Description recipe

Description recipe

Description recipe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5 Recipes<br />

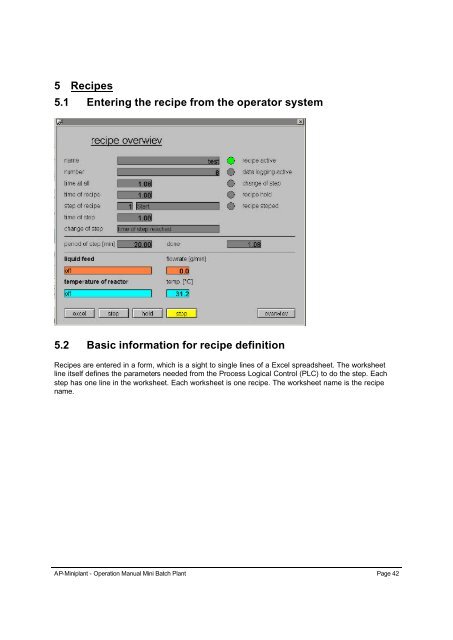

5.1 Entering the <strong>recipe</strong> from the operator system<br />

5.2 Basic information for <strong>recipe</strong> definition<br />

Recipes are entered in a form, which is a sight to single lines of a Excel spreadsheet. The worksheet<br />

line itself defines the parameters needed from the Process Logical Control (PLC) to do the step. Each<br />

step has one line in the worksheet. Each worksheet is one <strong>recipe</strong>. The worksheet name is the <strong>recipe</strong><br />

name.<br />

AP-Miniplant - Operation Manual Mini Batch Plant Page 42

Screen for <strong>recipe</strong> definition<br />

Recipes will be defined in the form shown above. Each register is a step.<br />

It is possible to change values in this form during the <strong>recipe</strong> is executed. It can take up to 10 seconds<br />

until the new value can be seen on the operator screen. The changes you make at the <strong>recipe</strong> during<br />

operation are resident and still valid when doing this <strong>recipe</strong> the next time.<br />

The most important parameter is the condition, where the steps are terminated and the next step is<br />

started. The other input fields allow you to enter the different set-points, ramps, constant values,<br />

on/off-values.<br />

This program can cause an error during evaluation of a macro-program. You should always answer<br />

the Windows-message with “stop program”. In this case the worksheet will appear again and you may<br />

have to start the program again with the button in the <strong>recipe</strong>-table.<br />

IMPORTANT:<br />

Do not push the „Stop“-Button and the safety question by mistake. Your experiment can be<br />

worthless.<br />

AP-Miniplant - Operation Manual Mini Batch Plant Page 43

Important:<br />

To be sure that a <strong>recipe</strong> value has been taken over into the Excel-worksheet, you have to leave the changed<br />

field button with the “Enter”- button or you have to press the acknowledge button.<br />

To be sure that your <strong>recipe</strong> has properly taken over all your important changes, just change the Step once<br />

to come back to the original one.<br />

Do not change the name or the place of the data file <strong>recipe</strong>.xls<br />

5.2.1 Change of Step<br />

The most important parameter is the one where you define how your step is terminated. In this plant<br />

you have the possibilities<br />

"time of step reached"<br />

"temperature of reactor reached"<br />

"pressure of reactor reached" (only possible in overpressure mode)<br />

"dosing mass of liquid feed reached"<br />

"dosing mass of solid feed reached"<br />

"torque of stirrer reactor reached"<br />

"change of step manually"<br />

"purge system w. pressure successful"<br />

"pressure test successful"<br />

5.2.2 Process parameter input<br />

The rest are the process values and set points you can send to the control system during a running<br />

Step. This is more or less self explaining for somebody who knows the plant.<br />

For some set points you have the possibility to enter a value for the Beginning and one for the End of<br />

a Step. A ramp will be calculated between this 2 values. This is only possible for time terminated<br />

steps. If you want a constant value, you have to enter the same value in both fields.<br />

The window structure is dynamic and some values are only visible in a certain constellation. For<br />

example if you are in a step where reaching a certain temperature will terminate the step, nobody<br />

knows exactly when this point is reached. Therefore it does not make a sense to enter a ramp function<br />

for the temperature set point. This is only useful in a time-terminated step. So in this case only one<br />

input field for the temperature set point is given.<br />

IMPORTANT:<br />

If you select or , be sure that your values in the<br />

inertisation sub screen in WinCC are as you want them. They are used and can not be<br />

influenced by the <strong>recipe</strong>.<br />

DANGER:<br />

If you select be aware of the fact that hydrogen is used to build up<br />

overpressure in any case, except there is Helium connected to the hydrogen input.<br />

5.2.3 Choosing a <strong>recipe</strong> or create a new one<br />

Recipes can be chosen in the Field right top of the screen left of the button. Please note that<br />

after choosing the <strong>recipe</strong> you have to press the enter button to show its parameters in the Register.<br />

AP-Miniplant - Operation Manual Mini Batch Plant Page 44

To delete <strong>recipe</strong>s you have to go to the Excel worksheet and delete it manually. This is only allowed<br />

for experts.<br />

Important:<br />

Make sure that you have a copy of the file before you delete single tables. Never delete the<br />

table named “data”. It is a necessary table for the start parameters and the file for stored data.<br />

New <strong>recipe</strong>s will always be created on the basis of an existing one. Please press the button top<br />

right of the screen. Choose a <strong>recipe</strong> as a basis. Enter the name of the new <strong>recipe</strong> and press .<br />

5.2.4 Step Name and Overview<br />

Under the Tab strip you can enter the name of the Step. The number will be generated automatically<br />

with a proceeding “S” for Step. Short names are recommended to keep the register smaller.<br />

If the register is wider than the screen, small arrows will appear top right which allow you to scroll to<br />

the steps in the invisible area.<br />

With the button you can go<br />

into a screen showing all the<br />

programmed steps.<br />

Selecting and double clicking a step<br />

brings you directly to this step in the<br />

<strong>recipe</strong> definition screen.<br />

AP-Miniplant - Operation Manual Mini Batch Plant Page 45

5.2.5 Paste new steps and delete steps<br />

New steps are generated copying old steps. You just go on the step you want to copy and press the<br />

button. Afterwards you can alter the values.<br />

A selected step will be deleted using the button. It is not possible to undo this operation.<br />

5.2.6 Recipe Start and Stop<br />

Input screen for identification data before the <strong>recipe</strong> is started<br />

Pressing the button opens another window. Here you have to enter the data to identify your<br />

experiment. It is also used to generate the file name. Therefore it is necessary, that your identification<br />

code is unique. The name of the data file is “Project”_”Experiment No.”_”Experiment Index”.xls. In the<br />

example above it would be P1_A01_21.xls. The data is stored in a folder named “Data” which is a<br />

subfolder of the named as the operator.<br />

The field table length gives you the possibility to define the length of a table of data which you select<br />

by making the cells in line 299 bold which you want to have in there.<br />

Important:<br />

If you press the button during a <strong>recipe</strong> by mistake and acknowledge the safety Question of<br />

the system with yes, your experiment is stopped.<br />

5.2.7 Data Acquisition<br />

To register the values you have to click the appropriate checkbox “data logging active” top left of the<br />

window.<br />

The button shows another form which will give you the possibilities you need after doing the<br />

experiments. You can generate curves, enter analytical values, show a table of the measured values.<br />

You can also open the files manually. They have a write-protection. The password to change the files<br />

is “example”.<br />

AP-Miniplant - Operation Manual Mini Batch Plant Page 46