Chilling Tendency and Chill of Cast Iron

Chilling Tendency and Chill of Cast Iron

Chilling Tendency and Chill of Cast Iron

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E. Fraś et al:<strong><strong>Chill</strong>ing</strong> <strong>Tendency</strong> <strong>and</strong> <strong>Chill</strong> <strong>of</strong> <strong>Cast</strong> <strong>Iron</strong> 179<br />

The theoretical predictions agree qualitatively with<br />

the available data in the literature. In particular, it is<br />

well known that the chill <strong>of</strong> cast iron decreases with<br />

increasing eutectic cell or nodule count N (<strong>and</strong> in consequence<br />

Ncr) as a result <strong>of</strong> inoculation, as well as decreased<br />

heating times <strong>and</strong> decreased bath superheating<br />

temperature [11] . It is also known that increasing C <strong>and</strong><br />

Si in the cast iron reduces the chill [11] . An increase in<br />

the carbon (1) increases the eutectic cell count in<br />

uninoculated cast iron or the number <strong>of</strong> nodules<br />

(Ncr) [11] , (2) decreases the proeutectic austenite fraction<br />

fγ (Table 1), (3) slightly narrows the ∆Tsc range (Eq. (9)<br />

<strong>and</strong> Table 1) <strong>and</strong> (4) decreases the austenite liquidus<br />

temperature Tl. Points 1 <strong>and</strong> 2 are the main reason for<br />

the reduction in the chill by carbon (Eqs. (1) <strong>and</strong> (2)).<br />

An increase in the silicon (1) reduces the growth coefficient<br />

for graphite eutectic µ (Table 1), (2) increases<br />

the cell or the number <strong>of</strong> nodules (Ncr) [11] , (3) decreases<br />

the proeutectic austenite fraction fγ (Table 1), (4)<br />

widens the ∆Tsc range (Eq. (9) <strong>and</strong> Table 1), <strong>and</strong> (5)<br />

decreases the austenite liquidus temperature Tl. The effects<br />

<strong>of</strong> increases in the number <strong>of</strong> cells or nodules <strong>and</strong><br />

<strong>of</strong> the proeutectic austenite fraction are the most important<br />

<strong>and</strong> as a result silicon reduces the chill (Eqs. (1)<br />

<strong>and</strong> (2)).<br />

In addition, the critical plate wall thicknesses, scr,<br />

<strong>and</strong> the wedge chill widths, W, according to Eqs. (1),<br />

(2), (3), <strong>and</strong> (6) increase as the ability <strong>of</strong> the mold to<br />

absorb heat, a, increases. scr <strong>and</strong> W also depend on B,<br />

B1, <strong>and</strong> B2 (Eq. (11)) <strong>and</strong>, hence, on the initial temperature,<br />

Ti, <strong>of</strong> the cast iron just after pouring into the<br />

mould. Higher pouring temperatures, Tp, will result in<br />

higher Ti. Therefore, decreasing Tp reduces φ parameter<br />

(Eq. (10)), thus increasing scr <strong>and</strong> W (Eqs. (1) <strong>and</strong> (2)).<br />

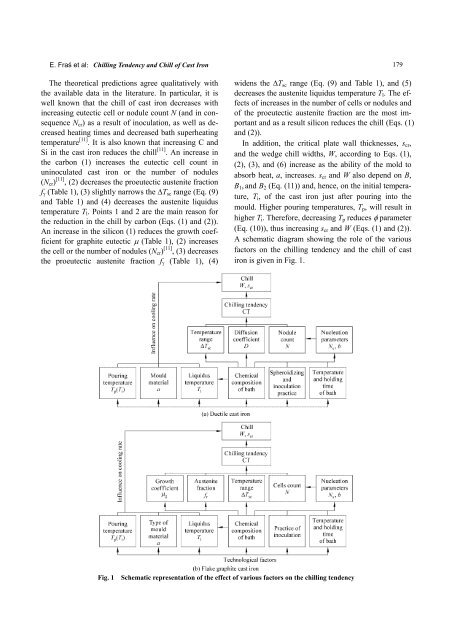

A schematic diagram showing the role <strong>of</strong> the various<br />

factors on the chilling tendency <strong>and</strong> the chill <strong>of</strong> cast<br />

iron is given in Fig. 1.<br />

Fig. 1 Schematic representation <strong>of</strong> the effect <strong>of</strong> various factors on the chilling tendency