Scale-up and Demonstration of Fischer-Tropsch Technology

Scale-up and Demonstration of Fischer-Tropsch Technology

Scale-up and Demonstration of Fischer-Tropsch Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6 D. Schanke et al.<br />

To date, more than 100 tonnes <strong>of</strong> catalyst have been produced for use in the semicommercial<br />

demo plant. The scale <strong>of</strong> production (<strong>up</strong> to 1 ton/d) ensures minimal scale<strong>up</strong><br />

risk for the catalyst manufacturing plant for a commercial project.<br />

5. Performance <strong>of</strong> the demonstration plant<br />

5.1. Catalytic performance<br />

During the catalyst manufacturing campaigns, an extensive program <strong>of</strong> quality control<br />

was carried out, using a pilot plant <strong>and</strong> other catalyst test reactors. After developing <strong>and</strong><br />

optimising the catalyst manufacturing procedures, the activity <strong>and</strong> selectivity <strong>of</strong> catalyst<br />

produced at large scale does not differ from catalyst produced in the laboratory.<br />

Furthermore, it was found that the catalyst activity <strong>and</strong> selectivity in the semicommercial<br />

demo plant was similar to what is usually observed in the pilot plant.<br />

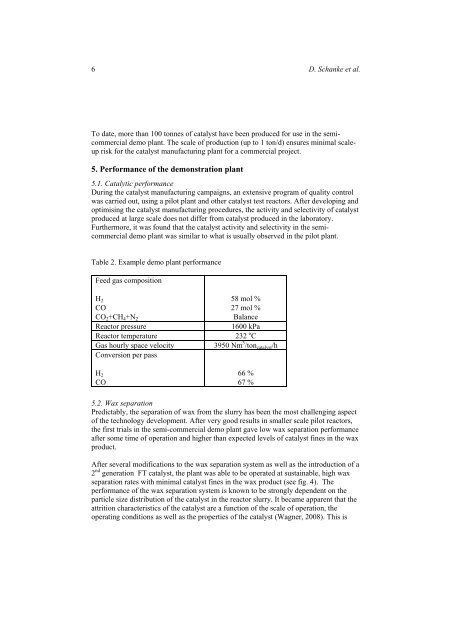

Table 2. Example demo plant performance<br />

Feed gas composition<br />

H2<br />

CO<br />

CO2+CH4+N2<br />

58 mol %<br />

27 mol %<br />

Balance<br />

Reactor pressure 1600 kPa<br />

Reactor temperature 232 o C<br />

Gas hourly space velocity 3950 Nm 3 /toncatalyst/h<br />

Conversion per pass<br />

H2<br />

CO<br />

66 %<br />

67 %<br />

5.2. Wax separation<br />

Predictably, the separation <strong>of</strong> wax from the slurry has been the most challenging aspect<br />

<strong>of</strong> the technology development. After very good results in smaller scale pilot reactors,<br />

the first trials in the semi-commercial demo plant gave low wax separation performance<br />

after some time <strong>of</strong> operation <strong>and</strong> higher than expected levels <strong>of</strong> catalyst fines in the wax<br />

product.<br />

After several modifications to the wax separation system as well as the introduction <strong>of</strong> a<br />

2 nd generation FT catalyst, the plant was able to be operated at sustainable, high wax<br />

separation rates with minimal catalyst fines in the wax product (see fig. 4). The<br />

performance <strong>of</strong> the wax separation system is known to be strongly dependent on the<br />

particle size distribution <strong>of</strong> the catalyst in the reactor slurry. It became apparent that the<br />

attrition characteristics <strong>of</strong> the catalyst are a function <strong>of</strong> the scale <strong>of</strong> operation, the<br />

operating conditions as well as the properties <strong>of</strong> the catalyst (Wagner, 2008). This is