong>Analyzer</strong>)<br />

Industrial Measurement

<strong>VMT</strong> <strong>GmbH</strong><br />

Stegwiesenstr. 24<br />

76646 Bruchsal - Germany<br />

Phone +49 7251 - 96 99-0<br />

Fax +49 7251 - 96 99-22<br />

E-Mail: ims@vmt-gmbh.de<br />

www.vmt-gmbh.de<br />

New River Kinematics<br />

309 McLaws Circle Suite B<br />

Williamsburg, VA 23185<br />

Phone +1(757) 565-1500<br />

Fax +1(757) 565-5900<br />

E-Mail: support@kinematics.com<br />

www.kinematics.com<br />

Since March 2003, <strong>VMT</strong> <strong>GmbH</strong> has been certified to DIN EN ISO 9001:2000.<br />

Features:<br />

› User-friendly graphical environment and instrument interfaces<br />

› Easy to use alignment and transformation tools<br />

› Wide range of different instrument interfaces<br />

› Common interface for instruments of the same type<br />

› Simultaneous measurement with any number of different<br />

instruments —> Process optimization and elimination of<br />

time-related bottlenecks<br />

› Bundle adjustment for different instruments and stations<br />

› Integrated, up-to-date programming language for automated<br />

measurement, analysis, reporting and archival processes<br />

› Traceability to national and international ISO standards<br />

› Customized reporting —> MS-Office, HTML, AVI-Movies, etc.<br />

› Simulation —> for measurement planning and precision estimation<br />

› 3D and 6D real time control<br />

› Perfect solution for the high demands on Geometric<br />

Dimensioning and Tolerancing