films and process sequence ... - Kodak

films and process sequence ... - Kodak

films and process sequence ... - Kodak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

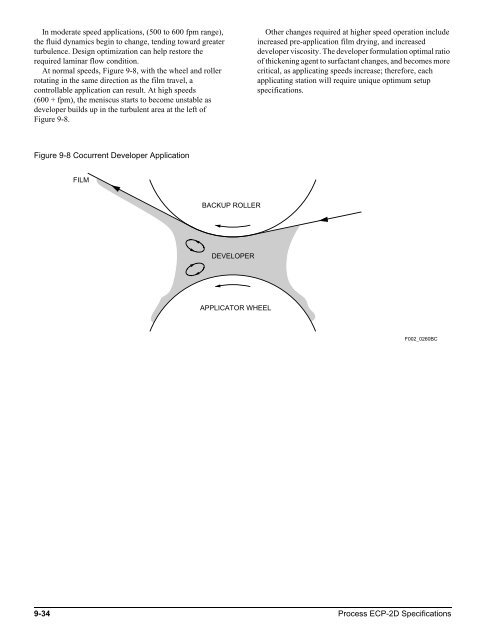

In moderate speed applications, (500 to 600 fpm range),<br />

the fluid dynamics begin to change, tending toward greater<br />

turbulence. Design optimization can help restore the<br />

required laminar flow condition.<br />

At normal speeds, Figure 9-8, with the wheel <strong>and</strong> roller<br />

rotating in the same direction as the film travel, a<br />

controllable application can result. At high speeds<br />

(600 + fpm), the meniscus starts to become unstable as<br />

developer builds up in the turbulent area at the left of<br />

Figure 9-8.<br />

Figure 9-8 Cocurrent Developer Application<br />

FILM<br />

BACKUP ROLLER<br />

DEVELOPER<br />

APPLICATOR WHEEL<br />

Other changes required at higher speed operation include<br />

increased pre-application film drying, <strong>and</strong> increased<br />

developer viscosity. The developer formulation optimal ratio<br />

of thickening agent to surfactant changes, <strong>and</strong> becomes more<br />

critical, as applicating speeds increase; therefore, each<br />

applicating station will require unique optimum setup<br />

specifications.<br />

F002_0260BC<br />

9-34 Process ECP-2D Specifications