Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PG&E EMERGING TECHNOLOGIES ASSESSMENT<br />

Operating Room LED Replacement<br />

Table of Contents<br />

1. Executive Summary .................................................................................................................................. 1<br />

2. Operating Room Lighting Replacement ....................................................................................................... 2<br />

3. Appendix I ................................................................................................................................................ 9<br />

HVAC Calculations & Tables ............................................................................................................... 10<br />

Lighting Calculations & Tables ........................................................................................................... 13<br />

OR 1 Internal Loads & Pictures .......................................................................................................... 15<br />

OR 2 Internal Loads & Pictures .......................................................................................................... 17<br />

OR 3 Internal Loads & Pictures .......................................................................................................... 19<br />

OR 4 Internal Loads & Pictures .......................................................................................................... 21<br />

OR 5 Internal Loads .......................................................................................................................... 23<br />

OR 6 Internal Loads .......................................................................................................................... 24<br />

OR 7 Internal Loads & Pictures .......................................................................................................... 25<br />

OR 8 Internal Loads .......................................................................................................................... 28<br />

OR 9 Internal Loads .......................................................................................................................... 29<br />

OR 10 Internal Loads & Pictures ........................................................................................................ 30<br />

OR 11 Internal Loads ........................................................................................................................ 32<br />

OR 12 Internal Loads & Pictures ........................................................................................................ 33<br />

4. Appendix II ............................................................................................................................................ 37<br />

5. Appendix III ........................................................................................................................................... 47<br />

6. Appendix IV ............................................................................................................................................ 79<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104

PACIFIC GAS & ELECTRIC has been investigating the<br />

advantages of utilizing emerging technologies, and performing an<br />

analysis of their associated energy savings. Upon being<br />

approached by Kaiser Permanente & Petaluma Valley Hospital for<br />

the installations of operating room LED (Light Emitting Diode)<br />

lighting fixtures a study was commissioned to determine the true<br />

savings of this application, and the associated economic benefits.<br />

The LED’s would replace their existing halogen surgical lights in the<br />

hospitals’ operating rooms. This study captured both the direct<br />

savings from the lower electrical demand equipment and the<br />

indirect savings from the associated HVAC loads.<br />

THE PROPOSED LED surgical lights would consume 54% of the<br />

energy required by halogens. Other significant benefits of the LED<br />

fixtures are an adjustable beam temperature (i.e. color), they are<br />

not subject to immediate burn out and the bulbs have a longer<br />

useful life.<br />

Executive Summary<br />

ADDITIONAL ENERGY BENEFITS to the direct power reduction for the LED lighting is in the reduced HVAC load for the<br />

associated hospital’s equipment. However, because of the way each of the hospital’s HVAC systems is currently controlled, the<br />

controls would require a minor setpoint adjustment to realize these additional savings. The HVAC system in both facilities is a<br />

constant volume system with reheat, which has constant supply air temperature setpoints. With the removal of the lighting’s heat<br />

load the reheat will increase in gas load of 1 therm/10 kWh of direct savings in lighting, unless the supply air temperature setpoint is<br />

raised to compensate for the reduced heat from the light fixture. By changing their associated setpoints the available indirect<br />

energy savings can be realized. The associated savings are 1 therm in gas and 17 kWh in HVAC savings for every 24 kWh of direct<br />

lighting savings.<br />

OPERATING ROOM LED FIXTURES have high first costs: $20,000 for each Halogen fixture and $27,000 for each LED fixture and<br />

have a lifespan of 15 years (for the fixtures). Because of the high cost of the fixture, the benefits associated with replacement based<br />

on just energy savings are not economically viable. However, if a replacement is performed there are real savings. LED<br />

Replacement savings are summarized as follows for Kaiser’s 12 Operating rooms, which are proportional to Petaluma:<br />

Table E1 – Savings Summary Per Year – Total of 12 OR LED replacement<br />

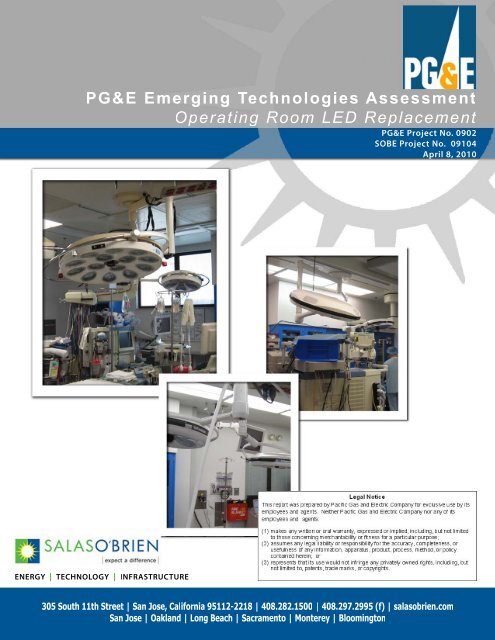

Figure E-1: Kaiser Operating Room & OR Lights<br />

Figure E-1: Kaiser Cardiac Operating Room with Halogen OR Lights<br />

No Control Changes Modify AHU Setpoint<br />

Direct Indirect Total Direct Indirect Total<br />

kWh 11,673 0 11,673 11,673 8,070 19,743<br />

Therms 0 -1,248 -1,248 0 481 481<br />

$ $1,051 -$998 $52 $1,051 $1,111 $2,161<br />

PG&E Incentive $584 $0 $584 $584 $0 $584<br />

Payback (Early Retirement, Avg.) 308 6,185 150<br />

Payback (Incremental) 79 1,595 39<br />

*This model is conservative because other areas would also have savings due to less reheat. PG&E does not pay an incentive for indirect savings.<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 1

BACKGROUND<br />

Pacific Gas & Electric has been investigating the advantages of<br />

utilizing emerging technologies, and have been performing an<br />

analysis to evaluate their true associated energy savings. They<br />

were approached by a number of hospitals for a proposed<br />

installation of LED lighting fixtures to replace their existing<br />

halogen surgical lights in their operating rooms. Of these<br />

facilities, PG&E determined to utilize Kaiser Permanente<br />

and Petaluma Valley hospital for their pilot program to<br />

commission a study for this application of this emerging<br />

technology. The goal of this study was to establish the<br />

total savings attributed to the fixture replacement. From<br />

this data the utility will determine how to incent these<br />

installations and the degree by which to encourage future<br />

installations.<br />

The study consisted of:<br />

1. A field study to establish the true baseline at both facilities.<br />

Operating Room Lighting Replacement<br />

2. A paper study of the associated savings of these<br />

installations.<br />

3. A study of the associated lighting quality.<br />

4. A metered study solely at Petaluma Valley Hospital to<br />

establish that the associated saving would be uniform.<br />

This study analyzed the true savings associated with the retrofit and<br />

its associated economic analysis. It has been designed to allow its<br />

application to be applied to future installations.<br />

FACILITY AND CURRENT CONDITIONS<br />

Kaiser’s 2425 Geary surgery center consists of 12 operating rooms<br />

on the 4 th floor of the facility. They are all located along a common<br />

corridor, and two of them were retrofitted from storage facilities.<br />

Appendix I contains the associated internal loads with each, as<br />

established by a field survey on May 1, 2009.<br />

Figure 1: Kaiser Operating Room<br />

Figure 2: Operating rooms have high equipment loads<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 2

Operating Room Lighting Replacement<br />

The operating rooms are served by two air handlers (AHU 5 & 7). Air Handler 7 handles 8 of the 12 operating rooms,<br />

and an even higher percentage of the required air; 74%, or 12,637 CFM, based on the May 31, 2009 air balance. This is<br />

57.7% of the 21,900 CFM air handler’s capacity. Air handler 5 is a 21,200 CFM air handler, which distributes a total of<br />

4,435 CFM to the remaining 4 operating rooms. The operating rooms are constant volume, 100% outdoor air units<br />

with hot water reheat. All of the air handlers in the hospital are served by a common chiller and steam boiler plant. Air<br />

is supplied overhead around the patient and onto the surgeons, and returned at floor level at the perimeter of the<br />

operating room. The schedules associated with this equipment are available in Appendix I.<br />

Figure 3: OR Supply Grille<br />

The units are controlled by a Johnson Controls Metasys system.<br />

Local control and thermostats are located in each of the surgical<br />

suites. The operating rooms are maintained in condition appropriate<br />

for surgery at all times. Room temperature is controlled by resetting<br />

the air handler’s supply air temperature to meet the maximum load<br />

on the system, and then incorporating reheat to obtain the required<br />

condition for the operating room, which typically is kept between<br />

65°F and 68°F. No humidity control is currently utilized. This<br />

control strategy has also been utilized at Petaluma Valley Hospital,<br />

although with a Delta Control system.<br />

The chiller plant consists of three water cooled chillers: 2 Centrifugal York chillers at 450 and 250 tons, and 1 150 Ton<br />

York YT screw chiller. These chillers are being utilized at a 43 degree supply temperature and a 20°F delta T. When<br />

load is increased facilities usually lowers the supply temperature. The heating hot water plant consists of 2 Bryan<br />

LMB750 steam boilers. The field readings indicate a supply of 320°F and 10 psi, and a return temperature of 120 F.<br />

Currently the associated air handlers are not meeting the requested setpoint. When plant field readings were taken the<br />

outdoor air temperature was above the limit of the air handlers, and the units were unable to hold the requested<br />

setpoint of 53°F. Air handler 5 was at 57.5°F, and air handler 7 was at 58.6°F. These units have passed their<br />

expected lifespan, and will be replaced. The new design will not be a direct replacement, but a transition to a common<br />

152,000 CFM air handler with a fan motor over 200 HP.<br />

Petaluma Valley Hospital’s surgery center consists of 4 operating suites, the layout of which is available in Appendix<br />

II. The operating rooms are denoted as Operating Rooms 1-3 & ORTHO. The facility is a two story hospital, with the<br />

surgical facilities being on the first floor. These are served by a single two speed air handling unit. Appendix III<br />

contains each OR’s specifications, the metered supply and return air data and the associated economic analysis of the<br />

OR LED replacement. Note that although the surgical suites are only utilized 68 hours a week, they must be<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 3

Operating Room Lighting Replacement<br />

maintained ready for surgery at all times. The operating rooms are constant volume, 100% outdoor air units with hot<br />

water reheat. The operating rooms at Petaluma pull a much lower percentage of the total air supplied by the air<br />

handler than Kaiser: 7%. The chiller plant consists of a 200 ton air cooled Trane reciprocating chiller and an 80 ton<br />

BAC ice chiller. These chillers are being utilized at a 42 degree supply temperature and a 16°F delta T.<br />

SURGICAL LIGHTS<br />

Each of the operating rooms contains two to three<br />

surgical lights, whose energy consumption is<br />

summarized in Table 1 (Petaluma is available in<br />

Appendix II). Pictures of these OR lighting fixtures may<br />

be seen in Appendix I. These Skytron halogen fixtures<br />

have a service life of 15 years and the majority will soon<br />

be in need of replacement. There is the possibility of<br />

early retirement if an adequate energy saving will justify<br />

it.<br />

Table 1: Kaiser OR Surgical Lights.<br />

Operating<br />

Room<br />

# of Luminaries<br />

per OR<br />

Watts for<br />

Light #1<br />

Watts for<br />

Light #2<br />

Figure 4: OR Surgical Light<br />

Watts for<br />

Light #3<br />

Total Lighting<br />

Watts per room<br />

1 3 200 200 320 720<br />

2 2 200 280 0 480<br />

3 3 200 200 320 720<br />

4 3 200 200 320 720<br />

5 3 200 200 560 960<br />

6 3 200 200 560 960<br />

7 3 200 200 560 960<br />

8 2 200 320 0 520<br />

9 3 200 200 320 720<br />

10 3 200 200 320 720<br />

11 2 200 320 0 520<br />

12 2 200 320 0 520<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 4

The lights output is controlled locally at a wall mounted<br />

knob (Figure 2). Dimmer knobs are also mounted<br />

directly to the fixture.<br />

Since these lights will need to be replaced in the near<br />

future an analysis of what type of fixture will replace<br />

the existing one was conducted. The two analyzed<br />

were LED OR lights and an in kind replacement of the<br />

existing halogen fixtures.<br />

Halogen lights have a number of problems with them:<br />

beam temperature, immediate failure, additional energy<br />

costs, and inability to adjust color. The beam<br />

temperature is critical as radiation is reduced, thus the<br />

surgeons are more comfortable, and the patient’s<br />

exposed tissue will not dry out as quickly, allowing<br />

longer surgeries. Halogen bulbs fail instantaneously,<br />

while LEDs dim out, so a catastrophic failure will not<br />

Operating Room Lighting Replacement<br />

occur and replacement can be scheduled. With beam Figure 5: OR Surgical Light Control Panel<br />

temperature adjustment LEDs can change their color,<br />

thus allowing ideal contrast for each procedure. This may allow superior outcomes for the patient.<br />

RESULTS<br />

There is a definitive direct saving in installing LED Lights into the operating rooms. Tables 2A & 2B summarizes these<br />

savings. An interesting note is that for the LED fixtures it doesn’t matter if it s a large or small luminaire, either way the<br />

consumption is 144W per fixture. This was pulled directly from Skytron’s product catalog (Appendix III), which is a<br />

likely manufacturer for this replacement.<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 5

Table 2A: Kaiser Operating Light Energy Consumption<br />

OR # Total<br />

Halogen<br />

Watts/Room<br />

Operating Room Lighting Replacement<br />

Total LED<br />

Lighting<br />

Watts per<br />

room<br />

Halogen<br />

kWh/yr*<br />

Halogen<br />

$/yr**<br />

LED<br />

kWh/yr*<br />

LED<br />

$/yr**<br />

Δ<br />

$/yr**<br />

1 720 432 2,938 $264 1,763 $159 $106<br />

2 480 288 1,224 $110 734 $66 $44<br />

3 720 432 2,203 $198 1,322 $119 $79<br />

4 720 432 2,938 $264 1,763 $159 $106<br />

5 960 432 2,693 $242 1,212 $109 $133<br />

6 960 432 2,693 $242 1,212 $109 $133<br />

7 960 432 2,693 $242 1,212 $109 $133<br />

8 520 288 1,326 $119 734 $66 $53<br />

9 720 432 2,203 $198 1,322 $119 $79<br />

10 720 432 1,836 $165 1,102 $99 $66<br />

11 520 288 1,326 $119 734 $66 $53<br />

12 520 288 1,591 $143 881 $79 $64<br />

All 8,520 4,608 25,663 $2,310 13,990 $1,259 $1,051<br />

*Please note: one week of use subtracted for the number of Holidays the rooms aren't utilized.<br />

**Assumes $0.09/kWh.<br />

Table 2B: Petaluma Operating Light Energy Consumption<br />

OR # Total<br />

Halogen<br />

Watts/Room<br />

Total LED<br />

Lighting<br />

Watts per<br />

room<br />

Halogen<br />

kWh/yr*<br />

Halogen<br />

$/yr**<br />

LED<br />

kWh/yr*<br />

LED<br />

$/yr**<br />

Δ $/yr**<br />

1 440 288 1,526 $137 999 $90 $47<br />

2 470 288 1,630 $147 999 $90 $57<br />

3 470 288 1,630 $147 999 $90 $57<br />

4 470 288 1,630 $147 999 $90 $57<br />

All 1850 1152 6,416 $577 3,995 $360 $218<br />

The final column in the above tables shows the direct savings associated with an LED lighting replacement. As the<br />

removal of these lights will reduce the load on the HVAC systems at the hospital an indirect savings calculation was also<br />

performed. The findings of this was that without a change in control setpoints the installation of the OR LEDs will<br />

cause no further electrical savings and a net increase in natural gas consumption. An explanation of these savings is<br />

available in Appendix IV. This is due to the operating rooms requirement of constant volume of air. In order to meet<br />

the required setpoint for the room the supplied air is reheated by the campus’ steam loop to the required temperature.<br />

Previously the operating room lights were providing a portion of this reheat, and with their removal the load will be<br />

transferred to the boiler plant. This averages an additional 0.1 therms/kWh saved.<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 6

Operating Room Lighting Replacement<br />

The operating theaters are the defining load on the air handlers, which dictate the setpoint of the supplied air of the air<br />

handler. If the operators adjust the setpoint of the supplied air to compensate for the drop in load there will be both<br />

electrical and thermal savings; an average of 0.69 kWh and .04 therms/direct kWh of reduction. Tables 3 and 4<br />

illustrate these savings. Petaluma’s results by OR are available in Appendix II, as well as the full calculations &<br />

supporting documentation. Kaiser’s calculations and supporting documentation is available in Appendix I. Note that<br />

the basis of the positive value without a controls change for Kaiser’s OR 6 is that the currently supplied cooling for that<br />

OR is greater than the supplied cooling.<br />

Table 3: Savings Summary<br />

Kaiser Petaluma Valley Hospital<br />

Do Nothing Modify AHU Setpoint Do Nothing Modify AHU Setpoint<br />

Direct Indirect Total Direct Indirect Total Direct Indirect Total Direct Indirect Total<br />

11,67<br />

11,67 11,67<br />

11,67<br />

25,17<br />

kWh 3 0 3 3 0 3 2,421 0 2,421 2,421 22,749 0<br />

Therms 0 -1,248 -1,248 0 -1,248 -1,248 0 343 343 0 139 139<br />

$1,05<br />

$1,05<br />

$2,37<br />

$ 1 -$874 -$874 1 -$874 $177 $218 $276 $492 $218 $2,159 6<br />

PG&E<br />

$3,41<br />

Incentive $584 $0 $584 $584 $0 $584 $121 $275 $396 $121 $3,296 7<br />

*These model are conservative because other areas would also have savings due to less reheat. PG&E does not pay an<br />

incentive for indirect savings.<br />

Table 4: Kaiser Unit Based Energy Savings<br />

OR CFM<br />

No<br />

Control<br />

Change<br />

Therms<br />

Saved<br />

/Year<br />

No<br />

Control<br />

Change<br />

Indirect $<br />

Savings<br />

/Year<br />

Direct<br />

kWh $<br />

Savings<br />

/Year<br />

Direct<br />

kWh<br />

Savings<br />

/Year<br />

Revised<br />

Therms<br />

/Year After<br />

Controls<br />

Modification<br />

Controls<br />

Changed<br />

Indirect<br />

$<br />

Savings<br />

/Year 1<br />

Simple<br />

Payback –<br />

Early<br />

Retirement,<br />

in years<br />

Simple<br />

Payback<br />

–<br />

Incr.<br />

Cost, in<br />

years<br />

1 945 -23.9 -$16.73 $105.75 1,175 24.6 $56.89 124 32.0<br />

2 1,231 -124.1 -$86.85 $44.06 490 40.3 $93.07 297 76.9<br />

3 1,081 -118.7 -$83.10 $79.32 881 16.1 $37.24 165 42.7<br />

4 2,166 -342.8 -$239.99 $105.75 1,175 57.5 $132.85 124 32.0<br />

5 2,140 -149.0 -$104.31 $133.29 1,481 43.1 $99.70 98 25.4<br />

6 1,668 84.5 $59.14 $133.29 1,481 19.7 $45.51 98 25.4<br />

7 1,940 -47.2 -$33.06 $133.29 1,481 33.2 $76.74 98 25.4<br />

8 1,249 -113.7 -$79.57 $53.24 592 36.8 $85.08 246 63.6<br />

9 1,162 -102.4 -$71.69 $79.32 881 20.1 $46.54 165 42.7<br />

10 1,358 -182.0 -$127.38 $66.10 734 76.1 $175.82 198 51.3<br />

11 1,036 -21.8 -$15.28 $53.24 592 56.7 $131.05 246 63.6<br />

12 1,096 -106.7 -$74.66 $63.89 710 56.4 $130.35 205 53.0<br />

Total 17,072 -1,247.8 -$873.49 $1,050 11,673 481 $1,110.84<br />

1<br />

Both thermal and kWh<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 7

CONCLUSIONS AND RECOMMENDATIONS<br />

Operating Room Lighting Replacement<br />

With an LED initial cost of $27,000/fixture and service life of 15 years an early retirement based on energy savings is<br />

not economically viable. Halogen replacement fixtures cost approximately $20,000. The incremental cost associated<br />

with this still will not justify their implementation based solely on energy, but the reliability of the fixtures and the other<br />

associated benefits warrant LEDs as a viable alternative at the end of the existing fixtures service life.<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 8

Appendix I<br />

This appendix contains the supporting documentation of the calculations detailed in this <strong>report</strong>. It is comprised of the<br />

following:<br />

1. HVAC Calculations and Tables<br />

2. Lighting Calculations and Tables<br />

3. OR Internal Loads and Pictures<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 9

lack is calculated program assumes OR is CV with HW Reheat, no humidity control<br />

red is input<br />

AHU Supply Temp<br />

green is assumption<br />

Setpoint<br />

AHU 5 53 Utility<br />

AHU 7 53 $/kWh $0.09<br />

$/Therm $0.80<br />

Boiler Plant Efficiency 80%<br />

Plant Eff. Coef = 1.3

Detailed Savings Analysis (Continued)<br />

No<br />

Possible Revised<br />

Thermal<br />

Control No Control<br />

AHU <br />

original Thermal Change Change<br />

Setpoint Thermal<br />

reheat reheat Therms Indirect $ Direct $ Direct kWh Adjustment reheat<br />

OR<br />

(therms) (therms) Saved Savings/yr Savings/yr Savings/yr (F)<br />

(therms)<br />

OR 1 -104.9 -81.0 -23.9 -$19.12 $105.75 1175 0.96 -129.5<br />

OR 2 412.8 536.8 -124.1 -$99.26 $44.06 490 0.49 372.5<br />

OR 3 324.5 443.2 -118.7 -$94.97 $79.32 881 0.84 308.4<br />

OR 4 1170.9 1513.7 -342.8 -$274.27 $105.75 1175 0.42 1113.4<br />

OR 5 343.4 492.4 -149.0 -$119.22 $133.29 1481 0.78 300.3<br />

OR 6 -590.6 -675.1 84.5 $67.59 $133.29 1481 1.00 -610.3<br />

OR 7 -63.8 -16.5 -47.2 -$37.78 $133.29 1481 0.86 -97.0<br />

OR 8 353.8 467.4 -113.7 -$90.94 $53.24 592 0.59 316.9<br />

OR 9 259.3 361.7 -102.4 -$81.93 $79.32 881 0.78 239.1<br />

OR 10 602.6 784.6 -182.0 -$145.58 $66.10 734 0.67 526.5<br />

OR 11 -13.6 8.2 -21.8 -$17.46 $53.24 592 0.71 -70.3<br />

OR 12 305.5 412.2 -106.7 -$85.33 $63.89 710 0.67 249.1<br />

Total -1,247.8 -$998.27 $1,050.56 11,673 2,519<br />

Do Nothing Total Annual Energy Savings: $52.29<br />

Savings Summary per Year<br />

Do Nothing Modify AHU Setpoint<br />

Direct Indirect Total Direct Indirect Total<br />

kWh 11,673 0 11,673 11,673 8,070 19,743<br />

Therms 0 -1,248 -1,248 0 481 481<br />

$ $1,050.56 -$998.27 $52.29 $1,050.56 $1,110.84 $2,161.40<br />

PG&E Incentive $584 $0 $584 $584 $0 $584<br />

*This model is conservative because other areas would also have savings due to less reheat<br />

Kaiser OR Loads rev2 Project No. 09104<br />

Page 11

List all affected AHUs<br />

CHW CHW<br />

CHW<br />

Savings Savings Bin Data for SF (%<br />

Savings CHW<br />

AHU CFM (BTU/Hr) (kW) when cooling) Hours of Cooling kWh Savings $<br />

5 21,200 15,312 0.86 64.65% 5,663 4,894 $440.50<br />

7 21,900 9,935 0.56 64.65% 5,663 3,176 $285.83<br />

TOTAL 8,070 $726.34<br />

Detailed Savings Analysis (Continued)<br />

Revised Controls Actual<br />

Thermal Changed Setpoint<br />

Savings After Indirect $ Adjustment Simple Payback Simple Payback<br />

OR Controls Savings/yr (F) (Rough, Replacement) (Rough, Incr. Cost)<br />

OR 1 24.6 $56.89 0.67 124 32.0<br />

OR 2 40.3 $93.07 0.42 297 76.9<br />

OR 3 16.1 $37.24 0.42 165 42.7<br />

OR 4 57.5 $132.85 0.42 124 32.0<br />

OR 5 43.1 $99.70 0.42 98 25.4<br />

OR 6 19.7 $45.51 0.42 98 25.4<br />

OR 7 33.2 $76.74 0.42 98 25.4<br />

OR 8 36.8 $85.08 0.42 246 63.6<br />

OR 9 20.1 $46.54 0.42 165 42.7<br />

OR 10 76.1 $175.82 0.67 198 51.3<br />

OR 11 56.7 $131.05 0.67 246 63.6<br />

OR 12 56.4 $130.35 0.67 205 53.0<br />

Total 481 $1,110.84<br />

Kaiser OR Loads rev2 Project No. 09104<br />

Page 12

$/kWh = 0.09<br />

OR Surgical light utilization estimate.<br />

6/19/2009<br />

Data Provided by: Todd Belforte (415-833-9723) todd.a.belforte@kp.org<br />

Total LED<br />

Lighting<br />

Watts per<br />

room<br />

Total<br />

Halogen<br />

Watts/Room<br />

Watts for<br />

light #3<br />

Watts for<br />

light #2<br />

Watts for<br />

light #1<br />

OR # Number of<br />

luminaires per<br />

lighting system (2<br />

or 3 )<br />

1 3 200 200 320 720 432<br />

2 2 200 280 0 480 288<br />

3 3 200 200 320 720 432<br />

4 3 200 200 320 720 432<br />

5 3 200 200 560 960 432<br />

6 3 200 200 560 960 432<br />

7 3 200 200 560 960 432<br />

8 2 200 320 0 520 288<br />

9 3 200 200 320 720 432<br />

10 3 200 200 320 720 432<br />

11 2 200 320 0 520 288<br />

12 2 200 320 0 520 288<br />

All 8,520 4,608<br />

Installed bulbs: 213<br />

*Please note: one week of use subtracted for the number of Holidays the rooms aren't utilized.<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 13

OR Surgical Light Direct Analysis<br />

6/19/2009<br />

Data Provided by: Todd Belforte (415-833-9723) todd.a.belforte@kp.org<br />

OR # Hours of Hours per Total Halogen Halogen LED LED LED Δ $/yr<br />

operation day hours kWh kWh/yr* $/yr kWh kWh/yr* $/yr<br />

M-F<br />

per /week<br />

/week<br />

week<br />

1 8-12 am 16 80 58 2,938 $264 35 1,763 $159 $106<br />

2 8-6 pm 10 50 24 1,224 $110 14 734 $66 $44<br />

3 8-8 pm 12 60 43 2,203 $198 26 1,322 $119 $79<br />

4 8-12 am 16 80 58 2,938 $264 35 1,763 $159 $106<br />

5 7-6 pm 11 55 53 2,693 $242 24 1,212 $109 $133<br />

6 7-6 pm 11 55 53 2,693 $242 24 1,212 $109 $133<br />

7 7-6 pm 11 55 53 2,693 $242 24 1,212 $109 $133<br />

8 8-6 pm 10 50 26 1,326 $119 14 734 $66 $53<br />

9 8-8 pm 12 60 43 2,203 $198 26 1,322 $119 $79<br />

10 8-6 pm 10 50 36 1,836 $165 22 1,102 $99 $66<br />

11 8-6 pm 10 50 26 1,326 $119 14 734 $66 $53<br />

12 8-8 pm 12 60 31 1,591 $143 17 881 $79 $64<br />

All 141 503 25,663 $2,310 274 13,990 $1,259 $1,051<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 14

OR 1 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

digital recording tower 1 120 12.43333333 11% 163 100% 163 555 0<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 3 120 5.4 26% 165 100% 165 563 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Bovie 1 250 4 44% 442 10% 44 151 0<br />

fluid warmer 1 120 1 32% 38 100% 38 130 0<br />

microscope 1 120 2.75 19% 63 100% 63 215 0<br />

unknown load machine 1 120 12 36% 525 100% 525 1,793 100%<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 6 384 100% 720 2,457 0 Total<br />

TOTAL 11,599 1,606 13,205<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 15

Operating Room 1<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 16

OR 2 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 5 120 9.0 26% 275 100% 275 938 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Bovie 1 120 7.1 44% 377 10% 38 128 0<br />

fluid warmer 1 120 1 32% 38 100% 38 130 0<br />

microscope 1 120 2.75 19% 63 100% 63 215 0<br />

unknown load machine 1 120 12 36% 525 100% 525 1,793 100%<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 5 480 100% 480 1,638 0 Total<br />

TOTAL 10,578 1,606 12,184<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 17

Operating Room 2<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 18

OR 3 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 3 120 5.4 26% 165 100% 165 563 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Monitor 1 120 3.6 24% 102 100% 102 347 0<br />

Bovie 1 120 7.1 44% 377 10% 38 128 0<br />

fluid warmer 1 120 1 32% 38 100% 38 130 0<br />

argon beam quagulator 1 120 11 59% 780 3% 23 80 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 6 720 100% 720 2,457 0 Total<br />

TOTAL 9,441 1,605 11,046<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 19

Operating Room 3<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 20

OR 4 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 7 120 12.6 26% 385 100% 385 1,314 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Monitor 3 120 3.6 24% 305 100% 305 1,042 0<br />

head lamp 1 120 1.7 90% 184 100% 184 626 0<br />

head lamp 2 1 120 7.1 90% 765 100% 765 2,610 1<br />

Warmer 1 120 12 32% 456 100% 456 1,556 0<br />

Bovie 2 250 4 44% 884 10% 88 302 0<br />

fluid warmer 1 120 1 32% 38 100% 38 130 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 10 720 100% 720 2,457 0 Total<br />

TOTAL 15,772 1,606 17,378<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 21

Operating Room 4<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 22

OR 5 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 6 120 10.8 26% 330 100% 330 1,126 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Ultrasound 2 120 15 80% 2,880 100% 2,880 9,827 0<br />

fluid warmer 1 120 1 32% 38 100% 38 130 0<br />

Warmer 1 120 12 32% 456 100% 456 1,556 0<br />

Monitor 3 120 3.6 24% 305 100% 305 1,042 0<br />

Bovie 2 250 4 44% 884 10% 88 302 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 10 960 100% 960 3,276 0 Total<br />

TOTAL 22,993 1,605 24,598<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 23

OR 6 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

profusion 1 120 1.5 19% 35 100% 35 119 0<br />

profusion 2 1 120 1.6 19% 37 100% 37 127 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 7 120 12.6 26% 385 100% 385 1,314 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

digital recording tower 1 120 12.43333333 11% 163 100% 163 555 0<br />

Data Manager 1 120 4.4 26% 135 100% 135 460 1<br />

Ultrasound 1 120 15 80% 1,440 100% 1,440 4,913 0<br />

cardiac monitor 1 120 6 57% 408 100% 408 1,392 0<br />

Warmer 1 120 12 32% 456 100% 456 1,556 0<br />

blanket pump 1 120 6.666666667 44% 354 100% 354 1,206 0<br />

Bovie 2 250 4 44% 884 10% 88 302 0<br />

josturn 1 120 18 3% 75 100% 75 256 0<br />

Datascope 1 120 4.1 19% 94 100% 94 320 0<br />

Headlight 1 120 3.0 100% 360 100% 360 1,228 0<br />

Eye Machine 1 120 8.3 15% 147 100% 147 502 0<br />

Monitor 3 120 3.6 24% 305 100% 305 1,042 0<br />

People (active) 7 1,750 2,100<br />

Patient 1 225 105<br />

Lighting 20 960 100% 960 3,276 0 Total<br />

TOTAL 24,805 2,206 27,011<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 24

OR 7 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

profusion 1 120 1.5 19% 35 100% 35 119 0<br />

profusion 2 1 120 1.6 19% 37 100% 37 127 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 7 120 12.6 26% 385 100% 385 1,314 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

digital recording tower 1 120 12.43333333 11% 163 100% 163 555 0<br />

Data Manager 1 120 4.4 26% 135 100% 135 460 1<br />

Philips ultrasound 1 120 15 59% 1,063 100% 1,063 3,627 0<br />

cardiac monitor 1 120 6 57% 408 100% 408 1,392 0<br />

Warmer 1 120 12 32% 456 100% 456 1,556 0<br />

blanket pump 1 120 6.666666667 44% 354 100% 354 1,206 0<br />

Bovie 2 250 4 44% 884 10% 88 302 0<br />

josturn 1 120 18 3% 75 100% 75 256 0<br />

Datascope 1 120 4.1 19% 94 100% 94 320 0<br />

Headlight 1 120 3.0 100% 360 100% 360 1,228 0<br />

Eye Machine 1 120 8.3 15% 147 100% 147 502 0<br />

Monitor 3 120 3.6 24% 305 100% 305 1,042 0<br />

People (active) 7 1,750 2,100<br />

Patient 1 225 105<br />

Lighting 20 960 100% 960 3,276 0 Total<br />

TOTAL 23,519 2,206 25,725<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 25

Operating Room 7<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 26

Operating Room 7<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 27

OR 8 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 4 120 7.2 26% 220 100% 220 751 0<br />

Warmer 1 120 9.5 32% 361 100% 361 1,232 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Bovie (bear hugger) 1 120 7.1 44% 377 10% 38 128 0<br />

Headlight 1 120 3.0 100% 360 100% 360 1,228 0<br />

Eye Machine 1 120 8.3 15% 147 100% 147 502 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 7 520 100% 520 1,774 0 Total<br />

TOTAL 11,351 1,605 12,956<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 28

OR 9 Internal Loads<br />

Load name Ext. Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

digital recording tower 1 120 12.43333333 11% 163 100% 163 555 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Computer 3 120 5.4 26% 165 100% 165 563 0<br />

Warmer 1 120 9.5 32% 361 100% 361 1,232 0<br />

Bovie (bear hugger) 1 120 7.1 44% 377 10% 38 128 0<br />

Monitor 1 120 3.6 24% 102 100% 102 347 0<br />

Compressor 1 120 0.7 26% 20 100% 20 68 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 12 720 100% 720 2,457 0 Total<br />

TOTAL 11,087 1,605 12,692<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 29

OR 10 Internal Loads<br />

Load name # Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Computer 5 - - - 275 100% 275 938 0<br />

Warmer 1 120 9.5 32% 361 100% 361 1,232 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Bovie (bear hugger) 1 120 7.1 44% 377 10% 38 128 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 7 720 100% 720 2,457 0 Total<br />

TOTAL 10,492 1,605 12,097<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 30

Operating Room 10<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 31

OR 11 Internal Loads<br />

Load name # Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

digital recording tower 1 120 12.43333333 11% 163 100% 163 555 0<br />

Computer 5 - - - 275 100% 275 938 0<br />

Warmer 1 120 9.5 32% 361 100% 361 1,232 0<br />

Bovie 1 120 2.5 44% 133 100% 133 452 0<br />

Likersher 1 250 4 44% 442 100% 442 1,508 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 7 520 100% 520 1,774 0 Total<br />

TOTAL 11,946 1,605 13,551<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 32

OR 12 Internal Loads<br />

Load name # Voltage Amps Percentage Watts Usage Effective Wattage Sensible btu/h Latent btu/h<br />

anesthia machine 1 120 13.5 66% 1,076 100% 1,076 3,670 0<br />

Pix 1 120 3 28% 100 100% 100 341 0<br />

Blood Refrigerator 1 120 1.5 41% 73 100% 73 250 0<br />

Computer 5 - - - 275 100% 275 938 0<br />

Warmer 1 120 9.5 32% 361 100% 361 1,232 0<br />

Bovie (bear hugger) 1 120 7.1 44% 377 10% 38 128 0<br />

People (active) 5 1,250 1,500<br />

Patient 1 225 105<br />

Lighting 7 520 100% 520 1,774 0 Total<br />

TOTAL 9,809 1,605 11,414<br />

2-22 Kaiser OR Loads rev2 Project No. 09104<br />

Page 33

Operating Room 12<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 34

Operating Room 12<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 35

Operating Room 12<br />

Salas O’Brien Engineers | expect a difference | Project No. 09104<br />

Page 36

lack is calculated Program Assumes OR is CV with HW Reheat, No Humidity Control<br />

red is input<br />

AHU Supply Temp<br />

green is assumption<br />

Setpoint<br />

AHU 3 50 Utility<br />

$/kWh $0.09<br />

$/Therm $0.80<br />

Boiler Plant Efficiency 80%<br />

Plant Eff. Coef = 1.1

Detailed Savings Analysis (Continued)<br />

Revised<br />

Thermal<br />

No Control No Control<br />

<br />

original Thermal Change Change<br />

Possible AHU Thermal<br />

reheat reheat Therms Indirect $ Direct $ Direct kWh Setpoint reheat<br />

OR<br />

(therms) (therms) Saved Savings/yr Savings/yr Savings/yr Adjustment (F) (therms)<br />

OR 1 -499.6 -602.0 102.4 $81.93 $47.44 527 1.38 -525.7<br />

OR 2 -384.4 -453.6 69.2 $55.34 $56.81 631 1.18 -425.5<br />

OR 3 -427.0 -506.8 79.8 $63.86 $56.81 631 1.24 -464.7<br />

OR 4 -474.9 -566.7 91.8 $73.44 $56.81 631 1.32 -508.8<br />

Total 343.2 $274.57 $217.86 2,421 -1,925<br />

Do Nothing Total Annual Energy Savings: $492.43<br />

Savings Summary per Year<br />

Do Nothing Modify AHU Setpoint<br />

Direct Indirect Total Direct Indirect Total<br />

kWh 2,421 0 2,421 2,421 22,749 25,170<br />

Therms 0 343 343 0 139 139<br />

$ $217.86 $274.57 $492.43 $217.86 $2,158.54 $2,376.40<br />

PG&E Incentive $121 $275 $396 $121 $3,296 $3,417<br />

*This model is conservative because other areas would also have savings due to less reheat<br />

Copy of 2 Petaulma OR Loads Project No.09104<br />

Page 38

List all affected AHUs<br />

CHW CHW Bin Data for<br />

Savings Savings SF (% when Hours of CHW Savings CHW Savings<br />

AHU CFM (BTU/Hr) (kW) cooling) Cooling kWh<br />

$<br />

3 24,870 31,712 3.71 70.05% 6,136 22,749 $2,047.45<br />

TOTAL 22,749 $2,047.45<br />

Detailed Savings Analysis (Continued)<br />

Revised<br />

Simple<br />

Thermal Controls Actual Payback Simple<br />

Savings Changed Setpoint (Rough, Payback<br />

After Indirect $ Adjustment Replacemen (Rough, Incr.<br />

OR<br />

Controls Savings/yr (F) t)<br />

Cost)<br />

OR 1 26.1 $20.88 1.18 51 12.3<br />

OR 2 41.1 $32.86 1.18 43 10.3<br />

OR 3 37.7 $30.18 1.18 43 10.3<br />

OR 4 34.0 $27.16 1.18 43 10.3<br />

Total 139 $111.09<br />

Copy of 2 Petaulma OR Loads Project No.09104<br />

Page 39

OR Surgical Light Utilization Estimate.<br />

$/kWh = 0.09<br />

6/19/2009<br />

Data Provided by: Todd Belforte (415-833-9723) todd.a.belforte@kp.org<br />

Total LED<br />

Lighting Watts<br />

per room<br />

Total<br />

Halogen<br />

Watts/Room<br />

Watts for<br />

light #3<br />

Watts for<br />

light #2<br />

Watts for<br />

light #1<br />

OR # Number of<br />

luminaires per<br />

lighting system (2<br />

or 3 )<br />

1 2 220 220 0 440 288<br />

2 2 235 235 0 470 288<br />

3 2 235 235 0 470 288<br />

4 2 235 235 0 470 288<br />

All 1,850 1,152<br />

*Please note: one week of use subtracted for the number of Holidays the rooms aren't utilized.<br />

OR # Hours of Hours per Total kWh Halogen Halogen $/yr<br />

operation M-F day hours per /week kWh/yr*<br />

week<br />

1 7.5 68 30 1,526 $137<br />

2 7.5 68 32 1,630 $147<br />

3 7.5 68 32 1,630 $147<br />

4 7.5 68 32 1,630 $147<br />

All 30 126 6,416 $577<br />

OR # LED kWh /week LED LED $/yr Δ $/yr<br />

kWh/yr*<br />

1 20 999 $90 $47<br />

2 20 999 $90 $57<br />

3 20 999 $90 $57<br />

4 20 999 $90 $57<br />

All 78 3,995 $360 $218<br />

Copy of 2 Petaulma OR Loads Project No. 09104<br />

Page 40

Page 41

Page 42

OR 1 Supply temp vs Delta T<br />

10<br />

90<br />

8<br />

80<br />

6<br />

70<br />

4<br />

60<br />

2<br />

50<br />

Supply Temp<br />

Delta T<br />

Delta T (F)<br />

0<br />

40<br />

Supply Temperature (F)<br />

-2<br />

30<br />

-4<br />

20<br />

-6<br />

10<br />

0<br />

-8<br />

5/7/2009 0:00 5/9/2009 0:00 5/11/2009 0:005/13/2009 0:005/15/2009 0:005/17/2009 0:005/19/2009 0:005/21/2009 0:00<br />

3-6 Petaluma Master Project No. 09104<br />

Page 43

OR 2 Supply temp vs Delta T<br />

10<br />

90<br />

80<br />

5<br />

70<br />

60<br />

0<br />

50<br />

Supply Temp<br />

Delta T<br />

Delta T (F)<br />

40<br />

-5<br />

Supply Temperature (F)<br />

30<br />

20<br />

-10<br />

10<br />

0<br />

-15<br />

5/11/2009 5/11/2009 0:00 12:00 5/12/2009 5/12/2009 0:00 12:00 5/13/2009 5/13/2009 0:00 12:00 5/14/2009 5/14/2009 0:00 12:00 5/15/2009 5/15/2009 0:00 12:00 5/16/2009 0:00<br />

3-6 Petaluma Master Project No. 09104<br />

Page 44

OR 4 Supply temp vs Delta T<br />

10<br />

100<br />

90<br />

5<br />

80<br />

70<br />

0<br />

60<br />

Supply Temp<br />

-5<br />

50<br />

Delta T<br />

Delta T (F)<br />

40<br />

Supply Temperature (F)<br />

-10<br />

30<br />

20<br />

-15<br />

10<br />

0<br />

-20<br />

5/7/2009 0:00 5/9/2009 0:00 5/11/2009 0:005/13/2009 0:005/15/2009 0:005/17/2009 0:005/19/2009 0:005/21/2009 0:00<br />

3-6 Petaluma Master Project No. 09104<br />

Page 45

OR 4 Return Temp<br />

90<br />

80<br />

70<br />

60<br />

50<br />

°F<br />

40<br />

30<br />

20<br />

10<br />

0<br />

5/8/2009 0:00 5/9/2009 0:00 5/10/2009 0:00 5/11/2009 0:00 5/12/2009 0:00 5/13/2009 0:00 5/14/2009 0:00 5/15/2009 0:00 5/16/2009 0:00<br />

3-6 Petaluma Master Project No. 09104<br />

Page 46

Focusable LED Lighting<br />

Page 47

Bright, Cool, Comfortable<br />

Color correct for every procedure. It’s like having two lighting systems in one!<br />

Surgeons can choose a Color Temperature of 4,000K (soft white) or 4,500K (bright<br />

white) to best suit individual needs. Aurora's Color Rendering Index (CRI) is 94.<br />

Optics provide bright and cool illumination with a lighting intensity of 106,490 lux<br />

(LED5) or 133,000 lux (LED7) per surgical lighthead.<br />

Minimal energy output keeps surgical conditions bright as well as comfortable,<br />

even for extended cases, translating also into years of energy cost savings.<br />

Focusable LED (Light Emitting Diode) lighting extends illumination range while<br />

retaining maximum intensity for greater distances such as those required for Ob-Gyn,<br />

Orthopedics, Vascular and Urology.<br />

Optimally bright, cool and color correct for surgeons and the entire surgical team.<br />

Redefining the term “bulb” life. Aurora LED pods are not bulbs and they do<br />

NOT “burn out”. LED Pods retain 90% of their original intensity even after 10 years<br />

(20,000+ hours) of use.<br />

Technology Leadership. Aurora LED is the ultra efficient, "Green Technology"<br />

surgical lighting system that conserves energy while providing bright, high intensity<br />

lighting for every procedure.<br />

1<br />

LED<br />

Surgical Lighting Leadership<br />

Page 48

The Color Temperature Choice That’s<br />

Always Right for You!<br />

It’s Like Having Two Lighting Systems in One!<br />

4,500K<br />

4,000K<br />

Color Temperature<br />

(bright white)<br />

Color Temperature<br />

(soft white)<br />

2<br />

Aurora LED’s<br />

Selectable Color<br />

Temperature Control.<br />

Selectable Color<br />

Temperature for Every<br />

Procedure<br />

Color correct temperature of<br />

4,000K or 4,500K can be flexibly<br />

determined case by case<br />

(or during the surgical case),<br />

based upon each surgeon’s<br />

individual needs and preferences.<br />

Page 49

LED Advanced Optics<br />

provide Superior Shadow Control<br />

Suspended<br />

LED<br />

Cold<br />

Mirror<br />

Reflector<br />

An independently suspended<br />

Aurora LED, positioned<br />

below its dedicated mini-cold<br />

mirror reflector.<br />

Multiple LEDs are delivered within each<br />

Aurora LED Pod.<br />

Aurora’s advanced LED optics utilize multiple, suspended<br />

LED light sources together with cold mirror reflective<br />

technology (CMRT). Aurora's advanced optics provide cool,<br />

high intensity lighting without glare, with excellent shadow<br />

control. Heat is the number one enemy of LED performance<br />

and longevity. By design, Aurora’s individually suspended<br />

LEDs are protected from heat, assuring maximum<br />

performance for the life of the LEDs.<br />

LED Pod<br />

Multiple LED pods (each equipped with<br />

7 LEDs and advanced cold mirror reflector<br />

optics) culminate together to deliver<br />

hundreds of high intensity lighting segments,<br />

forming a high intensity column of bright and<br />

focusable light to the surgical field, with<br />

superior shadow control and without glare.<br />

3<br />

Page 50

Green Technology Lighting<br />

Leadership and Energy Savings<br />

Aurora LED is as brightly illuminating to the surgical field as it is to your<br />

Operating Budget. Aurora provides<br />

high intensity lighting year after<br />

year with very low energy<br />

consumption, including LED<br />

lighting pods that retain 90%<br />

original intensity even<br />

after 10 years<br />

(20,000+ hours)<br />

of use.<br />

Aurora LED Pod<br />

LED requires<br />

less than 1/2 the energy needed<br />

to power traditional halogen systems!<br />

4<br />

10 YEAR Halogen Energy Use<br />

10 YEAR Aurora LED Energy Use<br />

Page 51

Aurora Focusable Lighting Leadership<br />

High Intensity<br />

Optics<br />

True Focus<br />

Control<br />

Bright, Cool<br />

Illumination<br />

5<br />

Selectable<br />

Color<br />

Temperature<br />

Green<br />

Technology<br />

Page 52

Low Energy<br />

Consumption<br />

10 Year Plus<br />

LED Pod Life<br />

Bright, Cool, Color Correct<br />

Optionally Camera<br />

Ready<br />

6<br />

Focusable LED Lighting<br />

Adaptable Configurations<br />

& Upgrades<br />

Page 53

True Focus Control<br />

LED Lighthead<br />

focused at 30 in.<br />

(76cm)<br />

20°<br />

LED Lighthead<br />

focused at 60 in.<br />

(152cm)<br />

360°<br />

90°<br />

360°<br />

360°<br />

360°<br />

LED Focusable<br />

Optics Advantage<br />

Extended working distances (beyond one meter)<br />

are not uncommon for several surgical procedures,<br />

including Ob-Gyn, Orthopedics, Vascular and<br />

Urology. Just a 1/4 turn of the sterile focus handle<br />

captures maximum intensity at any distance with<br />

unmatched lighting flexibility range and without<br />

having to reposition surgical lightheads.<br />

Bright, Cool, Color Correct Lighting at any distance and<br />

for every procedure.<br />

Flexibility<br />

Aurora LED provides featherlight maneuverability<br />

along with 360° rotation at all points of articulation,<br />

including 20° upward vertical movement for<br />

taller surgeons and 90° downward flexibility to<br />

deliver bright, cool and color correct lighting<br />

where it is needed most.<br />

7<br />

LED Positioning<br />

Page 54

LED<br />

Video Handle Camera (optional)<br />

TVII Camera Controller<br />

Aurora LED Lighting can be optionally equipped with<br />

a high quality, removable and transportable single<br />

chip handle camera, providing up to 10X Optical, 4X<br />

Digital Zoom.The TVII portable camera is compatible<br />

with any Aurora LED camera ready lighthead.<br />

8<br />

Page 55

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 24 in. (61 cm)<br />

Intensity: 4000K 106,490 lux (9,890 fc)<br />

4500K 90,700 lux (8,430 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

LED specifications<br />

LED5 LED7<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 35 LEDs (5 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 69½ in. (1765 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 102.3 lbs. (46.5 kg)<br />

Moment Load 393.2 ft.lbs/532.8 N-m)<br />

Arm Lengths<br />

Arm 37¼ in. (945 mm)<br />

Video Handle Camera Optional<br />

9<br />

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 30 in. (76.2 cm)<br />

Intensity: 4000K 133,000 lux (12,360 fc)<br />

4500K 122,560 lux (11,380 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 49 LEDs (7 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 77½ in. (1969 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 125 lbs. (56.8 kg)<br />

Moment Load 616.2 ft.lbs/835 N-m)<br />

Arm Lengths<br />

Arm 45 in. (1140 mm)<br />

Video Handle Camera Optional<br />

Refer to appropriate mounting structure guidelines and specific seismic calculations if applicable.<br />

Page 56

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 24 in. (61 cm) 24 in. (61 cm)<br />

Intensity: 4000K 212,980 lux (19,780 fc)<br />

4500K 181,400 lux (16,860 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 70 LEDs (10 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 69½ in. (1765 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 194.3 lbs. (88.3 kg)<br />

Moment Load 807.6 ft.lbs/1094.3 N-m)<br />

Arm Lengths<br />

Upper Arm 45 in. (1140 mm)<br />

Lower Arm 37¼ in. (945 mm)<br />

Video Handle Camera Optional<br />

LED specifications<br />

LED55 LED75<br />

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 30 in. (76 cm) 24 in. (61 cm)<br />

Intensity: 4000K 239,490 lux (22,250 fc)<br />

4500K 213,260 lux (19,810 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 84 LEDs (12 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 69½ in. (1765 mm)<br />

77½ in. (1969 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 214 lbs. (97.3 kg)<br />

Moment Load 983.5 ft.lbs/1332.6 N-m)<br />

Arm Lengths<br />

Upper Arm 45 in. (1140 mm)<br />

Lower Arm 37¼ in. (945 mm)<br />

Video Handle Camera Optional<br />

Refer to appropriate mounting structure guidelines and specific seismic calculations if applicable.<br />

10<br />

Page 57

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 24 in. (61 cm) 24 in. (61 cm)<br />

24 in. (61 cm)<br />

Intensity: 4000K 319,470 lux (29,670 fc)<br />

4500K 272,100 lux (25,290 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 105 LEDs (15 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 69½ in. (1765 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 291 lbs. (132.3 kg)<br />

Moment Load 1269.5 ft.lbs/1720.2 N-m)<br />

Arm Lengths<br />

Upper Arm 52½ in. (1335 mm)<br />

Middle Arm 45 in. (1140 mm)<br />

Lower Arm 37¼ in. (945 mm)<br />

Video Handle Camera Optional<br />

5085 Corporate Exchange Blvd. SE Grand Rapids, MI 49512<br />

1-800-SKYTRON (759-8766) Fax: 616-656-2906<br />

e-mail: sales@skytron.us<br />

LED specifications<br />

LED555 LED755<br />

Technical Data<br />

Optical Characteristics<br />

Diameter of Lighthead 30 in. (76.2 cm) 24 in. (61 cm)<br />

24 in. (61 cm)<br />

Intensity: 4000K 345,980 lux (32,140 fc)<br />

4500K 303,960 lux (28,250 fc)<br />

Diameter of Small Field 5 in. (15.2 cm)<br />

Diameter of Large Field 8 in. (20.3 cm)<br />

Depth of Volume of Light 30-60 in. (76.2-152.4 cm)<br />

Color of Rendering Index (Ra) 94<br />

Color Temperature 4000K, 4500K<br />

Infrared Filtration None (LED Technology)<br />

Radiant Energy Less than 5,000 micro<br />

Watts per cm²<br />

Electrical Characteristics<br />

Voltage at LED 3.5 VDC<br />

LED Life 20,000 hours plus<br />

Number of LEDs 119 LEDs (17 pods, 7 per pod)<br />

Video Camera Prewiring Optional<br />

Electrical Connections<br />

Input Voltage to Power Supply 120V, 1 Phase<br />

Frequency 60 Hz<br />

Output Voltage from Power<br />

Supply 30 VDC<br />

Physical Characteristics<br />

Vertical Travel 69½ in. (1765 mm)<br />

77½ in. (1969 mm)<br />

20° upward<br />

90° downward<br />

Lighthead Rotation 360°<br />

Pitch, Roll, Rotational Axis 360°<br />

Weight of Fixture 310.9 lbs. (141.3 kg)<br />

Moment Load 1445.4 ft.lbs/1958.5 N-m)<br />

Arm Lengths<br />

Upper Arm 52½ in. (1335 mm)<br />

Middle Arm 45 in. (1140 mm)<br />

Lower Arm 37¼ in. (945 mm)<br />

Video Handle Camera Optional<br />

Refer to appropriate mounting structure guidelines and specific seismic calculations if applicable.<br />

Local Representative<br />

9/2007<br />

Page 58

SERIES<br />

SURGICAL LIGHTS<br />

Skytron's Aurora LED Surgical Lighting provides advanced bright, cool and color<br />

correct illumination to the surgical field and a selectable color temperature of 4,000K<br />

(soft white) or 4,500K (bright white) based upon surgeon preference for every<br />

procedure. Focusable LEDs extend illumination range while retaining maximum<br />

intensity at any distance, with LED pod life retaining 90% of original intensity for an<br />

average of 10 years or 20,000 hours of use. Typical applications include General,<br />

Orthopedic, Plastics, Vascular, Cardiovascular, OB/GYN, Trauma, Neurosurgery and<br />

Urology.<br />

REV 9/08<br />

Page 59

LED5<br />

2267mm<br />

89 1/4"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

360º<br />

70mm<br />

2 3/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

110º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

CEILING HEIGHT<br />

<br />

<br />

<br />

4,000K=106,490 Lux (9,890fc)<br />

4,500K= 90,700 Lux (8,430fc)<br />

102.3 lbs./46.5 Kg.<br />

393.2 ft. lbs./532.8 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

144 watts (490 BTU/hr)<br />

2 amps<br />

Page 60

LED5TV<br />

2267mm<br />

89 1/4"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

360º<br />

70mm<br />

2 3/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

110º<br />

360º<br />

CAMERA<br />

READY<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

CEILING HEIGHT<br />

<br />

<br />

4,000K=106,490 Lux (9,890fc)<br />

4,500K= 90,700 Lux (8,430fc)<br />

106.7 lbs./48.5 Kg.<br />

426 ft. lbs./577.3 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

144 watts (490 BTU/hr)<br />

2 amps<br />

<br />

<br />

Page 61

LED7<br />

2716mm<br />

107"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

360º<br />

70mm<br />

2 3/4"<br />

1200mm<br />

47 1/4"<br />

360º<br />

110º<br />

360º<br />

Wall<br />

Control<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

425mm<br />

16 3/4"<br />

CEILING HEIGHT<br />

8'-3" min.<br />

10'-4" max.<br />

4,000K=133,000 Lux (12,360fc)<br />

4,500K=122,560 Lux (11,380fc)<br />

125 lbs./56.8 Kg.<br />

616.2 ft. lbs./835 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

144 watts (490 BTU/hr)<br />

1.2 amps<br />

<br />

<br />

Page 62

LED7TV<br />

2716mm<br />

107"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

360º<br />

70mm<br />

2 3/4"<br />

1200mm<br />

47 1/4"<br />

360º<br />

110º<br />

360º<br />

<br />

<br />

Wall<br />

Control<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

425mm<br />

16 3/4"<br />

TECHNICAL DATA CEILING HEIGHT<br />

120v, 60 Hz, 1 phase<br />

4,000K=133,000lux (12,360fc)<br />

144 watts (490 BTU/hr)<br />

4,500K=122,560lux (11,380fc)<br />

8'-4" min.<br />

1.2 amps<br />

129.4 lbs./58.8 Kg.<br />

10'-5" max.<br />

<br />

<br />

655.9 ft. lbs./888.8 N m<br />

Page 63

LED55<br />

2462mm<br />

97"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

1140mm<br />

45"<br />

70mm<br />

2 3/4"<br />

360º<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

CEILING HEIGHT<br />

8'-8" min.<br />

10'-4" max.<br />

4,000K=212,980 Lux (19,780fc)<br />

4,500K=181,400 Lux (16,860fc)<br />

194.3 lbs./88.3 Kg.<br />

807.6 ft. lbs./1,094.3 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

288 watts (980 BTU/hr)<br />

4 amps<br />

<br />

<br />

Page 64

LED55TV<br />

2462mm<br />

97"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

1140mm<br />

45"<br />

70mm<br />

2 3/4"<br />

360º<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

360º<br />

<br />

<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

TECHNICAL DATA CEILING HEIGHT<br />

120v, 60 Hz, 1 phase<br />

4,000K=212,980 Lux (19,780fc)<br />

288 watts (980 BTU/hr)<br />

4,500K=181,400 Lux (16,860fc)<br />

8'-9" min.<br />

4 amps<br />

198.7 lbs./90.3 Kg.<br />

10'-5" max.<br />

<br />

<br />

840.5 ft. lbs./1,138.9 N m<br />

Page 65

LED75<br />

2716mm<br />

107"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

1140mm<br />

45"<br />

70mm<br />

2 3/4"<br />

360º<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

110º<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

360º<br />

610mm<br />

24"<br />

425mm<br />

16 3/4"<br />

TECHNICAL DATA CEILING HEIGHT<br />

120v, 60 Hz, 1 phase<br />

4,000K=239,490 Lux (22,250fc)<br />

288 watts (980 BTU/hr)<br />

4,500K=213,260 Lux (19,810fc)<br />

8'-8" min.<br />

2.4 amps<br />

214 lbs./97.3 Kg.<br />

10'-4" max.<br />

<br />

<br />

983.5 ft. lbs./1,332.6 N m<br />

Page 66

LED75TV<br />

2716mm<br />

107"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

1140mm<br />

45"<br />

70mm<br />

2 3/4"<br />

360º<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

360º<br />

<br />

<br />

110º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

360º<br />

610mm<br />

24"<br />

425mm<br />

16 3/4"<br />

CEILING HEIGHT<br />

8'-9" min.<br />

10'-5" max.<br />

4,000K=239,490 Lux (22,250fc)<br />

4,500K=213,260 Lux (19,810fc)<br />

218.5 lbs./99.3 Kg.<br />

1,016.2 ft. lbs./1,377 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

288 watts (980 BTU/hr)<br />

2.4 amps<br />

<br />

<br />

Page 67

LED7TV5<br />

2716mm<br />

107"<br />

3/4" Diameter<br />

Conduit<br />

945mm<br />

37 1/4"<br />

1140mm<br />

45"<br />

70mm<br />

2 3/4"<br />

360º<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

110º<br />

360º<br />

360º<br />

<br />

<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

360º<br />

610mm<br />

24"<br />

425mm<br />

16 3/4"<br />

CEILING HEIGHT<br />

8'-9" min.<br />

10'-5" max.<br />

4,000K=239,490 Lux (22,250fc)<br />

4,500K=213,260 Lux (19,810fc)<br />

218.5 lbs./99.3 Kg.<br />

1,023.2 ft. lbs./1,386.5 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

288 watts (980 BTU/hr)<br />

2.4 amps<br />

Page 68

LED555<br />

2657mm<br />

105"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

1335mm<br />

52 1/2"<br />

945mm<br />

37 1/4"<br />

70mm<br />

2 3/4"<br />

360º<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

360º<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

CEILING HEIGHT<br />

9'-2" min.<br />

10'-4" max.<br />

4,000K=319,470lux (29,670fc)<br />

4,500K=272,100lux (25,290fc)<br />

291 lbs./132.3 Kg.<br />

1,269.5 ft. lbs./1,720.2 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

432 watts (1,469 BTU/hr)<br />

6 amps<br />

<br />

<br />

Page 69

LED555TV<br />

2657mm<br />

105"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

1335mm<br />

52 1/2"<br />

945mm<br />

37 1/4"<br />

70mm<br />

2 3/4"<br />

360º<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

110º<br />

360º<br />

<br />

<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

2032mm<br />

80"<br />

360º<br />

610mm<br />

24"<br />

CEILING HEIGHT<br />

9'-3" min.<br />

10'-5" max.<br />

4,000K=319,470lux (29,670fc)<br />

4,500K=272,100lux (25,290fc)<br />

295.5 lbs./134.3 Kg.<br />

1,269.5 ft. lbs./1,720.2 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

432 watts (1,469 BTU/hr)<br />

6 amps<br />

<br />

<br />

Page 70

LED755<br />

2911mm<br />

114 1/2"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

1335mm<br />

52 1/2"<br />

945mm<br />

37 1/4"<br />

70mm<br />

2 3/4"<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

360º<br />

110º<br />

110º<br />

360º<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

360º<br />

610mm<br />

24"<br />

425mm<br />

16 3/4"<br />

CEILING HEIGHT<br />

9'-2" min.<br />

10'-4" max.<br />

4,000K=345,980lux (32,140fc)<br />

4,500K=303,960lux (28,250fc)<br />

310.9 lbs./141.3 Kg.<br />

1,445.4 ft. lbs./1,958.5 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

432 watts (1,469 BTU/hr)<br />

3.6 amps<br />

<br />

<br />

Page 71

LED7TV55<br />

2911mm<br />

114 1/2"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

1335mm<br />

52 1/2"<br />

945mm<br />

37 1/4"<br />

70mm<br />

2 3/4"<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

360º<br />

110º<br />

110º<br />

360º<br />

360º<br />

360º<br />

<br />

<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />

77 1/2"<br />

2032mm<br />

80"<br />

360º<br />

360º<br />

610mm<br />

24"<br />

425mm<br />

16 3/4"<br />

CEILING HEIGHT<br />

9'-3" min.<br />

10'-5" max.<br />

4,000K=345,980lux (32,140fc)<br />

4,500K=303,960lux (28,250fc)<br />

315.3 lbs./143.3 Kg.<br />

1,485.2 ft. lbs./2,012.4 N m<br />

TECHNICAL DATA<br />

120v, 60 Hz, 1 phase<br />

432 watts (1,469 BTU/hr)<br />

3.6 amps<br />

<br />

<br />

Page 72

LED755TV<br />

2911mm<br />

114 1/2"<br />

3/4" Diameter<br />

Conduit<br />

1140mm<br />

45"<br />

1335mm<br />

52 1/2"<br />

945mm<br />

37 1/4"<br />

70mm<br />

2 3/4"<br />

1200mm<br />

47 1/4"<br />

1000mm<br />

39 1/2"<br />

360º<br />

360º<br />

360º<br />

110º<br />

110º<br />

360º<br />

<br />

<br />

360º<br />

360º<br />

Wall<br />

Control<br />

1765mm<br />

69 1/2"<br />

1969mm<br />