2011 Acer Corporate Responsibility Report - Acer Group

2011 Acer Corporate Responsibility Report - Acer Group

2011 Acer Corporate Responsibility Report - Acer Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

37<br />

Responsible Supply Chain<br />

Response to Conflict Mineral<br />

We are deeply concerned about the social and environmental<br />

issues related to the materials contained within product parts<br />

and to the manufacturing process. The rich mineral resources in<br />

the Democratic Republic of Congo (DRC) have fueled one of the<br />

world’s deadliest conflicts. We understand that most of our suppliers<br />

do not have direct purchasing relationships with mining companies.<br />

There are often multiple sources for metals including recycled<br />

metal, metal inventories and crude ore. However, we understand<br />

we have the opportunity to have a positive impact on this complex<br />

issue as an individual company, and we support the legislation of<br />

related regulations.<br />

Our Commitment<br />

<strong>Acer</strong> is committed to ensuring that working conditions in its supply<br />

chain are safe, that workers are treated with respect and dignity,<br />

and that business operations are environmentally responsible and<br />

ethical. As a result of this overarching commitment, <strong>Acer</strong> will not<br />

accept any supply chain activities in the DRC or adjoining countries<br />

that fuel conflict of tantalum, tin, tungsten, and gold. <strong>Acer</strong> supports<br />

the conflict mineral provisions contained within the Dodd-Frank Wall<br />

Street Reform and Consumer Protection Act (H.R. 4173), and will<br />

support similar requirements in other regions of the world. <strong>Acer</strong><br />

commits itself individually and through participation in the EICC/<br />

Global e-Sustainability Initiative (GeSI) Extractives Working <strong>Group</strong><br />

to support EICC/GeSI due diligence programs, OECD due diligence<br />

guidance and piloting, smelter audit and verification programs, inregion<br />

sourcing schemes, and engagement with stakeholders for<br />

collaboration and efficiency. <strong>Acer</strong> understands that a certification<br />

program may be a necessary solution in the future. <strong>Acer</strong> will<br />

support a certification process should all the relevant stakeholders<br />

agree to go down that path. In the meantime, <strong>Acer</strong> will continue to<br />

support the audit and verification programs established by the EICC<br />

and GeSI.<br />

Response to Conflict Mineral<br />

Our Actions<br />

Since 2009, <strong>Acer</strong> has engaged its suppliers to educate them on<br />

the issue and begin tracing its supply chain back to the source of<br />

cobalt, gold, palladium, tantalum, tin, and tungsten. Along with the<br />

survey, we also provided our suppliers with references including<br />

usage, major producers and consumption in the electronics industry<br />

of the minerals in question. The survey took six months and the<br />

response rate from our suppliers was over 90%. This engagement<br />

has given <strong>Acer</strong> an initial understanding of its supply chain with<br />

respect to these metals, and has prepared the foundation for future<br />

management of mineral sources. It has also helped us understand<br />

that only through industry collaboration can we be successful in<br />

managing mineral sources.<br />

In 2010, <strong>Acer</strong> began participation on the EICC/GeSI Extractives<br />

working group and Extractives Due Diligence sub-working group.<br />

<strong>Acer</strong> contributed to the development of the Conflict Minerals<br />

<strong>Report</strong>ing Template tool (Template), which facilitates disclosure<br />

and communication of information regarding smelters that provide<br />

material to a company’s supply chain. <strong>Acer</strong> also participated on the<br />

Template pilot by conducting a test-run with <strong>Acer</strong>’s suppliers and<br />

gathering feedback for further refinement of the Template.<br />

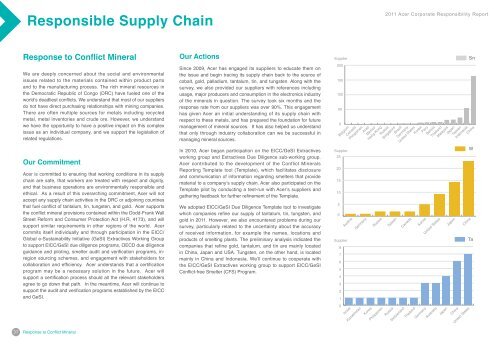

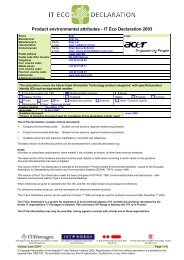

We adopted EICC/GeSI Due Diligence Template tool to investigate<br />

which companies refine our supply of tantalum, tin, tungsten, and<br />

gold in <strong>2011</strong>. However, we also encountered problems during our<br />

survey, particularly related to the uncertainty about the accuracy<br />

of received information, for example the names, locations and<br />

products of smelting plants. The preliminary analysis indicated the<br />

companies that refine gold, tantalum, and tin are mainly located<br />

in China, Japan and USA. Tungsten, on the other hand, is located<br />

mainly in China and Indonesia. We’ll continue to cooperate with<br />

the EICC/GeSI Extractives working group to support EICC/GeSI<br />

Conflict-free Smelter (CFS) Program.<br />

Supplier<br />

200<br />

150<br />

100<br />

50<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

Supplier<br />

Supplier<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Austria<br />

Israel<br />

Kazakhstan<br />

Germany<br />

Korea<br />

Russia<br />

Philippines<br />

<strong>2011</strong> <strong>Acer</strong> <strong>Corporate</strong> <strong>Responsibility</strong> <strong>Report</strong><br />

Taiwan<br />

Russia<br />

Switzerland<br />

Canada<br />

Korea<br />

United States<br />

Japan<br />

W<br />

China<br />

Sn<br />

Belgium<br />

Canada<br />

Philippines<br />

Arab<br />

Mexico<br />

Hong Kong<br />

Russia<br />

Singapore<br />

Brazil<br />

Germany<br />

United States<br />

Korea<br />

Peru<br />

Bolivia<br />

Thailand<br />

Malaysia<br />

Japan<br />

Taiwan<br />

Indonesia<br />

China<br />

Thailand<br />

Germany<br />

Australia<br />

Japan<br />

China<br />

United States<br />

Ta