volume 18 - issue 1 - Finn-Power International, Inc.

volume 18 - issue 1 - Finn-Power International, Inc.

volume 18 - issue 1 - Finn-Power International, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Efficient unloading – The C5 delivers the processed components to<br />

a freely programmable position on the table, increasing the<br />

operator’s efficiency. The entire material flow on the C5 can be<br />

conducted from just one side. This allows simple and efficient<br />

logistics and enables the machine to be positioned anywhere on the<br />

shop floor – even in a corner.<br />

Other unique features of the C5 turret punch press include:<br />

Tool Holders – <strong>Finn</strong>-<strong>Power</strong> incorporates an individual tool holder<br />

concept that allows customers to design their own turret layouts.<br />

Unlike other designs, specific tool stations are not machined into<br />

the turret. <strong>Finn</strong>-<strong>Power</strong> offers the only flexible selection of tool<br />

holders in the industry. Any major tooling style can be installed in<br />

a <strong>Finn</strong>-<strong>Power</strong> turret. Up to 10 auto-index, forming, or Multi-Tool ®<br />

stations may be installed in a <strong>Finn</strong>-<strong>Power</strong> turret.<br />

Auto-Index – <strong>Finn</strong>-<strong>Power</strong>’s unique auto-index system precisely<br />

rotates the punch and die in their tool holders. Rotation in .001<br />

degree programmable increments gives the machine the ability to<br />

rotate beyond 360 degrees, allowing the system to automatically<br />

select the shortest path to rotate to a programmed angle input into<br />

the NC part program with simplicity, speed, and reliability. Full<br />

tonnage can be used in any station, with any tool size, and at<br />

maximum material thickness. Prática has four auto-index stations.<br />

Multi-Tool ® — <strong>Finn</strong>-<strong>Power</strong>’s Multi-Tool stations increase the<br />

number of tools available in a turret, thus reducing set-up and<br />

increasing productivity. The Multi-Tool system allows multiple<br />

tools to be put in one station. <strong>Finn</strong>-<strong>Power</strong> Multi-Tool offers 6, 8,<br />

10, or 24 different punch/die combinations in only one station – a<br />

turret within a turret. Prática has four Multi-Tools – two 8-station<br />

and two 10-station. The company also utilizes the Roller Ball tool<br />

from Mate Precision Tooling. “<strong>Finn</strong>-<strong>Power</strong>’s Auto-Index and Multi<br />

Tool are very important features for us,” says Rezende. “We have<br />

been able to dramatically reduce our set up time with the additional<br />

tools in the turret.”<br />

Automatic Clamp Setting & Movement – <strong>Finn</strong>-<strong>Power</strong>’s patented<br />

automatic clamp setting PCS is a standard C5 feature. It<br />

automatically positions sheet clamps according to the numerical<br />

program, virtually eliminating dead zones. When changing<br />

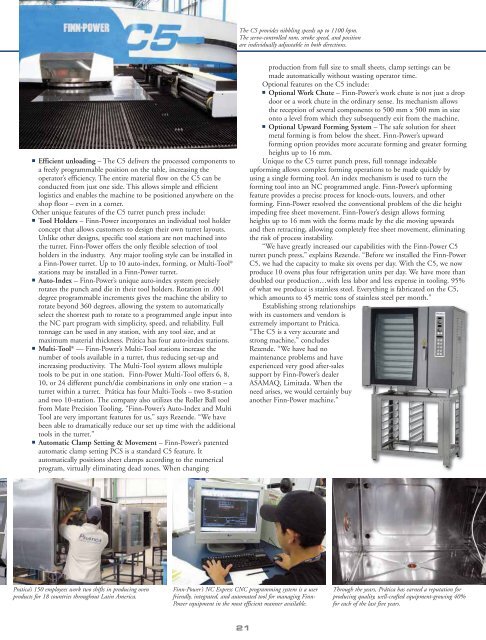

Pratica’s 150 employees work two shifts in producing oven<br />

products for <strong>18</strong> countries throughout Latin America.<br />

The C5 provides nibbling speeds up to 1100 hpm.<br />

The servo-controlled ram, stroke speed, and position<br />

are individually adjustable in both directions.<br />

<strong>Finn</strong>-<strong>Power</strong>’s NC Express CNC programming system is a user<br />

friendly, integrated, and automated tool for managing <strong>Finn</strong>-<br />

<strong>Power</strong> equipment in the most efficient manner available.<br />

21<br />

production from full size to small sheets, clamp settings can be<br />

made automatically without wasting operator time.<br />

Optional features on the C5 include:<br />

Optional Work Chute – <strong>Finn</strong>-<strong>Power</strong>’s work chute is not just a drop<br />

door or a work chute in the ordinary sense. Its mechanism allows<br />

the reception of several components to 500 mm x 500 mm in size<br />

onto a level from which they subsequently exit from the machine.<br />

Optional Upward Forming System – The safe solution for sheet<br />

metal forming is from below the sheet. <strong>Finn</strong>-<strong>Power</strong>’s upward<br />

forming option provides more accurate forming and greater forming<br />

heights up to 16 mm.<br />

Unique to the C5 turret punch press, full tonnage indexable<br />

upforming allows complex forming operations to be made quickly by<br />

using a single forming tool. An index mechanism is used to turn the<br />

forming tool into an NC programmed angle. <strong>Finn</strong>-<strong>Power</strong>’s upforming<br />

feature provides a precise process for knock-outs, louvers, and other<br />

forming. <strong>Finn</strong>-<strong>Power</strong> resolved the conventional problem of the die height<br />

impeding free sheet movement. <strong>Finn</strong>-<strong>Power</strong>’s design allows forming<br />

heights up to 16 mm with the forms made by the die moving upwards<br />

and then retracting, allowing completely free sheet movement, eliminating<br />

the risk of process instability.<br />

“We have greatly increased our capabilities with the <strong>Finn</strong>-<strong>Power</strong> C5<br />

turret punch press,” explains Rezende. “Before we installed the <strong>Finn</strong>-<strong>Power</strong><br />

C5, we had the capacity to make six ovens per day. With the C5, we now<br />

produce 10 ovens plus four refrigeration units per day. We have more than<br />

doubled our production…with less labor and less expense in tooling. 95%<br />

of what we produce is stainless steel. Everything is fabricated on the C5,<br />

which amounts to 45 metric tons of stainless steel per month.”<br />

Establishing strong relationships<br />

with its customers and vendors is<br />

extremely important to Prática.<br />

“The C5 is a very accurate and<br />

strong machine,” concludes<br />

Rezende. “We have had no<br />

maintenance problems and have<br />

experienced very good after-sales<br />

support by <strong>Finn</strong>-<strong>Power</strong>’s dealer<br />

ASAMAQ, Limitada. When the<br />

need arises, we would certainly buy<br />

another <strong>Finn</strong>-<strong>Power</strong> machine.”<br />

Through the years, Prática has earned a reputation for<br />

producing quality, well-crafted equipment-growing 40%<br />

for each of the last five years.