Water Well Manual (USAID).pdf - The Water, Sanitation and Hygiene

Water Well Manual (USAID).pdf - The Water, Sanitation and Hygiene

Water Well Manual (USAID).pdf - The Water, Sanitation and Hygiene

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

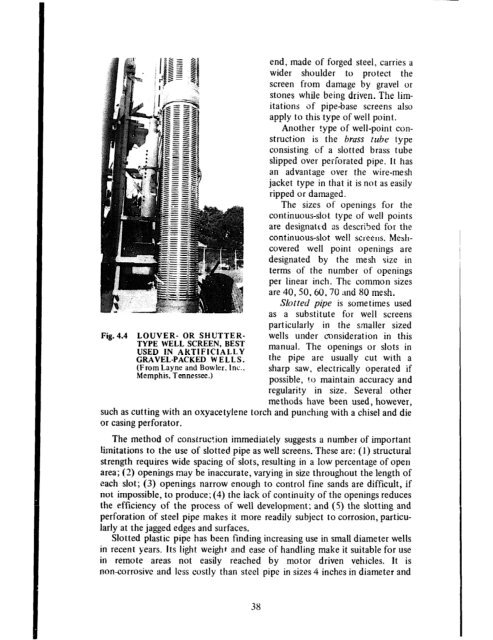

Fig.4.4 LOUVER- OR SHUTTER-<br />

TYPE WELL SCREEN, BEST<br />

USED IN ARTIFIClALLY<br />

GRAVEL-PACKED WELLS.<br />

(From Layne <strong>and</strong> Bowler, inc.,<br />

Memphis, Tennessee.)<br />

end, made of forged steel, carries a<br />

wider shoulder to protect the<br />

screen from damage by gravel or<br />

stones while being driven. <strong>The</strong> lim-<br />

itations of pipe-base screens also<br />

apply to this type of well point.<br />

Another type of well-point con-<br />

struction is the brass tube type<br />

consisting of a slotted brass tube<br />

slipped over perforated pipe. It has<br />

an advantage over the wire-mesh<br />

jacket type in that it is not as easily<br />

ripped or damaged.<br />

<strong>The</strong> sizes of openings for the<br />

continuous-slot type of well points<br />

are designated as described for the<br />

continuous-slot well screens. Mesh-<br />

covered well point openings are<br />

designated by the mesh size in<br />

terms of the number of openings<br />

per linear inch. <strong>The</strong> common sizes<br />

are 40,50,60,70 ;rnd 80 mesh.<br />

Slotted pipe is sometimes used<br />

as a substitute for well screens<br />

particularly in the smaller sized<br />

wells under consideration in this<br />

manual. <strong>The</strong> openings or slots in<br />

the pipe are usually cut with a<br />

sharp saw, electrically operated if<br />

possible, to maintain accuracy <strong>and</strong><br />

regularity in size. Several other<br />

methods have been used, however,<br />

such as cutting with an oxyacetylene torch <strong>and</strong> punching with a chisel <strong>and</strong> die<br />

or casing perforator.<br />

<strong>The</strong> method of construction immediately suggests a number of important<br />

limitations to the use of slotted pipe as well screens. <strong>The</strong>se are: (1) structural<br />

strength requires wide spacing of slots, resulting in a low percentage of open<br />

area; (2) openings may be inaccurate, varying in size throughout the length of<br />

each slot; (3) openings narrow enough to control fine s<strong>and</strong>s are difficult, if<br />

not impossible, to produce; (4) the lack of continuity of the openings reduces<br />

the efficiency of the process of well development; <strong>and</strong> (S) the slotting <strong>and</strong><br />

perforation of steel pipe makes it more readily subject to corrosion, particu-<br />

larly at the jagged edges <strong>and</strong> surfaces.<br />

Slotted plastic pipe has been finding increasing use in small diameter wells<br />

in recent years. Its light weight <strong>and</strong> ease of h<strong>and</strong>ling make it suitable for use<br />

in remote areas not easily reached by motor driven vehicles. It is<br />

noncorrosive <strong>and</strong> less costly than steel pipe in sizes 4 inches in diameter <strong>and</strong><br />

38