phase - Power Electronics

phase - Power Electronics

phase - Power Electronics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

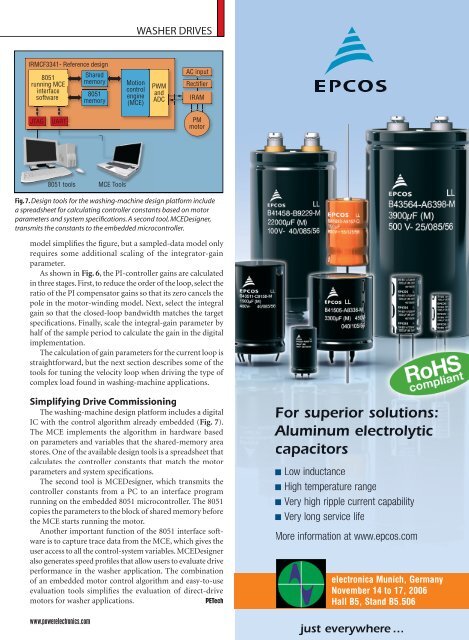

IRMCF3341- Reference design<br />

8051<br />

running MCE<br />

interface<br />

software<br />

Shared<br />

memory<br />

8051<br />

memory<br />

Motion<br />

control<br />

engine<br />

(MCE)<br />

PWM<br />

and<br />

ADC<br />

AC input<br />

Rectifier<br />

IRAM<br />

JTAG UART<br />

8051 tools<br />

MCE Tools<br />

WASHER DRIVES<br />

PM<br />

motor<br />

Fig. 7. Design tools for the washing-machine design platform include<br />

a spreadsheet for calculating controller constants based on motor<br />

parameters and system specifi cations. A second tool, MCEDesigner,<br />

transmits the constants to the embedded microcontroller.<br />

model simplifi es the fi gure, but a sampled-data model only<br />

requires some additional scaling of the integrator-gain<br />

parameter.<br />

As shown in Fig. 6, the PI-controller gains are calculated<br />

in three stages. First, to reduce the order of the loop, select the<br />

ratio of the PI compensator gains so that its zero cancels the<br />

pole in the motor-winding model. Next, select the integral<br />

gain so that the closed-loop bandwidth matches the target<br />

specifi cations. Finally, scale the integral-gain parameter by<br />

half of the sample period to calculate the gain in the digital<br />

implementation.<br />

The calculation of gain parameters for the current loop is<br />

straightforward, but the next section describes some of the<br />

tools for tuning the velocity loop when driving the type of<br />

complex load found in washing-machine applications.<br />

Simplifying Drive Commissioning<br />

The washing-machine design platform includes a digital<br />

IC with the control algorithm already embedded (Fig. 7).<br />

The MCE implements the algorithm in hardware based<br />

on parameters and variables that the shared-memory area<br />

stores. One of the available design tools is a spreadsheet that<br />

calculates the controller constants that match the motor<br />

parameters and system specifi cations.<br />

The second tool is MCEDesigner, which transmits the<br />

controller constants from a PC to an interface program<br />

running on the embedded 8051 microcontroller. The 8051<br />

copies the parameters to the block of shared memory before<br />

the MCE starts running the motor.<br />

Another important function of the 8051 interface software<br />

is to capture trace data from the MCE, which gives the<br />

user access to all the control-system variables. MCEDesigner<br />

also generates speed profi les that allow users to evaluate drive<br />

performance in the washer application. The combination<br />

of an embedded motor control algorithm and easy-to-use<br />

evaluation tools simplifi es the evaluation of direct-drive<br />

motors for washer applications. PETech<br />

For superior solutions:<br />

Aluminum electrolytic<br />

capacitors<br />

Low inductance<br />

High temperature range<br />

Very high ripple current capability<br />

Very long service life<br />

More information at www.epcos.com<br />

electronica Munich, Germany<br />

November 14 to 17, 2006<br />

Hall B5, Stand B5.506<br />

www.powerelectronics.com <strong>Power</strong> <strong>Electronics</strong> Technology<br />

just everywhere …