Commissioning of Electrical Systems for Command, Control

Commissioning of Electrical Systems for Command, Control

Commissioning of Electrical Systems for Command, Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TM 5-694<br />

(5) Volumetric leakage current. The current that flows through the volume insulation itself is volumetric<br />

leakage current. It is the current that is <strong>of</strong> primary interest in the evaluation <strong>of</strong> the condition <strong>of</strong> the insulation. In<br />

shielded power cable systems (rated > 5 kV), humidity, condensation, and precipitation on the surface <strong>of</strong> a<br />

termination can increase surface leakage current and volumetric leakage current. Surface leakage current and<br />

volumetric current added together is the quotient <strong>of</strong> the applied dc voltage and insulation resistance. In large ac<br />

rotating machines rated 10,000 kVA or greater and rated 6000 V or higher, moisture, on the end windings,<br />

increases surface leakage current and volumetric leakage current especially when dirt is also on the winding.<br />

Since the insulation may weaken over time, age may cause an increase in the various currents during testing.<br />

d. Insulation-resistance (megger) testing. For equipment containing electronic components, megger<br />

testing must not be per<strong>for</strong>med. However, this equipment should be tested according to manufacturer<br />

specifications. In an insulation-resistance test, an applied voltage, from 600 to 5000 volts, supplied from<br />

a source <strong>of</strong> constant potential, is applied across the insulation. The usual potential source is a<br />

megohmeter, also known as a megger, either hand or power operated that indicates the insulation<br />

resistance directly on a scale calibrated in megohms. A megohmeter that is a hand cranked, a rectifiertype,<br />

or battery-operated instrument is suitable <strong>for</strong> testing equipment rated up to 600 volts. For<br />

equipment rated over 600 volts, use <strong>of</strong> a 1000-volt or 2500-volt motor-driven or rectifier-type<br />

megohmeter is recommended <strong>for</strong> optimum test results. The quality <strong>of</strong> the insulation is evaluated based on<br />

the level <strong>of</strong> the insulation resistance. The insulation resistance <strong>of</strong> many types <strong>of</strong> insulation is variable<br />

with temperature, so the data obtained should be corrected to the standard temperature <strong>for</strong> the class <strong>of</strong><br />

equipment under test. Published charts similar to table 2-1 are available <strong>for</strong> this purpose. The megohm<br />

value <strong>of</strong> insulation resistance obtained will be inversely proportional to the volume <strong>of</strong> insulation being<br />

tested. For example, a cable 1000-ft (304.8 m) long would be expected to have one-tenth the insulation<br />

resistance <strong>of</strong> a cable 100-ft (30.48 m) long if all other conditions were identical. The insulation-resistance<br />

test is relatively easy to per<strong>for</strong>m and is a useful test used on all types and classes <strong>of</strong> electrical equipment.<br />

Its main value lies in the charting <strong>of</strong> data from periodic tests, corrected <strong>for</strong> temperature, over the life <strong>of</strong><br />

the equipment so that deteriorative trends might be detected.<br />

2-10<br />

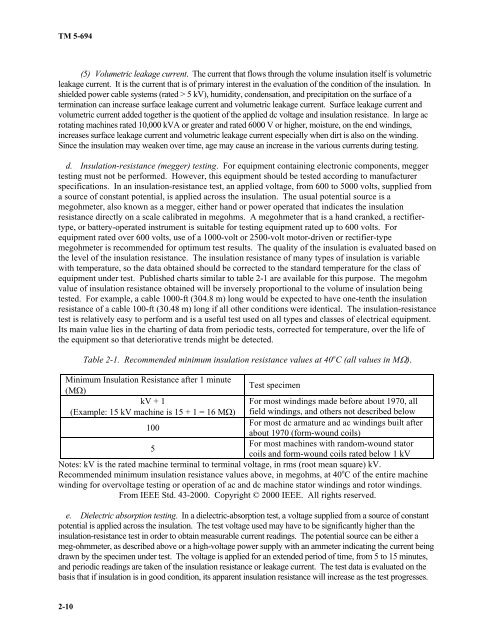

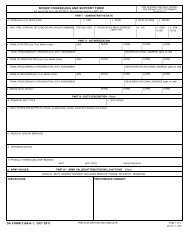

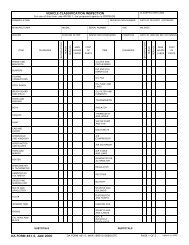

Table 2-1. Recommended minimum insulation resistance values at 40 o C (all values in MΩ).<br />

Minimum Insulation Resistance after 1 minute<br />

Test specimen<br />

(MΩ)<br />

kV + 1<br />

For most windings made be<strong>for</strong>e about 1970, all<br />

(Example: 15 kV machine is 15 + 1 = 16 MΩ) field windings, and others not described below<br />

For most dc armature and ac windings built after<br />

100<br />

about 1970 (<strong>for</strong>m-wound coils)<br />

For most machines with random-wound stator<br />

5<br />

coils and <strong>for</strong>m-wound coils rated below 1 kV<br />

Notes: kV is the rated machine terminal to terminal voltage, in rms (root mean square) kV.<br />

Recommended minimum insulation resistance values above, in megohms, at 40 o C <strong>of</strong> the entire machine<br />

winding <strong>for</strong> overvoltage testing or operation <strong>of</strong> ac and dc machine stator windings and rotor windings.<br />

From IEEE Std. 43-2000. Copyright © 2000 IEEE. All rights reserved.<br />

e. Dielectric absorption testing. In a dielectric-absorption test, a voltage supplied from a source <strong>of</strong> constant<br />

potential is applied across the insulation. The test voltage used may have to be significantly higher than the<br />

insulation-resistance test in order to obtain measurable current readings. The potential source can be either a<br />

meg-ohmmeter, as described above or a high-voltage power supply with an ammeter indicating the current being<br />

drawn by the specimen under test. The voltage is applied <strong>for</strong> an extended period <strong>of</strong> time, from 5 to 15 minutes,<br />

and periodic readings are taken <strong>of</strong> the insulation resistance or leakage current. The test data is evaluated on the<br />

basis that if insulation is in good condition, its apparent insulation resistance will increase as the test progresses.