Hetron-Ashland Resins

Hetron-Ashland Resins

Hetron-Ashland Resins

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

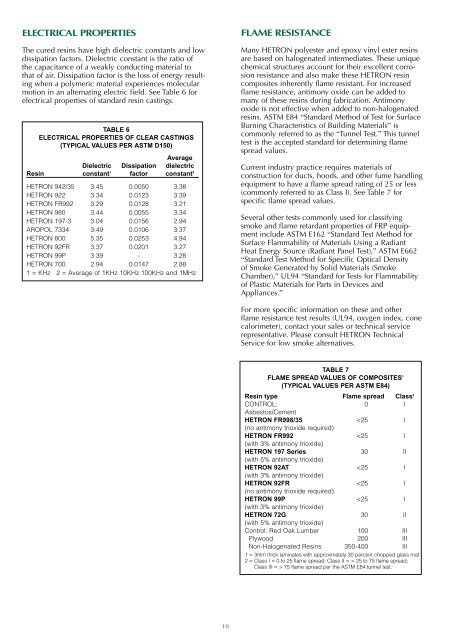

ELECTRICAL PROPERTIES<br />

The cured resins have high dielectric constants and low<br />

dissipation factors. Dielectric constant is the ratio of<br />

the capacitance of a weakly conducting material to<br />

that of air. Dissipation factor is the loss of energy resulting<br />

when a polymeric material experiences molecular<br />

motion in an alternating electric field. See Table 6 for<br />

electrical properties of standard resin castings.<br />

TABLE 6<br />

ELECTRICAL PROPERTIES OF CLEAR CASTINGS<br />

(TYPICAL VALUES PER ASTM D150)<br />

Average<br />

Dielectric Dissipation dielectric<br />

Resin constant1 factor constant2 HETRON 942/35 3.45 0.0050 3.38<br />

HETRON 922 3.34 0.0123 3.39<br />

HETRON FR992 3.29 0.0128 3.21<br />

HETRON 980 3.44 0.0055 3.34<br />

HETRON 197-3 3.04 0.0156 2.94<br />

AROPOL 7334 3.49 0.0106 3.37<br />

HETRON 800 5.35 0.0253 4.94<br />

HETRON 92FR 3.37 0.0201 3.27<br />

HETRON 99P 3.39 - 3.28<br />

HETRON 700 2.94 0.0147 2.88<br />

1 = KHz 2 = Average of 1KHz 10KHz 100KHz and 1MHz<br />

10<br />

FLAME RESISTANCE<br />

Many HETRON polyester and epoxy vinyl ester resins<br />

are based on halogenated intermediates. These unique<br />

chemical structures account for their excellent corrosion<br />

resistance and also make these HETRON resin<br />

composites inherently flame resistant. For increased<br />

flame resistance, antimony oxide can be added to<br />

many of these resins during fabrication. Antimony<br />

oxide is not effective when added to non-halogenated<br />

resins. ASTM E84 “Standard Method of Test for Surface<br />

Burning Characteristics of Building Materials’’ is<br />

commonly referred to as the “Tunnel Test.’’ This tunnel<br />

test is the accepted standard for determining flame<br />

spread values.<br />

Current industry practice requires materials of<br />

construction for ducts, hoods, and other fume handling<br />

equipment to have a flame spread rating of 25 or less<br />

(commonly referred to as Class I). See Table 7 for<br />

specific flame spread values.<br />

Several other tests commonly used for classifying<br />

smoke and flame retardant properties of FRP equipment<br />

include ASTM E162 “Standard Test Method for<br />

Surface Flammability of Materials Using a Radiant<br />

Heat Energy Source (Radiant Panel Test),’’ ASTM E662<br />

“Standard Test Method for Specific Optical Density<br />

of Smoke Generated by Solid Materials (Smoke<br />

Chamber),’’ UL94 “Standard for Tests for Flammability<br />

of Plastic Materials for Parts in Devices and<br />

Appliances.’’<br />

For more specific information on these and other<br />

flame resistance test results (UL94, oxygen index, cone<br />

calorimeter), contact your sales or technical service<br />

representative. Please consult HETRON Technical<br />

Service for low smoke alternatives.<br />

TABLE 7<br />

FLAME SPREAD VALUES OF COMPOSITES1 (TYPICAL VALUES PER ASTM E84)<br />

Resin type Flame spread Class2 CONTROL:<br />

Asbestos/Cement<br />

0 I<br />

HETRON FR998/35<br />

(no antimony trioxide required)<br />

![[ES] - LUPEROX K10 - 2008-04-02](https://img.yumpu.com/40905446/1/184x260/es-luperox-k10-2008-04-02.jpg?quality=85)