NTRD-02 Final Project Report The Effects of Low Rolling Resistance ...

NTRD-02 Final Project Report The Effects of Low Rolling Resistance ...

NTRD-02 Final Project Report The Effects of Low Rolling Resistance ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 J1321 TRACK TESTS AND RESULTS<br />

<strong>The</strong> new Texas Drayage Truck Test Cycle was used to evaluate low-mass low-rolling resistance<br />

tires on representative trucks in the SAE J1321 “Joint TMC/SAE Fuel Consumption Test<br />

Procedure Type II”. <strong>The</strong> test program was designed to evaluate both the fuel economy and the<br />

NOx impact <strong>of</strong> using the wide-single tires on drayage trucks while hauling chassis with<br />

corresponding containers. <strong>The</strong> test trucks were model year 2006 Freightliner Class 8 trucks with<br />

Detroit Diesel engines. In addition to gravimetric fuel tanks for measuring fuel economy, a<br />

Portable Emissions Monitoring System (PEMS) was installed in each truck to measure NOx.<br />

<strong>The</strong> PEMS units were Sensors, Inc. SEMTECH-D instruments.<br />

<strong>The</strong> J1321 recommended practice provides a standard test procedure for comparing the inservice<br />

fuel consumption <strong>of</strong> a vehicle operating under two conditions: a test and a baseline. An<br />

unchanging control vehicle is run in tandem with a test vehicle to provide an unchanging<br />

reference. <strong>The</strong> result <strong>of</strong> a test using this procedure is the percentage difference in fuel<br />

consumption or NOx emissions <strong>of</strong> the test vehicle in two different test configurations.<br />

<strong>The</strong> program setup is discussed in Section 5.1, the testing is discussed in Section 5.2, and the<br />

results from the track tests are presented in Section 5.3. A complete record <strong>of</strong> the track testing is<br />

available in Sh<strong>of</strong>fner et al. (2007).<br />

5.1 Program Setup<br />

Two truck and chassis/container combinations (each one designated a truck and trailer “rig”)<br />

were used for testing. <strong>The</strong> trucks were chosen to be as close to each other as possible in<br />

construction, age, and usage history. Note the similar VIN numbers and engine serial numbers in<br />

the specifications and data for the trucks, chassis trailers, and containers shown in Table 2. A<br />

photograph <strong>of</strong> one <strong>of</strong> the truck and trailer rigs is provided in Figure 9.<br />

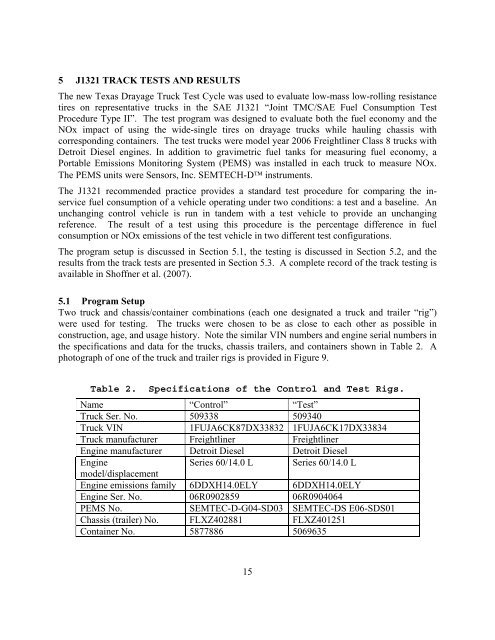

Table 2. Specifications <strong>of</strong> the Control and Test Rigs.<br />

Name “Control” “Test”<br />

Truck Ser. No. 509338 509340<br />

Truck VIN 1FUJA6CK87DX33832 1FUJA6CK17DX33834<br />

Truck manufacturer Freightliner Freightliner<br />

Engine manufacturer Detroit Diesel Detroit Diesel<br />

Engine<br />

Series 60/14.0 L Series 60/14.0 L<br />

model/displacement<br />

Engine emissions family 6DDXH14.0ELY 6DDXH14.0ELY<br />

Engine Ser. No. 06R09<strong>02</strong>859 06R0904064<br />

PEMS No. SEMTEC-D-G04-SD03 SEMTEC-DS E06-SDS01<br />

Chassis (trailer) No. FLXZ4<strong>02</strong>881 FLXZ401251<br />

Container No. 5877886 5069635<br />

15