volume 18 - issue 1 - Finn-Power International, Inc.

volume 18 - issue 1 - Finn-Power International, Inc.

volume 18 - issue 1 - Finn-Power International, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOCUS ON ROBOTICS<br />

New Advances in<br />

Material Handling Robotics<br />

Robotic automation has come along way in terms of the<br />

capability and flexibility in the last 25 years, with each year<br />

bringing greater advancements. Some are profound, such as<br />

Intelligent Vision Guided Robot Systems, which are dramatically changing<br />

the way systems are being designed. Robots that can see and think.<br />

Unheard of. Sometimes the changes are subtle but offer a huge advantage<br />

to the customer.<br />

The new M-10iA robot is an excellent example of how a small<br />

improvement on an already great product can result in a large payoff for<br />

the customer. The M-10iA is the next generation of FANUC Robotics<br />

high-performing six-axis material handling product line. With a standard<br />

payload of 10 kg, this robot is ideal for the quick and precise movements<br />

required in the press brake market.<br />

Hollow Wrist & Arm (Solution Arm)<br />

The most impressive new feature of the M-10iA is the hollow wrist<br />

and upper arm, also referred to as the Solution Arm. Automating a press<br />

brake application requires a dress out or cables to be attached to the<br />

robot’s wrist and arm. Dress-out cables are bulky when exposed and can<br />

interfere with the robot, tooling or peripheral equipment especially when<br />

the wrist is twisting. Complications range from damaged or twisted cables<br />

to completely severed cables.<br />

Failures in this area can lead<br />

to downtime and loss of<br />

production.<br />

The sleek design of the<br />

M-10iA hollow wrist and<br />

upper arm eliminates the<br />

need for complicated robot<br />

dress outs and offers reduced<br />

costs and improved reliability<br />

in return. Dress outs, cables<br />

and airlines are simply routed in the 50-mm hollow wrist and upper arm<br />

and are protected. This design also brings benefits of simplified wiring of<br />

electrical and pneumatic connections which saves integration costs. Simply<br />

enclosing the dress out improves cable life and reliability. The hollow wrist<br />

and arm is a unique feature of the M-10iA and is unmatched in the<br />

robotic industry.<br />

Doing More with the Allowable<br />

Payload (Moments and Inertia)<br />

Another key advantage to the M-10iA robot is that the allowable wrist<br />

moments and inertias are significantly higher than the previous model as<br />

well as similar class competitors’ products. The allowable wrist moment is<br />

70% higher than the previous model and the allowable wrist inertia is<br />

56% higher. In layman’s terms, these higher specifications allow users to<br />

have much larger tools and allow them to have the 10kg payload offset<br />

further away from the face of the robot. This is a key factor in the press<br />

brake market, where the robots are required to pick and place large sheets<br />

of sheet metal.<br />

Long Arm Product Variant<br />

Extremely versatile, the M-10iA is also available in a long arm version.<br />

The benefit of the long arm requires a slight sacrifice in the payload. The<br />

M-10iA payload decreases from 10kg to 6kg. However, if payload is not a<br />

pressing <strong>issue</strong>, the long arm version provides a significant benefit in terms<br />

by Kari DeSantis, Senior Marketing Analyst, FANUC Robotics America, <strong>Inc</strong>.<br />

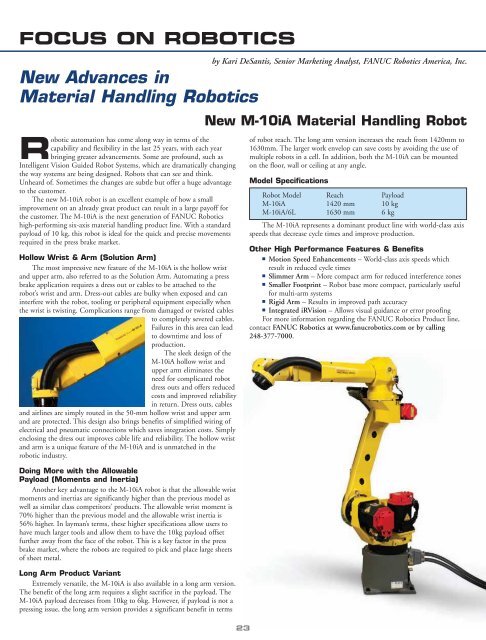

New M-10iA Material Handling Robot<br />

23<br />

of robot reach. The long arm version increases the reach from 1420mm to<br />

1630mm. The larger work envelop can save costs by avoiding the use of<br />

multiple robots in a cell. In addition, both the M-10iA can be mounted<br />

on the floor, wall or ceiling at any angle.<br />

Model Specifications<br />

Robot Model Reach Payload<br />

M-10iA 1420 mm 10 kg<br />

M-10iA/6L 1630 mm 6 kg<br />

The M-10iA represents a dominant product line with world-class axis<br />

speeds that decrease cycle times and improve production.<br />

Other High Performance Features & Benefits<br />

Motion Speed Enhancements – World-class axis speeds which<br />

result in reduced cycle times<br />

Slimmer Arm – More compact arm for reduced interference zones<br />

Smaller Footprint – Robot base more compact, particularly useful<br />

for multi-arm systems<br />

Rigid Arm – Results in improved path accuracy<br />

Integrated iRVision – Allows visual guidance or error proofing<br />

For more information regarding the FANUC Robotics Product line,<br />

contact FANUC Robotics at www.fanucrobotics.com or by calling<br />

248-377-7000.