DDR4 Design Considerations - EEWeb

DDR4 Design Considerations - EEWeb

DDR4 Design Considerations - EEWeb

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>EEWeb</strong> PULSE TECH ARTICLE<br />

signals. Therefore, the STOP signal will catch the START<br />

signal in the 16th delay comparator (2nd row, 3rd column).<br />

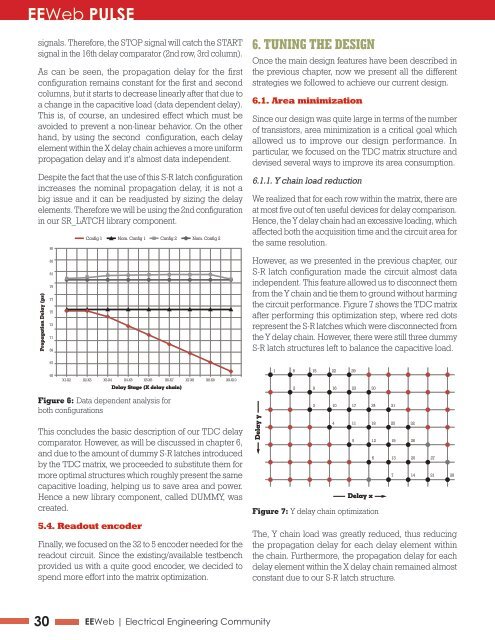

As can be seen, the propagation delay for the first<br />

configuration remains constant for the first and second<br />

columns, but it starts to decrease linearly after that due to<br />

a change in the capacitive load (data dependent delay).<br />

This is, of course, an undesired effect which must be<br />

avoided to prevent a non-linear behavior. On the other<br />

hand, by using the second configuration, each delay<br />

element within the X delay chain achieves a more uniform<br />

propagation delay and it’s almost data independent.<br />

Despite the fact that the use of this S-R latch configuration<br />

increases the nominal propagation delay, it is not a<br />

big issue and it can be readjusted by sizing the delay<br />

elements. Therefore we will be using the 2nd configuration<br />

in our SR_LATCH library component.<br />

Propagation Delay (ps)<br />

85<br />

83<br />

81<br />

79<br />

77<br />

75<br />

73<br />

71<br />

69<br />

67<br />

65<br />

Config 1<br />

Nom. Config 1 Config 2 Nom. Config 2<br />

X1-X2 X2-X3 X3-X4 X4-X5 X5-X6 X6-X7 X7-X8 X8-X9 X9-X10<br />

Delay Stage (X delay chain)<br />

Figure 6: Data dependent analysis for<br />

both configurations<br />

This concludes the basic description of our TDC delay<br />

comparator. However, as will be discussed in chapter 6,<br />

and due to the amount of dummy S-R latches introduced<br />

by the TDC matrix, we proceeded to substitute them for<br />

more optimal structures which roughly present the same<br />

capacitive loading, helping us to save area and power.<br />

Hence a new library component, called DUMMY, was<br />

created.<br />

5.4. Readout encoder<br />

Finally, we focused on the 32 to 5 encoder needed for the<br />

readout circuit. Since the existing/available testbench<br />

provided us with a quite good encoder, we decided to<br />

spend more effort into the matrix optimization.<br />

6. TUNING THE DESIGN<br />

Once the main design features have been described in<br />

the previous chapter, now we present all the different<br />

strategies we followed to achieve our current design.<br />

6.1. Area minimization<br />

Since our design was quite large in terms of the number<br />

of transistors, area minimization is a critical goal which<br />

allowed us to improve our design performance. In<br />

particular, we focused on the TDC matrix structure and<br />

devised several ways to improve its area consumption.<br />

6.1.1. Y chain load reduction<br />

We realized that for each row within the matrix, there are<br />

at most five out of ten useful devices for delay comparison.<br />

Hence, the Y delay chain had an excessive loading, which<br />

affected both the acquisition time and the circuit area for<br />

the same resolution.<br />

However, as we presented in the previous chapter, our<br />

S-R latch configuration made the circuit almost data<br />

independent. This feature allowed us to disconnect them<br />

from the Y chain and tie them to ground without harming<br />

the circuit performance. Figure 7 shows the TDC matrix<br />

after performing this optimization step, where red dots<br />

represent the S-R latches which were disconnected from<br />

the Y delay chain. However, there were still three dummy<br />

S-R latch structures left to balance the capacitive load.<br />

Delay y<br />

1 8 15 22 29<br />

2 9 16 23 30<br />

3 10 17 24 31<br />

4 11 18 25 32<br />

5 12 19 26<br />

Delay x<br />

Figure 7: Y delay chain optimization<br />

6 13 20 27<br />

7 14 21 28<br />

The, Y chain load was greatly reduced, thus reducing<br />

the propagation delay for each delay element within<br />

the chain. Furthermore, the propagation delay for each<br />

delay element within the X delay chain remained almost<br />

constant due to our S-R latch structure.<br />

6.1.2. Dummy structures<br />

After the Y chain optimization, most of the S-R latches had<br />

one of their input tied to ground. Looking at their gate<br />

level schematic, it was easy to conclude the following:<br />

• Since one NAND gate had an input tied to ground, its<br />

output is tied to 1. This output is used as one of the inputs<br />

of the other NAND gate within the component.<br />

• Removing the former NAND gate along with its<br />

associated inverter reduced the circuit area maintaining a<br />

constant propagation delay for the X chain delay elements.<br />

• However, since these structures do not commute,<br />

dynamic power consumption was not affected by this<br />

optimization.<br />

With these ideas in mind, we obtained the following<br />

structure for our DUMMY component, which is basically<br />

a capacitive load:<br />

6.2. Resolution optimization<br />

As shown in section 3.2, our TDC resolution is given by<br />

the following relationships:<br />

30 <strong>EEWeb</strong> | Electrical Engineering Community<br />

Visit www.eeweb.com<br />

VDD<br />

R#<br />

GND<br />

1<br />

Figure 8: Dummy component (transistor level)<br />

1<br />

NOTE: A further area optimization can be easily done by<br />

removing one of the pMOS transistors within the NAND<br />

gate since it is always OFF. However we did not realize<br />

that until later, we could not include it in the submitted<br />

TDC design.<br />

6.1.3. S-R latch optimization<br />

Our final area improvement dealt with the active S-R<br />

latches themselves. As we only used one of the device<br />

outputs, we just removed the unused output, along with its<br />

associated inverter. By introducing this modification, we<br />

did not observe any major change in the delay element’s<br />

propagation delay.<br />

VDD<br />

GND<br />

S# R#<br />

Figure 9: Final S-R latch component (transistor level)<br />

The following table summarizes all the relevant parameters<br />

needed for a given resolution ranging from 5 to 10 ps:<br />

Figure 10: TDC resolution chart<br />

Therefore, by just sizing the delay elements within both<br />

delay chains we can achieve any required resolution.<br />

However, our TDC architecture presents two major<br />

drawbacks in comparison with the linear Vernier delay<br />

line architecture:<br />

• Our resolution is totally dependent on the propagation<br />

delay of each delay elements, as can be seen in the<br />

table above. Ignoring this fact will cause the system to<br />

behave in an unpredictable and highly non-linear way.<br />

Hence bigger delay elements will be needed if aiming<br />

for high resolution.<br />

• Each delay element has to drive a larger load, due to the<br />

matrix configuration. Again, sizing becomes a problem<br />

for a given resolution, limiting our design space.<br />

Due to this, we aimed for a 9 ps resolution, which is<br />

slightly better than the proposed in the midterm report<br />

and does not imply too large transistors.<br />

Q<br />

31