Effects of Mechanical and Chemical Variations in Process ... - Kodak

Effects of Mechanical and Chemical Variations in Process ... - Kodak

Effects of Mechanical and Chemical Variations in Process ... - Kodak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

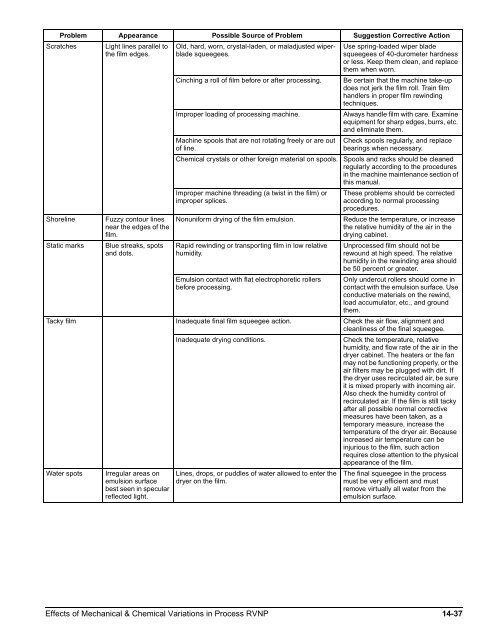

Problem Appearance Possible Source <strong>of</strong> Problem Suggestion Corrective Action<br />

Scratches Light l<strong>in</strong>es parallel to<br />

the film edges.<br />

Shorel<strong>in</strong>e Fuzzy contour l<strong>in</strong>es<br />

near the edges <strong>of</strong> the<br />

film.<br />

Static marks Blue streaks, spots<br />

<strong>and</strong> dots.<br />

Old, hard, worn, crystal-laden, or maladjusted wiperblade<br />

squeegees.<br />

Use spr<strong>in</strong>g-loaded wiper blade<br />

squeegees <strong>of</strong> 40-durometer hardness<br />

or less. Keep them clean, <strong>and</strong> replace<br />

them when worn.<br />

C<strong>in</strong>ch<strong>in</strong>g a roll <strong>of</strong> film before or after process<strong>in</strong>g. Be certa<strong>in</strong> that the mach<strong>in</strong>e take-up<br />

does not jerk the film roll. Tra<strong>in</strong> film<br />

h<strong>and</strong>lers <strong>in</strong> proper film rew<strong>in</strong>d<strong>in</strong>g<br />

techniques.<br />

Improper load<strong>in</strong>g <strong>of</strong> process<strong>in</strong>g mach<strong>in</strong>e. Always h<strong>and</strong>le film with care. Exam<strong>in</strong>e<br />

equipment for sharp edges, burrs, etc.<br />

<strong>and</strong> elim<strong>in</strong>ate them.<br />

Mach<strong>in</strong>e spools that are not rotat<strong>in</strong>g freely or are out<br />

<strong>of</strong> l<strong>in</strong>e.<br />

Check spools regularly, <strong>and</strong> replace<br />

bear<strong>in</strong>gs when necessary.<br />

<strong>Chemical</strong> crystals or other foreign material on spools. Spools <strong>and</strong> racks should be cleaned<br />

regularly accord<strong>in</strong>g to the procedures<br />

<strong>in</strong> the mach<strong>in</strong>e ma<strong>in</strong>tenance section <strong>of</strong><br />

this manual.<br />

Improper mach<strong>in</strong>e thread<strong>in</strong>g (a twist <strong>in</strong> the film) or<br />

improper splices.<br />

These problems should be corrected<br />

accord<strong>in</strong>g to normal process<strong>in</strong>g<br />

procedures.<br />

Nonuniform dry<strong>in</strong>g <strong>of</strong> the film emulsion. Reduce the temperature, or <strong>in</strong>crease<br />

the relative humidity <strong>of</strong> the air <strong>in</strong> the<br />

dry<strong>in</strong>g cab<strong>in</strong>et.<br />

Rapid rew<strong>in</strong>d<strong>in</strong>g or transport<strong>in</strong>g film <strong>in</strong> low relative<br />

humidity.<br />

Emulsion contact with flat electrophoretic rollers<br />

before process<strong>in</strong>g.<br />

Unprocessed film should not be<br />

rewound at high speed. The relative<br />

humidity <strong>in</strong> the rew<strong>in</strong>d<strong>in</strong>g area should<br />

be 50 percent or greater.<br />

Only undercut rollers should come <strong>in</strong><br />

contact with the emulsion surface. Use<br />

conductive materials on the rew<strong>in</strong>d,<br />

load accumulator, etc., <strong>and</strong> ground<br />

them.<br />

Tacky film Inadequate f<strong>in</strong>al film squeegee action. Check the air flow, alignment <strong>and</strong><br />

cleanl<strong>in</strong>ess <strong>of</strong> the f<strong>in</strong>al squeegee.<br />

Inadequate dry<strong>in</strong>g conditions. Check the temperature, relative<br />

humidity, <strong>and</strong> flow rate <strong>of</strong> the air <strong>in</strong> the<br />

dryer cab<strong>in</strong>et. The heaters or the fan<br />

may not be function<strong>in</strong>g properly, or the<br />

air filters may be plugged with dirt. If<br />

the dryer uses recirculated air, be sure<br />

it is mixed properly with <strong>in</strong>com<strong>in</strong>g air.<br />

Also check the humidity control <strong>of</strong><br />

recirculated air. If the film is still tacky<br />

after all possible normal corrective<br />

measures have been taken, as a<br />

temporary measure, <strong>in</strong>crease the<br />

temperature <strong>of</strong> the dryer air. Because<br />

<strong>in</strong>creased air temperature can be<br />

<strong>in</strong>jurious to the film, such action<br />

requires close attention to the physical<br />

appearance <strong>of</strong> the film.<br />

Water spots Irregular areas on<br />

emulsion surface<br />

best seen <strong>in</strong> specular<br />

reflected light.<br />

L<strong>in</strong>es, drops, or puddles <strong>of</strong> water allowed to enter the<br />

dryer on the film.<br />

The f<strong>in</strong>al squeegee <strong>in</strong> the process<br />

must be very efficient <strong>and</strong> must<br />

remove virtually all water from the<br />

emulsion surface.<br />

<strong>Effects</strong> <strong>of</strong> <strong>Mechanical</strong> & <strong>Chemical</strong> <strong>Variations</strong> <strong>in</strong> <strong>Process</strong> RVNP 14-37