Container cranes for Eurogate Bremerhaven and Hamburg

Container cranes for Eurogate Bremerhaven and Hamburg

Container cranes for Eurogate Bremerhaven and Hamburg

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Innovation <strong>and</strong> Competence<br />

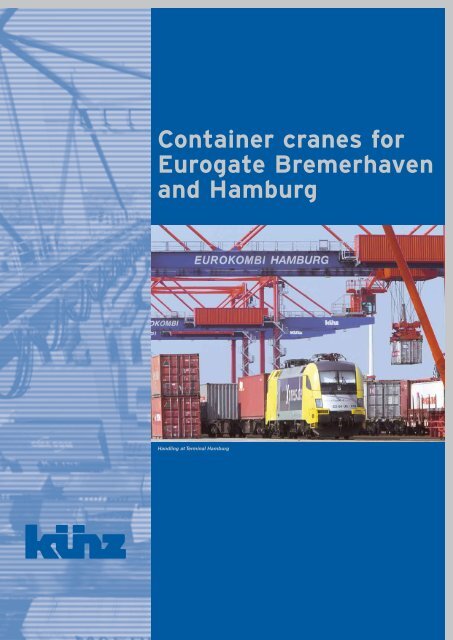

<strong>Container</strong> <strong>cranes</strong> <strong>for</strong><br />

<strong>Eurogate</strong> <strong>Bremerhaven</strong><br />

<strong>and</strong> <strong>Hamburg</strong><br />

H<strong>and</strong>ling at Terminal <strong>Hamburg</strong>

Kuenz provides high efficiency <strong>and</strong> coordinated operations.<br />

Kuenz quality convinces in<br />

intermodal container h<strong>and</strong>ling.<br />

The Rail-Terminal <strong>Bremerhaven</strong><br />

Kuenz provides smooth connections<br />

to the European hinterl<strong>and</strong><br />

The Terminal <strong>and</strong> Logistic Group <strong>Eurogate</strong>, with headquarters<br />

in Bremen, Germany, operates Deep Sea Terminals on the<br />

North Sea, in the Mediterranean region <strong>and</strong> on the Atlantic<br />

ocean, with excellent connections to the hinterl<strong>and</strong> of Europe.<br />

With 10 terminal locations h<strong>and</strong>ling 14,2 Million TEU (2008),<br />

<strong>Eurogate</strong> is one of Europe`s largest terminal operators. The<br />

<strong>Eurogate</strong> <strong>Container</strong> Terminal at <strong>Hamburg</strong> is currently using<br />

six large-vessel berths. 2,7 Million TEU are h<strong>and</strong>led per<br />

year on an area of 1,4 Million m². <strong>Bremerhaven</strong> is <strong>Eurogate</strong>´s<br />

largest container terminal with an area of 2 Million m² <strong>and</strong><br />

h<strong>and</strong>ling of 5,5 Million TEU.<br />

Between 2002–2008, Kuenz installed eight <strong>cranes</strong> <strong>for</strong> the train<br />

terminals. By the end of 2009 another four container <strong>cranes</strong><br />

will be commissioned at the <strong>Hamburg</strong> <strong>and</strong> <strong>Bremerhaven</strong><br />

harbour rail heads.<br />

Technical Data <strong>for</strong> the <strong>Hamburg</strong><br />

<strong>and</strong> <strong>Bremerhaven</strong> Rail Cranes<br />

The rail mounted container gantry <strong>cranes</strong> are designed as<br />

two-girder bridge. The steel construction of the gantry consists<br />

of the hinged post, the fixed post <strong>and</strong> the main girders with<br />

suspension. The hoisting rope reeving <strong>for</strong> the containerhoisting<br />

gear is executed as a rigid rope-tower. This system<br />

enables swing-free travel in gantry <strong>and</strong> trolley direction,<br />

as well as with the slewing gear. This guarantees efficient<br />

h<strong>and</strong>ling.

The good experience gained with the operation of the<br />

first four RMGs (supplied in 2002) was a key issue <strong>for</strong><br />

the further cooperation with Kuenz <strong>for</strong> the Eurokombi<br />

expansion project in <strong>Hamburg</strong>. Kuenz convinced again<br />

with experienced project management <strong>and</strong> the perfect<br />

quality of the <strong>cranes</strong>.<br />

Christof Ricke, Project Manager Lifting Equipment <strong>Eurogate</strong> <strong>Hamburg</strong><br />

Patented Technology by Kuenz –<br />

rotating travelling gear<br />

The lifetime of the wheels is limited by the wear of the wheel flanges.<br />

This wear is caused by off-track running of the wheels. Tolerances <strong>and</strong><br />

temperature changes affect the amount of wear caused by off-track<br />

running.<br />

Rotating travelling gear by Kuenz<br />

The patented Kuenz solution allows <strong>for</strong> swivelling of the travel unit in<br />

the horizontal direction to compensate <strong>for</strong> any inclination of the travel<br />

unit. That means: all wheels are running on the track. Stabilizers on<br />

both sides of the travel unit make it possible <strong>for</strong> optimized transmission<br />

of the <strong>for</strong>ces to the steel structure.<br />

This solution enables a major wear-reduction of the wheel flanges,<br />

which means a significant increase in the lifetime of the wheels.<br />

"The good experience gained by our collegues in<br />

<strong>Hamburg</strong> was a key issue <strong>for</strong> the decision in working<br />

together with Kuenz.<br />

Kuenz confirmed the <strong>Hamburg</strong> experience with a well<br />

established project management <strong>and</strong> the perfect quality<br />

of the <strong>cranes</strong> also <strong>for</strong> the <strong>Bremerhaven</strong> project.<br />

Lutz Werner, Project Engineer <strong>Eurogate</strong> <strong>Bremerhaven</strong><br />

Technical Data <strong>Container</strong> <strong>cranes</strong><br />

Location <strong>Hamburg</strong><br />

Technical Data<br />

Capacity spreader 41 t<br />

Track width 38,25 m<br />

Length boom 15,50 m<br />

Length boom 14,25 m<br />

Working speeds<br />

Hoist – rated load 0–20 m/min<br />

Hoist – part load 0–40 m/min<br />

Gantry drive 0–120 m/min<br />

Trolley drive 0–150 m/min<br />

Slewing 0–2 U/min<br />

Lifting height 13,6 m<br />

Length of craneway 730 m<br />

Power<br />

Hoist 220 kW / 60 % ED<br />

Gantry drive 24 x 18,4 kW / 60 % ED<br />

Trolley drive 4 x 36 kW / 60 % ED<br />

Slewing drive 2 x 7 kW / 40 % ED<br />

Location <strong>Bremerhaven</strong><br />

Technical Data<br />

Capacity spreader 41 t<br />

Track width 32,4 m<br />

Length boom 17,00 m<br />

Length boom 5,00 m<br />

Working speed<br />

Hoist rated load 0–20 m/min<br />

Hoist part load 0–40 m/min<br />

Gantry drive 0–120 m/min<br />

Trolley drive 0–150 m/min<br />

Slewing 0–2 U/min<br />

Lifting height 13,8 m<br />

Length of craneway 900 m<br />

Power<br />

Hoist 220 kW / 60 % ED<br />

Gantry drive 24 x 18,0 kW / 60 % ED<br />

Trolley drive 4 x 36 kW / 60 % ED<br />

Slewing drive 2 x 7 kW / 40 % ED<br />

www.kuenz.com<br />

Innovation <strong>and</strong> Competence

The best references<br />

are successful projects.<br />

Further in<strong>for</strong>mation: www.kuenz.com<br />

DUSS – Stuttgart, Germany<br />

Kuenz provides efficient h<strong>and</strong>ling<br />

in compact design.<br />

Wiencont – Vienna, Freudenau<br />

Hans Künz GmbH, A-6971 Hard, Phone +43 5574 6883 0, Fax +43 5574 6883 19<br />

sales@kuenz.com, service@kuenz.com, www.kuenz.com<br />

Approved Kuenz tecnology guarantees<br />

h<strong>and</strong>ling of all container dimensions.<br />

Bertschi – Schwarzheide<br />

Secure h<strong>and</strong>ling with tank-containers<br />

is guaranteed by Kuenz.<br />

Innovation <strong>and</strong> Competence