April - Library

April - Library

April - Library

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AMMJ Lessons Learnt In 45 Years of Condition Monitoring 2<br />

Case study 7<br />

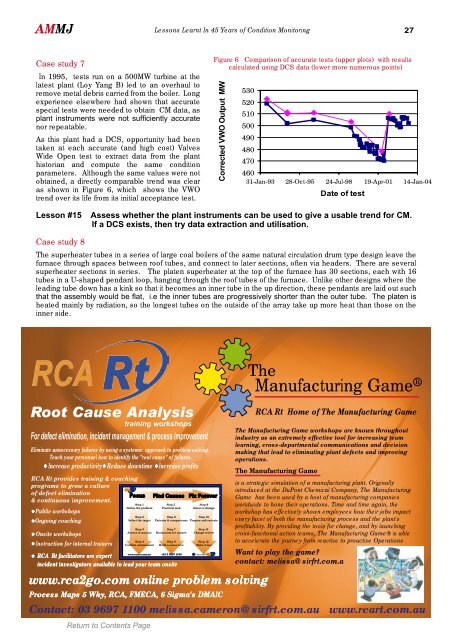

In 1995, tests run on a 500MW turbine at the<br />

latest plant (Loy Yang B) led to an overhaul to<br />

remove metal debris carried from the boiler. Long<br />

experience elsewhere had shown that accurate<br />

special tests were needed to obtain CM data, as<br />

plant instruments were not sufficiently accurate<br />

nor repeatable.<br />

As this plant had a DCS, opportunity had been<br />

taken at each accurate (and high cost) Valves<br />

Wide Open test to extract data from the plant<br />

historian and compute the same condition<br />

parameters. Although the same values were not<br />

obtained, a directly comparable trend was clear<br />

as shown in Figure 6, which shows the VWO<br />

trend over its life from its initial acceptance test.<br />

Lesson #15 Assess whether the plant instruments can be used to give a usable trend for CM.<br />

If a DCS exists, then try data extraction and utilisation.<br />

Case study 8<br />

460<br />

31-Jan-93 28-Oct-95 24-Jul-98 19-Apr-01 14-Jan-04<br />

The superheater tubes in a series of large coal boilers of the same natural circulation drum type design leave the<br />

furnace through spaces between roof tubes, and connect to later sections, often via headers. There are several<br />

superheater sections in series. The platen superheater at the top of the furnace has 30 sections, each with 16<br />

tubes in a U-shaped pendant loop, hanging through the roof tubes of the furnace. Unlike other designs where the<br />

leading tube down has a kink so that it becomes an inner tube in the up direction, these pendants are laid out such<br />

that the assembly would be flat, i.e the inner tubes are progressively shorter than the outer tube. The platen is<br />

heated mainly by radiation, so the longest tubes on the outside of the array take up more heat than those on the<br />

inner side.<br />

Eliminate unnecessary failures by using a systemic approach to problem solving.<br />

Teach your personnel how to identify the "root cause" of failures.<br />

Increase productivity Reduce downtime Increase profits<br />

RCA Rt provides training & coaching<br />

programs to grow a culture<br />

of defect elimination<br />

& continuous improvement.<br />

Public workshops<br />

Ongoing coaching<br />

Onsite workshops<br />

Instruction for internal trainers<br />

Focus Find Causes Fix Forever<br />

Step 1<br />

Define the problem<br />

Step 2<br />

Select the target<br />

Step 3<br />

Assess & monitor<br />

Step 4<br />

Confirm containment<br />

Step 5<br />

Practical look<br />

Step 6<br />

Patterns & comparisons<br />

Step 7<br />

Brainstorm for causes<br />

Step 8<br />

Build a cause tree<br />

RCA Rt facilitators are expert<br />

incident investigators available to lead your team onsite<br />

Step 9<br />

Select a change<br />

Step 10<br />

Prepare and execute<br />

Step 11<br />

Change review<br />

Step 12<br />

Make it last<br />

www.rcart.com.au +61 3 9697 1100 Copyright<br />

Figure 6 Comparison of accurate tests (upper plots) with results<br />

calculated using DCS data (lower more numerous points)<br />

Corrected VWO Output MW<br />

530<br />

520<br />

510<br />

500<br />

490<br />

480<br />

470<br />

www.rca2go.com online problem solving<br />

Process Maps 5 Why, RCA, FMECA, 6 Sigma's DMAIC<br />

Date of test<br />

The<br />

R<br />

Manufacturing Game<br />

RCA Rt Home of The Manufacturing Game<br />

The Manufacturing Game workshops are known throughout<br />

industry as an extremely effective tool for increasing team<br />

learning, cross-departmental communications and decision<br />

making that lead to eliminating plant defects and improving<br />

operations.<br />

The Manufacturing Game<br />

is a strategic simulation of a manufacturing plant. Originally<br />

introduced at the DuPont Chemical Company, The Manufacturing<br />

Game has been used by a host of manufacturing companies<br />

worldwide to hone their operations. Time and time again, the<br />

workshop has effectively shown employees how their jobs impact<br />

every facet of both the manufacturing process and the plant's<br />

profitability. By providing the tools for change, and by launching<br />

cross-functional action teams, The Manufacturing Game® is able<br />

to accelerate the journey from reactive to proactive Operations<br />

Want to play the game?<br />

contact: melissa@sirfrt.com.a<br />

Contact: 03 9697 1100 melissa.cameron@sirfrt.com.au www.rcart.com.au