Download PDF - Voith Turbo

Download PDF - Voith Turbo

Download PDF - Voith Turbo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

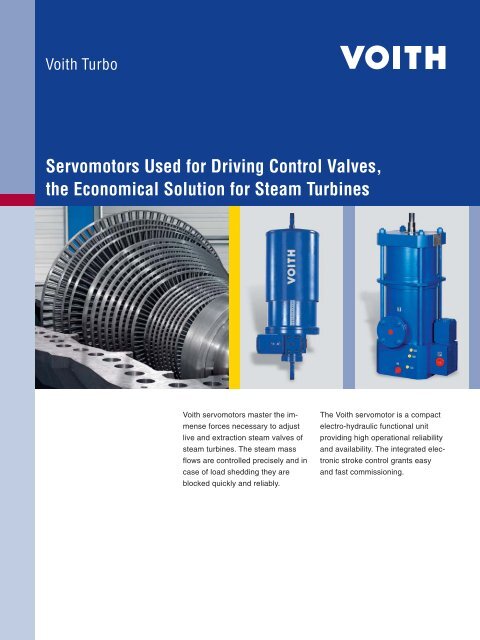

Servomotors Used for Driving Control Valves,<br />

the Economical Solution for Steam Turbines<br />

<strong>Voith</strong> servomotors master the immense<br />

forces necessary to adjust<br />

live and extraction steam valves of<br />

steam turbines. The steam mass<br />

flows are controlled precisely and in<br />

case of load shedding they are<br />

blocked quickly and reliably.<br />

The <strong>Voith</strong> servomotor is a compact<br />

electro-hydraulic functional unit<br />

providing high operational reliability<br />

and availability. The integrated electronic<br />

stroke control grants easy<br />

and fast commissioning.

2<br />

Why do you still assemble your own control drive?<br />

<strong>Voith</strong> offers your individual servomotor factory-assembled.<br />

<strong>Voith</strong>’s servomotor – this is all you need on your parts list.<br />

The control of steam turbines<br />

typically requires a large variety<br />

of com ponents, such as hydraulic,<br />

mechanic and electronic parts, all<br />

of which need to be independently<br />

designed, administrated, assembled<br />

and then commissioned.<br />

These components are intelligently<br />

combined within the <strong>Voith</strong> servomotor<br />

into one compact and suitable<br />

functional unit. The <strong>Voith</strong> servomotor<br />

is a sophisticated and truly<br />

economic solution.

<strong>Voith</strong> Servomotors – Fields of Application<br />

Steam turbine for generator drive, equipped<br />

with low-pressure servomotors SMRA 13xxx<br />

Steam turbine for generator drive, equipped<br />

with high-pressure servomotors SMRA 11xxx<br />

In many fields, users already derive benefit from <strong>Voith</strong> <strong>Turbo</strong>’s<br />

experience in controlling valves on steam turbines, be it live<br />

steam control or extraction control. They reap the benefits<br />

arising from the technical and economic advantages of the<br />

<strong>Voith</strong> servomotor.<br />

Steam turbine for generator drive, equipped<br />

with low-pressure servomotors SMRA 51xxx<br />

Steam turbine for generator drive, equipped<br />

with high-pressure servomotors SMRA 41xxx<br />

3

4<br />

We also offer the appropriate servomotor for your turbine<br />

Low-pressure series:<br />

pressure range up to 25 bar<br />

SMRA 13xxx: Link joint at bottom SMRA 51xxx: Flanged version<br />

SMRA 13001 SMRA 13002 SMRA 13004 SMRA 13401 SMRA 51101 SMRA 51201 SMRA 51301 SMRA 51401<br />

The most convincing and decisive<br />

technical features of the <strong>Voith</strong> servomotor<br />

series:<br />

Substantial savings<br />

<strong>Voith</strong> servomotors allow substantial<br />

savings in regard to design, materials<br />

management, production and<br />

service.<br />

Individual solutions<br />

Within a wide range, <strong>Voith</strong> servomotors<br />

offer individual solutions<br />

for existing machinery and provide<br />

high functionality while still being<br />

economic and reliable.<br />

Long-time experience<br />

The <strong>Voith</strong>’s servomotor series benefits<br />

from many years of experience<br />

in the area of control systems and<br />

actuators.<br />

Integrated electronic stroke<br />

control<br />

The control of steam turbines frequently<br />

requires extensive adjustments<br />

between the controller,<br />

position pickup and actuator. <strong>Voith</strong>’s<br />

servomotors have integrated electronic<br />

stroke control, hence no<br />

tuning is required during test run<br />

and commissioning.

High-pressure series:<br />

pressure range up to 160 bar<br />

SMRA 11xxx: Hinge bearing on both sides SMRA 41xxx: Flanged version<br />

SMRA 11012 SMRA 11011 SMRA 11023 SMRA 11024 SMRA 41111 SMRA 41201 SMRA 41301 SMRA 41401<br />

Hysteresis-free design<br />

The combination of mechanical and<br />

hydraulic components commonly<br />

creates hysteresis which could lead<br />

to instability at critical operating<br />

points. The virtually hysteresis-free<br />

<strong>Voith</strong> servomotor ensures extraordinarily<br />

high operating stability.<br />

High control accuracy<br />

For special applications, extreme<br />

accuracy is required in regard to<br />

linearity, hysteresis, reproducibility<br />

and temperature drift. This is no<br />

problem for the <strong>Voith</strong> servomotor.<br />

Explosion-proof design<br />

For applications in explosion<br />

hazardous areas, the stroke has<br />

historically been commonly fed back<br />

mechanically. The explosion-proof<br />

design of the <strong>Voith</strong> servomotor<br />

offers continuous electronic control<br />

and stroke feedback.<br />

Dirt-resistant<br />

Usually, hydraulic supply systems<br />

on turbomachinery are only provided<br />

with lube oil. Lube oil’s quality<br />

just works well for the <strong>Voith</strong><br />

servomotor.<br />

Emergency shutdown<br />

Even if all auxiliary energies fail, the<br />

trip function has to be guaranteed.<br />

The restoring spring and the adapted<br />

hydraulic pilot control of the<br />

<strong>Voith</strong> servomotor are designed to<br />

meet this requirement.<br />

High dynamics<br />

Load shedding of generators<br />

require rapid closing of the valves.<br />

The high dynamics of the servomotor<br />

readily satisfy this requirement<br />

without any difficulty.<br />

5

6<br />

Technical data<br />

Valid for all series<br />

Ambient conditions<br />

Temperature - 20 °C to + 80 °C<br />

Degree of protection IP 65 to DIN 40 050<br />

Explosion protection (optionally)<br />

Hydraulic data<br />

II 2G EEx de IIB T4, Ta = - 20 ... + 60 °C<br />

Hydraulic fluid Mineral oil to DIN 51 524<br />

Viscosity ISO VG 32 up to ISO VG 46 to DIN 51 519<br />

Oil temperature<br />

Electric data<br />

+ 10 °C up to + 65 °C (+ 60 °C for explosion-proof design)<br />

Supply voltage 24 VDC ± 15%<br />

Power consumption 1 A, max. 3 A für approx. 3 s max.<br />

Stroke set position 4 – 20 mA (for position 0% – 100%)<br />

Stroke remote indication 4 – 20 mA (for position 0% – 100%)<br />

Electro-magnetic compatibility<br />

Accuracies<br />

Basic specification EN 61 000-6-4 (emission), EN 61 000-6-2 (immunity to interference).<br />

Emission test radio interference radiation to EN 55 011 Group 1, Class A.<br />

Immunity test to EN 61 000-4-2, EN 61 000-4-3, EN 61 000-4-4, EN 61 000-4-6.<br />

Linearity ± 0.15% of maximum stroke<br />

Hysteresis 0.005% of maximum stroke<br />

Reproducibility 0.015% of maximum stroke<br />

Temperature drift 0.04% of maximum stroke / °C

Series<br />

SMRA 13xxx:<br />

Low-pressure; link joint at bottom<br />

Type SMRA SMRA SMRA<br />

13001 13002 13004<br />

1) Piston spindle stroke electronically adjustable from 50 – 100 %.<br />

2) At nominal pressure.<br />

3) All data without consideration of tolerances and friction.<br />

4) Fail-safe position piston spindle deliverable also in reversed form.<br />

Design with deviating technical data possible upon request.<br />

Subject to technical modifications.<br />

SMRA<br />

13401<br />

SMRA 51xxx:<br />

Low-pressure; flanged version<br />

SMRA<br />

51101<br />

SMRA<br />

51201<br />

SMRA<br />

51301<br />

Mechanical data<br />

Piston / spindle diameter 152 /34.9 mm 203.2 / 44.5 mm 254.6 / 50.8 mm 304.8 / 63.5 mm 110 / 28 mm 160 / 28 mm 200 / 45 mm<br />

Maximum piston spindle stroke1) 105 mm 35 mm 203 mm 210 mm 90 mm<br />

Closing speed full stroke < 0.4 s < 0.6 s < 0.8 s < 0.3 s<br />

Opening speed full stroke2) < 2 s < 2 s<br />

Spring tension at piston spindle<br />

stroke 0 mm3) Double-acting operating cylinder, no retracting spring 1,500 N 3,000 N 5,000 N<br />

Spring tension at maximum piston<br />

spindle stroke3) Double-acting operating cylinder, no retracting spring 7,200 N 15,000 N 25,000 N<br />

Opening force at piston spindle<br />

stroke 0 mm2)3) Opening/(closing) force at maximum<br />

piston spindle stroke2)3) 13,700 N 25,900 N 40,500 N 55,800 N 13,100 N 28,000 N 42,680 N<br />

14,500 N 24,700 N 38,900 N 58,300 N 7,400 N 16,000 N 22,680 N<br />

Fail-safe position piston spindle extended 4) retracted 4) extended 4) extended<br />

H x L x W [mm] 780 x 570 x 460 800 x 640 x 390 930 x 580 x 410 1080 x 715 x 410 810 x 262 x 320 810 x 385 x 360 990 x 220 x 395<br />

Weight<br />

Hydraulic data<br />

240 kg 310 kg 435 kg 520 kg 130 kg 200 kg 290 kg<br />

Nominal pressure 8 bar 16 bar<br />

Maximum pressure 16 bar 25 bar<br />

7

SMRA<br />

51401<br />

SMRA 11xxx:<br />

High-pressure; link joint at bottom<br />

SMRA<br />

11012<br />

SMRA<br />

11011<br />

SMRA<br />

11023<br />

SMRA<br />

11024<br />

SMRA 41xxx:<br />

High-pressure; flanged version<br />

SMRA<br />

41111<br />

SMRA<br />

41201<br />

SMRA<br />

41301<br />

SMRA<br />

41401<br />

250 / 50 mm 80 / 45 mm 80 / 45 mm 80 / 45 mm 110 / 50 mm 80 / 45 mm 110 / 50 mm 125 / 55 mm 160 / 63 mm<br />

250 mm 85 mm 120 mm 200 mm 120 mm 55 mm<br />

< 0.3 s < 0.3 s<br />

< 3 s < 1 s < 1 s<br />

3,000 N 15,000 N 12,500 N 5,000 N 16,000 N 25,000 N 42,000 N<br />

9,000 N 21,800 N 25,000 N 26,500 N 13,000 N 29,000 N 39,000 N 52,000 N<br />

97,000 N 39,900 N 42,400 N 108,000 N 75,500 N 104,000 N 121,400 N 230,000 N<br />

91,000 N 33,100 N 29,900 N 28,400 N 94,000 N 67,500 N 91,000 N 107,400 N 219,000 N<br />

retracted extended retracted extended<br />

1000 x 550 x 460 969 x 513 x 363 1130 x 470 x 380 1200 x 550 x 400 985 x 460 x 340 1300 x 360 x 445 1340 x 500 x 380 1355 x 545 x 400<br />

450 kg 170 kg 232 kg 290 kg 220 kg 400 kg 500 kg<br />

21 bar 160 bar 160 bar<br />

200 bar 200 bar<br />

8

9<br />

Function<br />

Process controller<br />

Functional view servomotor SMRA 11xxx<br />

x<br />

-<br />

w +<br />

X1<br />

-<br />

KPU<br />

KPD<br />

+<br />

X0<br />

Control magnet<br />

U Mag<br />

U Hall<br />

+24V<br />

In order to achieve a variable steam<br />

mass flow, the control system specifies<br />

a position setpoint w (4 – 20 mA)<br />

for the <strong>Voith</strong> servomotor. The electronics<br />

integrated in the servomotor<br />

transform this position setpoint w<br />

into a proportional piston spindle<br />

stroke and via a directly cou pled<br />

valve or one connected via a lever<br />

system into a steam mass flow.<br />

U F<br />

The <strong>Voith</strong> servomotor is the sophisticated and compact electrohydraulic<br />

functional unit comprising a <strong>Voith</strong> control magnet<br />

(VRM) with integrated positioner, hydraulic pilot control, electronic<br />

stroke measurement (position pick up sensor) and a<br />

hydraulic cylinder.<br />

F Mag<br />

Hydraulic pilot<br />

control<br />

T P<br />

Live steam<br />

The electronically measured actual<br />

position value x is led back to the<br />

control electronics and is made<br />

available to the control system.<br />

F F<br />

Hydrauliccylinder<br />

s<br />

i<br />

s<br />

Position<br />

pick up<br />

sensor<br />

Steam control valve<br />

T Tank connection<br />

P Oil supply terminal (input)<br />

X0, X1 Parameters for stroke<br />

adjustment (potentiometers)<br />

KPU, KPD Control gains (potentiometers)<br />

w Position nominal value<br />

(4 – 20 mA)<br />

x Position actual value<br />

(4 – 20 mA)<br />

FMag Magnetic force<br />

FF Force for control spring<br />

UHall Hall voltage<br />

UMag Reference variable for<br />

solenoid force FMag U Voltage<br />

s Stroke<br />

i Position pick up sensor current<br />

signal<br />

In order to achieve high speeds,<br />

two-stage hydraulic pilot controls<br />

are used in the SMRA 13xxx<br />

double-acting servomotors. The<br />

enormous closing speed of the<br />

single-acting SMRA 51xxx and<br />

SMRA 41xxx servomotors is<br />

achieved through an additional<br />

plate valve integrated in the<br />

servomotor.

<strong>Voith</strong> <strong>Turbo</strong> GmbH & Co. KG<br />

Electronic Drive Systems<br />

<strong>Voith</strong>str. 1<br />

74564 Crailsheim, Germany<br />

Tel. +49 7951 32-470<br />

Fax +49 7951 32-605<br />

turcon@voith.com<br />

www.voithturbo.com/actuation-control-turbomachinery<br />

cr 302 en, 05.2010, aik / WA, 1.500. Dimensions and illustrations without obligation. Subject to change.