Hetron-Ashland Resins

Hetron-Ashland Resins

Hetron-Ashland Resins

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EPOXY VINYL ESTER RESIN<br />

COMPOSITES<br />

Bisphenol A based epoxy vinyl ester resins are<br />

methacrylated epoxy difunctional polyesters. Novolac<br />

modified epoxy vinyl ester resins have higher functionality.<br />

Vinyl esters are classified separately from polyesters<br />

due to their enhanced mechanical properties.<br />

They offer excellent physical strength and, in general,<br />

much better impact and thermal shock resistance than<br />

polyester resins. While the standard epoxy vinyl ester<br />

resins are limited to 105-120˚C in most applications,<br />

other versions with higher-density crosslinking are<br />

suitable for temperatures above 120˚C.<br />

These resins exhibit excellent resistance to acids,<br />

alkalis, hypochlorites, and many solvents. They are also<br />

suitable for flakeglass and fiberglass reinforced linings,<br />

coatings, and monolithic topping for tanks, vats, floors,<br />

troughs, and similar applications.<br />

HIGH PERFORMANCE EPOXY VINYL<br />

ESTER RESIN COMPOSITES<br />

Manufactured under a patented process, these resins<br />

offer maximum corrosion and temperature resistance to<br />

acids, alkalis, hypochlorites, and many solvents. These<br />

products have been formulated for maximum performance<br />

with methyl ethyl ketone peroxides. It is well documented<br />

that these catalysts provide optimal cure and<br />

thus maximum corrosion resistance.<br />

• HETRON 942/35: A bisphenol A epoxy vinyl ester<br />

resin with improved thermal properties, formulated<br />

with less than 35% styrene. Provides superior<br />

corrosion resistance to hydrocarbon solvents.<br />

6<br />

• HETRON 980/35: A phenolic novolac epoxy vinyl<br />

ester resin formulated with less than 35% styrene.<br />

Provides maximum heat and corrosion resistance to<br />

strong oxidizing chemicals.<br />

• HETRON FR998/35: Highly flame retardant epoxy<br />

vinyl ester resin formulated with less than 35%<br />

styrene. Excellent thermal properties and superior<br />

corrosion resistance to hydrocarbon solvents and<br />

oxidizing media. See Table 7 for ASTM E84 flame<br />

spread values for this and other flame retardant<br />

resins.<br />

• HETRON 970/35: Highly crosslinked novolac<br />

epoxy vinyl ester resin with superior solvent and<br />

acid resistance.<br />

EPOXY VINYL ESTER RESIN<br />

COMPOSITES<br />

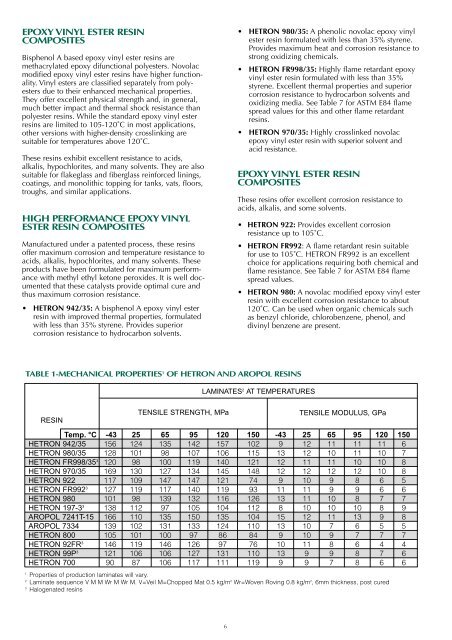

TABLE 1-MECHANICAL PROPERTIES 1 OF HETRON AND AROPOL RESINS<br />

RESIN<br />

These resins offer excellent corrosion resistance to<br />

acids, alkalis, and some solvents.<br />

• HETRON 922: Provides excellent corrosion<br />

resistance up to 105˚C.<br />

• HETRON FR992: A flame retardant resin suitable<br />

for use to 105˚C. HETRON FR992 is an excellent<br />

choice for applications requiring both chemical and<br />

flame resistance. See Table 7 for ASTM E84 flame<br />

spread values.<br />

• HETRON 980: A novolac modified epoxy vinyl ester<br />

resin with excellent corrosion resistance to about<br />

120˚C. Can be used when organic chemicals such<br />

as benzyl chloride, chlorobenzene, phenol, and<br />

divinyl benzene are present.<br />

LAMINATES 2 AT TEMPERATURES<br />

TENSILE STRENGTH, MPa TENSILE MODULUS, GPa<br />

Temp. °C -43 25 65 95 120 150 -43 25 65 95 120 150<br />

HETRON 942/35 156 124 135 142 157 102 9 12 11 11 11 6<br />

HETRON 980/35 128 101 98 107 106 115 13 12 10 11 10 7<br />

HETRON FR998/35 3 120 98 100 119 140 121 12 11 11 10 10 8<br />

HETRON 970/35 169 130 127 134 145 148 12 12 12 12 10 8<br />

HETRON 922 117 109 147 147 121 74 9 10 9 8 6 5<br />

HETRON FR992 3 127 119 117 140 119 93 11 11 9 9 6 6<br />

HETRON 980 101 98 139 132 116 126 13 11 10 8 7 7<br />

HETRON 197-3 3 138 112 97 105 104 112 8 10 10 10 8 9<br />

AROPOL 7241T-15 166 110 135 150 135 104 15 12 11 13 9 8<br />

AROPOL 7334 139 102 131 133 124 110 13 10 7 6 5 5<br />

HETRON 800 105 101 100 97 86 84 9 10 9 7 7 7<br />

HETRON 92FR 3 146 119 146 126 97 76 10 11 8 6 4 4<br />

HETRON 99P 3 121 106 106 127 131 110 13 9 9 8 7 6<br />

HETRON 700 90 87 106 117 111 119 9 9 7 8 6 6<br />

1 Properties of production laminates will vary.<br />

2 Laminate sequence V M M Wr M Wr M. V=Veil M=Chopped Mat 0.5 kg/m 2 Wr=Woven Roving 0.8 kg/m 2 , 6mm thickness, post cured<br />

3 Halogenated resins

![[ES] - LUPEROX K10 - 2008-04-02](https://img.yumpu.com/40905446/1/184x260/es-luperox-k10-2008-04-02.jpg?quality=85)