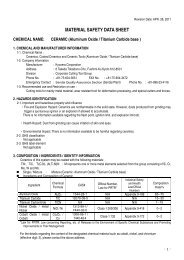

High-Efficiency Facemill MFPN - Kyocera

High-Efficiency Facemill MFPN - Kyocera

High-Efficiency Facemill MFPN - Kyocera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

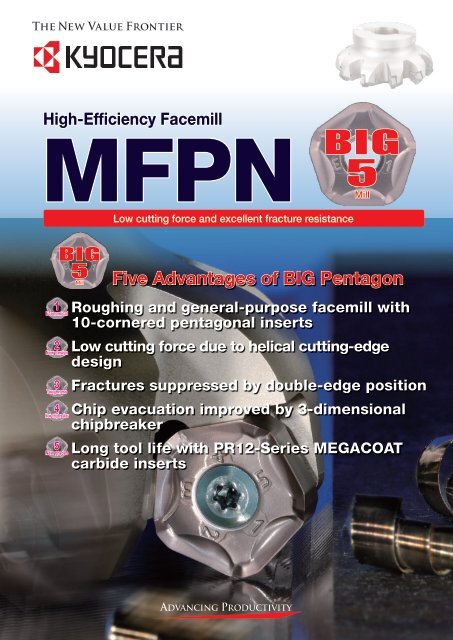

<strong>High</strong>-<strong>Efficiency</strong> <strong>Facemill</strong><br />

<strong>MFPN</strong><br />

Low cutting force and excellent fracture resistance<br />

1<br />

Economical<br />

2<br />

New design<br />

3<br />

Toughness<br />

4<br />

New chipbreaker<br />

5<br />

New grades<br />

BIG<br />

5<br />

5Mill Mill<br />

BIG<br />

5<br />

5Mill Mill<br />

Five Advantages of BIG Pentagon<br />

Roughing and general-purpose facemill with<br />

10-cornered pentagonal inserts<br />

Low cutting force due to helical cutting-edge<br />

design<br />

Fractures suppressed by double-edge position<br />

Chip evacuation improved by 3-dimensional<br />

chipbreaker<br />

Long tool life with PR12-Series MEGACOAT<br />

carbide inserts

1<br />

1<br />

2<br />

3<br />

Wiper edge<br />

BIG<br />

5<br />

5Mill Mill<br />

Economical<br />

New design<br />

Toughness<br />

Pioneering a new era<br />

Roughing and general-purpose facemill with<br />

10-cornered pentagonal inserts<br />

ap (mm) Depth of cut<br />

12<br />

10<br />

8<br />

6<br />

5<br />

4<br />

3<br />

2<br />

0.5<br />

Two-face restraint<br />

Major<br />

cutting edge<br />

BI<br />

Low cutting force due to helical cutting-edge<br />

5<br />

design<br />

MSRS<br />

Conventional<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6<br />

fz (mm/t) Feed per tooth<br />

+10°<br />

(A.R.)<br />

Main cutting edge<br />

No. 1<br />

<strong>MFPN</strong><br />

<strong>High</strong> feed machining substantially improves efficiency<br />

NEW<br />

<strong>MFPN</strong><br />

■Pentagonal double-sided tip excellent for<br />

constraining stability<br />

■10-cornered insert cuts cost per corner<br />

■Helical cutting-edge design with low<br />

cutting force reduces chattering<br />

■Helical cutting-edge design<br />

·<strong>High</strong> rake angle (A.R. Max. +10°)<br />

0.7<br />

Cutting edge<br />

angle 45°<br />

BI<br />

Principal force<br />

Feed force<br />

Back force 5M<br />

Fractures suppressed with double-edge position<br />

■Double-edge position<br />

·Major cutting edge makes chips thin,<br />

thereby reducing impact load at entrance<br />

and exit of workpiece<br />

Double-edge position<br />

Five Advantages of BIG Pentagon<br />

Main cutting edge<br />

No. 2<br />

Cutting force comparison (N)<br />

2000<br />

1600<br />

1200<br />

800<br />

400<br />

●Cutting force comparison<br />

0<br />

<strong>High</strong>ly stabilized accuracy due to two-face<br />

constraint facing the major cutting edge<br />

16% reduction in comparison<br />

with competitor A<br />

14% reduction in<br />

comparison with GM<br />

GM SM<br />

Competitor A Competitor B<br />

●Cutting conditions<br />

Workpiece :S50C<br />

Vc=150m/min, fz=0.1mm/t, apxae=5x105 mm, Machine :M/C(BT50)<br />

●Fracture resistance comparison<br />

PNMU1205ANER-GM<br />

(PR1225)<br />

Competitor C<br />

(PVD negative insert)<br />

Competitor D<br />

(PVD negative insert)<br />

No. of impacts<br />

0 5 10 15 20<br />

×<br />

×<br />

×<br />

×<br />

×<br />

×<br />

fz=0.5mm/t fz=0.6mm/t fz=0.7mm/t<br />

●Cutting conditions<br />

Workpiece :SCM440(38~42HS)<br />

Machine :BT50 M/C<br />

Vc=100m/min, fz=0.5~0.7mm/t,<br />

apxae=2x100mm (workpiece with 20mm width slot)<br />

0.5mm/t<br />

0.6mm/t<br />

0.7mm/t<br />

:No cracks<br />

× : Insert cracks

AT Hard<br />

ill<br />

<strong>High</strong>-<strong>Efficiency</strong> <strong>Facemill</strong><br />

<strong>MFPN</strong><br />

Milling-Facing PeNtagonal type<br />

5<br />

New grades<br />

G<br />

4<br />

New<br />

chipbreaker<br />

Long tool life with PR12-Series<br />

MEGACOAT carbide inserts<br />

■MEGACOAT<br />

·Long tool life and high-speed milling due to high hardness and<br />

high oxidation resistance<br />

●Wear comparison<br />

Flank wear [mm]<br />

●Cutting conditions<br />

Workpiece :SCM440H<br />

Vc=250m/min, fz =0.12mm/t<br />

apxae=2x85mm, Cutter Dia.:125mm<br />

Cut distance per 1 path:340mm<br />

3-dimensional chipbreaker<br />

improves chip evacuation<br />

■Smooth chip evacuation reduces chip-biting<br />

·3-types of chipbreakers enable coverage of a wide range<br />

of milling conditions<br />

Chipbreaker Applications Shape<br />

GM General<br />

SM<br />

GH<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.00<br />

0 20 40 60 80<br />

Cutting time [min]<br />

Low cutting<br />

force<br />

Heavy<br />

milling<br />

ap (mm) Depth of cut<br />

6<br />

3<br />

1<br />

Competitor E<br />

Competitor F<br />

Competitor G<br />

PR1225<br />

SM<br />

Hardness(GPa)<br />

40<br />

30<br />

20<br />

10<br />

GM<br />

TiC<br />

TiCN<br />

MEGACOAT<br />

TiN<br />

TiAlN<br />

(ref:carbide)<br />

0 200 400 600 800 1000 1200<br />

Oxidation temperature (˚C)<br />

GH<br />

MEGACOAT<br />

Insert grades Workpiece<br />

PR1225<br />

PR1210<br />

Steel / Stainless steel<br />

Cast iron / Titanium alloy<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

fz (mm/t) Feed per tooth<br />

2

3<br />

■<strong>MFPN</strong>45<br />

●Holder Dimension<br />

Bore Dia. Inch spec<br />

mm spec<br />

Coarse pitch<br />

Cross pitch<br />

Extra cross pitch<br />

Coarse pitch<br />

Cross pitch<br />

Extra cross pitch<br />

Description<br />

Stock<br />

E<br />

a<br />

No.of<br />

Insert<br />

ød<br />

b<br />

ød2<br />

ød1<br />

øD<br />

øD1<br />

45˚<br />

6<br />

H<br />

E<br />

a<br />

Rake<br />

Angle(°)<br />

ød<br />

b<br />

ød1<br />

øD<br />

øD1<br />

Dimension(mm)<br />

45˚<br />

6<br />

H<br />

A.R. R.R.<br />

max +10°<br />

Fig.1 Fig.2 Fig.3<br />

øD øD1 ød ød1 ød2 H E a b ød3 ød4<br />

E<br />

øD=63 -10°<br />

øD=80 -8°<br />

øD=100-250 -6°<br />

ød<br />

b<br />

ød2<br />

ød1<br />

øD<br />

øD1<br />

ød3<br />

ød4<br />

45˚<br />

Shape Weight<br />

(kg)<br />

<strong>MFPN</strong> 45080R-5T<br />

45100R-6T<br />

45125R-7T<br />

●<br />

●<br />

●<br />

5<br />

6<br />

7<br />

80<br />

100<br />

125<br />

93<br />

113<br />

138<br />

25.4<br />

31.75<br />

38.1<br />

22<br />

48<br />

58<br />

13<br />

-<br />

50<br />

27<br />

32<br />

36<br />

6<br />

8<br />

10<br />

9.5<br />

12.7<br />

15.9<br />

- -<br />

Fig.1<br />

Fig.2<br />

1.1<br />

1.4<br />

2.6<br />

45160R-8T<br />

45200R-10T<br />

45250R-12T<br />

●<br />

●<br />

●<br />

8<br />

10<br />

12<br />

160<br />

200<br />

250<br />

173<br />

213<br />

263<br />

50.8<br />

47.625<br />

72<br />

110 101.6<br />

63<br />

38<br />

40<br />

11<br />

14<br />

19.1<br />

25.4 18 26 Fig.3<br />

4.0<br />

6.7<br />

9.4<br />

<strong>MFPN</strong> 45080R-6T<br />

45100R-8T<br />

45125R-10T<br />

●<br />

●<br />

●<br />

6<br />

8<br />

10<br />

80<br />

100<br />

125<br />

93<br />

113<br />

138<br />

25.4<br />

31.75<br />

38.1<br />

22<br />

48<br />

58<br />

13<br />

-<br />

50<br />

27<br />

32<br />

36<br />

6<br />

8<br />

10<br />

9.5<br />

12.7<br />

15.9<br />

- -<br />

Fig.1<br />

Fig.2<br />

1.1<br />

1.4<br />

2.7<br />

45160R-12T<br />

45200R-14T<br />

45250R-16T<br />

●<br />

●<br />

●<br />

12<br />

14<br />

16<br />

160<br />

200<br />

250<br />

173<br />

213<br />

263<br />

50.8<br />

47.625<br />

72<br />

110 101.6<br />

63<br />

38<br />

40<br />

11<br />

14<br />

19.1<br />

25.4 18 26 Fig.3<br />

4.0<br />

6.9<br />

9.6<br />

<strong>MFPN</strong> 45080R-8T<br />

45100R-10T<br />

45125R-13T<br />

●<br />

●<br />

●<br />

8<br />

10<br />

13<br />

80<br />

100<br />

125<br />

93<br />

113<br />

138<br />

25.4<br />

31.75<br />

38.1<br />

22<br />

48<br />

58<br />

13<br />

-<br />

50<br />

27<br />

32<br />

36<br />

6<br />

8<br />

10<br />

9.5<br />

12.7<br />

15.9<br />

- -<br />

Fig.1<br />

Fig.2<br />

1.1<br />

1.3<br />

2.7<br />

45160R-16T<br />

45200R-18T<br />

45250R-20T<br />

●<br />

●<br />

●<br />

16<br />

18<br />

20<br />

160<br />

200<br />

250<br />

173<br />

213<br />

263<br />

50.8<br />

47.625<br />

72<br />

110 101.6<br />

63<br />

38<br />

40<br />

11<br />

14<br />

19.1<br />

25.4 18 26 Fig.3<br />

4.0<br />

6.9<br />

9.6<br />

<strong>MFPN</strong> 45063R-4T-M<br />

45080R-5T-M<br />

45100R-6T-M<br />

45125R-7T-M<br />

45160R-8T-M<br />

45200R-10T-M<br />

45250R-12T-M<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

4<br />

5<br />

6<br />

7<br />

8<br />

10<br />

12<br />

63<br />

80<br />

100<br />

125<br />

160<br />

200<br />

250<br />

76<br />

93<br />

113<br />

138<br />

173<br />

213<br />

263<br />

22<br />

27<br />

32<br />

40<br />

60<br />

19<br />

22<br />

48<br />

58<br />

68<br />

110<br />

11<br />

13<br />

-<br />

66.7<br />

101.6<br />

40<br />

50<br />

63<br />

21<br />

24<br />

30<br />

32<br />

40<br />

6.3<br />

7<br />

8<br />

9<br />

14<br />

10.4<br />

12.4<br />

14.4<br />

16.4<br />

25.7<br />

-<br />

14<br />

18<br />

-<br />

20<br />

26<br />

Fig.1<br />

Fig.2<br />

Fig.3<br />

0.5<br />

1.1<br />

1.4<br />

2.6<br />

3.8<br />

6.4<br />

9.1<br />

<strong>MFPN</strong> 45063R-5T-M<br />

45080R-6T-M<br />

45100R-8T-M<br />

45125R-10T-M<br />

45160R-12T-M<br />

45200R-14T-M<br />

45250R-16T-M<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

5<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

63<br />

80<br />

100<br />

125<br />

160<br />

200<br />

250<br />

76<br />

93<br />

113<br />

138<br />

173<br />

213<br />

263<br />

22<br />

27<br />

32<br />

40<br />

60<br />

19<br />

22<br />

48<br />

58<br />

68<br />

110<br />

11<br />

13<br />

-<br />

66.7<br />

101.6<br />

40<br />

50<br />

63<br />

21<br />

24<br />

30<br />

32<br />

40<br />

6.3<br />

7<br />

8<br />

9<br />

14<br />

10.4<br />

12.4<br />

14.4<br />

16.4<br />

25.7<br />

-<br />

14<br />

18<br />

-<br />

20<br />

26<br />

Fig.1<br />

Fig.2<br />

Fig.3<br />

0.5<br />

1.0<br />

1.4<br />

2.5<br />

3.8<br />

6.5<br />

9.1<br />

<strong>MFPN</strong> 45063R-6T-M<br />

45080R-8T-M<br />

45100R-10T-M<br />

45125R-13T-M<br />

45160R-16T-M<br />

45200R-18T-M<br />

45250R-20T-M<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

6<br />

8<br />

10<br />

13<br />

16<br />

18<br />

20<br />

63<br />

80<br />

100<br />

125<br />

160<br />

200<br />

250<br />

76<br />

93<br />

113<br />

138<br />

173<br />

213<br />

263<br />

22<br />

27<br />

32<br />

40<br />

60<br />

19<br />

22<br />

48<br />

58<br />

68<br />

110<br />

11<br />

13<br />

-<br />

-<br />

66.7<br />

101.6<br />

40<br />

50<br />

63<br />

21<br />

24<br />

30<br />

32<br />

40<br />

6.3<br />

7<br />

8<br />

9<br />

14<br />

10.4<br />

12.4<br />

14.4<br />

16.4<br />

25.7<br />

-<br />

14<br />

18<br />

-<br />

20<br />

26<br />

Fig.1<br />

Fig.2<br />

Fig.3<br />

0.5<br />

1.1<br />

1.3<br />

2.6<br />

3.9<br />

6.6<br />

9.3<br />

6<br />

H<br />

Shim<br />

Yes<br />

-<br />

-<br />

Yes<br />

-<br />

-<br />

●:Std. Stock

■Spare Parts<br />

●Spare parts (mm / inch common spec)<br />

Coarse pitch<br />

Cross pitch<br />

Extra cross pitch<br />

MP-1<br />

Description<br />

Clamp<br />

Screw<br />

Wrench<br />

TT DTM<br />

Spare Parts<br />

Shim Shim Screw Wrench<br />

Anti-seize<br />

Compound<br />

MP-1<br />

Arbar<br />

Clamp Screw<br />

<strong>MFPN</strong> 45063R-4T-M<br />

HH10x30<br />

<strong>MFPN</strong> 45080R-5T-(M) SB-50140TR TT-15 <strong>MFPN</strong>-45 SPW-7050 LW-5 HH12x40<br />

<strong>MFPN</strong> 45100R-6T-(M)<br />

45250R-12T-(M)<br />

for Insert Clamp<br />

Recommended torque is<br />

4.2 Nm.<br />

-<br />

for Shim Clamp<br />

Recommended torque is<br />

6.0 Nm.<br />

MP-1<br />

-<br />

<strong>MFPN</strong> 45063R-5T-M<br />

HH10x30<br />

<strong>MFPN</strong> 45080R-6T-(M) SB-50140TR TT-15 HH12x40<br />

<strong>MFPN</strong> 45100R-8T-(M) for Insert Clamp<br />

- - - - MP-1<br />

Recommended torque is<br />

-<br />

45250R-16T-(M)<br />

4.2 Nm.<br />

<strong>MFPN</strong> 45063R-6T-M<br />

HH10x30<br />

<strong>MFPN</strong> 45080R-8T-(M) SB-40140TRN - DTM-15 HH12x40<br />

<strong>MFPN</strong> 45100R-10T-(M)<br />

for Insert Clamp<br />

- - - MP-1<br />

45250R-20T-(M)<br />

Recommended torque is<br />

3.5 Nm.<br />

-<br />

~<br />

~<br />

~<br />

∙Coat Anti-seize Compound (MP-1) thinly on portion of taper and thread when insert is fixed.<br />

■Insert description Classification of usage P<br />

●Milling Inserts (with hole) ★ Roughing / 1st Choice<br />

Roughing / 2nd Choice<br />

■ Finishing / 1st Choice<br />

Finishing / 2nd Choice<br />

Shape<br />

Handled insert indicates Right-Hand<br />

General<br />

Low cutting force<br />

Tough Edge (for heavy milling)<br />

Z<br />

Z<br />

Z<br />

X<br />

X<br />

X<br />

A<br />

A<br />

A<br />

T<br />

T<br />

T<br />

Ød<br />

Ød<br />

Ød<br />

(Hardened material is applicable only under<br />

45HRC)<br />

Description<br />

PNMU 1205ANER-GM<br />

Steel ★<br />

Die Steel ★<br />

M Stainless Steel ★<br />

K<br />

Gray Cast Iron<br />

Nodular Cast Iron<br />

★<br />

★<br />

N Non-ferrous Material<br />

S<br />

Heat-resistant Alloy<br />

Titanium alloy<br />

★<br />

★<br />

H Hardened material<br />

Dimension(mm) MEGACOAT<br />

A T ød X Z PR1225 PR1210<br />

17.88 5.56<br />

● ●<br />

PNMU 1205ANER-SM 6.2 2.0 2.0 ● ●<br />

PNMU 1205ANER-GH 17.98 6.17 ● ●<br />

●Reference for selecting a facemill and insert suitable for each milling purpose<br />

Milling Purpose<br />

General milling for steel and alloy steel<br />

Steel and alloy steel (to prevent chattering due to low rigidity<br />

machine or poor clamping power)<br />

Productivity oriented (Running cost decrease) (Over ap=4 mm,<br />

over fz=0.35 mm/t)<br />

Genral milling for stainless steel<br />

Stainless steel (to prevent chattering due to low rigidity<br />

machine or poor clamping power)<br />

Cast iron (for processing efficiency improvement)<br />

Cast iron (Over ap=4 mm, over fz=0.35 mm/t)<br />

Coarse<br />

pitch<br />

<strong>Facemill</strong>-type Chipbreaker<br />

Cross pitch<br />

Extra cross<br />

pitch<br />

●:Std. Stock<br />

GM SM GH<br />

4

5<br />

■Case studies<br />

·Construction machine part<br />

·Vc=170m/min<br />

·apxae=4x10mm<br />

·fz=0.3mm/t<br />

·Vf=1350mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45125R-10T<br />

(10 edges)<br />

·Insert<br />

PNMU1205ANER-GM<br />

(PR1225)<br />

<strong>MFPN</strong><br />

(PR1225)<br />

Competitor H<br />

SS400<br />

Face milling (with meltdown surface)<br />

1500<br />

·<strong>MFPN</strong> facemill enables stable milling due to reduced chip-biting and<br />

edge cracks<br />

·<strong>MFPN</strong> facemill, no chattering, showed 3 times longer tool life than<br />

competitor<br />

·Construction machine part<br />

·Vc=175m/min<br />

·apxae=1.5x100mm<br />

·fz=0.19mm/t<br />

·Vf=790mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45160R-12T<br />

(12 edges)<br />

·Insert<br />

PNMU1205ANER-GM<br />

(PR1225)<br />

<strong>MFPN</strong><br />

(PR1225)<br />

Competitor J<br />

3pcs/edge<br />

Alloy steel<br />

Total D.O.C.:15mm<br />

2pcs/edge<br />

1pcs/edge<br />

1pcs/edge<br />

100<br />

200<br />

3 times<br />

longer tool life<br />

Evaluation by the user<br />

·<strong>MFPN</strong> facemill showed 2 times longer tool life than competitor<br />

·Competitor caused cracks by chip-biting. <strong>MFPN</strong> facemill had no<br />

cracks and allowed stable milling<br />

·<strong>MFPN</strong> facemill enabled twice the table feed rate compared with the<br />

competitor. Milling efficiency improved two-fold.<br />

100<br />

ø400<br />

2 times<br />

longer tool life<br />

Evaluation by the user<br />

·Pipe<br />

·Vc=180m/min<br />

·apxae=2x80mm<br />

·fz=0.44mm/t<br />

·Vf=2010mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45125R-10T<br />

(10 edges)<br />

·Insert<br />

PNMU1205ANER-GM<br />

(PR1210)<br />

<strong>MFPN</strong><br />

(PR1210)<br />

Competitor I<br />

FCD450<br />

ø3000<br />

·<strong>MFPN</strong> facemill showed 1.5 times longer tool life than the competitor<br />

·<strong>High</strong> feed rate of <strong>MFPN</strong> allowed 1.3 times higher milling efficiency<br />

compared to the competitor<br />

·Press die<br />

·Vc=130m/min<br />

·apxae=6x150mm<br />

·fz=0.15mm/t<br />

·Vf=460mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45160R-12T<br />

(12 edges)<br />

·Insert<br />

PNMU1205ANER-GM<br />

(PR1210)<br />

<strong>MFPN</strong><br />

(PR1225)<br />

Competitor K<br />

FCD600<br />

Face milling<br />

3pcs/edge<br />

2pcs/edge<br />

Cutting time<br />

128 minutes<br />

3000<br />

Cutting time<br />

167 minutes<br />

80<br />

2000<br />

1.5 times<br />

longer tool life<br />

Evaluation by the user<br />

·<strong>High</strong>ly stable milling into the entrance of workpiece and less vibration<br />

than the competitor<br />

·Cleanly curled chips which barely cause chip-biting<br />

·Cutting speed has been changed Vc=110 m/min of conventional<br />

competitor's to Vc=130 m/min, thereby the milling efficiency of<br />

<strong>MFPN</strong> increased 1.2 times<br />

300<br />

Milling efficiency<br />

increased 1.2 times<br />

Evaluation by the user

■Case studies<br />

·Plate<br />

·Vc=230m/min<br />

·apxae=5.0x80mm<br />

·fz=0.19mm/t<br />

·Vf=1090mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45160R-12T<br />

(12 edges)<br />

·Insert<br />

PNMU1205ANER-SM<br />

(PR1225)<br />

<strong>MFPN</strong><br />

(PR1225)<br />

Competitor L<br />

(for roughing)<br />

SS400<br />

2000<br />

·<strong>MFPN</strong> facemill causes no vibration, enabling stable milling, even<br />

though the number of cutting edges of facemill has been increased<br />

by 4 and the feed per tooth has been increased by 1.3 times<br />

·Does not generate much heat after milling and obtains the lustrous<br />

surface finish without burrs<br />

·Milling efficiency increased 2.6 times with the high cutting conditions<br />

·Plate<br />

·Vc=180m/min<br />

·apxae=3x80mm<br />

·fz=0.15mm/t<br />

·Vf=690mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45125R-10T<br />

(10 edges)<br />

·Insert<br />

PNMU1205ANER-GM<br />

(PR1225)<br />

[Conventional]<br />

Vc=140m/min<br />

apxae=3x80mm<br />

fz=0.11mm/t<br />

(Vf=230mm/min)<br />

Cutting time 7.3<br />

minutes<br />

(4 passes)<br />

Cutting time 19 minutes<br />

(4 passes)<br />

SCM415<br />

300<br />

80<br />

Milling efficiency<br />

increased 2.6 times<br />

Evaluation by the user<br />

·Even if the cutting speed and feed rate are raised up to the level of the<br />

conventional tool, the tool life of <strong>MFPN</strong> remains unchanged and milling<br />

efficiency increases by 2.6 times<br />

·<strong>MFPN</strong> vibrates less right at entrance and exit on workpiece with reduced<br />

cutting sound<br />

400<br />

Evaluation by the user<br />

· Shaft (End face milling)<br />

·Vc=140m/min<br />

·apxae=0.4x50mm<br />

·fz=0.19mm/t<br />

·Vf=635mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45080R-6T<br />

(6 edges)<br />

·Insert<br />

PNMU1205ANER-SM<br />

(PR1225)<br />

Alloy steel<br />

End face milling<br />

·Although the conventional tool causes chattering, <strong>MFPN</strong> facemill<br />

suppresses chattering, enabling stable milling<br />

·Even if the feed rate is raised to 1.9 times, the insert wears less and<br />

there is no cracks on the insert<br />

·Both the milling efficiency and the tool life have been improved<br />

·Case<br />

·Vc=90m/min<br />

·apxae=0.4x50mm<br />

·fz=0.19mm/t<br />

·Vf=410mm/min<br />

·DRY<br />

·Cutter<br />

<strong>MFPN</strong>45080R-6T<br />

(6 edges)<br />

·Insert<br />

PNMU1205ANER-SM<br />

(PR1225)<br />

<strong>MFPN</strong><br />

(PR1225)<br />

Competitor M<br />

(for roughing)<br />

SUS304<br />

500<br />

800<br />

1.5pcs/edge<br />

1pcs/edge<br />

ø90<br />

Evaluation by the user<br />

·Even when the cutting depth, cutting speed and feed rate cannot be<br />

raised due to the low rigidity of a workpiece, <strong>MFPN</strong> facemill enables<br />

stable milling without chattering and also has an improved tool life of<br />

1.5 times<br />

600<br />

Milling efficiency<br />

increased 1.5 times<br />

Evaluation by the user<br />

6

■Precautions for use (How to mount an insert)<br />

1.Be sure to remove dust and chips from the insert mounting pocket.<br />

2.After applying anti-seize compound on portion of taper and thead, while pressing the insert against the constraint<br />

surfaces, put the screw into the hole of the insert and tighten the screw with appropriate torque. See Fig. 1 and Fig. 2.<br />

Recommended tightening torque → The torque for coarse pitch and cross pitch (using M5 screw) is 4.2 Nm.<br />

The torque for extra cross pitch (using M4 screw) is 3.5 Nm.<br />

3.After tightening the screw, make sure that there is no clearance between the insert seat surface and the bearing surface of<br />

the holder and between the insert side surfaces and the constraint surface of the holder.<br />

4.To change the cutting edge of the insert, turn the insert counterclockwise (see Fig. 3). Insert corner identification number is<br />

stamped on the top surface of insert except SM chipbreaker(Fig. 4).<br />

To protect the wiper edge, use the corners of insert in the sequence of corner numbers.<br />

Constraint<br />

surface<br />

■ Recommended conditions<br />

Work Piece Material<br />

Insert<br />

Grade<br />

Cutting Speed<br />

(m/min)<br />

Chipbreaker<br />

fz(mm/t) Feed per tooth<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

Carbon Steel<br />

SxxC<br />

PR1225 120~180~250<br />

GM★<br />

SM 0.06<br />

0.1<br />

● 0.12<br />

● 0.2<br />

0.25<br />

0.4<br />

GH 0.2<br />

● 0.4 0.7<br />

Alloy Steel<br />

SCM<br />

PR1225 100~160~220<br />

GM★<br />

SM 0.06<br />

0.1 ● 0.2<br />

● 0.12<br />

0.25<br />

0.4<br />

GH 0.2 ● 0.4<br />

0.6<br />

Die Steel<br />

SKD/NAK<br />

PR1225 80~140~180<br />

GM★<br />

SM 0.06<br />

0.1<br />

● 0.1<br />

● 0.2<br />

0.2<br />

0.35<br />

GH 0.2 ● 0.35 0.5<br />

Stainless Steel<br />

SUS304 PR1225 100~150~200<br />

GM<br />

SM★ 0.06<br />

0.1 ● 0.2<br />

● 0.12<br />

0.25<br />

0.4<br />

Gray Cast Iron<br />

FC<br />

PR1210 120~180~250<br />

GM★<br />

SM 0.06<br />

0.1 ● 0.2<br />

● 0.12 0.25<br />

0.4<br />

GH 0.2<br />

● 0.4 0.7 0.7<br />

Nodular Cast Iron<br />

FCD<br />

PR1210 100~150~200<br />

GM★<br />

SM 0.06<br />

0.1<br />

● 0.1<br />

● 0.2<br />

0.2<br />

0.35<br />

GH 0.2 ● 0.35 0.5<br />

Titanium Alloy PR1210 30~50~70 SM★ 0.06 ● 0.08 0.15<br />

Cutter Specifications<br />

Coarse pitch (with shim)<br />

Cross pitch (without shim)<br />

(For GH chipbreaker, recommend under fz=0.4<br />

mm/t.)<br />

Extra cross pitch (without shim)<br />

The use of the GH breaker is not recommended.<br />

Side surface<br />

of insert<br />

Fig.1 Fig.2 Fig.3 Fig.4<br />

Top surface<br />

of insert<br />

Insert corner<br />

identication number<br />

❋The bold-faced number indicates a center value of recommended condition. ★:1st Recommendation :2nd Recommendation