22-inch Variable Speed Drill Press - JET Tools

22-inch Variable Speed Drill Press - JET Tools

22-inch Variable Speed Drill Press - JET Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

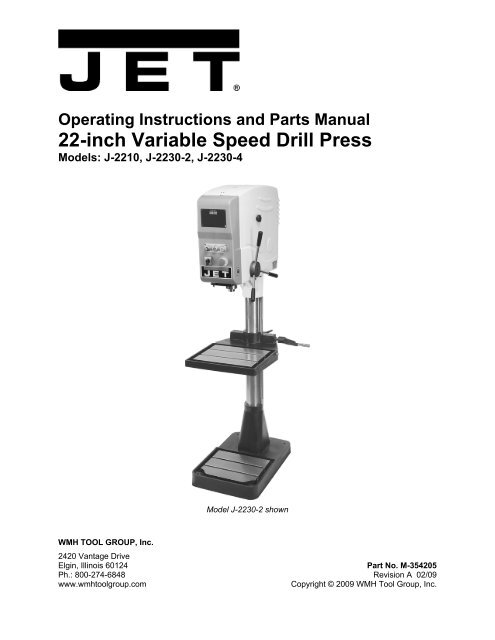

Operating Instructions and Parts Manual<br />

<strong>22</strong>-<strong>inch</strong> <strong>Variable</strong> <strong>Speed</strong> <strong>Drill</strong> <strong>Press</strong><br />

Models: J-<strong>22</strong>10, J-<strong>22</strong>30-2, J-<strong>22</strong>30-4<br />

WMH TOOL GROUP, Inc.<br />

Model J-<strong>22</strong>30-2 shown<br />

2420 Vantage Drive<br />

Elgin, Illinois 60124 Part No. M-354205<br />

Ph.: 800-274-6848 Revision A 02/09<br />

www.wmhtoolgroup.com Copyright © 2009 WMH Tool Group, Inc.

Warranty and Service<br />

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our<br />

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of<br />

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or<br />

perform routine maintenance and major repair on your <strong>JET</strong>® tools. For the name of an Authorized Service Center in<br />

your area call 1-800-274-6848.<br />

MORE INFORMATION<br />

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check<br />

with your local WMH Tool Group distributor, or visit jettools.com.<br />

WARRANTY<br />

<strong>JET</strong> products carry a limited warranty which varies in duration based upon the product (MW stands for Metalworking,<br />

WW stands for Woodworking).<br />

WHAT IS COVERED?<br />

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,<br />

abrasives and other consumables are excluded from warranty coverage.<br />

WHO IS COVERED?<br />

This warranty covers only the initial purchaser of the product.<br />

WHAT IS THE PERIOD OF COVERAGE?<br />

The general <strong>JET</strong> warranty lasts for the time period specified in the product literature of each product.<br />

WHAT IS NOT COVERED?<br />

Five Year and Lifetime Warranties do not cover products used for commercial, industrial or educational purposes.<br />

Products with Five Year or Lifetime Warranties that are used for commercial, industrial or education purposes revert<br />

to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence<br />

or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.<br />

HOW TO GET SERVICE<br />

The product or par t must be returned for examination, postage prepaid, to a location designated by us. For the name<br />

of the location nearest you, please call 1-800-274-6848.<br />

You must provide proof of initial purchase date and an explanation of the complaint must accompany the<br />

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,<br />

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that<br />

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,<br />

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be<br />

responsible for the shipping and handling costs of the return.<br />

HOW STATE LAW APPLIES<br />

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.<br />

LIMITATIONS ON THIS WARRANTY<br />

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR<br />

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND<br />

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED<br />

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.<br />

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,<br />

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE<br />

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR<br />

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.<br />

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information<br />

and are not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those<br />

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.<br />

<strong>JET</strong>® branded products are not sold in Canada by WMH Tool Group.<br />

2

Table of Contents<br />

Table of Contents..........................................................................................................................................3<br />

Warning.........................................................................................................................................................4<br />

Introduction ...................................................................................................................................................6<br />

Specifications ................................................................................................................................................6<br />

Features and Terminology ............................................................................................................................7<br />

Unpacking and Setup....................................................................................................................................8<br />

Contents of the Shipping Container ..........................................................................................................8<br />

Handle Assembly.......................................................................................................................................8<br />

Electrical Connections...............................................................................................................................8<br />

Extension Cords ........................................................................................................................................9<br />

Operating Controls ........................................................................................................................................9<br />

Adjustments ................................................................................................................................................10<br />

Work Table ..............................................................................................................................................10<br />

Arbor/Chuck Removal .............................................................................................................................10<br />

Belt Position (<strong>Speed</strong> Adjustment)............................................................................................................11<br />

Operation.....................................................................................................................................................11<br />

Drive Belt Replacement...........................................................................................................................12<br />

<strong>Drill</strong>ing Recommendations ..........................................................................................................................13<br />

<strong>Speed</strong>s for <strong>Drill</strong>ing ...................................................................................................................................13<br />

Feeds for <strong>Drill</strong>ing .....................................................................................................................................13<br />

Indication of Extreme <strong>Speed</strong>s/Feeds ......................................................................................................13<br />

Troubleshooting ..........................................................................................................................................14<br />

Replacement Parts......................................................................................................................................15<br />

Exploded View: Headstock Assembly.....................................................................................................15<br />

Parts List: Headstock Assembly..............................................................................................................16<br />

Exploded View: Headstock Cover Assembly ..........................................................................................18<br />

Parts List: Headstock Cover Assembly ...................................................................................................19<br />

Exploded View: Base and Column Assembly .........................................................................................20<br />

Parts List: Base and Column Assembly ..................................................................................................21<br />

Electrical Connections – 1 Phase, 230V.....................................................................................................<strong>22</strong><br />

Electrical Connections – 3 Phase, 230V.....................................................................................................23<br />

Electrical Connections – 3 Phase, 460V.....................................................................................................24<br />

3

Warning<br />

1. Read and understand the entire owners manual before attempting assembly or operation.<br />

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with<br />

all of these warnings may cause serious injury.<br />

3. Replace warning labels if they become obscured or removed.<br />

4. This drill press is designed and intended for use by properly trained and experienced personnel only.<br />

If you are not familiar with the proper and safe operation of a drill press, do not use until proper<br />

training and knowledge have been obtained.<br />

5. Do not use this drill press for other than its intended use. If used for other purposes, WMH Tool<br />

Group disclaims any real or implied warranty and holds itself harmless from any injury that may result<br />

from that use.<br />

6. Always wear approved safety glasses with side shields while using this drill press. (Everyday<br />

eyeglasses only have impact resistant lenses; they are not safety glasses.)<br />

7. Before operating this drill press, remove tie, rings, watches and other jewelry, and roll sleeves up past<br />

the elbows. Remove all loose clothing and confine long hair. Non-slip footwear and safety shoes are<br />

recommended, as well as anti-skid floor strips.<br />

8. Wear ear protectors (plugs or muffs) during extended periods of operation.<br />

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities<br />

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples<br />

of these chemicals are:<br />

• Lead from lead based paint.<br />

• Crystalline silica from bricks, cement and other masonry products.<br />

• Arsenic and chromium from chemically treated lumber.<br />

Your risk of exposure varies, depending on how often you do this type of work. To reduce your<br />

exposure to these chemicals, work in a well-ventilated area and work with approved safety<br />

equipment, such as face or dust masks that are specifically designed to filter out microscopic<br />

particles.<br />

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.<br />

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.<br />

12. Make certain the machine is properly grounded.<br />

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.<br />

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting<br />

wrenches are removed from the machine before turning it on.<br />

15. All work must be secured using either clamps or a vise to the drill press table. It is unsafe to use your<br />

hands to hold any workpiece being drilled.<br />

16. Keep hands in sight; do not put hands or fingers around, on, or below any rotating cutting tools.<br />

Leather safety gloves should be used when handling any sharp objects or cutting tools.<br />

17. <strong>Drill</strong> press head and table shall be securely locked to the column before operating the machine. Make<br />

a habit of checking this before each operating session.<br />

18. Avoid contact with coolant, especially the eyes and face area.<br />

19. Keep safety guards in place at all times when the machine is in use. If removed for maintenance<br />

purposes, use extreme caution and replace the guards immediately after maintenance is complete.<br />

20. Make sure the drill press is firmly anchored to the floor before use.<br />

4

21. Check damaged parts. Before further use of the machine, a guard or other part that is damaged<br />

should be carefully checked to determine that it will operate properly and perform its intended<br />

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting<br />

and any other conditions that may affect its operation. A guard or other part that is damaged should<br />

be properly repaired or replaced.<br />

<strong>22</strong>. Provide for adequate space surrounding work area and non-glare, overhead lighting.<br />

23. Keep the floor around the machine clean and free of scrap material, oil and grease.<br />

24. Keep visitors a safe distance from the work area. Keep children away.<br />

25. Make your workshop child proof with padlocks, master switches or by removing starter keys.<br />

26. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are<br />

careless acts that can result in serious injury.<br />

27. Maintain a balanced stance at all times so that you do not fall or lean against the rotating tool or other<br />

moving parts. Do not overreach or use excessive force to perform any machine operation.<br />

28. Always use the correct tooling. Tooling must be maintained and properly sharpened. All tooling must<br />

be run at the proper speeds and feed rates as they apply to the job. Use only recommended<br />

accessories and follow those manufacturer’s instructions pertaining to them. Tooling shall not be<br />

forced into any workpiece but fed according to the proper specifications.<br />

29. Use recommended accessories; improper accessories may be hazardous.<br />

30. Turn off the machine and disconnect from power before cleaning. Use a brush or compressed air to<br />

remove chips or debris — do not use your hands.<br />

31. Do not stand on the machine. Serious injury could occur if the machine tips over.<br />

32. Never leave the machine running unattended. Turn the power off and do not leave the machine until it<br />

comes to a complete stop.<br />

33. Remove loose items and unnecessary work pieces from the area before starting the machine.<br />

34. Failure to follow the above instructions may result in risk of personal injury or damage to the machine.<br />

Familiarize yourself with the following safety notices used in this manual:<br />

This means that if precautions are not heeded, it may result in minor injury and/or<br />

possible machine damage.<br />

even death.<br />

This means that if precautions are not heeded, it may result in serious injury or possibly<br />

5

Introduction<br />

This manual is provided by WMH Tool Group covering the safe operation and maintenance procedures<br />

for the <strong>JET</strong> Model J-<strong>22</strong>10 and J-<strong>22</strong>30 <strong>Drill</strong> <strong>Press</strong>es. This manual contains instructions on installation,<br />

safety precautions, general operating procedures, maintenance instructions and parts breakdown. This<br />

machine has been designed and constructed to provide years of trouble free operation if used in<br />

accordance with instructions set forth in this manual. If there are any questions or comments, please<br />

contact either your local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web<br />

site: www.wmhtoolgroup.com.<br />

Specifications<br />

Model:.....................................................................J-<strong>22</strong>10 ......................... J-<strong>22</strong>30-2 ......................J-<strong>22</strong>30-4<br />

Stock Number .......................................................354205 ............................354206 ........................ 354207<br />

Motor ...................................................... 2HP, 1Ph, 230V ..............2HP, 3Ph, 230V .......... 2HP, 3Ph, 460V<br />

<strong>Drill</strong>ing Capacity (in.)<br />

Cast Iron............................................................1-1/4 ............................... 1-1/4 ............................1-1/4<br />

Steel ..................................................................1-1/8 ............................... 1-1/8 ............................1-1/8<br />

Column Diameter (in.) .............................................4-5/16 ............................. 4-5/16 ..........................4-5/16<br />

Maximum Dimension Spindle to Column (in.)...............11 ....................................11 ................................ 11<br />

Spindle Taper........................................................... MT-3 ............................... MT-3 ............................MT-3<br />

Spindle Travel (in.) ..........................................................5 ......................................5 .................................. 5<br />

Spindle Dimension to Base (in.)..............................46-1/2 ............................. 46-1/2 ..........................46-1/2<br />

Spindle Dimension to Table (in.).............................32-3/4 ............................. 32-3/4 ..........................32-3/4<br />

Table Size (in.) ..........................................16-1/8 x 19-1/4 ............... 16-1/8 x 19-1/4 ............16-1/8 x 19-1/4<br />

Number of T-slots.............................. 2 in table, 2 in base ........ 2 in table, 2 in base .....2 in table, 2 in base<br />

Spindle <strong>Speed</strong> Range (RPM) ............60-450 & 240-1800 ...........60-450 & 120-900 ....... 60-450 & 120-900<br />

....................................................................................N/A .......120-900 & 240-1800 ... 120-900 & 240-1800<br />

Overall Height (in.) ........................................................73 ....................................73 ................................ 73<br />

Base Size (in.)...........................................19-3/8 x 29-1/4 ............... 19-3/8 x 29-1/4 ............19-3/8 x 29-1/4<br />

Table Travel (in.) .....................................................26-1/2 ............................. 26-1/2 ..........................26-1/2<br />

Net Weight – approximate (lbs.) .................................660 ..................................660 .............................. 660<br />

Shipping Weight – approximate (lbs.) .........................790 ..................................790 .............................. 790<br />

The above specifications were current at the time this manual was published, but because of our policy of<br />

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and<br />

without prior notice, without incurring obligations.<br />

6

Features and Terminology<br />

Figure 1<br />

7

Unpacking and Setup<br />

Open shipping container and check for shipping<br />

damage. Report any damage immediately to<br />

your distributor and shipping agent. Do not<br />

discard any shipping material until the <strong>Drill</strong><br />

<strong>Press</strong> is installed and running properly.<br />

Compare the contents of your container with the<br />

following parts list to make sure all parts are<br />

intact. Missing parts, if any, should be reported<br />

to your distributor. Read this manual thoroughly<br />

for installation, maintenance and safety<br />

instructions.<br />

Contents of the Shipping Container<br />

1 <strong>Drill</strong> <strong>Press</strong><br />

1 Drift Key<br />

2 Keys (for lockout switch)<br />

3 Handles<br />

1 Hex (Allen) wrench, 6mm<br />

1 Owner's Manual<br />

1 Warranty Card<br />

Remove all packing material from around the<br />

drill press, remove the four bolts in the base,<br />

and lift the drill press from the pallet using forklift<br />

or hoist.<br />

The drill press should be secured to a concrete<br />

floor for optimum stability. The base of the drill<br />

press has four mounting holes for this purpose.<br />

The drill press should be level and rest solidly<br />

on the floor. Place shims under the base as<br />

needed to level the drill press.<br />

When securing the base to the floor, apply even<br />

torque to the fasteners to prevent distortion of<br />

the base.<br />

Handle Assembly<br />

Insert the three handles into the hub (Figure 2).<br />

Use a wrench on the flats to tighten the handles<br />

to the hub.<br />

Before operating the drill press, give it an overall<br />

inspection to make sure all components are<br />

functioning properly.<br />

Electrical Connections<br />

Electrical connections must<br />

be made by a qualified electrician in<br />

compliance with all relevant codes. The<br />

machine must be properly grounded to help<br />

prevent electrical shock and possible fatal<br />

injury.<br />

8<br />

Figure 2

A power plug is not provided with the drill press.<br />

You may either connect the proper UL/CSA<br />

listed plug, or "hard-wire" the machine directly to<br />

a service panel, provided there is a disconnect<br />

near the machine for the operator. During hardwiring<br />

of the machine, make sure the fuses have<br />

been removed or the breakers have been<br />

tripped in the circuit to which the drill press will<br />

be connected. Place a warning placard on the<br />

fuse holder or circuit breaker to prevent it being<br />

turned on while the machine is being wired.<br />

When the 3-phase model is properly wired, the<br />

spindle turns clockwise in a conventional drilling<br />

rotation. If the spindle rotates the wrong<br />

direction, disconnect the machine from power<br />

and switch any two of the three incoming leads.<br />

Consult the electrical diagrams on pages <strong>22</strong>-24<br />

for further clarification of wiring.<br />

This machine must be grounded. Grounding<br />

provides a path of least resistance to help divert<br />

current away from the operator in case of<br />

electrical malfunction.<br />

Make sure the voltage of your power supply<br />

matches the specifications on the motor plate of<br />

the machine.<br />

Extension Cords<br />

For circuits which are far away from the<br />

electrical service box, the wire size must be<br />

increased in order to deliver ample voltage to<br />

the motor. An undersized cord will cause a drop<br />

in line voltage resulting in loss of power and<br />

overheating.<br />

The chart in Figure 3 shows the recommended<br />

size cord to use for branch circuits and<br />

extension cords. The smaller the gauge number<br />

the heavier the cord. If in doubt, use the next<br />

heavier wire gauge.<br />

Operating Controls<br />

(Figure 4)<br />

The keyed On/Off Switch activates power to<br />

the drill press, and can be locked in the OFF<br />

position to prevent unauthorized use.<br />

The Selector Switch is used to determine<br />

direction of spindle rotation (Fwd/Rev) and to set<br />

the speed range (1 or 2).<br />

The Emergency Stop button is for fast shut<br />

down of drilling operations. Before re-starting<br />

the drill press, rotate the emergency stop button<br />

clockwise until it disengages. NOTE: Use the<br />

basic stop button for normal stoppage of drill<br />

rotation.<br />

9<br />

Recommended Gauges (AWG) of Extension Cords<br />

Amps<br />

25<br />

feet<br />

Extension Cord Length *<br />

50<br />

feet<br />

75<br />

feet<br />

100<br />

feet<br />

150<br />

feet<br />

200<br />

feet<br />

< 5 16 16 16 14 12 12<br />

5 to 8 16 16 14 12 10 NR<br />

8 to 12 14 14 12 10 NR NR<br />

12 to 15 12 12 10 10 NR NR<br />

15 to 20 10 10 10 NR NR NR<br />

21 to 30 10 NR NR NR NR NR<br />

*based on limiting the line voltage drop to 5V at 150% of the<br />

rated amperes.<br />

NR: Not Recommended.<br />

Figure 3<br />

Figure 4

The Depth Indicator (Figure 5) can be set for<br />

drilling depths up to 5”.<br />

1. To set the Depth Indicator, lower the end of<br />

the drill against the surface into which the<br />

hole is to be drilled.<br />

2. Loosen the handle on the pointer, and slide it<br />

to the approximate position on the depth<br />

gauge which matches your hole depth.<br />

3. Tighten the handle, and then use the knurled<br />

wheel to fine-adjust the pointer into position.<br />

4. When drilling the hole, lower the spindle until<br />

the pointer reaches zero.<br />

A <strong>Speed</strong> Setting Handwheel is provided on the<br />

left side of the head. The handwheel is turned<br />

clockwise to increase spindle speed and<br />

counterclockwise to reduce speed. Check the<br />

speed by viewing the LED readout. <strong>Speed</strong> is<br />

also dependent upon the belt and pulley<br />

configuration (see “Belt Position”).<br />

Only turn the speed setting<br />

handwheel while the motor is running,<br />

otherwise damage to the speed adjustment<br />

mechanism may occur.<br />

Adjustments<br />

Work Table<br />

The table can be raised or lowered to<br />

accommodate the height of the workpiece. It<br />

should be raised enough to allow for minimum<br />

spindle movement. To raise or lower the table,<br />

loosen the two locking handles and rotate the<br />

crank handle. Always re-tighten both locking<br />

handles before operating.<br />

The work table can also be rotated on the<br />

column by loosening the two locking handles<br />

and shifting the table (along with the rack). This<br />

is usually done when drilling large workpieces,<br />

with the table shifted out of the way and the<br />

work piece secured by using jigs in the T-slots<br />

on the machine’s base.<br />

Arbor/Chuck Removal<br />

(An arbor and chuck are not included with the<br />

drill press.)<br />

1. Disconnect machine from power source.<br />

2. Lower the spindle and rotate it by hand until<br />

the slots in spindle and quill are aligned<br />

(Figure 6).<br />

3. Insert the drift key through the slot and tap it<br />

in with a wood or rubber mallet until the<br />

arbor/chuck drops out. Hold the arbor/chuck<br />

to prevent it from falling.<br />

10<br />

Figure 5<br />

Figure 6

Be sure to remove drift key<br />

from spindle before starting the drill press.<br />

Belt Position (<strong>Speed</strong> Adjustment)<br />

1. To change the speed range of the drill press,<br />

remove the access door on the side of the<br />

head.<br />

2. Loosen the locking handles and pull the<br />

tension lever to release tension on the belt.<br />

See Figure 7.<br />

NOTE: The handles are adjustable. Simply<br />

pull down on the handle, rotate it on its hub,<br />

then release it, making sure it seats itself<br />

properly on the hub.<br />

3. Move the belt to the other set of pulleys, push<br />

the tension lever back into place and retighten<br />

the locking handles.<br />

4. Close the access door.<br />

Figure 8 shows the speed ranges according to<br />

belt position and the setting of the selection<br />

switch on the front of the drill head.<br />

Operation<br />

The following operating and safety precautions<br />

must be observed in order to avoid harm to the<br />

operator or damage to the drill press.<br />

1. The work table must be locked to the<br />

column so it will not be forced down the<br />

column.<br />

2. Be sure the belt is tightened to the proper<br />

tension.<br />

3. Do not begin drilling until you are certain<br />

that the workpiece is held down securely.<br />

4. Make sure the drive motor is running before<br />

turning the speed setting handwheel in<br />

either direction.<br />

5. Make sure the drill is secured in the spindle<br />

or chuck before attempting to use the drill<br />

press.<br />

6. Make sure the spindle taper is clean and<br />

free of burrs, scoring and galling to ensure<br />

maximum gripping.<br />

11<br />

Figure 7<br />

3 Phase Model<br />

Belt on upper pulleys<br />

Selector Switch at 1: 120-900 RPM<br />

Selector Switch at 2: 240-1800 RPM<br />

Belt on lower pulleys<br />

Selector Switch at 1: 60-450 RPM<br />

Selector Switch at 2: 120-900 RPM<br />

1 Phase Model<br />

Belt on upper pulleys<br />

240-1800 RPM<br />

Belt on lower pulleys<br />

60-450 RPM<br />

Figure 8

Maintenance<br />

Make sure to disconnect<br />

electrical power to the drill press before<br />

performing maintenance, to avoid the<br />

possibility of inadvertent operation and<br />

exposure to potentially lethal voltage levels.<br />

Drive Belt Replacement<br />

1. Remove the pulley access door.<br />

2. Start drill press. Set speed control to highest<br />

speed. Stop drill press.<br />

3. Disconnect electrical power by pulling out<br />

the plug or switching off the circuit.<br />

4. Remove the handwheel and/or the turret<br />

hub, and remove the headstock cover.<br />

5. Release tension from the belt, and remove<br />

belt.<br />

6. Install the replacement belt and tension it.<br />

Tighten both locking handles. Re-install the<br />

pulley access door.<br />

7. Re-connect the drill press to power, and<br />

operate it to verify correct belt movement.<br />

If the power cord is worn, cut, or damaged in<br />

any way, have it replaced immediately.<br />

Following are lubrication recommendations for<br />

drill press components (Figures 9 and 10):<br />

Spindle pulley drive: Lubricate spindle splines<br />

occasionally with light grease.<br />

Quill and column: Lubricate with light film of<br />

SAE-20 oil.<br />

Rack: Lubricate regularly with SAE 20 oil (clean<br />

rack with kerosene before applying oil).<br />

Table raising shaft: Lubricate with oil through<br />

the oil fittings.<br />

12<br />

Figure 9<br />

Figure 10

<strong>Drill</strong>ing Recommendations<br />

<strong>Speed</strong>s for <strong>Drill</strong>ing<br />

The speed of a drill is usually measured in terms<br />

of the rate at which the outer periphery of the<br />

tool moves in relation to the work being drilled.<br />

The common term for this is Surface Feet per<br />

Minute (SFM). The relationship of SFM is<br />

expressed in the following formulas:<br />

SFM=0.26 x RPM x <strong>Drill</strong> Diameter (in <strong>inch</strong>es)<br />

RPM=3.8 x _________SFM_________<br />

<strong>Drill</strong> diameter (in <strong>inch</strong>es)<br />

In general, the higher the speed the shorter the<br />

drill life. Operating at the low end of the speed<br />

range for a particular material will result in<br />

longer life. The most efficient speed for<br />

operating a drill depends on many variables:<br />

1. Composition and hardness of material.<br />

2. Depth of the hole.<br />

3. Efficiency of the cutting fluid.<br />

4. Type and condition of the drilling machine.<br />

5. Desired quality of the hole.<br />

6. Difficulty of set-up.<br />

Feeds for <strong>Drill</strong>ing<br />

The feed of a drill is governed by the size of the<br />

tool and the material drilled. Because the feed<br />

rate partially determines the rate of production<br />

and also is a factor in tool life, it should be<br />

chosen carefully for each job. In general, the<br />

most effective feeds will be found in the ranges<br />

shown in Figure 11.<br />

Indication of Extreme <strong>Speed</strong>s/Feeds<br />

Figure 12 shows recommended speed ranges<br />

for high speed steel drills.<br />

A drill that splits up the web is evidence of too<br />

much feed or insufficient tip clearance at the<br />

center as a result of improper grinding. The<br />

rapid wearing away of the extreme outer corners<br />

of the cutting edges indicates that the speed is<br />

too high. A drill chipping or breaking out at the<br />

cutting edges indicates that either the feed is too<br />

heavy or the drill has been ground with too<br />

much tip clearance.<br />

In cases where carbon steel drills are<br />

applicable, the drill should be run at speeds of<br />

from 40 to 50 percent of those given in Figure<br />

12.<br />

13<br />

Feed Rates per <strong>Drill</strong> Size<br />

Diameter of <strong>Drill</strong><br />

(<strong>inch</strong>es)<br />

Feed per Revolution<br />

(<strong>inch</strong>es)<br />

Under 1/8 0.001 to 0.002<br />

1/8 to 1/4 0.002 to 0.004<br />

1/4 to 1/2 0.004 to 0.007<br />

1/2 to 5/8 0.007 to 0.015<br />

Figure 11<br />

<strong>Speed</strong>s for High <strong>Speed</strong> Steel <strong>Drill</strong>s<br />

Material<br />

<strong>Speed</strong><br />

(SFPM)<br />

Alloy Steel – 300 to 400 Brinell 20-30<br />

Stainless Steel 30-40<br />

Automotive Steel Forgings 40-50<br />

Tool Steel, 1.2C 50-60<br />

Steel, .4C to .5C 70-80<br />

Mild Machinery Steel, .2C to .3C 80-110<br />

Hard Chilled Cast Iron 30-40<br />

Medium Hard Cast Iron 70-100<br />

Soft Cast Iron 100-150<br />

Malleable Iron 80-90<br />

High Nickel Steel or Monel 40-50<br />

High Tensile Bronze 70-150<br />

Ordinary Brass and Bronze 200-300<br />

Aluminum and its Alloys 200-300<br />

Magnesium and its Alloys 250-400<br />

Slate, Marble, and Stone 15-25<br />

Plastics and similar material (Bakelite) 100-150<br />

Wood 300-400<br />

Titanium Alloys 10-25<br />

Titanium Alloy Sheet 50-60<br />

Figure 12

Troubleshooting<br />

Trouble Probable Cause Remedy<br />

Spindle does not turn.<br />

Spindle is noisy.<br />

<strong>Drill</strong> stalls.<br />

Poorly drilled holes.<br />

Motor overheating.<br />

Motor overload protector tripped. <strong>Press</strong> motor overload reset button.<br />

Circuit breaker tripped. Re-set circuit breaker.<br />

Branch circuit breaker tripped or fuse<br />

blown.<br />

14<br />

Re-set branch circuit breaker/replace<br />

fuse.<br />

Open wire in switch circuit. Repair open circuit.<br />

Defective switch. Replace switch.<br />

Broken drive belt. Replace drive belt.<br />

Damaged spindle bearings. Replace bearings.<br />

Worn spline. Replace spline.<br />

Worn drive belt.<br />

Excessive feed rate for size of drill and<br />

material being drilled. No cutting fluid or<br />

improper cutting fluid.<br />

Check condition of belt. Replace if glazed<br />

or slipping on pulleys.<br />

Reduce feed pressure or use cutting fluid.<br />

Use correct cutting fluid.<br />

<strong>Drill</strong> is dull. Sharpen or replace drill.<br />

Lack of rigidity in hold-down method.<br />

<strong>Speed</strong> too fast for material and drill size.<br />

Feed too fast for material and drill size. Reduce feed rate.<br />

No fluid, or improper cutting fluid or<br />

coolant being used.<br />

Improperly ground drill bit.<br />

Electrical circuit fault.<br />

Oversize drill. Reduce drill size.<br />

Excessive feed rate. Reduce feed rate.<br />

No cutting fluid, or incorrect type of fluid.<br />

Check that all T-slot hold-downs are tight<br />

and that table lock and drill head bolts are<br />

tight.<br />

Check spindle speed recommendations.<br />

Reduce speed if necessary.<br />

Use cutting fluid, or change to proper fluid<br />

or coolant for material being drilled.<br />

Check for proper angles and reliefs. Regrind<br />

to proper geometry, or replace.<br />

Check current draw in circuit. Make sure<br />

current draw is the same as rating on<br />

motor plate.<br />

Use correct cutting fluid for the material<br />

and drill.<br />

Table can not be raised. Lack of lubrication. Lubricate. See page 12.<br />

No speed readout. <strong>Speed</strong> pickup out of adjustment or failed.<br />

Adjust gap between speed pickup and<br />

post spindle pulley. If there is no readout<br />

on the LED speed indicator after adjusting<br />

the gap, replace the speed pickup. NOTE:<br />

This adjustment should be made by a<br />

qualified technician.

Replacement Parts<br />

Replacement parts are listed on the following pages. To order parts or reach our service department, call<br />

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model<br />

Number and Serial Number of your machine available when you call will allow us to serve you quickly and<br />

accurately.<br />

Exploded View: Headstock Assembly<br />

35 31<br />

36 32<br />

27<br />

26<br />

25<br />

23<br />

16<br />

15<br />

14<br />

13<br />

12<br />

30<br />

29<br />

28<br />

9<br />

34<br />

24<br />

<strong>22</strong> 18<br />

20<br />

107<br />

19A<br />

11<br />

21 18<br />

19 106<br />

10<br />

37<br />

103<br />

104<br />

105<br />

D<br />

9<br />

28<br />

31<br />

B<br />

17<br />

8<br />

66<br />

65<br />

64<br />

62<br />

61<br />

59<br />

48<br />

48<br />

1<br />

C<br />

A<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

57<br />

67<br />

63<br />

60<br />

58<br />

56<br />

55<br />

46<br />

45<br />

15<br />

21<br />

44<br />

43<br />

42<br />

40<br />

101<br />

79<br />

81<br />

98<br />

97<br />

96<br />

95<br />

94<br />

93<br />

92<br />

94<br />

91<br />

51<br />

52<br />

D<br />

102<br />

100<br />

77<br />

99<br />

90<br />

88<br />

87<br />

58<br />

86<br />

54<br />

53<br />

50<br />

49<br />

48<br />

47<br />

39<br />

89<br />

38<br />

41<br />

4<br />

85<br />

B<br />

84<br />

83<br />

82<br />

81<br />

16<br />

80<br />

79<br />

78<br />

77<br />

76<br />

75<br />

74<br />

73<br />

94<br />

72<br />

71<br />

70<br />

69<br />

68<br />

2

Parts List: Headstock Assembly<br />

Index No. Part No. Description Size Qty<br />

1 ...............<strong>22</strong>10-201..................Headstock ............................................................ .................................... 1<br />

2 ...............<strong>22</strong>10-202..................Strain Relief Connector........................................ PG13.5........................ 3<br />

3 ...............<strong>22</strong>10-203..................Handle Hub .......................................................... .................................... 1<br />

4 ...............TS-1504061 .............Socket Head Cap Screw...................................... M8x30 .........................5<br />

5 ...............<strong>22</strong>10-205..................Pin ........................................................................ Ø8x30 ......................... 1<br />

.................<strong>22</strong>10-206A ...............Handle Assembly (Item #6 & #7) ......................... .................................... 1<br />

6 ...............<strong>22</strong>10-206..................Handle.................................................................. .................................... 3<br />

7 ...............<strong>22</strong>10-207..................Handle Grip.......................................................... .................................... 3<br />

8 ...............<strong>22</strong>10-208..................Feed Shaft............................................................ .................................... 1<br />

9 ...............TS-1524031 .............Set Screw............................................................. M8x12 ......................... 2<br />

10 .............<strong>22</strong>10-210..................Star Washer ......................................................... M4............................... 2<br />

11 .............TS-1532042 .............Pan Head Screw .................................................. M4x12 ......................... 1<br />

.................<strong>22</strong>10-212A ...............Spring Cap Assembly (Item #12 & #13) .............. .................................... 1<br />

12 .............<strong>22</strong>10-212..................Spring................................................................... .................................... 1<br />

13 .............<strong>22</strong>10-213..................Spring Cap ........................................................... .................................... 1<br />

14 .............TS-1533042 .............Pan Head Screw .................................................. M5x12 ......................... 2<br />

15 .............<strong>22</strong>10-215..................Spring Seat Shaft................................................. .................................... 1<br />

16 .............TS-1504121 .............Socket Head Cap Screw...................................... M8x60 ......................... 2<br />

17 .............<strong>22</strong>10-217..................Shaft..................................................................... .................................... 1<br />

18 ............TS-1540071 .............Hex Nut ................................................................ M10............................ 2<br />

19 .............<strong>22</strong>10-219..................Clamp................................................................... .................................... 2<br />

20 .............<strong>22</strong>10-<strong>22</strong>0..................Scale Collar.......................................................... .................................... 1<br />

21 .............<strong>22</strong>10-<strong>22</strong>1..................Drive Screw.......................................................... 2x5 .............................. 6<br />

<strong>22</strong> .............TS-1523021 .............Set Screw............................................................. M6x8 ........................... 1<br />

23 .............<strong>22</strong>10-<strong>22</strong>3..................Hand Wheel ......................................................... .................................... 1<br />

24 .............<strong>22</strong>10-<strong>22</strong>4..................Handle.................................................................. .................................... 3<br />

25 .............<strong>22</strong>10-<strong>22</strong>5..................Key ....................................................................... 5x5x<strong>22</strong> ........................ 1<br />

26 .............TS-1550071 .............Flat Washer.......................................................... M10............................. 1<br />

27 .............TS-<strong>22</strong>10161 .............Hex Cap Screw .................................................... M10x16 ....................... 1<br />

28 .............<strong>22</strong>10-<strong>22</strong>8..................Bushing ................................................................ .................................... 2<br />

29 .............<strong>22</strong>10-<strong>22</strong>9A ...............Bracket................................................................. .................................... 1<br />

30 .............TS-1504041 .............Socket Head Cap Screw...................................... M8x20 ......................... 4<br />

31 .............TS-1551061 .............Lock Washer ........................................................ M8............................... 5<br />

32 .............TS-1540071 .............Hex Nut ................................................................ M10............................. 3<br />

34 .............<strong>22</strong>10-234..................Rack ..................................................................... .................................... 1<br />

35 .............TS-1504081 .............Socket Head Cap Screw...................................... M8x40 ......................... 1<br />

36 .............<strong>22</strong>10-236A ...............Moving Bracket .................................................... .................................... 1<br />

37 .............<strong>22</strong>10-237A ...............Socket Head Cap Screw...................................... M10x100 ..................... 1<br />

38 .............<strong>22</strong>10-238..................Spindle ................................................................. .................................... 1<br />

39 .............TS-1504091 .............Socket Head Cap Screw...................................... M8x45 ......................... 1<br />

40 .............<strong>22</strong>10-240..................Adjustment Nut .................................................... .................................... 1<br />

41 .............<strong>22</strong>10-241..................Seat...................................................................... .................................... 1<br />

42 .............<strong>22</strong>10-242..................Scale Bolt............................................................. .................................... 1<br />

43 .............<strong>22</strong>10-243..................Set Block.............................................................. .................................... 1<br />

44 .............<strong>22</strong>10-244..................Pointer.................................................................. .................................... 1<br />

45 .............<strong>22</strong>10-245..................Locking Handle .................................................... M6x40 ......................... 1<br />

46 .............<strong>22</strong>10-246..................C-Ring.................................................................. STW-20....................... 1<br />

47 .............<strong>22</strong>10-247..................O-Ring.................................................................. P62.............................. 1<br />

48 .............BB-6008ZZ...............Ball Bearing.......................................................... 6008ZZ........................ 3<br />

49 .............<strong>22</strong>10-249..................Quill ...................................................................... .................................... 1<br />

50 .............BB-6006ZZ...............Ball Bearing.......................................................... 6006ZZ........................ 1<br />

51 .............<strong>22</strong>10-251..................Pin ........................................................................ .................................... 2<br />

52 .............TS-1504061 .............Socket Head Cap Screw...................................... M8x30 ......................... 2<br />

53 .............<strong>22</strong>10-253..................Bearing Lock Washer........................................... .................................... 1<br />

54 .............<strong>22</strong>10-254..................Bearing Nut .......................................................... .................................... 1<br />

55 .............<strong>22</strong>10-255..................C-Ring.................................................................. STW-40....................... 1<br />

56 .............TS-1490041 .............Hex Cap Screw .................................................... M8x25 ......................... 2<br />

16

57 .............<strong>22</strong>10-257..................Bearing Housing .................................................. .................................... 1<br />

58 .............TS-1550061 .............Flat Washer.......................................................... M8............................... 3<br />

59 .............<strong>22</strong>10-259..................Driving Sleeve...................................................... .................................... 1<br />

60 .............<strong>22</strong>10-260..................Key ....................................................................... 6x6x40 ........................ 1<br />

61 .............<strong>22</strong>10-261..................Spindle Pulley ...................................................... 1Ph.............................. 1<br />

.................<strong>22</strong>10-261A ...............Spindle Pulley ...................................................... 3Ph.............................. 1<br />

62 .............TS-1524061 .............Set Screw............................................................. M8x25 ......................... 2<br />

63 .............<strong>22</strong>10-263..................Sensor Seat ......................................................... .................................... 1<br />

64 .............TS-1501061 .............Socket Head Cap Screw...................................... M4x20 ......................... 3<br />

65 .............<strong>22</strong>10-265..................Inductive Ring ...................................................... .................................... 1<br />

66 .............<strong>22</strong>10-266..................C-Ring.................................................................. STW-30....................... 1<br />

67 .............<strong>22</strong>10-267A ...............Belt (1Ph) ............................................................. 270J-8R ...................... 1<br />

.................<strong>22</strong>10-267..................Belt (3Ph) ............................................................. 280J-8R ...................... 1<br />

68 .............<strong>22</strong>10-268..................Motor .................................................................... 2HP, 1Ph, 230V .......... 1<br />

.................<strong>22</strong>302-268................Motor .................................................................... 2HP, 3Ph, 230V ......... 1<br />

.................<strong>22</strong>304-268................Motor .................................................................... 2HP, 3Ph, 460V .......... 1<br />

69 .............BB-6002ZZ...............Ball Bearing.......................................................... 6002ZZ........................ 1<br />

70 .............<strong>22</strong>10-270..................Worm Shaft .......................................................... .................................... 1<br />

71 .............<strong>22</strong>10-271..................Key ....................................................................... 8x7x40 ........................ 1<br />

72 .............<strong>22</strong>10-272..................O-Ring.................................................................. .................................... 1<br />

73 .............<strong>22</strong>10-273..................Seal ...................................................................... .................................... 1<br />

74 .............<strong>22</strong>10-274..................Motor Seat............................................................ .................................... 1<br />

75 .............TS-1550031 .............Flat Washer.......................................................... M5............................... 5<br />

76 .............TS-<strong>22</strong>35601 .............Socket Head Cap Screw...................................... M5x60 ......................... 5<br />

77 .............TS-1502041 .............Socket Head Cap Screw...................................... M5x16 ....................... 10<br />

78 .............<strong>22</strong>10-278..................Shaft Sleeve......................................................... .................................... 1<br />

79 .............<strong>22</strong>10-279..................Key ....................................................................... .................................... 2<br />

80 .............TS-1550061 .............Flat Washer.......................................................... M8............................... 1<br />

81 .............<strong>22</strong>10-281..................Pulley ................................................................... .................................... 2<br />

82 .............<strong>22</strong>10-282..................Belt ....................................................................... 950VB 28 <strong>22</strong> ............... 1<br />

83 .............<strong>22</strong>10-283..................Pulley ................................................................... .................................... 1<br />

84 .............BB-6010ZZ...............Ball Bearing.......................................................... 6010ZZ........................ 1<br />

85 .............TS-1550061 .............Flat Washer.......................................................... M8............................... 5<br />

86 .............<strong>22</strong>10-286..................Locking Handle .................................................... 3/8x20 ......................... 1<br />

87 .............<strong>22</strong>10-287..................Ball Knob.............................................................. .................................... 2<br />

88 .............<strong>22</strong>10-288..................Lever .................................................................... .................................... 2<br />

89 .............TS-0561031 .............Hex Nut ................................................................ 3/8-16.......................... 2<br />

90 .............<strong>22</strong>10-290..................Bearing Housing .................................................. .................................... 1<br />

91 .............<strong>22</strong>10-266..................C-Ring.................................................................. STW-30....................... 1<br />

92 .............<strong>22</strong>10-292..................Locking Handle .................................................... 3/8x50 ......................... 1<br />

93 .............<strong>22</strong>10-293..................Bushing ................................................................ .................................... 1<br />

94 .............BB-6206ZZ...............Ball Bearing.......................................................... 6206ZZ........................ 3<br />

95 .............<strong>22</strong>10-295..................Pulley ................................................................... 1Ph.............................. 1<br />

.................<strong>22</strong>10-295A ...............Pulley ................................................................... 3Ph.............................. 1<br />

96 .............<strong>22</strong>10-296..................Spring Seat .......................................................... .................................... 1<br />

97 .............<strong>22</strong>10-297..................Spring................................................................... .................................... 1<br />

98 .............<strong>22</strong>10-298..................Pulley ................................................................... .................................... 1<br />

99 .............<strong>22</strong>10-299..................Driving Sleeve...................................................... .................................... 1<br />

100 ...........<strong>22</strong>10-2100................Shaft..................................................................... .................................... 1<br />

101 ...........<strong>22</strong>10-2101................Key ....................................................................... 8x7x100 ...................... 1<br />

102 ...........<strong>22</strong>10-2102................C-Ring.................................................................. STW-25....................... 1<br />

103 ...........<strong>22</strong>10-2103................Motor Cord ........................................................... 1Ph.............................. 1<br />

.................<strong>22</strong>302-2103..............Motor Cord ........................................................... 3Ph.............................. 1<br />

104 ...........<strong>22</strong>10-2104................Power Cord .......................................................... 1Ph.............................. 1<br />

.................<strong>22</strong>302-2104..............Power Cord .......................................................... 3Ph.............................. 1<br />

105 ...........<strong>22</strong>10-2105................Clamp................................................................... .................................... 2<br />

106 ...........TS-1505061 .............Socket Head Cap Screw...................................... M10x40 ....................... 1<br />

107 ...........TS-1505041 .............Socket Head Cap Screw...................................... M10x30 ....................... 1<br />

17

Exploded View: Headstock Cover Assembly<br />

18

Parts List: Headstock Cover Assembly<br />

Index No. Part No. Description Size Qty<br />

1 ...............TS-1534032 .............Pan Head Screw .................................................. M6x10 ....................... 12<br />

2 ...............TS-1550041 .............Flat Washer.......................................................... M6............................... 4<br />

3 ...............J-<strong>22</strong>10-303...............Cover Plate .......................................................... .................................... 1<br />

4 ...............<strong>22</strong>10-304..................Cord Protector...................................................... .................................... 1<br />

5 ...............<strong>22</strong>10-305..................Cover.................................................................... .................................... 1<br />

6 ...............TS-2171012 .............Pan Head Screw .................................................. M4x6 ........................... 7<br />

7 ...............TS-1532042 .............Pan Head Screw .................................................. M4x12 ......................... 1<br />

8 ...............<strong>22</strong>10-308..................Support................................................................. .................................... 2<br />

9 ...............TS-<strong>22</strong>84082 .............Pan Head Screw .................................................. M4x8 ......................... 18<br />

10 .............TS-1540021 .............Hex Nut ................................................................ M4............................... 1<br />

11 .............<strong>22</strong>10-210..................Star Washer ......................................................... M4............................... 2<br />

12 .............<strong>22</strong>10-312..................Bracket................................................................. .................................... 1<br />

13 .............<strong>22</strong>10-313..................Nylon Set Screw .................................................. M4x6 ........................... 1<br />

14 .............<strong>22</strong>10-314..................Sensor.................................................................. .................................... 1<br />

15 .............<strong>22</strong>10-315..................Pushbutton Start Switch....................................... .................................... 1<br />

16 .............<strong>22</strong>10-316..................Emergency Stop Label......................................... .................................... 1<br />

17 .............<strong>22</strong>10-317..................Emergency Stop Switch....................................... .................................... 1<br />

18 .............<strong>22</strong>10-318..................Forward/ Reverse Switch..................................... 1Ph.............................. 1<br />

.................<strong>22</strong>302-318................Forward/ Reverse Switch..................................... 3Ph.............................. 1<br />

19 .............<strong>22</strong>10-319..................Pushbutton Stop Switch....................................... .................................... 1<br />

20 .............<strong>22</strong>10-320..................Safety Lock Switch............................................... .................................... 1<br />

.................<strong>22</strong>10-320-1...............Safety Lock Switch Key (Set of 2) ....................... .................................... 1<br />

21 .............<strong>22</strong>10-321..................Switch Label......................................................... .................................... 1<br />

<strong>22</strong> .............TS-<strong>22</strong>84121 .............Flat Head Screw .................................................. M4x12 ......................... 4<br />

23 .............<strong>22</strong>10-323..................Front Cover .......................................................... .................................... 1<br />

24 .............<strong>22</strong>10-324..................LED Readout Cover............................................. .................................... 1<br />

25 .............<strong>22</strong>10-325..................LED Readout ....................................................... .................................... 1<br />

26 .............<strong>22</strong>10-326..................Connector Bracket ............................................... .................................... 1<br />

27 .............<strong>22</strong>10-327..................Relay.................................................................... 2HP, 1Ph, 230V .......... 1<br />

.................<strong>22</strong>302-327................Relay.................................................................... 2HP, 3Ph, 230V .......... 1<br />

.................<strong>22</strong>304-327................Relay.................................................................... 2HP, 3Ph, 460V .......... 1<br />

28 .............<strong>22</strong>10-328..................Contactor Switch.................................................. .................................... 1<br />

29 .............<strong>22</strong>10-329..................Fuse ..................................................................... 2A................................ 1<br />

30 .............<strong>22</strong>10-330..................Connector Bracket ............................................... .................................... 1<br />

31 .............<strong>22</strong>10-331..................Tapping Screw ..................................................... M4x12 ......................... 2<br />

32 .............<strong>22</strong>10-332..................Bracket................................................................. .................................... 1<br />

33 .............<strong>22</strong>10-333..................Pointer.................................................................. .................................... 1<br />

34 .............<strong>22</strong>10-334..................Tapping Screw ..................................................... M5x8 ........................... 5<br />

35 .............<strong>22</strong>10-335..................Scale Bracket....................................................... .................................... 1<br />

36 .............<strong>22</strong>10-336..................Scale .................................................................... .................................... 1<br />

37 .............TS-1550021 .............Flat Washer.......................................................... M4............................... 2<br />

38 .............TS-<strong>22</strong>84082 .............Screw ................................................................... M4x8 ........................... 2<br />

39 .............<strong>22</strong>10-339..................Plate ..................................................................... .................................... 1<br />

40 .............TS-<strong>22</strong>84082 .............Screw ................................................................... M4x8 ......................... 18<br />

41 .............J-<strong>22</strong>10-341...............Left Side Cover .................................................... .................................... 1<br />

42 .............<strong>22</strong>10-342..................Plate ..................................................................... .................................... 1<br />

43 .............J-<strong>22</strong>10-343...............Right Side Cover.................................................. .................................... 1<br />

44 .............J-<strong>22</strong>10-344...............Access Door......................................................... .................................... 1<br />

45 .............TS-0561031 .............Hex Nut ................................................................ 3/8-16.......................... 1<br />

46 .............JC-M05 ....................Door Latch............................................................ .................................... 1<br />

47 .............<strong>22</strong>10-347..................Knob..................................................................... .................................... 1<br />

48 .............TS-1534032 .............Pan Head Screw .................................................. M6x10 ......................... 8<br />

49 .............TS-1550041 .............Flat Washer.......................................................... M6............................... 4<br />

.................<strong>22</strong>304-350................Transformer (Only for 460V) - Not Shown ........... ....................................1<br />

19

Exploded View: Base and Column Assembly<br />

20

Parts List: Base and Column Assembly<br />

Index No. Part No. Description Size Qty<br />

1 ...............J-<strong>22</strong>10-101...............Base ..................................................................... .................................... 1<br />

2 ...............J-<strong>22</strong>10-102...............Lower Column Holder .......................................... .................................... 1<br />

3 ...............<strong>22</strong>10-103..................Rack ..................................................................... .................................... 1<br />

4 ...............<strong>22</strong>10-104..................Column................................................................. .................................... 1<br />

5 ...............<strong>22</strong>10-105..................Pinion Gear .......................................................... .................................... 1<br />

6 ...............<strong>22</strong>10-106..................Worm Shaft .......................................................... .................................... 1<br />

7 ...............<strong>22</strong>10-107..................Bushing ................................................................ .................................... 1<br />

8 ...............<strong>22</strong>10-108..................Spring Pin............................................................. Ø5x30 ......................... 1<br />

9 ...............<strong>22</strong>10-109..................Bushing ................................................................ .................................... 1<br />

10 .............TS-1540061 .............Hex Nut ................................................................ M8............................... 1<br />

11 .............<strong>22</strong>10-111..................Set Screw............................................................. M8x30 ......................... 1<br />

12 .............<strong>22</strong>10-112..................Shaft..................................................................... .................................... 1<br />

13 .............<strong>22</strong>10-113..................Locking Handle .................................................... .................................... 2<br />

14 .............<strong>22</strong>10-114..................Fitting ................................................................... .................................... 2<br />

15 .............J-<strong>22</strong>10-115...............Table .................................................................... .................................... 1<br />

16 .............<strong>22</strong>10-116..................Plug ...................................................................... PT 3/8-19 .................... 2<br />

17 .............TS-1505061 .............Socket Head Cap Screw...................................... M10x40 ....................... 6<br />

18 .............TS-1551071 .............Lock Washer ........................................................ M10........................... 10<br />

19 .............TS-1505101 .............Socket Head Cap Screw...................................... M10x60 ....................... 4<br />

20 .............J-<strong>22</strong>10-120...............Holder Bracket ..................................................... .................................... 1<br />

21 .............TS-1506051 .............Socket Head Cap Screw...................................... M12x40 ....................... 4<br />

<strong>22</strong> .............TS-2361121 .............Lock Washer ........................................................ M12............................. 4<br />

23 .............<strong>22</strong>10-123..................Handle Assembly ................................................. .................................... 1<br />

24 .............<strong>22</strong>10-124..................Drift Key ............................................................... .................................... 1<br />

25 .............TS-152707 ...............Hex Wrench ......................................................... 6mm............................ 1<br />

21

Electrical Connections – 1 Phase, 230V<br />

<strong>22</strong>

Electrical Connections – 3 Phase, 230V<br />

23

Electrical Connections – 3 Phase, 460V<br />

WMH Tool Group, Inc.<br />

2420 Vantage Drive<br />

Elgin, Illinois 60124<br />

Phone: 800-274-6848<br />

www.wmhtoolgroup.com<br />

24