Issue 6 - faculty.ait.ac.th - Asian Institute of Technology

Issue 6 - faculty.ait.ac.th - Asian Institute of Technology

Issue 6 - faculty.ait.ac.th - Asian Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Energy Use and Pollution in <strong>th</strong>e Tea Industry<br />

Energy-Environment Highlights<br />

Energy and environmental audit in tea f<strong>ac</strong>tories have been conducted wi<strong>th</strong>in <strong>th</strong>e framework <strong>of</strong> <strong>th</strong>e project “Small and Medium<br />

Scale Industries (SMIs) in Asia: Energy, Environment and Climate Interrelations. This issue presents some results <strong>of</strong> energy use<br />

and pollution in <strong>th</strong>e audited tea f<strong>ac</strong>tories in Sri Lanka and Vietnam.<br />

Sri Lanka<br />

Sri Lanka is <strong>th</strong>e world’s largest exporter <strong>of</strong> bl<strong>ac</strong>k tea and produced about 280 million kg <strong>of</strong> tea in 1998. The land under tea cultivation<br />

is about 189,000 hectares. The tea produced in Sri Lanka is mainly <strong>of</strong> or<strong>th</strong>odox type (more <strong>th</strong>an 93%) and <strong>th</strong>e remaining is<br />

<strong>th</strong>e CTC (crush, tear and curl) type. At present, <strong>th</strong>ere are 634 f<strong>ac</strong>tories operating in Sri Lanka providing employment to about<br />

650,000 people including <strong>th</strong>ose who are engaged in cultivation. It is estimated <strong>th</strong>at around 100,000 personnel are employed in<br />

f<strong>ac</strong>tories.<br />

Table 1. Specific Energy Consumption and Emission Produced in <strong>th</strong>ree Sri Lankan Tea F<strong>ac</strong>tories<br />

High Grown Mid Grown Low Grown<br />

Table 1 pre- Category<br />

sents <strong>th</strong>e specific<br />

energy conand<br />

electricity)<br />

<strong>th</strong>e <strong>th</strong>ree tea<br />

Specific energy<br />

consumption<br />

Thermal (kWh<strong>th</strong>/kg)<br />

Electrical(kWhe/kg)<br />

7.4<br />

0.61<br />

5.28<br />

0.56<br />

6.23<br />

0.48<br />

sumption (<strong>th</strong>ermal<br />

and emission in<br />

producing regions.<br />

CO2 (kg/kg <strong>of</strong> product)* 1.1 a<br />

Specific emission<br />

Vietnam<br />

Region<br />

Tea is grown mainly in <strong>th</strong>e nor<strong>th</strong>ern provinces <strong>of</strong> Vietnam and in Lam Dong Province in <strong>th</strong>e Sou<strong>th</strong>. There are 75 state-owned<br />

tea processing bases in <strong>th</strong>e country <strong>of</strong> which 30 belong to <strong>th</strong>e Vietnam National Tea Corporation. There are also more <strong>th</strong>an<br />

1,200 non-state small-scaled enterprises and tens <strong>of</strong> <strong>th</strong>ousands <strong>of</strong> households involved in processing tea. The two main kinds <strong>of</strong><br />

tea products <strong>of</strong> Vietnam are bl<strong>ac</strong>k tea and green tea. Technologies used in producing bl<strong>ac</strong>k tea are Or<strong>th</strong>odox and CTC, while<br />

Chinese, Taiwanese, Japanese and traditional Vietnamese technologies are used in producing green tea.<br />

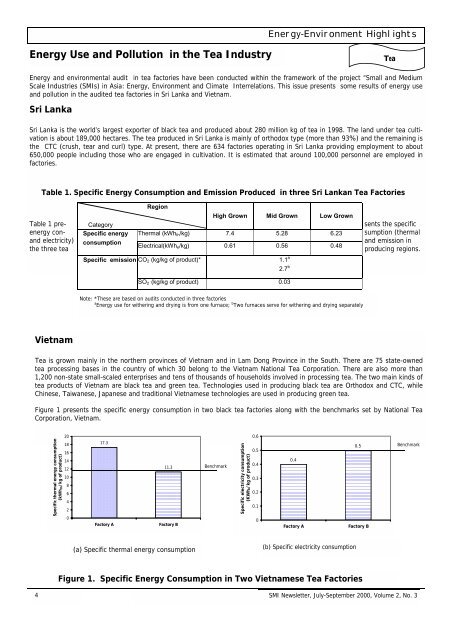

Figure 1 presents <strong>th</strong>e specific energy consumption in two bl<strong>ac</strong>k tea f<strong>ac</strong>tories along wi<strong>th</strong> <strong>th</strong>e benchmarks set by National Tea<br />

Corporation, Vietnam.<br />

Specific <strong>th</strong>ermal energy consumption<br />

(kWh<strong>th</strong>/kg <strong>of</strong> product)<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Figure 1. Specific Energy Consumption in Two Vietnamese Tea F<strong>ac</strong>tories<br />

4 SMI Newsletter, July-September 2000, Volume 2, No. 3<br />

2.7 b<br />

SO2 (kg/kg <strong>of</strong> product) 0.03<br />

Note: *These are based on audits conducted in <strong>th</strong>ree f<strong>ac</strong>tories<br />

a Energy use for wi<strong>th</strong>ering and drying is from one furn<strong>ac</strong>e; b Two furn<strong>ac</strong>es serve for wi<strong>th</strong>ering and drying separately<br />

17.3<br />

11.3<br />

F<strong>ac</strong>tory A F<strong>ac</strong>tory B<br />

(a) Specific <strong>th</strong>ermal energy consumption<br />

Benchmark<br />

Specific electricity consumption<br />

(KWhe/kg <strong>of</strong> product)<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

0.4<br />

(b) Specific electricity consumption<br />

0.5<br />

F<strong>ac</strong>tory A F<strong>ac</strong>tory B<br />

Tea<br />

Benchmark