Article. Energy in fokus - from Kyoto to Copenhagen. - AgroTech

Article. Energy in fokus - from Kyoto to Copenhagen. - AgroTech

Article. Energy in fokus - from Kyoto to Copenhagen. - AgroTech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mart<strong>in</strong> Lykke Rytter Jensen and Bo Nørregaard Jørgensen, University of Southern Denmark, The Maersk Mc-K<strong>in</strong>ney Moller Institute,<br />

Campusvej 55, DK-5230 Odense M, Denmark<br />

Oliver Körner, <strong>AgroTech</strong>, Højbakkegaard Allé 21, DK-2630 Taastrup, Denmark, Carl-Ot<strong>to</strong> Ot<strong>to</strong>sen, University of Aarhus,<br />

Faculty of Agricultural Sciences, Department of Horticulture, Kirst<strong>in</strong>ebjergvej 10, Postboks 102, DK-5792 Aarslev, Denmark<br />

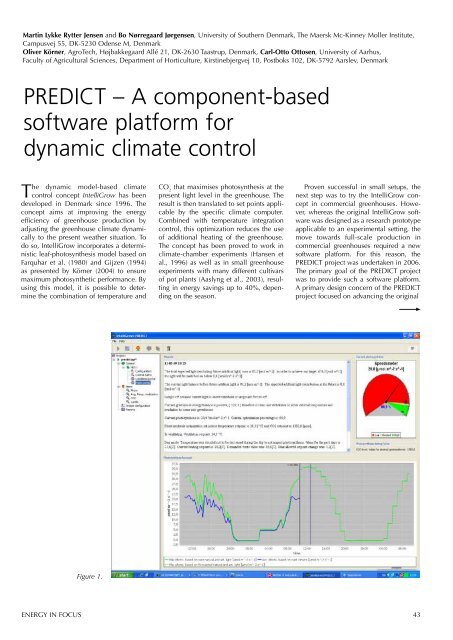

is caused by lack of CO2. The graph also shows the maximum pho<strong>to</strong>synthesis we can expect <strong>in</strong> the<br />

near future (green dashed l<strong>in</strong>e). This pho<strong>to</strong>synthesis is cont<strong>in</strong>uously calculated based on irradiation<br />

data <strong>from</strong> the most current weather forecast. When a cloudy day is expected, the control system wil<br />

au<strong>to</strong>matically turn on artificial light earlier <strong>in</strong> an attempt <strong>to</strong> achieve a specified light sum. The<br />

PREDICT – A component-based<br />

software platform for<br />

dynamic climate control<br />

grower can use the forecast <strong>to</strong> see how much artificial light will be needed and potentially adapt the<br />

light strategy before it is executed. The transition of this version of the PREDICT software <strong>in</strong><strong>to</strong><br />

commercial greenhouses was planned as a three-phase process. In the first phase, the software was<br />

tested and demonstrated <strong>to</strong> growers <strong>in</strong> a greenhouse research facility. Here, the software gives the<br />

growers advice on optimal climate control with respect <strong>to</strong> production rate. In the second phase, the<br />

software was <strong>in</strong>stalled at Danish Growers. To start with, the software runs <strong>in</strong> simulated mode; that is<br />

the software only computes the climate set po<strong>in</strong>ts, it does not effectuate them. The primary purpose<br />

of this phase is <strong>to</strong> allow the growers <strong>to</strong> become familiar with the software, how it operates, and understand<br />

the effect of dynamic climate control. The f<strong>in</strong>al phase is active control where the PRE-<br />

DICT software takes control of the climate based on overall goals set by the grower. Through the<br />

The dynamic model-based development climate of COa new that maximises component-based pho<strong>to</strong>synthesis software at the platform Proven for successful dynamic <strong>in</strong> climate small setups, control, the the PRE-<br />

2<br />

control concept IntelliGrow DICT has project been has present contributed light level with <strong>in</strong> the extended greenhouse. knowledge The next of step the was implication <strong>to</strong> try the of IntelliGrow <strong>in</strong>creas<strong>in</strong>g conthe<br />

ab-<br />

developed <strong>in</strong> Denmark s<strong>in</strong>ce straction 1996. The level result of climate is then control. translated This <strong>to</strong> set knowledge po<strong>in</strong>ts appli- is crucial cept <strong>in</strong> for commercial develop<strong>in</strong>g greenhouses. the next Howe- generation of<br />

concept aims at improv<strong>in</strong>g <strong>in</strong>telligent the energy climate-control cable by the components.<br />

specific climate computer. ver, whereas the orig<strong>in</strong>al IntelliGrow soft-<br />

efficiency of greenhouse production by Comb<strong>in</strong>ed with temperature <strong>in</strong>tegration ware was designed as a research pro<strong>to</strong>type<br />

adjust<strong>in</strong>g the greenhouse climate References dynami- control, this optimization reduces the use applicable <strong>to</strong> an experimental sett<strong>in</strong>g, the<br />

cally <strong>to</strong> the present weather Hansen situation. JM, To Ehler of additional N, Karlsen heat<strong>in</strong>g P, Høgh-Schmidt of the greenhouse. K, Rosenqvist move <strong>to</strong>wards E. (1996). full-scale A computer production controlled <strong>in</strong><br />

do so, IntelliGrow <strong>in</strong>corporates chamber a determisystem<br />

The designed concept has for been greenhouse proved <strong>to</strong> microclimate work <strong>in</strong> commercial modell<strong>in</strong>g greenhouses and control. required Acta a Hort. new<br />

nistic leaf-pho<strong>to</strong>synthesis model 440:310-315.<br />

based on climate-chamber experiments (Hansen et software platform. For this reason, the<br />

Farquhar et al. (1980) and Gijzen Aaslyng, (1994) J.M., al., Lund, 1996) J.B., as well Ehler, as <strong>in</strong> N. small and Rosenqvist, greenhouse E. PREDICT (2003) project IntelliGrow: was undertaken a greenhouse <strong>in</strong> 2006. compo-<br />

as presented by Körner (2004) nent-based <strong>to</strong> ensure climate experiments control with system. many different Environmental cultivars Modell<strong>in</strong>g The primary & goal Software of the 18: PREDICT 657-666 project<br />

maximum pho<strong>to</strong>synthetic performance. Gijzen H. By (1994) of pot Ontwikkel<strong>in</strong>g plants (Aaslyng van et al., een 2003), simulatiemodel resul- was voor <strong>to</strong> provide transpiratie such a en software wateropname platform. en van<br />

us<strong>in</strong>g this model, it is possible een <strong>to</strong> <strong>in</strong>tegral deter- gewasmodel. t<strong>in</strong>g <strong>in</strong> energy (Development sav<strong>in</strong>gs up <strong>to</strong> 40%, of a depen- simulation A primary model design for transpiration concern of the and PREDICT water uptake<br />

m<strong>in</strong>e the comb<strong>in</strong>ation of temperature and an and <strong>in</strong>tegral d<strong>in</strong>g crop on model), the season. AB-DLO, Wagen<strong>in</strong>gen, The project Netherlands. focused on advanc<strong>in</strong>g pp. 90. the orig<strong>in</strong>al<br />

Farquhar G.D., Von Caemmerer S., Berry J.A. (1980) A biochemical model of pho<strong>to</strong>synthetic CO2<br />

assimilation <strong>in</strong> leaves of C3 species. Planta 149:78-90.<br />

Körner O. (2004) Evaluation of crop pho<strong>to</strong>synthesis models for dynamic climate control. Acta<br />

Horticulturae 654:295-302.<br />

Figure 1.<br />

ENERGY IN FOCUS 43