TECHNICAL REPORT 92-14 - Nagra

TECHNICAL REPORT 92-14 - Nagra

TECHNICAL REPORT 92-14 - Nagra

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

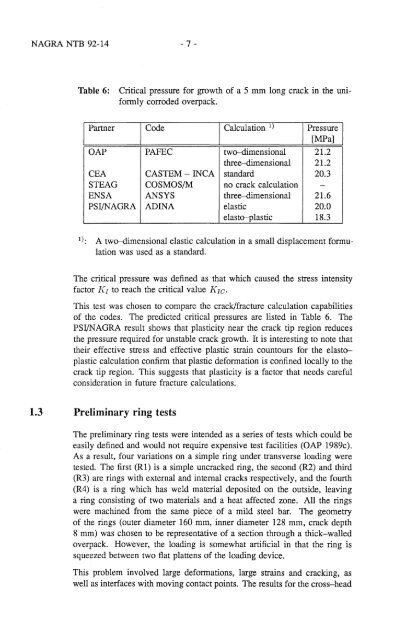

NAGRA NTB <strong>92</strong>-<strong>14</strong> - 7 -<br />

Table 6: Critical pressure for growth of a 5 mm long crack in the uniformly<br />

corroded overpack.<br />

I Partner<br />

OAP PAFEC<br />

CEA CASTEM - INCA<br />

STEAG COSMOS/M<br />

ENSA ANSYS<br />

PSI/NAGRA ADINA<br />

I Calculation 1)<br />

two-dimensional<br />

three-dimensional<br />

standard<br />

no crack calculation<br />

three-dimensional<br />

elastic<br />

elasto-plastic<br />

Pressure I<br />

I [MPa]<br />

21.2<br />

21.2<br />

20.3<br />

-<br />

21.6<br />

20.0<br />

18.3<br />

1): A two-dimensional elastic calculation in a small displacement formulation<br />

was used as a standard.<br />

The critical pressure was defined as that which caused the stress intensity<br />

factor !{I to reach the critical value !{IC.<br />

This test was chosen to compare the crack/fracture calculation capabilities<br />

of the codes. The predicted critical pressures are listed in Table 6. The<br />

PSI/NAGRA result shows that plasticity near the crack tip region reduces<br />

the pressure required for unstable crack growth. It is interesting to note that<br />

their effective stress and effective plastic strain countours for the elastoplastic<br />

calculation confirm that plastic deformation is confined locally to the<br />

crack tip region. This suggests that plasticity is a factor that needs careful<br />

consideration in future fracture calculations.<br />

1.3 Preliminary ring tests<br />

The preliminary ring tests were intended as a series of tests which could be<br />

easily defined and would not require expensive test facilities (OAP 1989c).<br />

As a result, four variations on a simple ring under transverse loading were<br />

tested. The first (Rl) is a simple uncracked ring, the second (R2) and third<br />

(R3) are rings with external and internal cracks respectively, and the fourth<br />

(R4) is a ring which has weld material deposited on the outside, leaving<br />

a ring consisting of two materials and a heat affected zone. All the rings<br />

were machined from the same piece of a mild steel bar. The geometry<br />

of the rings (outer diameter 160 mm, inner diameter 128 mm, crack depth<br />

8 mm) was chosen to be representative of a section through a thick-walled<br />

overpack. However, the loading is somewhat artificial in that the ring is<br />

squeezed between two fiat plattens of the loading device.<br />

This problem involved large deformations, large strains and cracking, as<br />

well as interfaces with moving contact points. The results for the cross-head