Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

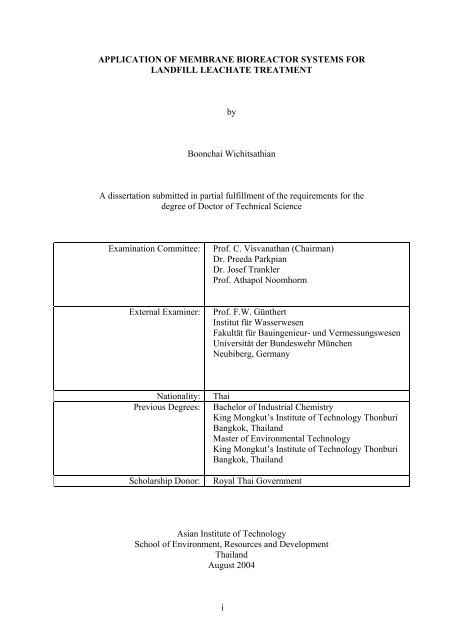

APPLICATION OF MEMBRANE BIOREACTOR SYSTEMS FOR<br />

LANDFILL LEACHATE TREATMENT<br />

i<br />

by<br />

Boonchai Wichitsa<strong>th</strong>ian<br />

A dissertation submitted in partial fulfillment <strong>of</strong> <strong>th</strong>e requirements for <strong>th</strong>e<br />

degree <strong>of</strong> Doctor <strong>of</strong> Technical Science<br />

Examination Committee: Pr<strong>of</strong>. C. Visvana<strong>th</strong>an (Chairman)<br />

Dr. Preeda Parkpian<br />

Dr. Josef Trankler<br />

Pr<strong>of</strong>. A<strong>th</strong>apol Noomhorm<br />

External Examiner: Pr<strong>of</strong>. F.W. Gün<strong>th</strong>ert<br />

Institut für Wasserwesen<br />

Fakultät für Bauingenieur- und Vermessungswesen<br />

Universität der Bundeswehr München<br />

Neubiberg, Germany<br />

Nationality: Thai<br />

Previous Degrees: B<strong>ac</strong>helor <strong>of</strong> Industrial Chemistry<br />

King Mongkut’s <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong> Thonburi<br />

Bangkok, Thailand<br />

Master <strong>of</strong> Environmental <strong>Technology</strong><br />

King Mongkut’s <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong> Thonburi<br />

Bangkok, Thailand<br />

Scholarship Donor: Royal Thai Government<br />

<strong>Asian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Technology</strong><br />

School <strong>of</strong> Environment, Resources and Development<br />

Thailand<br />

August 2004

Acknowledgements<br />

I would like to deeply express my pr<strong>of</strong>ound gratitude to his advisor, Pr<strong>of</strong>. C.<br />

Visvana<strong>th</strong>an for kindly giving his stimulating ideas, valuable guidance, numerous<br />

constructive suggestions and encouragement <strong>th</strong>rough his study at AIT. The au<strong>th</strong>or also<br />

would like to <strong>th</strong>ank Dr. Preeda Parkpian, Dr. Josef Trankler, Dr. David A. Luketina, Dr.<br />

Lee Seung-Hwan, and Pr<strong>of</strong>. A<strong>th</strong>apol Noomhorm for <strong>th</strong>eir valuable comments, critical ideas<br />

and serving as members <strong>of</strong> examination committee.<br />

I am greatly indebted to Pr<strong>of</strong>. F.W. Gun<strong>th</strong>ert for kindly <strong>ac</strong>cepting to serve as<br />

External Examiner. His valuable advice, guidance and pr<strong>of</strong>essional comments are highly<br />

appreciated.<br />

I gratefully <strong>ac</strong>knowledge to Royal Thai Government for <strong>th</strong>e financial support.<br />

I am very grateful to Ms. Sindhuja Sankaran and Ms. Loshnee Nair for providing<br />

comments and helping <strong>th</strong>roughout my study at AIT.<br />

I sincerely would like to <strong>th</strong>ank all staffs and my lab colleagues in <strong>th</strong>e<br />

Environmental Engineering Program for friendship, help, and moral support, which<br />

contributed in various ways to <strong>th</strong>e completion <strong>of</strong> <strong>th</strong>is dissertation.<br />

Sincere gratitude is expressed to <strong>th</strong>e Pa<strong>th</strong>um<strong>th</strong>ani municipality and Ram-indra<br />

transfer station <strong>of</strong>fice, Thailand, for <strong>th</strong>e useful information and assistance on <strong>th</strong>e le<strong>ac</strong>hate<br />

and sample collection.<br />

Finally, I would like to express my deepest gratitude and dedicate <strong>th</strong>is research<br />

work to my parents, all family members and special friends, whose love, assisted me<br />

<strong>th</strong>rough difficult times and contributed to <strong>th</strong>e success <strong>of</strong> <strong>th</strong>is study.<br />

ii

Abstr<strong>ac</strong>t<br />

Landfill le<strong>ac</strong>hate is a complex wastewater wi<strong>th</strong> considerable variation in bo<strong>th</strong> quality<br />

and quantity. The composition and concentration <strong>of</strong> pollutants are influenced by <strong>th</strong>e types<br />

<strong>of</strong> waste deposited, hydrogeological f<strong>ac</strong>tors, and more significantly by <strong>th</strong>e age <strong>of</strong> <strong>th</strong>e<br />

landfill site. In general, le<strong>ac</strong>hate is highly contaminated wi<strong>th</strong> organic contaminants<br />

measured as chemical oxygen demand (COD) and biochemical oxygen demand (BOD),<br />

and also wi<strong>th</strong> high ammonium nitrogen concentration. Biological processes have been<br />

found ineffective for le<strong>ac</strong>hate from relatively old landfill. In le<strong>ac</strong>hate containing high<br />

concentrations <strong>of</strong> organic and nitrogen compounds such cases result in possible serious<br />

environmental problems near <strong>th</strong>e landfill site.<br />

This research was undertaken to investigate <strong>th</strong>e performance <strong>of</strong> a membrane<br />

biore<strong>ac</strong>tor (MBR) using mixed yeast culture (YMBR) and mixed b<strong>ac</strong>teria culture (BMBR)<br />

in treating raw le<strong>ac</strong>hate containing high organic and nitrogen concentrations. The<br />

inhibition effects <strong>of</strong> ammonium nitrogen and lead on yeast and b<strong>ac</strong>teria cultures were<br />

determined by measuring <strong>th</strong>e oxygen uptake rate (OUR) using <strong>th</strong>e respirometric me<strong>th</strong>od.<br />

Fur<strong>th</strong>ermore, for bo<strong>th</strong> YMBR and BMBR, treating <strong>th</strong>e stripped le<strong>ac</strong>hate, <strong>th</strong>ey were<br />

assessed <strong>th</strong>e treatment efficiency to compare <strong>th</strong>e results wi<strong>th</strong> <strong>th</strong>ose treating <strong>th</strong>e raw<br />

le<strong>ac</strong>hate.<br />

The inhibition experiment revealed <strong>th</strong>at a b<strong>ac</strong>teria culture was very sensitive to<br />

ammonium nitrogen when it was compared to a yeast culture. Also <strong>th</strong>e values <strong>of</strong> biokinetic<br />

coefficients showed <strong>th</strong>at <strong>th</strong>e specific grow<strong>th</strong> rate (µ) in b<strong>ac</strong>teria system was influenced. At<br />

ammonium concentration <strong>of</strong> 2,000 mg/L, <strong>th</strong>e response <strong>of</strong> OUR inhibition in a b<strong>ac</strong>teria<br />

system was approximately 37% whereas it was around 6% in a yeast system. Fur<strong>th</strong>ermore,<br />

bo<strong>th</strong> yeast and b<strong>ac</strong>teria cultures were also sensitive to lead.<br />

In a MBR, treating raw le<strong>ac</strong>hate, <strong>th</strong>e COD removal rate for BMBR was slightly<br />

lower <strong>th</strong>an <strong>th</strong>e YMBR for varied hydraulic retention time (HRT) at high volumetric<br />

loading rate. The average COD removal efficiency in BMBR was 62±2% while in YMBR<br />

was 65±2%. The YMBR could obtain higher COD removal rate at higher volumetric<br />

loading rate <strong>th</strong>an <strong>th</strong>e BMBR. This indicated <strong>th</strong>at <strong>th</strong>e yeast system can treat le<strong>ac</strong>hate<br />

containing high organic and nitrogen concentrations. The average TKN removal efficiency<br />

for bo<strong>th</strong> BMBR and YMBR systems was from 14-25% and 19-29%, respectively. The<br />

nitrite and nitrate concentrations (NO2 - and NO3 - ) were found to be very low.<br />

The comparative evaluation <strong>of</strong> treatment performance <strong>of</strong> MBR, treating stripped<br />

le<strong>ac</strong>hate, was examined. The COD removal <strong>of</strong> bo<strong>th</strong> BMBR and YMBR was above 70% at<br />

HRT 16 h and 24 h. As a result, <strong>th</strong>e pretreatment wi<strong>th</strong> ammonia stripping prior to BMBR<br />

showed more significant improvement in terms <strong>of</strong> COD removal when it was compared to<br />

YMBR. This could be confirmed <strong>th</strong>at <strong>th</strong>e trend <strong>of</strong> inhibition effect on b<strong>ac</strong>teria was<br />

dependent upon <strong>th</strong>e ammonium nitrogen concentration. The range <strong>of</strong> BOD concentration<br />

<strong>of</strong> effluents from bo<strong>th</strong> YMBR and BMBR, treating <strong>th</strong>e stripped le<strong>ac</strong>hate was from 30-55<br />

mg/L. This level followed <strong>th</strong>e present effluent standard. Al<strong>th</strong>ough BOD could be reduced<br />

to lower values wi<strong>th</strong> <strong>th</strong>ese me<strong>th</strong>ods, <strong>th</strong>e treated le<strong>ac</strong>hate still contained a large quantity <strong>of</strong><br />

refr<strong>ac</strong>tory organic compounds. This might be due to <strong>th</strong>e contribution <strong>of</strong> <strong>th</strong>e slowly<br />

biodegradable organics and non-biodegradable organics contained in <strong>th</strong>e le<strong>ac</strong>hate.<br />

Therefore, <strong>th</strong>ey should be fur<strong>th</strong>er treated in a post treatment for elevating <strong>th</strong>e final effluent<br />

to meet <strong>th</strong>e present effluent standard or even increasing <strong>th</strong>e biodegradable organics.<br />

iii

Under <strong>th</strong>e same operating conditions, <strong>th</strong>e YMBR could run under transmembrane<br />

pressure (TMP) 1.3-2.5 times lower <strong>th</strong>an <strong>th</strong>e BMBR wi<strong>th</strong> <strong>th</strong>e significantly reduced<br />

membrane fouling rate. This might be due to <strong>th</strong>e soluble extr<strong>ac</strong>ellular polymeric substances<br />

(soluble EPS). Hence, yeast system could enhance membrane performance and had <strong>th</strong>e<br />

potential to improve <strong>th</strong>e treatment system due to reduction <strong>of</strong> operational problems. In<br />

addition, b<strong>ac</strong>teria sludge showed a better dewatering quality compared to <strong>th</strong>at <strong>of</strong> <strong>th</strong>e yeast<br />

sludge.<br />

iv

Table <strong>of</strong> Contents<br />

Chapter Title Page<br />

Title Page i<br />

Acknowledgements ii<br />

Abstr<strong>ac</strong>t iii<br />

Table <strong>of</strong> Contents v<br />

List <strong>of</strong> Tables viii<br />

List <strong>of</strong> Figures x<br />

List <strong>of</strong> Abbreviations xii<br />

1 Introduction 1<br />

1.1 B<strong>ac</strong>kground 1<br />

1.2 Objectives <strong>of</strong> <strong>th</strong>e Study 3<br />

1.3 Scope <strong>of</strong> <strong>th</strong>e Study 4<br />

2 Literature Review 5<br />

2.1 Introduction 5<br />

2.2 Solid Waste Management Pr<strong>ac</strong>tices 6<br />

2.3 Municipal Solid Waste Landfill 7<br />

2.4 Municipal Solid Waste Landfill Le<strong>ac</strong>hate 7<br />

2.5 Le<strong>ac</strong>hate Composition and Char<strong>ac</strong>teristics 8<br />

2.6 Molecular Weight Distribution in Landfill Le<strong>ac</strong>hate 11<br />

2.7 F<strong>ac</strong>tors Affecting Le<strong>ac</strong>hate Composition 12<br />

2.7.1 Seasonal Variation 13<br />

2.7.2 Landfill Age 14<br />

2.7.3 Composition <strong>of</strong> <strong>th</strong>e Waste Dumped 16<br />

2.7.4 Geological Char<strong>ac</strong>teristic 16<br />

2.7.5 Filling Technique 16<br />

2.8 Le<strong>ac</strong>hate Treatment 17<br />

2.8.1 Biological Treatment Processes 18<br />

2.8.2 Physical Treatment 24<br />

2.8.3 Chemical Treatment 30<br />

2.8.4 Natural Le<strong>ac</strong>hate Treatment Systems 33<br />

2.8.5 Co-Treatment wi<strong>th</strong> Municipal Wastewater 35<br />

2.9 Combined Treatment F<strong>ac</strong>ility 36<br />

2.9.1 Biological Treatment and Reverse Osmosis 36<br />

2.9.2 Micr<strong>of</strong>iltration and Reverse Osmosis 37<br />

2.9.3 Denitrification-Nitrification/Ultrafiltration and Reverse Osmosis 38<br />

2.9.4 MBR-UV and Ozone-Reverse Osmosis 39<br />

2.10 Microbial Toxicity 39<br />

2.11 Membrane Biore<strong>ac</strong>tors 41<br />

2.11.1 Membrane Configuration 42<br />

2.11.2 Application <strong>of</strong> Membrane Biore<strong>ac</strong>tors 44<br />

2.11.3 Sludge Char<strong>ac</strong>teristics 45<br />

2.12 Yeasts 49<br />

2.12.1 Introduction 49<br />

2.12.2 Applications <strong>of</strong> Yeasts for Wastewater Treatment 49<br />

v

2.13 Rationale for <strong>th</strong>e Study and Proposed Treatment Sequence 52<br />

2.13.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic 52<br />

2.13.2 Need for Ammonia Stripping 52<br />

2.13.3 Need for Membrane Biore<strong>ac</strong>tors 53<br />

3 Me<strong>th</strong>odology 54<br />

3.1 Introduction 54<br />

3.2 Le<strong>ac</strong>hate Char<strong>ac</strong>terization 54<br />

3.3 Seed Study 55<br />

3.3.1 Yeast and B<strong>ac</strong>terial Sludge 55<br />

3.3.2 Acclimatization 56<br />

3.4 Toxicity Studies 56<br />

3.4.1 Ammonia Toxicity 57<br />

3.4.2 Lead Toxicity 58<br />

3.5 Ammonia Stripping 58<br />

3.6 Membrane Biore<strong>ac</strong>tor 59<br />

3.6.1 Membrane Resistance Measurement 59<br />

3.6.2 Experimental Set-up 60<br />

3.6.3 Parametric Studies 62<br />

3.6.4 Molecular Weight Distribution 62<br />

3.6.5 Sludge Char<strong>ac</strong>terization 64<br />

3.7 Ammonia Stripping Coupled Membrane Biore<strong>ac</strong>tor 64<br />

3.8 Analytical Me<strong>th</strong>ods 65<br />

4 Results and Discussion 67<br />

4.1 Simulation <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristic for Treatment <strong>of</strong><br />

Middle Aged Le<strong>ac</strong>hate 67<br />

4.2 Biokinetic Studies 68<br />

4.2.1 Acclimatization <strong>of</strong> Mixed Yeast and B<strong>ac</strong>terial Sludge 68<br />

4.2.2 Kinetics <strong>of</strong> Yeast and B<strong>ac</strong>terial Grow<strong>th</strong> 72<br />

4.2.3 Toxicity Studies 75<br />

4.3 Application <strong>of</strong> Yeast and B<strong>ac</strong>teria Based Membrane Biore<strong>ac</strong>tors<br />

in Le<strong>ac</strong>hate Treatment 80<br />

4.3.1 Initial Membrane Resistance 81<br />

4.3.2 Optimization <strong>of</strong> HRT in Terms <strong>of</strong> Membrane Biore<strong>ac</strong>tor<br />

Treatment Efficiency 82<br />

4.3.3 Membrane Fouling and Membrane Resistance 89<br />

4.4 Application <strong>of</strong> Yeast and B<strong>ac</strong>teria Based Membrane Biore<strong>ac</strong>tors<br />

in Ammonia Stripped Le<strong>ac</strong>hate Treatment 91<br />

4.4.1 Ammonia Stripping Studies 91<br />

4.4.2 Membrane Resistance and Membrane Cleaning 95<br />

4.4.3 Performance <strong>of</strong> Ammonia Stripping Coupled Membrane<br />

Biore<strong>ac</strong>tor Process 97<br />

4.5 O<strong>th</strong>er Studies 106<br />

4.5.1 Biodegradability <strong>of</strong> <strong>th</strong>e Le<strong>ac</strong>hate 106<br />

4.5.2 Molecular Weight Cut-<strong>of</strong>f 110<br />

4.5.3 Sludge Properties 115<br />

4.5.4 EPS Formation 116<br />

4.5.5 Conductivity and TDS 117<br />

vi

4.5.6 Cost Analysis for Operation 117<br />

5 Conclusions and Recommendations 119<br />

5.1 Conclusions 119<br />

5.2 Recommendations for Future Work 121<br />

References 123<br />

Appendix A: Pictures <strong>of</strong> Experiments 141<br />

Appendix B: Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Experimental<br />

Data <strong>of</strong> Acclimation 145<br />

Appendix C: Experimental Data <strong>of</strong> Biokinetic Study and<br />

Toxicity Study 149<br />

Appendix D: Membrane Resistance Studies 155<br />

Appendix E: MBR wi<strong>th</strong>out Ammonia Stripping 163<br />

Appendix F: Ammonia Stripping Studies 171<br />

Appendix G: MBR wi<strong>th</strong> Ammonia Stripping 174<br />

Appendix H: O<strong>th</strong>er Studies 179<br />

vii

List <strong>of</strong> Tables<br />

Tables Title Page<br />

2.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic in Acidogenic and Me<strong>th</strong>anogenic Phase<br />

in a Landfill 8<br />

2.2 Comparison <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristics <strong>of</strong> Landfills Surveyed in<br />

Asia, Europe and America 10<br />

2.3 Relation between Landfill Age, Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Treatments 11<br />

2.4 Classification <strong>of</strong> Types <strong>of</strong> Substances Using Molecular Weight Cut<strong>of</strong>f 12<br />

2.5 Variation <strong>of</strong> COD, BOD & BOD/COD wi<strong>th</strong> Increasing Landfill Ages 15<br />

2.6 Nitrogen Concentrations from Various Sources 15<br />

2.7 Nitrogen Concentration Ranges in <strong>th</strong>e Le<strong>ac</strong>hate for Landfill Stabilization 15<br />

2.8 Summary <strong>of</strong> Biokinetic Coefficient <strong>of</strong> Activated Sludge Process for<br />

Landfill Le<strong>ac</strong>hate Treatment 19<br />

2.9 Operational and Environmental Conditions for Nitrification-<br />

Denitrification Processes 23<br />

2.10 Treatment Efficiencies <strong>of</strong> Different Aerobic Biological Treatment<br />

Systems 25<br />

2.11 Treatment Efficiencies <strong>of</strong> Different Anaerobic Biological Treatment<br />

Systems 26<br />

2.12 Membrane Processes 28<br />

2.13 Removal Efficiency <strong>of</strong> Moderate to High Concentrations <strong>of</strong> Pollutants<br />

Using Nan<strong>of</strong>iltration, Ultrafiltration and Reverse Osmosis 28<br />

2.14 Typical Reverse Osmosis Plant Performance for Le<strong>ac</strong>hate Purification,<br />

Germany 30<br />

2.15 Treatment Efficiencies <strong>of</strong> Different Physico-chemical Treatment Systems 34<br />

2.16 Typical Le<strong>ac</strong>hate Composition at E<strong>ac</strong>h Stage <strong>of</strong> Le<strong>ac</strong>hate Treatment Plant 39<br />

2.17 Inhibitory Effect <strong>of</strong> Various Toxicants 41<br />

2.18 Advantages and Disadvantages <strong>of</strong> Membrane Biore<strong>ac</strong>tors 43<br />

2.19 Operating Conditions <strong>of</strong> Membrane Biore<strong>ac</strong>tor Process for Treatment<br />

<strong>of</strong> Different Kinds <strong>of</strong> Wastewater 46<br />

2.20 Operating Conditions <strong>of</strong> Yeast System Compared wi<strong>th</strong> Activated<br />

Sludge Process 51<br />

2.21 Performance <strong>of</strong> Yeast Based Treatment System in Dried Food Products<br />

and Marine Product Industry 51<br />

3.1 Composition <strong>of</strong> Simulated Le<strong>ac</strong>hate 55<br />

3.2 Operating Conditions for Yeast and B<strong>ac</strong>teria Acclimatization 56<br />

3.3 Operating Conditions for Yeast and B<strong>ac</strong>teria Mixtures in Respirometer 57<br />

3.4 Description <strong>of</strong> <strong>th</strong>e Chemical Cleaning 60<br />

3.5 Technical Parameters <strong>of</strong> <strong>th</strong>e Experimental Plant 60<br />

3.6 Experimental Operating Conditions <strong>of</strong> YMBR and BMBR Systems 62<br />

3.7 Char<strong>ac</strong>teristics <strong>of</strong> Ultrafiltration Membrane 64<br />

3.8 Parameters and Their Analytical Me<strong>th</strong>ods 66<br />

4.1 Compositions <strong>of</strong> Le<strong>ac</strong>hate Simulated from Le<strong>ac</strong>hates Obtained from<br />

Pa<strong>th</strong>um-<strong>th</strong>ani Landfill Site (PS) and Ram-Indra Transfer Station (RIS) 67<br />

4.2 Biokinetic Coefficients <strong>of</strong> Yeast and B<strong>ac</strong>teria Sludge for <strong>th</strong>e Le<strong>ac</strong>hates 74<br />

4.3 Effect <strong>of</strong> Free Ammonia Concentration on Yield Coefficient and <strong>th</strong>e<br />

Specific Grow<strong>th</strong> Rate <strong>of</strong> <strong>th</strong>e B<strong>ac</strong>terial Sludge 76<br />

viii

4.4 Effect <strong>of</strong> Free Ammonia Concentration on Yield Coefficient and <strong>th</strong>e<br />

Specific Grow<strong>th</strong> Rate <strong>of</strong> <strong>th</strong>e Yeast Sludge 77<br />

4.5 Substrate Utilization by <strong>th</strong>e Yeast and B<strong>ac</strong>terial Sludge 79<br />

4.6 COD Removal Efficiency in YMBR System at Different HRT 85<br />

4.7 COD Removal Efficiency in BMBR System at Different HRT 86<br />

4.8 TKN Removal Efficiency in YMBR System 88<br />

4.9 TKN Removal Efficiency in BMBR System 88<br />

4.10 Membrane Cleaning Frequency in <strong>th</strong>e MBR Systems 90<br />

4.11 Membrane Resistance in <strong>th</strong>e MBR Systems 90<br />

4.12 Variation in Ammonia Removal Efficiency 94<br />

4.13 Determination <strong>of</strong> Membrane Resistance <strong>of</strong> Membrane Module after<br />

Clogging in BMBR system (A = 0.42 m2; Pore Size = 0.1 µm) 96<br />

4.14 Contribution <strong>of</strong> BOD at 5, 10 and 15 Days to <strong>th</strong>e Total 20 Days BOD 108<br />

4.15 Sludge Properties in <strong>th</strong>e YMBR and BMBR Systems 115<br />

4.16 MLSS and MLVSS Concentrations in Yeast and B<strong>ac</strong>teria Re<strong>ac</strong>tors 116<br />

4.17 Bound EPS Concentration in <strong>th</strong>e YMBR and BMBR Systems 116<br />

4.18 Soluble EPS Concentration in <strong>th</strong>e YMBR and BMBR Systems 116<br />

4.19 Conductivity and TDS Concentrations in Le<strong>ac</strong>hate and Effluents 117<br />

4.20 Cost <strong>of</strong> Chemical Used for pH Adjustment 118<br />

4.21 Total Chemical Cost Requirement for E<strong>ac</strong>h Treatment System 118<br />

ix

List <strong>of</strong> Figures<br />

Figures Title Page<br />

2.1 Schematic Representation <strong>of</strong> a Typical Engineered Landfill 6<br />

2.2 Changes in Significant Parameters during Different Phases <strong>of</strong><br />

Landfill Stabilization 7<br />

2.3 Variation in Significant Pollutant Ratios wi<strong>th</strong> Increase in Age<br />

<strong>of</strong> <strong>th</strong>e Landfill 9<br />

2.4 Water Movements in <strong>th</strong>e Landfill 13<br />

2.5 Le<strong>ac</strong>hate Productions and Rainfall Variation wi<strong>th</strong> Time 14<br />

2.6 Treatment <strong>of</strong> Landfill Le<strong>ac</strong>ahte wi<strong>th</strong> Two Stage Reverse Osmosis 29<br />

2.7 Schematic Diagram <strong>of</strong> Biological Treatment and Reverse Osmosis<br />

for Le<strong>ac</strong>hate Treatment 37<br />

2.8 Schematic Diagram <strong>of</strong> Micr<strong>of</strong>iltration/Reverse Osmosis for<br />

Le<strong>ac</strong>hate Treatment 38<br />

2.9 Schematic Diagram <strong>of</strong> Denitrification-Nitrification/UF and<br />

Reverse Osmosis for Le<strong>ac</strong>hate Treatment 38<br />

2.10 Schematic Diagrams <strong>of</strong> (a) External Recirculation MBR and<br />

(b) Submerged MBR System 42<br />

3.1 Flowchart Showing Different Stages <strong>of</strong> Experimental Study 54<br />

3.2 Diagram Illustrating <strong>th</strong>e Enrichment Procedure 55<br />

3.3 Respirometer 57<br />

3.4 Experiments Conducted to Optimize Ammonia Stripping 59<br />

3.5 Schematic Diagrams <strong>of</strong> Membrane Biore<strong>ac</strong>tor wi<strong>th</strong> and wi<strong>th</strong>out<br />

Ammonia Stripping 61<br />

3.6 Me<strong>th</strong>odology for Performing Molecular Weight Cut-<strong>of</strong>f Distribution 63<br />

3.7 Flowchart Showing Ammonia Stripping Coupled MBR Process 65<br />

4.1 Variation in F/M and COD Removal Efficiency in Yeast Sludge 69<br />

4.2 Variation in F/M and COD Removal Efficiency in B<strong>ac</strong>terial Sludge 69<br />

4.3 Increase in Biomass during Acclimatization <strong>of</strong> <strong>th</strong>e B<strong>ac</strong>terial Sludge 70<br />

4.4 Increase in Biomass during Acclimatization <strong>of</strong> <strong>th</strong>e Yeast Sludge 71<br />

4.5 Predominantly Spherical and Egg-shaped Yeasts wi<strong>th</strong> Budding in<br />

<strong>th</strong>e Yeast Re<strong>ac</strong>tor (x1500) 71<br />

4.6 B<strong>ac</strong>teria Cells in <strong>th</strong>e Mixed B<strong>ac</strong>teria Sludge: a) Gram Negative and<br />

b) Gram Positive (x1500) 72<br />

4.7 Specific Grow<strong>th</strong> Rate <strong>of</strong> Mixed B<strong>ac</strong>teria Sludge wi<strong>th</strong> Increasing<br />

Substrate Concentration 72<br />

4.8 Specific Grow<strong>th</strong> Rate <strong>of</strong> Mixed Yeast Sludge wi<strong>th</strong> Increasing<br />

Substrate Concentration 72<br />

4.9 Inhibition <strong>of</strong> <strong>th</strong>e Yeast and B<strong>ac</strong>terial Culture wi<strong>th</strong> Increasing<br />

Ammonium Chloride Concentration 77<br />

4.10 Inhibitory Effect <strong>of</strong> Lead in B<strong>ac</strong>terial Sludge 79<br />

4.11 Inhibition Effect <strong>of</strong> Lead in Yeast Sludge 80<br />

4.12 Variation in Transmembrane Pressure wi<strong>th</strong> Permeate Flux (a) YMBR<br />

and (b) BMBR 81<br />

4.13 Variation in Organic Load wi<strong>th</strong> HRT 83<br />

4.14 Variation in MLSS in <strong>th</strong>e MBR Systems 83<br />

4.15 Variation in pH in <strong>th</strong>e MBR Systems 84<br />

x

4.16 COD Concentration in <strong>th</strong>e Influent and Effluent in <strong>th</strong>e BMBR and<br />

YMBR at Different HRT 84<br />

4.17 COD Removal Efficiency in <strong>th</strong>e BMBR and YMBR at Different HRT 85<br />

4.18 Variations in COD Removal Rate as a Function <strong>of</strong> F/M Ratio 86<br />

4.19 TKN Removal Efficiency in <strong>th</strong>e YMBR and BMBR wi<strong>th</strong> HRT 87<br />

4.20 Cleaning <strong>of</strong> membranes in <strong>th</strong>e YMBR and BMBR system in<br />

relation to TMP 90<br />

4.21 Variation in <strong>th</strong>e Ammonia Removal Efficiency wi<strong>th</strong> pH 93<br />

4.22 Ammonia Removal Efficiency wi<strong>th</strong> Varying Velocity Gradient and pH 93<br />

4.23 Trans-membrane Pressure Variation in MBR Process for Ammonia<br />

Stripped Le<strong>ac</strong>hate Treatment 96<br />

4.24 Variation in COD at 16 and 24 h HRT 98<br />

4.25 Variation in MLSS at 16 and 24 h HRT 98<br />

4.26 COD Removal wi<strong>th</strong> and wi<strong>th</strong>out Ammonia Stripping at 16 and 24 h HRT 99<br />

4.27 Expected and Actual Improvement in COD Removal wi<strong>th</strong> Ammonia<br />

Stripping in <strong>th</strong>e YMBR and BMBR Systems 100<br />

4.28 BOD in <strong>th</strong>e BMBR and YMBR Effluent at 16 h HRT 101<br />

4.29 BOD in <strong>th</strong>e BMBR and YMBR Effluent at 24 h HRT 101<br />

4.30 BOD Removal Efficiency in <strong>th</strong>e BMBR and YMBR Systems 102<br />

4.31 BOD/COD <strong>of</strong> <strong>th</strong>e BMBR and YMBR Effluent 102<br />

4.32 Influent and Effluent Nitrogen Content in BMBR at (a) 16 h HRT and<br />

(b) 24 h HRT 103<br />

4.33 Influent and Effluent Nitrogen Content in YMBR at (a) 16 h HRT and<br />

(b) 24 h HRT 104<br />

4.34 Overall TKN Removal in BMBR and YMBR wi<strong>th</strong> and wi<strong>th</strong>out<br />

Ammonia Stripping 105<br />

4.35 TKN Removal in MBR Process at 16 and 24 h HRT 106<br />

4.36 Change <strong>of</strong> OUR at Different Time Period for Le<strong>ac</strong>hate Sample 107<br />

4.37 20 Days BOD <strong>of</strong> <strong>th</strong>e Raw Le<strong>ac</strong>hate and Stripped Le<strong>ac</strong>hate 109<br />

4.38 20 Days BOD <strong>of</strong> <strong>th</strong>e YMBR and BMBR Effluents 109<br />

4.39 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Raw Le<strong>ac</strong>hate, Stripped Le<strong>ac</strong>hate,<br />

B<strong>ac</strong>terial and Yeast Effluents 111<br />

4.40 Percent Contribution <strong>of</strong> Various Molecular Weight Compounds to<br />

<strong>th</strong>e Total COD 111<br />

4.41 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Le<strong>ac</strong>hate (a) COD (mg/L) (b) COD (%) 113<br />

4.42 Molecular Weight Cut-<strong>of</strong>f <strong>of</strong> Le<strong>ac</strong>hate (a) BOD (mg/L) (b) BOD (%) 114<br />

xi

List <strong>of</strong> Abbreviations<br />

AAS Atomic Absorption Spectrophotometer<br />

AnSBR Anaerobic Sequencing Batch Re<strong>ac</strong>tors<br />

AOX Adsorbable Organic Halogens<br />

AS Activated Sludge<br />

BACFB Biological Activated Carbon Fluidized Bed Process<br />

BOD Biochemical Oxygen Demand<br />

BMBR B<strong>ac</strong>terial Membrane Biore<strong>ac</strong>tors<br />

C Carbon<br />

cm Centimeter<br />

COD Chemical Oxygen Demand<br />

CST Capillary Suction Time<br />

d Day<br />

Da Daltons<br />

DO Dissolved Oxygen<br />

DOC Dissolved Organic Carbon<br />

DSVI Diluted Sludge Volume Index<br />

EMBR Extr<strong>ac</strong>tive Membrane Biore<strong>ac</strong>tor<br />

EPS Extr<strong>ac</strong>ellular Polymeric Substances<br />

F/M Food/Microorganism ratio<br />

FS Fixed Solids<br />

g Gram<br />

G Mean velocity gradient<br />

GAC Granular Activated Carbon<br />

h Hour<br />

HRT Hydraulic Retention Time<br />

J Permeate flux<br />

k Substrate removal rate<br />

kDa Kilo Daltons<br />

kg Kilogram<br />

kPa Kilo Pascal<br />

kWh Kilowatt-hour<br />

kd Endogenous decay coefficient<br />

ke Mean re<strong>ac</strong>tion rate coefficient<br />

Ks Half-velocity constant<br />

L Liter<br />

m Meter<br />

m 2 Square meter<br />

m 3 Cubic meter<br />

m 3 /d Cubic meter per day<br />

mg/L Milligram per liter<br />

min Minute<br />

MAACFB Microorganism Att<strong>ac</strong>hed Activated Carbon Fluidized Bed Process<br />

MABR Membrane Aeration Biore<strong>ac</strong>tors<br />

MBR Membrane Biore<strong>ac</strong>tor<br />

MF Micr<strong>of</strong>iltration<br />

MLSS Mixed Liquor Suspended Solids<br />

MLVSS Mixed Liquor Volatile Suspended Solids<br />

MW Molecular Weight<br />

xii

MWCO Molecular Weight Cut-<strong>of</strong>f<br />

MWW Municipal Wastewater<br />

N Nitrogen<br />

NF Nan<strong>of</strong>iltration<br />

NH3-N Ammonia Nitrogen<br />

NH4-N Ammonium Nitrogen<br />

NO2-N Nitrite Nitrogen<br />

NO3-N Nitrate Nitrogen<br />

NOM Natural Organic Matter<br />

OLR Organic Loading Rate<br />

OUR Oxygen Uptake Rate<br />

P Phosphorus<br />

Pa Pascal<br />

PAC Powder Activated Carbon<br />

PS Pa<strong>th</strong>um<strong>th</strong>ani Landfill Site<br />

R Filtration resistance<br />

Rc Resistance due to cake layer<br />

Rm Intrinsic resistance<br />

Rn Resistance due to irreversible fouling<br />

Rt Total resistance<br />

RBC Rotating Biological Cont<strong>ac</strong>tor<br />

RIS Ram-indra Transfer Station<br />

RO Reverse Osmosis<br />

rpm Rotations per minute<br />

s Seconds<br />

So/Xo Substrate/Biomass ratio<br />

Ss Readily biodegradable organics<br />

SBR Sequencing Batch Re<strong>ac</strong>tor<br />

SCBP Suspended Carrier Bi<strong>of</strong>ilm Process<br />

SD Standard Deviation<br />

SRT Sludge Retention Time<br />

SS Suspended Solids<br />

SVI Sludge Volume Index<br />

T Temperature<br />

TDS Total Dissolved Solid<br />

TOC Total Organic Carbon<br />

TKN Total Kjedahl Nitrogen<br />

TMP Transmembrane Pressure<br />

TS Total Solids<br />

TVS Total Volatile Solids<br />

U Substrate Utilization Rate<br />

UASB Upflow Anaerobic Sludge Blanket<br />

UF Ultrafiltration<br />

USB/AF Upflow Hybrid Sludge Bed/Fixed Bed Anaerobic<br />

UV Ultraviolet<br />

VFA Volatile Fatty Acid<br />

VLR Volumetric Loading Rate<br />

VS Volatile Solids<br />

VSS Volatile Suspended Solids<br />

Xs Slowly biodegradable organics<br />

xiii

Y Yield coefficient<br />

YMBR Yeast Membrane Biore<strong>ac</strong>tor<br />

Өc Solid retention time<br />

o C Degree Celsius<br />

∆P Transmembrane Ppessure<br />

µ Vicosity<br />

µm Micrometer<br />

µmax Maximum specific grow<strong>th</strong> rate<br />

µS/cm Microsiemens per centimeter<br />

xiv

1.1 B<strong>ac</strong>kground<br />

Chapter 1<br />

Introduction<br />

Rapid industrialization and urbanization has resulted in an immense environmental<br />

degradation. Population grow<strong>th</strong> and poor environmental management pr<strong>ac</strong>tices have led to<br />

deterioration <strong>of</strong> environmental quality in most <strong>of</strong> <strong>th</strong>e developing countries. The<br />

composition <strong>of</strong> <strong>th</strong>e domestic refuse has radically changed in char<strong>ac</strong>ter over <strong>th</strong>e last fifty<br />

years, due to <strong>th</strong>e rise <strong>of</strong> an affluent society. In recent years, solid waste management has<br />

gained focus in many countries. Source reduction, reuse and recycling <strong>of</strong> waste,<br />

composting, incineration and landfill disposal are few <strong>of</strong> <strong>th</strong>e solid waste management<br />

appro<strong>ac</strong>hes pr<strong>ac</strong>ticed in different countries. The suitability <strong>of</strong> <strong>th</strong>ese appro<strong>ac</strong>hes differs from<br />

pl<strong>ac</strong>e to pl<strong>ac</strong>e. Municipal solid waste disposal in <strong>th</strong>e landfill is <strong>th</strong>e most common, cheap<br />

and easiest municipal solid waste management pr<strong>ac</strong>tice followed <strong>th</strong>roughout <strong>th</strong>e world.<br />

However, landfill requires a close environmental engineering surveillance in its design and<br />

operation as it is likely to generate le<strong>ac</strong>hate which would potentially contaminate nearby<br />

groundwater and surf<strong>ac</strong>e water. Wi<strong>th</strong> <strong>th</strong>e changing nature <strong>of</strong> domestic refuse composition<br />

over <strong>th</strong>e years, <strong>th</strong>e proportion <strong>of</strong> refuse available for decomposition has greatly increased<br />

and <strong>th</strong>us <strong>th</strong>e organic streng<strong>th</strong> <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate has increased, resulting in its greater potential<br />

to pollute water. A need exist to focus on <strong>th</strong>e environmental problems concerned wi<strong>th</strong><br />

domestic landfill disposal to protect <strong>th</strong>e environment and prevent adverse heal<strong>th</strong> affects.<br />

Surf<strong>ac</strong>e water <strong>th</strong>at percolates <strong>th</strong>rough <strong>th</strong>e landfill and le<strong>ac</strong>hes out organic and<br />

inorganic constituents from <strong>th</strong>e solid waste is termed le<strong>ac</strong>hate. Landfill le<strong>ac</strong>hate production<br />

starts at <strong>th</strong>e early stages <strong>of</strong> <strong>th</strong>e landfill and continues several decades even after landfill<br />

closure. Landfill le<strong>ac</strong>hate is mainly generated by <strong>th</strong>e infiltrating water, which passes<br />

<strong>th</strong>rough <strong>th</strong>e solid waste fill and f<strong>ac</strong>ilitates transfer <strong>of</strong> contaminants from solid phase to<br />

liquid phase. Due to <strong>th</strong>e inhomogeneous nature <strong>of</strong> <strong>th</strong>e waste and because <strong>of</strong> <strong>th</strong>e differing<br />

comp<strong>ac</strong>tion densities <strong>th</strong>at will be encountered, water will be able to percolate <strong>th</strong>rough and<br />

appear as le<strong>ac</strong>hate at <strong>th</strong>e base <strong>of</strong> <strong>th</strong>e site. If no remedial measures are taken to prevent<br />

continual inputs <strong>of</strong> water to <strong>th</strong>e wastes, <strong>th</strong>is could pose adverse environmental imp<strong>ac</strong>ts.<br />

Landfill le<strong>ac</strong>hate is high streng<strong>th</strong> wastewater which contains high concentrations <strong>of</strong><br />

organic matter and ammonium nitrogen. There is a fluctuation in <strong>th</strong>e composition <strong>of</strong><br />

organic, inorganic and heavy metal components in <strong>th</strong>e le<strong>ac</strong>hate making <strong>th</strong>em more difficult<br />

to be dealt wi<strong>th</strong>. The composition depends on <strong>th</strong>e landfill age, <strong>th</strong>e quality and quantity <strong>of</strong><br />

solid waste, <strong>th</strong>e biological and chemical processes occurring in <strong>th</strong>e landfill, and <strong>th</strong>e amount<br />

<strong>of</strong> precipitation and percolation. When <strong>th</strong>e le<strong>ac</strong>hate containing high streng<strong>th</strong> organic matter<br />

and ammonia is discharged wi<strong>th</strong>out treatment, it can stimulate algae grow<strong>th</strong> <strong>th</strong>rough<br />

nutrient enrichment, deplete dissolved oxygen, and cause toxic effects in <strong>th</strong>e surrounding<br />

water environment. Landfill design and operation have a major imp<strong>ac</strong>t and influence on <strong>th</strong>e<br />

le<strong>ac</strong>hate generation. This le<strong>ac</strong>hate varies from landfill to landfill and over time and sp<strong>ac</strong>e in<br />

a particular landfill wi<strong>th</strong> fluctuations apparent over short and long-term periods due to<br />

climatic, hydrogeology and waste composition variations (Keenan, et al., 1984). Generally,<br />

le<strong>ac</strong>hate contaminants are measured in terms <strong>of</strong> chemical oxygen demand (COD) and<br />

biological oxygen demand (BOD), halogenated hydrocarbons and heavy metals. In<br />

addition, le<strong>ac</strong>hate usually contains high concentrations <strong>of</strong> inorganic salts - mainly sodium<br />

1

chloride, carbonate and sulfate and is dependent on <strong>th</strong>e waste composition land-filled. An<br />

average fresh domestic refuse le<strong>ac</strong>hate can have a BOD <strong>of</strong> around 15,000 mg/L. When<br />

compared to an average raw sewage BOD <strong>of</strong> 200 mg/L, it can be seen <strong>th</strong>at landfill le<strong>ac</strong>hate<br />

is around 75 times as strong in terms <strong>of</strong> its polluting potential.<br />

Sufficient means have to be evolved to deal wi<strong>th</strong> landfill le<strong>ac</strong>hate so <strong>th</strong>at its imp<strong>ac</strong>t<br />

can be minimized. Le<strong>ac</strong>hate treatment and prevention or minimization <strong>of</strong> le<strong>ac</strong>hate<br />

generation is primarily <strong>th</strong>e two prime options available for landfill le<strong>ac</strong>hate management.<br />

Disposal <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate in <strong>th</strong>e sewer is an attr<strong>ac</strong>tive option, but <strong>th</strong>e variation in <strong>th</strong>e quality<br />

<strong>of</strong> <strong>th</strong>e sewage and le<strong>ac</strong>hate and remoteness <strong>of</strong> <strong>th</strong>e landfill sites make <strong>th</strong>is option difficult<br />

pr<strong>ac</strong>tically. Le<strong>ac</strong>hate treatment has inevitably become a much more widespread<br />

requirement at landfills. It is a technology which has only developed in 1980 in <strong>th</strong>e UK,<br />

but is now advancing rapidly as experience is being gained on full scale landfills<br />

(Robinson, et al., 1992).The main environmental problem experienced at landfills has<br />

resulted from a loss <strong>of</strong> le<strong>ac</strong>hate from <strong>th</strong>e site and <strong>th</strong>e subsequent contamination <strong>of</strong><br />

surrounding land and water. Improvements in landfill engineering has been aimed at<br />

reducing le<strong>ac</strong>hate production, collecting and treating le<strong>ac</strong>hate prior to discharge and<br />

<strong>th</strong>ereby limiting le<strong>ac</strong>hate infiltration to <strong>th</strong>e surrounding soil (Farquhar, 1989). However a<br />

need exists to develop reliable, sustainable options to effectively manage le<strong>ac</strong>hate<br />

generation and treatment. In designing a le<strong>ac</strong>hate treatment scheme, <strong>th</strong>e process must<br />

reflect <strong>th</strong>e possibility <strong>th</strong>at treatment techniques which work well for a young le<strong>ac</strong>hate may<br />

become wholly inadequate as <strong>th</strong>e landfill age increases.<br />

There are difficulties concerned wi<strong>th</strong> <strong>th</strong>e treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate. First, <strong>th</strong>e<br />

variability and streng<strong>th</strong> <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate have important waste treatment application. Second,<br />

<strong>th</strong>e changes encountered from landfill to landfill are such <strong>th</strong>at waste treatment technology<br />

applicable at one site may not be directly transferable to o<strong>th</strong>er location. Third, fluctuations<br />

in <strong>th</strong>e le<strong>ac</strong>hate quality which occur over bo<strong>th</strong> short and long interval must be <strong>ac</strong>counted for<br />

in <strong>th</strong>e treatment design and long interval must be <strong>ac</strong>counted for in <strong>th</strong>e treatment design.<br />

Current treatment pr<strong>ac</strong>tices in developed countries advocate le<strong>ac</strong>hate minimization<br />

by operating landfills as dry as possible; <strong>th</strong>is poses <strong>th</strong>e problem <strong>of</strong> long-term landfill<br />

stabilization. The alternative <strong>of</strong> operating <strong>th</strong>e landfill as wet as possible by le<strong>ac</strong>hate recirculation<br />

does address <strong>th</strong>e problem <strong>of</strong> le<strong>ac</strong>hate treatment by reducing organics. However,<br />

<strong>th</strong>is me<strong>th</strong>od does not prove effective in treating “hard COD” or refr<strong>ac</strong>tory compounds and<br />

nitrogen. Therefore, it does not meet municipal discharge standards. Various biological<br />

treatment me<strong>th</strong>ods have been employed for <strong>th</strong>e treatment <strong>of</strong> le<strong>ac</strong>hate from municipal solid<br />

waste landfill. Extended aeration systems, sequencing batch re<strong>ac</strong>tors and aerated lagoons<br />

can <strong>ac</strong>t as robust, stable and reliable means <strong>of</strong> treating le<strong>ac</strong>hate. These treatment systems<br />

were found to be inefficient for le<strong>ac</strong>hate containing high streng<strong>th</strong> organic substances and<br />

ammonia nitrogen. In addition, <strong>th</strong>e organic loading and pH are significant in influencing<br />

<strong>th</strong>e grow<strong>th</strong> <strong>of</strong> nitrifying b<strong>ac</strong>teria in nitrification process (Aberling, et al., 1992; Bea, et al.,<br />

1997; Kabdasli, et al., 2000). Due to high ammonia concentrations in <strong>th</strong>e le<strong>ac</strong>hate,<br />

ammonia toxicity and sludge properties are affected in <strong>th</strong>e biological treatment systems. A<br />

reed bed treatment system can also be designed to treat effluent by passing it <strong>th</strong>rough <strong>th</strong>e<br />

rhizomes <strong>of</strong> <strong>th</strong>e reed. However, such treatment systems would not deal satisf<strong>ac</strong>torily<br />

because reed bed are poor in removing ammonia. Additionally, ammonium concentration<br />

as high as approximately 1,000 mg/L <strong>of</strong> untreated le<strong>ac</strong>hate feed, might be directly toxic<br />

(Robinson, et al., 1992). The physical treatment systems used for treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate<br />

include <strong>ac</strong>tivated carbon adsorption, filtration, evaporation; etc. These processes are<br />

2

generally unsuccessful in removal <strong>of</strong> organic material from <strong>th</strong>e raw le<strong>ac</strong>hate. The chemical<br />

me<strong>th</strong>ods include coagulation and precipitation and oxidation <strong>of</strong> <strong>th</strong>e organics. The<br />

disadvantage <strong>of</strong> <strong>th</strong>e coagulation and precipitation is <strong>th</strong>at large amounts <strong>of</strong> sludge are<br />

produced which is difficult to manage. Nei<strong>th</strong>er biological nor chemical/physical treatment<br />

separately <strong>ac</strong>hieves high removal efficiency. Physical-chemical treatment is needed to<br />

remove <strong>th</strong>e metals and hydrolyze some <strong>of</strong> <strong>th</strong>e organics whilst biological treatment is<br />

necessary for stabilization and degradation <strong>of</strong> organic matter. Looking into <strong>th</strong>ese aspects,<br />

landfill le<strong>ac</strong>hate treatment requires some advanced treatment technique, to meet <strong>th</strong>e<br />

required effluent standards.<br />

Membrane biore<strong>ac</strong>tor systems are an example <strong>of</strong> an emerging advanced le<strong>ac</strong>hate<br />

treatment technology. Application <strong>of</strong> <strong>th</strong>e membrane coupled <strong>ac</strong>tivated sludge process in<br />

le<strong>ac</strong>hate treatment is very promising because <strong>of</strong> <strong>th</strong>e expected effluent quality. The design<br />

<strong>of</strong> <strong>th</strong>e membrane biore<strong>ac</strong>tor is becoming more affordable and <strong>th</strong>e equipment more reliable.<br />

Membrane biore<strong>ac</strong>tor systems are suspended grow<strong>th</strong> <strong>ac</strong>tivated sludge treatment systems<br />

<strong>th</strong>at rely upon <strong>th</strong>e membrane equipment for liquid/solid separation prior to <strong>th</strong>e discharge <strong>of</strong><br />

<strong>th</strong>e le<strong>ac</strong>hate. Two reasons <strong>th</strong>at exist for <strong>th</strong>e poor removal efficiency <strong>of</strong> <strong>th</strong>e individual<br />

treatment system is <strong>th</strong>e high percentage <strong>of</strong> high molecular weight organic material and<br />

ammonium concentration to be removed and biological inhibition caused by <strong>th</strong>e heavy<br />

metal which may be present in <strong>th</strong>e le<strong>ac</strong>hate.<br />

Sufficient knowledge about <strong>th</strong>e capability and <strong>th</strong>e performance <strong>of</strong> membrane<br />

biore<strong>ac</strong>tors plants for le<strong>ac</strong>hate treatment is yet to be found. Moreover, membrane systems<br />

are <strong>of</strong>ten subjected to clogging and <strong>th</strong>is poses serious problems for operation and<br />

maintenance. In order to reduce <strong>th</strong>e problems <strong>of</strong> frequent membrane clogging, <strong>th</strong>e<br />

application <strong>of</strong> yeast culture to treat wastewater can be considered. The membrane<br />

biore<strong>ac</strong>tor system wi<strong>th</strong> yeast can be employed to treat <strong>th</strong>e wastewater containing high<br />

amount <strong>of</strong> dissolved solids, high concentrations <strong>of</strong> organic matter and o<strong>th</strong>er substances,<br />

which are difficult to treat using conventional biological systems.<br />

Consequently, depending on <strong>th</strong>e char<strong>ac</strong>teristics <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate, a combination <strong>of</strong><br />

biological and physio-chemical processes can <strong>ac</strong>hieve high removal efficiencies. Thus, <strong>th</strong>e<br />

objective <strong>of</strong> <strong>th</strong>is study is introducing <strong>th</strong>e emerging technology <strong>of</strong> membrane biore<strong>ac</strong>tors<br />

and its role in le<strong>ac</strong>hate treatment. Thereafter, a rationale has been developed for <strong>th</strong>e<br />

treatment <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate produced under tropical conditions <strong>of</strong> Thailand. The experiments<br />

have been conducted in <strong>th</strong>e laboratory to find <strong>th</strong>e performance <strong>of</strong> membrane biore<strong>ac</strong>tor<br />

using yeast culture (YMBR) and b<strong>ac</strong>teria culture (BMBR) and coupled wi<strong>th</strong> ammonia<br />

stripping for removal <strong>of</strong> organic substances from <strong>th</strong>e landfill le<strong>ac</strong>hate. This treatment<br />

system could <strong>ac</strong>t as an innovative appro<strong>ac</strong>h in <strong>th</strong>e future wi<strong>th</strong> regard to <strong>th</strong>e landfill<br />

management pr<strong>ac</strong>tices.<br />

1.2 Objectives <strong>of</strong> <strong>th</strong>e Study<br />

The objectives <strong>of</strong> <strong>th</strong>is study are to investigate <strong>th</strong>e performance <strong>of</strong> membrane<br />

biore<strong>ac</strong>tor using yeast culture and b<strong>ac</strong>teria culture and to examine <strong>th</strong>e prospects <strong>of</strong><br />

applying membrane biore<strong>ac</strong>tor in landfill le<strong>ac</strong>hate treatment. The specific objectives are as<br />

follows:<br />

3

1. To investigate and evaluate <strong>th</strong>e performance <strong>of</strong> membrane biore<strong>ac</strong>tor using yeast<br />

culture (YMBR) and b<strong>ac</strong>teria culture (BMBR) for <strong>th</strong>e treatment <strong>of</strong> landfill le<strong>ac</strong>hate<br />

containing high organic and high ammonia concentrations;<br />

2. To investigate and evaluate <strong>th</strong>e performance <strong>of</strong> ammonia stripping coupled<br />

membrane biore<strong>ac</strong>tor process for <strong>th</strong>e landfill le<strong>ac</strong>hate treatment and to compare <strong>th</strong>e<br />

results wi<strong>th</strong> <strong>th</strong>e treatment performance wi<strong>th</strong>out pre-treatment;<br />

3. To evaluate <strong>th</strong>e respiratory inhibition effects <strong>of</strong> ammonia and lead concentrations on<br />

mixed yeast and mixed b<strong>ac</strong>teria culture;<br />

4. To investigate <strong>th</strong>e potential <strong>of</strong> ammonia stripping for ammonia removal and examine<br />

<strong>th</strong>e f<strong>ac</strong>tors influencing <strong>th</strong>e ammonia removal efficiency;<br />

5. To understand <strong>th</strong>e effect <strong>of</strong> membrane fouling <strong>th</strong>rough sludge char<strong>ac</strong>teristics.<br />

1.3 Scope <strong>of</strong> <strong>th</strong>e Study<br />

To <strong>ac</strong>hieve <strong>th</strong>e above mentioned objectives, <strong>th</strong>e following tasks are undertaken:<br />

1. Char<strong>ac</strong>terization and mixing <strong>of</strong> le<strong>ac</strong>hates obtained from Pa<strong>th</strong>um<strong>th</strong>ani landfill site<br />

(PS) and Ram-indra transfer station (RIS) was done to simulate a medium-aged<br />

le<strong>ac</strong>hate. The le<strong>ac</strong>hate COD concentration was maintained at 8,000±1,000 mg/L,<br />

BOD/COD ratio at 0.40±0.05, and TKN concentration at 1,900±100 mg/L. This<br />

laboratory simulated le<strong>ac</strong>hate was used to evaluate <strong>th</strong>e performance <strong>of</strong> <strong>th</strong>e treatment<br />

process.<br />

2. The yeast culture membrane biore<strong>ac</strong>tor (YMBR) and b<strong>ac</strong>teria culture based<br />

membrane biore<strong>ac</strong>tor (BMBR) were optimized varying <strong>th</strong>e HRT and MLSS<br />

concentrations. The optimum operational condition was evaluated in terms <strong>of</strong> organic<br />

and TKN removal efficiencies and membrane filtration performance.<br />

3. The removal <strong>of</strong> ammonia <strong>th</strong>rough ammonia stripping was carried out by varying <strong>th</strong>e<br />

pH, gradient velocity and cont<strong>ac</strong>t time. The process efficiency was evaluated in<br />

terms <strong>of</strong> ammonia removal efficiency. After <strong>th</strong>e optimization <strong>of</strong> <strong>th</strong>e operating<br />

conditions <strong>of</strong> <strong>th</strong>e ammonia stripping and <strong>th</strong>e membrane biore<strong>ac</strong>tor, <strong>th</strong>e optimum<br />

conditions were used to assess <strong>th</strong>e efficiency <strong>of</strong> <strong>th</strong>e membrane biore<strong>ac</strong>tor using <strong>th</strong>e<br />

b<strong>ac</strong>terial and yeast culture along wi<strong>th</strong> <strong>th</strong>e ammonia stripping.<br />

4. To evaluate <strong>th</strong>e inhibition effects <strong>of</strong> ammonium (NH4-N) and lead (Pb) on mixed<br />

yeast and mixed b<strong>ac</strong>teria sludge. The NH4-N concentration was varied from 200 to<br />

2,000 mg/L in bo<strong>th</strong> sludge. The lead nitrate (Pb(NO3)2) concentration in <strong>th</strong>e b<strong>ac</strong>teria<br />

system was varied from 20 to 100 mg/L while in <strong>th</strong>e yeast system was varied from 2<br />

to 25 mg/L. The inhibitory effect was measured in terms <strong>of</strong> oxygen uptake rate<br />

(OUR) using respirometric me<strong>th</strong>od.<br />

5. The sludge char<strong>ac</strong>teristics were analyzed to understand <strong>th</strong>eir relationship wi<strong>th</strong> <strong>th</strong>e<br />

EPS formation in <strong>th</strong>e membrane biore<strong>ac</strong>tor. The molecular weight cut-<strong>of</strong>f was also<br />

done in <strong>th</strong>e sludge along wi<strong>th</strong> <strong>th</strong>e fr<strong>ac</strong>tion causing COD.<br />

4

2.1 Introduction<br />

Chapter 2<br />

Literature Review<br />

A landfill is any form <strong>of</strong> waste land, ranging from an uncontrolled rubbish "dump" to<br />

a full "containment" site engineered wi<strong>th</strong> high standards to protect <strong>th</strong>e environment. The<br />

landfill is <strong>th</strong>e most economical form <strong>of</strong> solid waste disposal as adverse environmental<br />

effects and o<strong>th</strong>er risks and inconveniences are minimized, <strong>th</strong>ereby allowing waste to<br />

decompose under controlled conditions until it eventually transforms into relatively inert,<br />

stabilized material (Robinson and Maris, 1983). Most landfills can be operated<br />

satisf<strong>ac</strong>torily for at least some period in <strong>th</strong>eir lifetime in <strong>th</strong>is manner and in absence <strong>of</strong> any<br />

significant negative environmental imp<strong>ac</strong>t.<br />

Unfortunately, in warmer climates, <strong>th</strong>e increase in le<strong>ac</strong>hate production after<br />

precipitation is rapid (Lema, et al., 1988) due to rainfall exceeding <strong>th</strong>e amount which can<br />

be effectively evaporated during winter or rainy seasons. Hence, le<strong>ac</strong>hate generation needs<br />

to be controlled and effective le<strong>ac</strong>hate treatment options have to be identified in order to<br />

avoid negative imp<strong>ac</strong>ts caused by <strong>th</strong>e le<strong>ac</strong>hate.<br />

A common pr<strong>ac</strong>tice in controlling le<strong>ac</strong>hate generation is to control <strong>th</strong>e water<br />

infiltration in <strong>th</strong>e landfill by waste comp<strong>ac</strong>tion as it reduces <strong>th</strong>e infiltration rate. Fur<strong>th</strong>er, by<br />

designing water pro<strong>of</strong> covers and growing plants on <strong>th</strong>e soil covers <strong>of</strong> <strong>th</strong>e waste,<br />

infiltration can be minimized. Figure 2.1 presents a typical engineered landfill. The landfill<br />

le<strong>ac</strong>hate char<strong>ac</strong>teristic is controlled by solid waste char<strong>ac</strong>teristics, moisture content, pH,<br />

redox potential, temperature, etc. The presence <strong>of</strong> moisture is necessary for <strong>th</strong>e biological<br />

conversions wi<strong>th</strong>in <strong>th</strong>e landfill and for landfill stabilisation, which occurs when <strong>th</strong>ere is<br />

insufficient moisture. Degradation processes wi<strong>th</strong>in <strong>th</strong>e landfill are also temperature<br />

dependent. The pH and redox potential set <strong>th</strong>e conditions for <strong>th</strong>e different phases <strong>of</strong><br />

degradation and biological processes wi<strong>th</strong>in <strong>th</strong>e landfill. Thus, <strong>th</strong>e microbial composition<br />

wi<strong>th</strong>in <strong>th</strong>e landfill effectively contributes to <strong>th</strong>e landfill stabilization.<br />

After <strong>th</strong>e initial period <strong>of</strong> waste pl<strong>ac</strong>ement in a landfill, microbial processes proceed<br />

under anoxic conditions. Hydrolytic and fermentative microbial processes solubilize <strong>th</strong>e<br />

waste components during <strong>th</strong>e <strong>ac</strong>id fermentation phase producing organic <strong>ac</strong>ids, alcohols,<br />

ammonia, carbon dioxide and o<strong>th</strong>er low molecular weight compounds as major products.<br />

This process occurs at a low pH (typically around 5) and is enhanced by <strong>th</strong>e presence <strong>of</strong><br />

moisture wi<strong>th</strong>in <strong>th</strong>e landfill. After several mon<strong>th</strong>s, <strong>th</strong>e me<strong>th</strong>ane fermentation stage occurs.<br />

Me<strong>th</strong>anogenic le<strong>ac</strong>hate is neutral in pH and possesses moderate organic compounds which<br />

are not easily degradable and are fermented to yield me<strong>th</strong>ane, carbon dioxide and o<strong>th</strong>er<br />

gaseous end products (Harmsen, 1983; Farquhar, 1989).<br />

5

Perimeter<br />

Collection Pipe<br />

Cap Drainage<br />

System<br />

Filter<br />

Layer<br />

Comp<strong>ac</strong>ted<br />

soil<br />

Le<strong>ac</strong>hate Collection<br />

System<br />

Leak Detection<br />

System<br />

Figure 2.1 Schematic Representation <strong>of</strong> a Typical Engineered Landfill<br />

2.2 Solid Waste Management Pr<strong>ac</strong>tices<br />

The safe and reliable long-term disposal <strong>of</strong> solid waste is an important component in<br />

solid waste management. Municipal solid waste consists <strong>of</strong> inorganic substances such as<br />

boxes, grass clippings, furniture, clo<strong>th</strong>ing, bottles, food scraps, newspapers, and appliances<br />

along wi<strong>th</strong> organic waste. There are different me<strong>th</strong>ods employed in solid waste<br />

management. Few <strong>of</strong> <strong>th</strong>e management pr<strong>ac</strong>tices are as follows:<br />

(a) Reduction in <strong>th</strong>e exploitation <strong>of</strong> <strong>th</strong>e resources and <strong>th</strong>e minimization <strong>of</strong> waste<br />

(b) Increase in recovery/reuse by pl<strong>ac</strong>ing increased responsibility on <strong>th</strong>e producer<br />

(c) Incineration<br />

(d) Composting<br />

(e) Landfilling, etc.<br />

Landfilling or <strong>th</strong>e land disposal is today <strong>th</strong>e most commonly used me<strong>th</strong>od for waste<br />

disposal. Landfill has been <strong>th</strong>e most economical and environmentally <strong>ac</strong>ceptable me<strong>th</strong>od<br />

for <strong>th</strong>e disposal <strong>of</strong> solid waste <strong>th</strong>roughout <strong>th</strong>e world. Even wi<strong>th</strong> <strong>th</strong>e implementation <strong>of</strong><br />

waste reduction, recycling and transformation technologies, disposal <strong>of</strong> solid waste in <strong>th</strong>e<br />

landfill still remains an important component <strong>of</strong> <strong>th</strong>e solid waste management strategies.<br />

Concerns wi<strong>th</strong> <strong>th</strong>e landfilling <strong>of</strong> solid waste are related to (1) <strong>th</strong>e controlled release<br />

<strong>of</strong> landfill gases <strong>th</strong>at might migrate <strong>of</strong>f-site and cause odor and o<strong>th</strong>er potentially dangerous<br />

conditions, (2) <strong>th</strong>e imp<strong>ac</strong>t <strong>of</strong> <strong>th</strong>e uncontrolled discharge <strong>of</strong> landfill gases on <strong>th</strong>e green<br />

house effect in <strong>th</strong>e atmosphere , (3) <strong>th</strong>e uncontrolled release <strong>of</strong> le<strong>ac</strong>hate <strong>th</strong>at may migrate<br />

down to underlying groundwater or to surf<strong>ac</strong>e water, (4) <strong>th</strong>e breeding and harboring <strong>of</strong><br />

disease vectors in an improperly managed landfills, and (5) <strong>th</strong>e heal<strong>th</strong> and environmental<br />

imp<strong>ac</strong>ts associated wi<strong>th</strong> <strong>th</strong>e release <strong>of</strong> tr<strong>ac</strong>e gases arising from <strong>th</strong>e hazardous materials.<br />

2.3 Municipal Solid Waste Landfill<br />

Gas Vent<br />

Solid waste<br />

Drainage<br />

Layer<br />

Top Soil<br />

Drainage Layer<br />

Low Permeability Soil<br />

6<br />

Collection<br />

Pipes<br />

Collection<br />

Pipes<br />

Native Soil Foundation<br />

Final Soil Cover<br />

Filter Layer<br />

Barrier Layer<br />

(FML)<br />

Top Liner<br />

(FML)<br />

Upper<br />

Component<br />

Lower Component<br />

(Comp<strong>ac</strong>ted Soil)<br />

Protective Soil<br />

or Cover

In <strong>th</strong>e municipal solid waste landfill, biodegradable waste constituents are converted<br />

into intermediates and end products, primarily by initial hydrolysis to intermediate<br />

substrates which support <strong>ac</strong>idogenesis and product are subsequently utilized as precursor<br />

for gas formation during me<strong>th</strong>anogenesis in <strong>th</strong>e five degradation phases (Pohland and<br />

Harper, 1985; Pohland and Kim, 1999). Figure 2.2 represents variation in concentrations <strong>of</strong><br />

significant parameters during <strong>th</strong>e five degradation phases.<br />

High<br />

Concentration<br />

Low<br />

Redox<br />

Potential<br />

Figure 2.2 Changes in Significant Parameters during Different Phases <strong>of</strong> Landfill<br />

Stabilization (Pohland and Harper, 1985)<br />

The trend in <strong>th</strong>e degradation phase may not uniform <strong>th</strong>roughout <strong>th</strong>e landfill since<br />

<strong>th</strong>ere are certain regions in <strong>th</strong>e landfill which are dominated by a particular degradation<br />

phase. Hence, <strong>th</strong>e le<strong>ac</strong>hate generated is a combination <strong>of</strong> <strong>th</strong>e products <strong>of</strong> different<br />

microbial and physico-chemical processes taking pl<strong>ac</strong>e wi<strong>th</strong>in <strong>th</strong>e landfill.<br />

2.4 Municipal Solid Waste Landfill Le<strong>ac</strong>hate<br />

Landfill le<strong>ac</strong>hate is a high-streng<strong>th</strong> wastewater formed as a result <strong>of</strong> percolation <strong>of</strong><br />

rainwater and moisture <strong>th</strong>rough waste in a landfill. The liquid medium absorbs nutrients<br />

and contaminants from <strong>th</strong>e waste and <strong>th</strong>us posing hazard to <strong>th</strong>e receiving water bodies.<br />

Le<strong>ac</strong>hate contains many substances, depending upon <strong>th</strong>e types <strong>of</strong> waste disposed into <strong>th</strong>e<br />

landfill. Le<strong>ac</strong>hate may be toxic to life or may simply alter <strong>th</strong>e ecology <strong>of</strong> <strong>th</strong>e stream<br />

watercourse, if not removed by treatment.<br />

Depending on <strong>th</strong>e geographical and geological nature <strong>of</strong> a landfill site, le<strong>ac</strong>hate may<br />

seep into <strong>th</strong>e ground and possibly enter groundwater sources. Though part <strong>of</strong> <strong>th</strong>e<br />

contaminants from <strong>th</strong>e le<strong>ac</strong>hate can be removed by natural processes wi<strong>th</strong>in <strong>th</strong>e ground,<br />

groundwater contamination can be hazardous as drinking water sources may be affected.<br />

The simplest me<strong>th</strong>od <strong>of</strong> le<strong>ac</strong>hate treatment is disposal into <strong>th</strong>e public sewer. However,<br />

as <strong>th</strong>ere is considerable difference between <strong>th</strong>e le<strong>ac</strong>hate and domestic wastewater<br />

char<strong>ac</strong>teristics, <strong>th</strong>e volume <strong>of</strong> le<strong>ac</strong>hate discharged is limited. Fur<strong>th</strong>er, depending on<br />

7<br />

Heavy Metal<br />

Emission<br />

Carbon<br />

Emission<br />

Aerobic Acidogenic Me<strong>th</strong>anogenic Oxidation Wea<strong>th</strong>ering<br />

Degradation Phases

le<strong>ac</strong>hate char<strong>ac</strong>teristics, it may be necessary to pre-treat le<strong>ac</strong>hate prior to discharge in<br />

wastewater treatment plants so <strong>th</strong>at it does not upset <strong>th</strong>e biological process nor cause any<br />

operational and maintenance problems in <strong>th</strong>e treatment plant. In determining a treatment<br />

scheme for le<strong>ac</strong>hate treatment, it is also necessary to determine whe<strong>th</strong>er <strong>th</strong>e le<strong>ac</strong>hate<br />

effluent meets sewer or water body discharge standards.<br />

2.5 Le<strong>ac</strong>hate Composition and Char<strong>ac</strong>teristics<br />

During <strong>th</strong>e first few years (< 5 years), <strong>th</strong>e landfill is in <strong>ac</strong>idogenic phase and <strong>th</strong>e<br />

le<strong>ac</strong>hate generated is generally referred to as “young” or carbon-based le<strong>ac</strong>hate due to <strong>th</strong>e<br />

high concentration <strong>of</strong> organic carbon present. Landfill greater <strong>th</strong>an 10 years old are<br />

generally in <strong>th</strong>e me<strong>th</strong>anogenic phase and <strong>th</strong>e le<strong>ac</strong>hate generated is referred to as “old” or<br />

nitrogen-based le<strong>ac</strong>hate (Mavinic, 1998). Table.2.1 gives <strong>th</strong>e char<strong>ac</strong>teristic <strong>of</strong> le<strong>ac</strong>hate<br />

present in <strong>ac</strong>idogenic and me<strong>th</strong>anogenic phases.<br />

Table 2.1 Le<strong>ac</strong>hate Char<strong>ac</strong>teristic in Acidogenic and Me<strong>th</strong>anogenic Phase in a Landfill<br />

(Ehrig, 1998)<br />

Parameter Unit Average Range<br />

Acidogenic Phase<br />

pH 6.1 4.5 to 7.5<br />

BOD5 mg/L 13,000 4,000 to 40,000<br />

COD mg/L 22,000 6,000 to 60,000<br />

BOD5/COD 0.58 -<br />

SO4 mg/L 500 70 to 1,750<br />

Ca mg/L 1,200 10 to 2,500<br />

Mg mg/L 470 50 to 1,150<br />

Fe mg/L 780 20 to 2,100<br />

Mn mg/L 25 0.3 to 65<br />

Zn mg/L 5 0.1 to 120<br />

Me<strong>th</strong>anogenic Phase<br />

pH 8 7.5 to 9<br />

BOD5 mg/L 180 20 to 550<br />

COD mg/L 3,000 500 to 4,500<br />

BOD5/COD 0.06 -<br />

SO4 mg/L 80 10 to 420<br />

Ca mg/L 60 20 to 600<br />

Mg mg/L 180 40 to 350<br />

Fe mg/L 15 3 to 280<br />

Mn mg/L 0.7 0.03 to 45<br />

Zn mg/L 0.6 0.03 to 4<br />

The differences in le<strong>ac</strong>hate quality can be due to varied reasons, which can be<br />

categorised into four major divisions, namely <strong>th</strong>e waste (type <strong>of</strong> waste, degree <strong>of</strong><br />

decomposition, and possible seasonal variance), landfill environment (phase <strong>of</strong> degradation,<br />

humidity, temperature etc.), filling technique (comp<strong>ac</strong>ting, cover, height <strong>of</strong> landfill layers,<br />

etc.) and sampling (me<strong>th</strong>od <strong>of</strong> analysis and point <strong>of</strong> sample collection).<br />

The f<strong>ac</strong>tors affecting <strong>th</strong>e le<strong>ac</strong>hate quality is inter-related and affects <strong>th</strong>e overall<br />

variance in le<strong>ac</strong>hate quality and char<strong>ac</strong>terization. The changes in <strong>th</strong>e BOD/COD,<br />

8

COD/TOC, VS/FS and VFA/TOC ratios <strong>of</strong> le<strong>ac</strong>hate are depends greatly on <strong>th</strong>e age <strong>of</strong> <strong>th</strong>e<br />

landfill (Chian and DeWalle, 1976; Kylefors, 1997). Figure 2.3 represents <strong>th</strong>e trend <strong>of</strong><br />

le<strong>ac</strong>hate variation and over <strong>th</strong>e period <strong>of</strong> time in <strong>th</strong>e landfill. During <strong>th</strong>e initial stages, <strong>th</strong>e<br />

landfill is aerobic rich in biodegradable organic content. As <strong>th</strong>e landfill age increases, <strong>th</strong>e<br />

microorganism present in <strong>th</strong>e landfill tend to degrade <strong>th</strong>ese organic compounds into<br />

inorganic components. When anaerobic phase begins, <strong>th</strong>e COD starts increasing causing a<br />

decrease in BOD/COD ratio. This decrease in BOD/COD ratio observed, suggests <strong>th</strong>e<br />

change in biodegradability <strong>of</strong> <strong>th</strong>e le<strong>ac</strong>hate wi<strong>th</strong> time. For young landfill, <strong>th</strong>e ratio is around<br />

0.5-0.8 while it re<strong>ac</strong>hes almost 0.1 in <strong>th</strong>e old landfill. The reason for low biodegradability<br />

in <strong>th</strong>e old landfill could be due to <strong>th</strong>e presence <strong>of</strong> humic and fluvic <strong>ac</strong>ids.<br />

Figure 2.3 Variation in Significant Pollutant Ratios wi<strong>th</strong> Increase in Age <strong>of</strong> <strong>th</strong>e Landfill<br />

(Chian and DeWalle, 1976)<br />

The ammonium concentration in <strong>th</strong>e le<strong>ac</strong>hate also varies wi<strong>th</strong> age <strong>of</strong> <strong>th</strong>e landfill, wi<strong>th</strong><br />

young le<strong>ac</strong>hate having a high COD (>5,000 mg/L) and low nitrogen content (< 400 mg<br />

N/L) and old le<strong>ac</strong>hate having a high concentrations <strong>of</strong> ammonia (> 400 mg N/L) and<br />

recalcitrant compounds and a low biodegradable organic fr<strong>ac</strong>tion (BOD5/COD = 0.1).<br />

Municipal solid waste landfill in Asia (except Japan) is char<strong>ac</strong>terized by 60 to 90 %<br />

organic waste and 3 to 18 % plastic (Agamu<strong>th</strong>u, 1999). Le<strong>ac</strong>hate char<strong>ac</strong>teristics <strong>of</strong> landfills<br />

surveyed in Asia including Thailand, Europe, and America are presented in Table 2.2. The<br />

char<strong>ac</strong>teristic <strong>of</strong> le<strong>ac</strong>hate from different landfill site as reported show a great variation. It is<br />

dependent on <strong>th</strong>e solid waste composition, landfill site location, and local climate. The<br />

BOD and COD concentrations decrease as <strong>th</strong>e landfill age increases.<br />

9

Table 2.2 Comparison <strong>of</strong> Le<strong>ac</strong>hate Char<strong>ac</strong>teristics <strong>of</strong> Landfills Surveyed in Asia, Europe and America<br />

Thailand 1,2 Malaysia 3<br />

Parameter<br />

Air Sabak Taman HongKong<br />

Phitsanuklok Pa<strong>th</strong>um<strong>th</strong>ani Nakhonpa<strong>th</strong>om Pa<strong>th</strong>um<strong>th</strong>ani On-Nutch Hitam Bernam Beringin<br />

4<br />

USA 5<br />

Europe 6<br />

Years in<br />

operation 1 3 4 9 20 5 7 16 6 10 1 5 16 -<br />

1,540- 1,200- 3,750- 10,700- 3,230- 800-<br />

300-<br />

Alkalinity 300-4,700 918-4,250 960-2,740 6,620 - 9,000 1,550 9,375 11,700 4,940 4,000 5,810 2,250 11,500<br />

pH 7.1-8.3 8.2-8.9 8.2-8.5 8.1 7.5 7.6-8.8 8.0-801 7.8-8.7 8.1-8.6 7.6-8.1 5.2-6.4 6.3 - 5.3-8.5<br />

1,625- 420-<br />

2,320-<br />

Chloride - 1,220-5,545 655-2,200 2,530 - 3,200<br />

410-<br />

1,820 875-2,875 2,740 522-853 600-800 1,330 70 -<br />

SS 1,950 29-110 8.4-15.7 12.5 488 1,250 111-920 420-1,150 40-53 3-124 - - - -<br />

13,930-<br />

10,300-<br />

TS 6,700 350-1,598 274-1,200 848 11,320 15,380 - 13,680 - - 100-700 - - -<br />

1,724- 1,250- 1,960- 2,460-<br />

10,000-<br />

150-<br />

COD 4,900-11,000 1,488-3,200 800-3,575 3,200 1,200 7,038 2,570 5,500 2,830 641-873 40,000 8,000 400 100,000<br />

1,120- 726-<br />

7,500-<br />

100-<br />

BOD 3,000-7,150 198-260 100-240 280 130 1,800 1,210 562-1,990 - - 28,000 4,000 80 90,000<br />

2,219- 889-<br />

TKN - 240-452 64-1,260 1,256 700 131-930 - 104-1,014 2,860 1,180 - - - 50-5,000<br />

1,190- 784-<br />

NH3-N 150-1,250 - - - - 2-32 3-8 2-47 2,700 1,156 56-482 - - 1-1500<br />

Ni 0.02-1.56 0.01-0.42 0.1 0.25 0.035 0.13-0.95 - 0-0.6 - - - - - 0.02-2.05<br />

Cd 0.037 0.02 0.001 0.002 - 0-0.23 0-0.001 0-0.15 - - -

Table 2.3 presents <strong>th</strong>e general le<strong>ac</strong>hate char<strong>ac</strong>teristics wi<strong>th</strong> age and suitability <strong>of</strong><br />

treatment options in terms <strong>of</strong> biodegradable, intermediate and stabilized landfill le<strong>ac</strong>hate.<br />

As <strong>th</strong>e young landfill is rich in organic, biological treatment is more appropriate <strong>th</strong>an<br />

physico-chemical which is suitable for <strong>th</strong>e old landfill. However, effectiveness <strong>of</strong><br />

combined treatment process for <strong>th</strong>e treatment <strong>of</strong> a le<strong>ac</strong>hate produced at specific landfill age<br />

has not been considered. Individual treatment options cannot be a long-term solution for<br />

le<strong>ac</strong>hate treatment as <strong>th</strong>ey are not effective in treating le<strong>ac</strong>hate generated at different period<br />

<strong>of</strong> time and do not adapt to changing le<strong>ac</strong>hate char<strong>ac</strong>teristics.<br />

Table 2.3 Relation between Landfill Age, Le<strong>ac</strong>hate Char<strong>ac</strong>teristics and Treatments<br />

(Amokrane, et al., 1997)<br />

Landfill Age (years) < 5 (young) 5 to 10 (medium) > 10 (old)<br />

Le<strong>ac</strong>hate Type I (biodegradable) II (intermediate) III (stabilized)<br />

pH < 6.5 6.5 to 7.5 > 7.5<br />