Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

םירטליפה םג ןכו , HPLC<br />

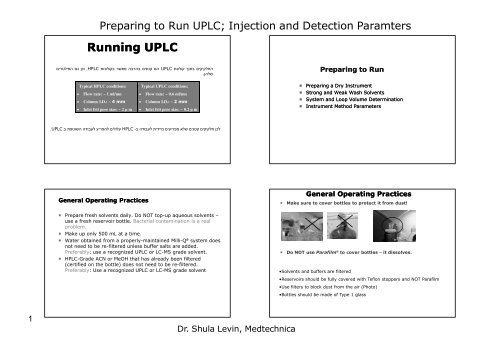

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

<strong>Running</strong> <strong>UPLC</strong><br />

תונולוקב רשאמ הברהב םינטק םה <strong>UPLC</strong> תנולוק ךותב םיקיקלחה<br />

. ןהלש<br />

Typical HPLC conditions:<br />

• Flow rate: ~ 1 ml/mn<br />

• Column I.D.: ~ 4 mm<br />

• Inlet frit pore size: ~ 2 µ m<br />

Typical <strong>UPLC</strong> conditions:<br />

• Flow rate: ~ 0.6 ml/mn<br />

• Column I.D.: ~ 2 mm<br />

• Inlet frit pore size: ~ 0.2 µ m<br />

. <strong>UPLC</strong> ב תפטושה הדובעל עירפהל םילולע HPLC -ב<br />

הדובעל תידיימ םיעירפמ אלש םינטק םיקיקלח ןכל<br />

General Operating Practices<br />

Prepare fresh solvents daily. Do NOT top-up aqueous solvents –<br />

use a fresh reservoir bottle. Bacterial contamination is a real<br />

problem.<br />

Make up only 500 mL at a time.<br />

Water obtained from a properly-maintained Milli-Q ® system does<br />

not need to be re-filtered unless buffer salts are added.<br />

Preferably: use a recognized <strong>UPLC</strong> or LC-MS grade solvent.<br />

HPLC-Grade ACN or MeOH that has already been filtered<br />

(certified on the bottle) does not need to be re-filtered.<br />

Preferably: Use a recognized <strong>UPLC</strong> or LC-MS grade solvent<br />

Dr. Shula Levin, Medtechnica<br />

Preparing to Run<br />

Preparing a Dry Instrument<br />

Strong and Weak Wash Solvents<br />

System and Loop Volume Determination<br />

Instrument Method Parameters<br />

General Operating Practices<br />

Make sure to cover bottles to protect it from dust!<br />

Do NOT use Parafilm ® to cover bottles – it dissolves.<br />

•Solvents and buffers are filtered<br />

•Reservoirs should be fully covered with Teflon stoppers and NOT Parafilm<br />

•Use filters to block dust from the air (Photo)<br />

•Bottles should be made of Type 1 glass

2<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

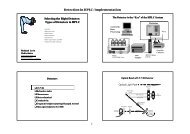

General Operating Recommendations<br />

Use only Pyrex (Borosilicate 3.3) bottles. DURAN bottles<br />

dissolve at high pH (>9).<br />

Use highest quality solvents, water, buffers and additives.<br />

Flush buffers out of system with water after use (use 10-20%<br />

organic in water for storage).<br />

Keep all 4 solvent lines primed (use 10-20% organic in water for<br />

unused lines).<br />

Keep seal wash primed.<br />

Re-prime solvent lines before starting.<br />

Use 100 µL mixer for TFA/ACN gradients at low wavelengths.<br />

Solvent Filters<br />

Critical Clean<br />

Stainless Steel (7 pack)700003616<br />

Stainless Steel (1/pk) 700003615<br />

Titanium (7 pack) 700003530<br />

Titanium (1 pack) 700003546<br />

Solvent filter assembly 289002172<br />

Solvent filter insert 5 µm 700002756<br />

PAT (PEEK Alloyed with Teflon) filter<br />

PSL901292 2 µm<br />

PSL901294 5 µm<br />

Dr. Shula Levin, Medtechnica<br />

CORNING PYREX ® Type 1, Class A, Borosilicate Bottles<br />

SCHOTT DURAN ® Borosilicate Glass 3.3 Bottles<br />

Mobile Phase Preparation<br />

Filtration on membrane:<br />

Also: if Biolab solvents: Use ULC/MS grade only!<br />

Actions : Solvent degassing and filtration<br />

— Potential of impurities in filtration<br />

o GHP, PTFE, Nylon, or PVDF<br />

— Pores diameter : 0.2 µm.<br />

— Volatile additives may evaporate.<br />

NOTE: Refer to ‘Controlling Contamination in<br />

UltraPerformance LC/MS and HPLC Systems’<br />

715001307D available from Waters Corp.

3<br />

Bottle Caps<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

WAT062341 4 L bottle (large neck)<br />

WAT062479 1 L bottle (small neck)<br />

No Parafilm ® or other plastic films to cover solvent reservoirs<br />

Daily Startup<br />

Set up each module in turn:<br />

—Solvent Manager:<br />

o Prime the solvent lines (2 mins each).<br />

o Set analytical flow to equilibrate column.<br />

—Sample Manager:<br />

o Prime wash and sample syringes (6 cycles).<br />

o Characterize needle seal and system volume.<br />

—Detector:<br />

o Turn on lamp (needs >½ hr).<br />

o Check and record reference and sample energy.<br />

Can do these operations simultaneously<br />

Use the System Startup Button<br />

Dr. Shula Levin, Medtechnica<br />

Startup the System According to Instructions<br />

http://www.forumsci.co.il/HPLC/<strong>UPLC</strong>_setup_21-9_09_Empower.pdf<br />

Recommended Solvents List<br />

ACQUITY <strong>UPLC</strong> System recommended Solvents<br />

Methanol Methanol/water mixtures<br />

Water Acetonitrile/water mixtures<br />

Acetonitrile (ACN) Isopropanol (IPA)<br />

Sample diluents (in addition to the solvents listed above)<br />

Dimethyl sulfoxide (DMSO) Dimethylformamide (DMF)<br />

Additives / Modifiers<br />

0.2% formic acid 0.1% trifluoroacetic acid (TFA)<br />

0.1% triethyl amine (TEA) 0.1% hexafluorobuteric acid<br />

10mM phosphate buffer 10mM ammonium bicarbonate<br />

50mM ammonium hydroxide 50mM ammonium acetate<br />

0.1% Ethylenediaminetetraacetic acid (EDTA)<br />

Cleaners<br />

Phosphoric acid (=30%) Sodium hydroxide (=1M)<br />

ACQUITY <strong>UPLC</strong> System non-recommended Solvents<br />

Methylene-Chloride Chloroform<br />

Strong acids >5%<br />

Ethyl Acetate Toluene<br />

Chlorinated solvents: (Trichlorobenzene)

4<br />

0.040<br />

0.030<br />

0.020<br />

AU<br />

0.010<br />

0.000<br />

-0.010<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Injection Parameters<br />

Mounting of the loop<br />

MUST BE PROPER!!<br />

5.605.705.805.906.006.106.206.306.40<br />

Minutes<br />

Typical problem with bad peek<br />

connections<br />

First blank 0.1 %<br />

Second blank 0.01 %.<br />

.<br />

With proper Peek<br />

connections<br />

First blank

5<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Recommendations for ACQUITY <strong>UPLC</strong> Sample<br />

Manager Injection Methods<br />

Wash Solvent description<br />

There are two wash solvents<br />

— Strong Needle Wash<br />

o Tubing flushing<br />

o Elimination of components injected<br />

o Never injected<br />

— Weak Needle Wash<br />

o Strong solvent elimination<br />

o Injected with the sample in partial loop pressure assist mode<br />

Dr. Shula Levin, Medtechnica<br />

Wash cycle after injection<br />

needle<br />

VDD<br />

Sample Syringe<br />

BSM<br />

loop<br />

Wash block<br />

to column and<br />

detector<br />

Possible contaminated<br />

area<br />

VDD<br />

Sample Syringe<br />

Wash Solvent Considerations<br />

BSM<br />

loop<br />

to column and<br />

detector<br />

Strong needle wash<br />

followed by weak needle<br />

wash<br />

As a general principle, strong and weak solvents should include the<br />

same organic species<br />

— This may not always be practicable, especially in the case of “sticky”<br />

samples. You may, however use a 100% organic strong wash solvent<br />

Do not use salt buffers in wash solvents<br />

Wash volume ratio (weak to strong)<br />

— Should be about 3:1, weak wash to strong<br />

— Sufficient to ensure the weak wash flushes the strong from the needle<br />

and sample loop<br />

For more details on solvents, see the section titled “Selecting weak<br />

wash and strong wash solvents” in the ACQUITY Operators Guide

6<br />

Strong Wash Solvent<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Flushes internal and external portion of the needle to prevent<br />

carryover<br />

Typically stronger than sample and mobile phase to dissolve<br />

sample residue<br />

Function performed in the wash station<br />

Strong solvent should be no stronger than the concentration<br />

needed to reduce carryover to an acceptable level<br />

Strong wash solvent does not contact the sample<br />

Weak Wash Solvent<br />

Purges needle and syringe fluid path<br />

Must be compatible with sample solvent<br />

For best results, weak wash solvent should be equivalent to<br />

the following (excluding buffers):<br />

— mobile phase composition (for isocratic separations)<br />

— initial gradient condition (for gradient separations)<br />

— If you dilute the samples, match the weak wash solvent to the<br />

sample diluent<br />

Degassed for good hydraulic properties<br />

Dr. Shula Levin, Medtechnica<br />

Strong Wash Solvent<br />

Choose based on the chemistry application<br />

100% organic solvent is acceptable<br />

— Except THF<br />

— Do not add acid or base in 100% organic solvent<br />

Prime using the needle wash function<br />

Default value is 200 µL<br />

— 200 µL is a typical value for this function<br />

Weak Wash Solvent<br />

Compatible with initial gradient conditions and sample<br />

solubility<br />

Avoid buffers<br />

— increases the risks of precipitation at re-equilibration<br />

Five prime cycles fully replace wash solvents<br />

Default value is 200 µL

7<br />

THREE injection methods available:<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

ACQUITY <strong>UPLC</strong> Sample Manager<br />

Injection Methods<br />

1. Full Loop Injection Method/Mode as the injection technique using<br />

“Pressure Assist”<br />

o Injects 100% of actual loop volume<br />

2. Partial Loop Injection Method/Mode using “Needle Overfill” as the<br />

injection technique<br />

o Selectable: Recommended from 10% to 75% of total loop volume<br />

3. Partial Loop Injection Method/Mode using “Pressure Assist” as the<br />

injection technique<br />

o Selectable: Recommended from 10% to 50% of total loop volume<br />

Full Loop Injection<br />

Step 1 – Aspirate sample and air gap<br />

Dr. Shula Levin, Medtechnica<br />

Full Loop Injection<br />

Example of a 20 µL injection with a 4X overfill<br />

20 µL Sample<br />

Weak Wash<br />

Solvent<br />

Air Gap<br />

Sample<br />

Sample<br />

Weak Wash<br />

Solvent<br />

Air Gap<br />

30 µL<br />

sample<br />

volume<br />

Sample Loop<br />

Volume Injected<br />

Overfill Factor 1 to 4<br />

30 µL<br />

sample<br />

volume<br />

Full Loop Injection<br />

Step 2 – Pressurize and position sample in valve

8<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Full Loop Injection<br />

Step 3 – Position sample and overfill the loop<br />

Sample Loop contains only sample<br />

No Air Gaps<br />

No weak wash<br />

Summary of Full Loop injection mode<br />

Best accuracy and precision performance<br />

Needs multiple loop volumes of additional sample to be used per<br />

injection<br />

Larger overfill factors are required for smaller loops<br />

Need to change injection loops to vary volume<br />

Dr. Shula Levin, Medtechnica<br />

Full Loop Injection<br />

Step 4 – Sample Injection<br />

Summary of Full Loop<br />

Injection Mode<br />

BENEFITS<br />

— Best accuracy and precision performance<br />

TRADEOFF<br />

— Needs multiple loop volumes of additional sample to be used per<br />

injection<br />

o larger overfill factors are required for smaller loops (buffer zone<br />

improvement)<br />

— Need to change injection loops to vary volume

9<br />

Partial Loop Injection<br />

Weak Wash<br />

Solvent<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Sample<br />

Air Gap<br />

Sample Loop<br />

Volume Injected<br />

Pressure Assist Injection Sequence<br />

Step 1 – Aspirate sample and air gap<br />

Weak Wash<br />

Solvent<br />

Dr. Shula Levin, Medtechnica<br />

Partial Loop (Pressure Assist)<br />

Loop Volume (µL) Needle Overfill<br />

1 Not Recommended<br />

2 Not Recommended<br />

5 Not Recommended<br />

10 1.0 – 5.0<br />

20 2.0 – 10.0<br />

50 5.0 – 25.0<br />

Pressure Assist Injection Sequence<br />

Step 2 – Pressurize and position sample in valve

10<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Pressure Assist Injection Sequence<br />

Step 3 – Position the sample<br />

Summary of Partial Loop<br />

using Pressure Assist<br />

Shorter Cycle Time than PLUNO<br />

No sample cushion<br />

Sample volume is conserved<br />

Recommended for large sample loop injections<br />

Performance dependency on weak wash solvent matching to mobile<br />

phase<br />

Air Gaps injected onto Column<br />

Accuracy is generally lower compared to Needle Overfill<br />

Has lower injection range, within a given loop for partial loop<br />

injections. Injection range is from 10 – 50% of the loop volume<br />

Accuracy and Precision are lower than Full Loop Mode<br />

Dr. Shula Levin, Medtechnica<br />

Pressure Assist Injection Sequence<br />

Step 4 – Injection valve injects sample<br />

Sample Loop contains<br />

Sample, air gaps and weak wash<br />

Partial Loop Using Needle Overfill

11<br />

Summary of Partial Loop<br />

using Pressure Assist<br />

BENEFITS:<br />

— Short Cycle Time<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

— Sample volume is conserved<br />

— Recommended for large sample loop injections<br />

TRADEOFF:<br />

— Accuracy and Precision are lower than Full Loop Mode<br />

— Performance dependency on weak wash solvent matching to mobile<br />

phase<br />

— Accuracy is generally lower compared to Needle Overfill<br />

Partial Loop using Needle Overfill<br />

Step 1– Aspirate Sample and Air Gap<br />

Dr. Shula Levin, Medtechnica<br />

Partial Loop Using Needle Overfill<br />

Partial Loop using Needle Overfill<br />

Step 2 – Injection Sequence

12<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Partial Loop using Needle Overfill<br />

Step 3 – Injection Sequence<br />

Partial Loop using Needle Overfill<br />

Step 5 – Injection Sequence<br />

Dr. Shula Levin, Medtechnica<br />

Partial Loop using Needle Overfill<br />

Step 4 – Injection Sequence<br />

Partial Loop using Needle Overfill<br />

Step 1– Aspirate Sample and Air Gap

13<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Partial Loop using Needle Overfill<br />

Step 2 – Injection Sequence<br />

Partial Loop using Needle Overfill<br />

Step 4 – Injection Sequence<br />

Dr. Shula Levin, Medtechnica<br />

Partial Loop using Needle Overfill<br />

Step 3 – Injection Sequence<br />

Partial Loop using Needle Overfill<br />

Step 5 – Injection Sequence

14<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Summary of Partial Loop<br />

using Needle Overfill<br />

No weak wash injected onto column<br />

— mobile phase and sample injected<br />

Air gap not injected on column<br />

Sample does not come into contact with weak wash<br />

Recommended for partial loop injections, especially from small<br />

loops because accuracy is improved compared to Pressure Assist<br />

Partial loop injections<br />

Has wider linear range, can inject from 10 – 75% of the loop<br />

volume<br />

Cycle time depending on aspiration rate (with smaller loops the<br />

time increases)<br />

Needs 15 µL additional sample to be used for cushion volume per<br />

injection irregardless of injection size<br />

Accuracy and precision lower than full loop mode<br />

Injection Air Gap<br />

Automatic or manual<br />

Full loop or partial loop injection<br />

— Critical for partial loop injection<br />

Full loop<br />

Dr. Shula Levin, Medtechnica<br />

— Air gap<br />

Manual settings<br />

(need to be set)<br />

Injection Parameters<br />

Injection Parameters<br />

Automatic settings<br />

(already set in the software<br />

See HELP)<br />

Good Repeatability:<br />

Setting Up the Sample Manager<br />

o 4 µL for 30 µL needle<br />

o 2 µL for 15 µL needle<br />

— Overfill factor depends on loop size<br />

o see Help for Automatic parameters<br />

— Metering device compatible with sample volume<br />

Partial loop<br />

— Low draw speed for low volume<br />

— Pre and post air gap are essential<br />

— Automatic parameters<br />

o Pre and post air gap of 1 µL<br />

o 100 µL per minute

15<br />

Strong Contaminations<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

If the system is contaminated, some spare parts must be<br />

changed<br />

— Why:<br />

Air Gap<br />

o Due to previous bad or not appropriate washing, contamination<br />

has been accumulated and then released since the system is not<br />

able to compensate anymore<br />

o Manual washing is not strong enough to eliminate carry-over<br />

— How: Which spare parts must be changed<br />

o Seal wash of the wash station<br />

o Needle<br />

o VDD (bubble detector)<br />

o Loop<br />

Question:<br />

— 1) Should I use air gap?<br />

o Yes or No?<br />

o Which one?<br />

• Pre air, post air or both?<br />

— 2) What volume?<br />

Question:<br />

— Should I use?<br />

o Full loop<br />

o Partial loop injection<br />

Dr. Shula Levin, Medtechnica<br />

Strong Washing<br />

Main Parameters Summary<br />

— Strong solvent 200 µL<br />

Weak Wash<br />

— Weak solvent 600 µL<br />

Full loop or partial loop injection<br />

— Use automatic settings<br />

Air gap<br />

— For partial injection<br />

— Automatic<br />

Draw speed<br />

— Automatic<br />

Pre and Post Air Gap Influence: Example<br />

4 4 1 140787 132577 96240 57406 136252 95577 45260 16142<br />

0 0 1 90362 85040 62005 42553 92886 64077 30046 12199<br />

Diffusion effect 55.80% 55.90% 55.21% 34.90% 46.69% 49.16% 50.64% 32.32%<br />

4 4 1 140787 132577 96240 57406 136252 95577 45260 16142<br />

0 4 1 89291 84372 63720 40764 85074 61209 29754 11578<br />

Diffusion effect 57.67% 57.13% 51.04% 40.83% 60.16% 56.15% 52.11% 39.42%<br />

4 4 1 140787 132577 96240 57406 136252 95577 45260 16142<br />

4 0 1 120864 113953 81763 52170 122771 85128 39046 14816<br />

Diffusion effect<br />

16.48% 16.34% 17.71% 10.04% 10.98% 12.27% 15.91% 8.95%

16<br />

Air Gap Effects<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

pre – air gap is more critical than post – air gap<br />

automatic<br />

Pre air gap Post air gap Peak area Peak height % area difference<br />

Automatic (1) Automatic (1) 38889 27156<br />

0,0<br />

4 0 38488 26796 98.97<br />

4 4 38179 26592 98.17<br />

0 4 30866 21404 79.37<br />

0 0 30748 21413 79.07<br />

Air Gap Settings<br />

Automatic settings<br />

— Pre and post air gap<br />

— 4 µL each<br />

— 1 µL for PLUNO<br />

Manual settings<br />

— Lower values:<br />

0,4<br />

o Sample diffusion providing peak area and peak height reduction<br />

— Higher values:<br />

o Can effect the chromatogram<br />

• Higher peak height RSD<br />

• Loss of resolution<br />

4,4<br />

4,0<br />

Air Gap<br />

Dr. Shula Levin, Medtechnica<br />

Large air gap volume can effect the chromatogram.<br />

Detection Mechanisms<br />

System Configuration<br />

Detector Designs<br />

Importance of Sampling Rate<br />

Detector Requirements

17<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Designing for <strong>UPLC</strong><br />

ACQUITY <strong>UPLC</strong> columns produce small volume peaks<br />

To avoid band spreading and maintain concentration the flow cell<br />

volume must be corresponding low<br />

If you use conventional flow cells the path length must be reduced<br />

which results in a loss of sensitivity<br />

<strong>UPLC</strong> detection requires cells that are designed for minimal<br />

dispersion, low cell volumes and optimum light throughput<br />

Importance of Sampling Rate<br />

Must ensure enough points are collected across a peak to<br />

adequately define the peak shape: 20-50 points across the<br />

peak.<br />

Peak detection algorithms require a minimum number of points<br />

across a peak to distinguish it from baseline noise and correctly<br />

determine peak lift off and touch down<br />

A peak which does not have enough data points will be difficult to<br />

integrate and therefore have irreproducible peak areas and<br />

heights.<br />

Dr. Shula Levin, Medtechnica<br />

ACQUITY <strong>UPLC</strong> TUV and PDA<br />

– Features<br />

Light guided flow cell design<br />

Two flow cell options<br />

Low noise electronics<br />

— High brightness lamp<br />

Support for data rates up to 80 Hz<br />

— Independent data rate and filter constants<br />

Console Control<br />

Effect of Sampling Rate on Chromatography –<br />

TUV<br />

AU<br />

0.080<br />

0.070<br />

0.060<br />

0.050<br />

0.040<br />

0.030<br />

0.020<br />

0.010<br />

0.000<br />

1 pt/s<br />

5 pts/s<br />

40 pts/s<br />

0.50 0.52 0.54 0.56 0.58 0.60 0.62<br />

Minutes<br />

0.64 0.66 0.68 0.70 0.72 0.74

18<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Effect of Sampling Rate on Reproducibility<br />

Sampling<br />

Rate<br />

Points<br />

Across<br />

Peak<br />

Peak<br />

Area<br />

Peak Area<br />

%RSD<br />

Peak<br />

Height<br />

Peak<br />

Height<br />

%RSD<br />

1 pt/s 2 44125 2.436 27451 15.515<br />

2 pts/s 4 32822 1.790 41207 13.455<br />

5 pts/s 7 31554 0.971 67355 3.962<br />

10 pts/s 13 31321 1.129 73638 1.015<br />

20 pts/s 25 31284 0.603 76001 1.156<br />

40 pts/s 49 31534 0.284 77606 1.127<br />

Measured for Peak #5 - Phenacetin<br />

Filtering Constant At High Data Rates<br />

AU<br />

0.080<br />

0.070<br />

0.060<br />

0.050<br />

0.040<br />

0.030<br />

0.020<br />

0.010<br />

0.000<br />

No Filtering<br />

0.1s<br />

0.3s<br />

0.5s<br />

1.0s<br />

0.50 0.52 0.54 0.56 0.58 0.60 0.62 0.64 0.66 0.68 0.70 0.72 0.74 0.76 0.78 0.80<br />

Minutes<br />

Dr. Shula Levin, Medtechnica<br />

Tunable Ultra Violet Specifications<br />

Wavelength Range 190 – 700 nm<br />

Increased data acquisition rates<br />

— Maximum 80 pts per second in single wavelength mode<br />

— Maximum 2 pts per second in dual wavelength mode<br />

Optimized time constant to filter smaller peak widths<br />

Two flow cells<br />

— Analytical<br />

— High Sensitivity<br />

ACQUITY PDA Detector<br />

Wavelength Range 190 – 500 nm<br />

MassLynx v4.0/4.1<br />

—80 pts/sec maximum data rate<br />

—0, 1, 2, or 3 second time constants<br />

—3D mode only<br />

Empower build 1154/2154<br />

—80 pts/sec maximum data rate<br />

—0.1 – 3.0 seconds- time constants<br />

—2D or 3D Mode<br />

Two flow cells<br />

—Analytical<br />

—High Sensitivity

19<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Conditions:<br />

Influence of Detector Settings: Sampling Rate<br />

Chromatographic Conditions :<br />

Column: ACQUITY BEH C 18 2.1 x 30 mm, 1.7 µm<br />

Mobile Phase A: 0.1% Formic Acid in H 2O<br />

Mobile Phase B: 0.1% Formic Acid in ACN<br />

Flow Rate: As indicated<br />

Isocratic: 97% A: 3% B<br />

Injection Volume: 2.0 µL<br />

Sample Diluent: 0.2% Formic Acid in water<br />

Strong Needle Wash: 50 µL 50 ACN: 50 H 2O<br />

Weak Needle Wash: 500 µL 0.1% Formic Acid in<br />

H 2O<br />

Temperature: 32°C<br />

Detection: UV @ 280 nm<br />

Time Constant: 0.1<br />

Sampling rate: as indicated<br />

Instrument: <strong>UPLC</strong>: Waters ACQUITY <strong>UPLC</strong>, with<br />

TUV detector<br />

Influence of Detector Settings:<br />

Sampling Rate<br />

Analytes (Caffeine and Metabolites):<br />

1. 1-methylxanthene<br />

2. 1,3-dimethyluric acid<br />

3. Theobromine<br />

4. 1,7-dimethyluric acid<br />

5. 1,7-dimethylxanthene<br />

6. Caffeine<br />

Influence of Sampling Rate on Peak Height<br />

Sampling Rate 40 32 20 10 5 2 1<br />

1-methylxanthene 27145 27284 27525 26815 26694 21370 13530<br />

1,3-dimethyluric acid 41173 41191 41869 41173 41221 36798 26356<br />

theobromine 56726 56624 57589 56673 56578 51930 38274<br />

1,7-dimethyluric acid 25182 25015 25501 24917 25009 23586 20093<br />

1,7-dimethylxanthene 18910 16717 18311 16739 17912 17829 15984<br />

caffeine 14405 14103 14024 14367 13901 14201 13529<br />

Influence of Sampling Rate on Resolution<br />

Sampling Rate<br />

1-methylxanthene<br />

40 32 20 10 5 2 1<br />

1,3-dimethyluric acid 6.9 6.98 6.91 6.96 6.7 5.84 4.79<br />

theobromine 1.9 1.86 1.93 1.87 1.87 1.78 1.44<br />

1,7-dimethyluric acid 7.81 7.75 7.71 7.84 7.67 7.23 6.73<br />

1,7-dimethylxanthene 2.36 2.29 2.36 2.42 2.37 2.43 2.09<br />

caffeine 16.29 16.39 16.27 16.14 16.24 15.98 15.5<br />

Dr. Shula Levin, Medtechnica<br />

Influence of Detector Settings:<br />

Sampling Rate<br />

AU<br />

AU<br />

AU<br />

0.05<br />

0.00<br />

0.05<br />

0.00<br />

0.05<br />

0.00<br />

0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50<br />

Minutes<br />

0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50<br />

Minutes<br />

Conditions:<br />

Influence of Detector Settings: Time Constant<br />

40 Hz<br />

5 Hz<br />

1 Hz<br />

Chromatographic Conditions :<br />

Analytes (Caffeine and Metabolites):<br />

Column: ACQUITY BEH C18 2.1 x 30 mm, 1.7 µm 1. 1-methylxanthene<br />

Mobile Phase A: 0.1% Formic Acid in H2O 2. 1,3-dimethyluric acid<br />

Mobile Phase B: 0.1% Formic Acid in ACN<br />

3. Theobromine<br />

Flow Rate: As indicated<br />

4. 1,7-dimethyluric acid<br />

Isocratic: 97% A : 3% B<br />

Injection Volume: 2.0 µL<br />

Sample Diluent: 0.2% Formic Acid in water<br />

Strong Needle Wash: 50 µL 50 ACN : 50 H2O Weak Needle Wash: 500 µL 0.1% Formic Acid in<br />

H2O Temperature: 32°C<br />

Detection: UV @ 280 nm<br />

Time Constant: as indicated<br />

Sampling rate: 20 pts/sec<br />

Instrument: <strong>UPLC</strong>: Waters ACQUITY <strong>UPLC</strong>, with<br />

TUV detector<br />

5.<br />

6.<br />

1,7-dimethylxanthene<br />

Caffeine

20<br />

AU<br />

AU<br />

AU<br />

0.05<br />

0.00<br />

0.05<br />

0.00<br />

0.05<br />

0.00<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Influence of Detector Settings:<br />

Time Constant<br />

0.00 1.00 2.00 3.00 4.00<br />

Minutes<br />

Resolution/Low Dispersion Flow Cell<br />

A light guiding flow cell is<br />

essentially an optical fiber<br />

whose core material is a fluid<br />

The optical fiber consists of a<br />

core material surrounded by a<br />

cladding layer (Teflon AF).<br />

Light is guided through the core<br />

by the process of total internal<br />

reflection;<br />

— light rays that encounter the<br />

interface between the core and<br />

cladding are reflected back into<br />

the core with essentially 100%<br />

efficiency<br />

Light Path<br />

α Mobile Phase<br />

T c = 0<br />

T c = 1.5<br />

T c = 2.5<br />

TeflonAF<br />

TeflonAF<br />

Dr. Shula Levin, Medtechnica<br />

Influence of Detector Settings:<br />

Time Constant<br />

Influence of Time Constant on Peak Height<br />

Time Constant 0 0.1 0.5 1 1.5 2 2.5<br />

1-methylxanthene 27525 26592 19732 13094 9615 7475 5923<br />

1,3-dimethyluric acid 41869 40811 33662 24129 18370 14791 15241<br />

Theobromine 57589 56123 47629 35066 27099 21813 18653<br />

1,7-dimethyluric acid 25501 25121 23014 18704 15325 12503 10522<br />

1,7-dimethylxanthene 18311 18916 17631 14724 12382 10126 8674<br />

Caffeine 14024 14069 14253 13456 13057 12445 11338<br />

Influence of Time Constant on Resolution<br />

Time Constant 0 0.1 0.5 1 1.5 2 2.5<br />

1-methylxanthene<br />

1,3-dimethyluric acid 6.91 6.64 5.24 3.53<br />

Theobromine 1.93 1.87 1.53 1.08<br />

1,7-dimethyluric acid 7.71 7.58 6.79 5.19 3.68<br />

1,7-dimethylxanthene 2.36 2.37 2.18 1.8 1.45 1.22 1.02<br />

Caffeine 16.27 16.5 16.19 15.09 13.47 12.18 10.87<br />

Zooming In<br />

Mechanism of Total Internal Reflectance<br />

— The TIR condition requires that a component of the incident wave<br />

penetrates the AF, typically to a small fraction of the wavelength of<br />

incident light.<br />

90-α<br />

Teflon ® AF, n(w)<br />

Mobile Phase, n(f)

21<br />

Teflon ® AF light guiding<br />

flow cells may, with time,<br />

develop absorbance<br />

baselines that exhibit<br />

curvature.<br />

This is attributed to<br />

changes in optical<br />

characteristics of AF<br />

surface due to<br />

contaminants.<br />

These “changes” effect TIR<br />

efficiency.<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Why is Flow Cell<br />

Maintenance Important?<br />

Light Guided Flow Cell Maintenance<br />

Prevent build-up of contaminants:<br />

—Always maintain fluid flow through the cell<br />

o Avoid “Lamp ON - Flow OFF” condition<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

o Make clean connections to cell<br />

—Flush new columns<br />

Dormant cells<br />

0<br />

06-Oct-2005 11:09:15 grd s wp1114.arw<br />

-0.05<br />

0 0.5 1 1.5 2 2.5 3 3.5 4<br />

Example of baseline curvature. The top plot is a chromatogram of a<br />

gradient separation. The bottom plot is zoomed vertically to show<br />

more clearly the magnitude of the baseline curvature.<br />

—Pre-flush with clean mobile phase, dry with clean air purge, then<br />

plug ports<br />

Certain low strength, acid-based, wash solutions can help<br />

reduce baseline curvature if contamination occurs<br />

—Example – 1% weak concentration formic acid solution<br />

Dr. Shula Levin, Medtechnica<br />

The Median Baseline Filter (MBF)<br />

— A processing tool for alleviating baseline curvature<br />

MBF Off<br />

MBF On<br />

— The MBF operates during acquisition in real time on the chromatogram<br />

whose baseline is to be corrected.<br />

— The MBF automatically extracts the baseline, smoothes it, and then<br />

subtracts the smoothed baseline from the original chromatogram.<br />

— Result is a chromatogram with greatly reduced baseline curvature.<br />

TUV Flow Cells<br />

High Sensitivity<br />

25 mm Pathlength<br />

2400 nL Volume<br />

Analytical<br />

10 mm Pathlength<br />

500 nL Volume

22<br />

AU<br />

ACQUITY PDA<br />

Flow Cell Options<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

High Sensitivity Analytical<br />

25 mm Pathlength<br />

2400 nL Volume<br />

Flow Cell Signal Comparison<br />

0.0060<br />

0.0055<br />

0.0050<br />

0.0045<br />

0.0040<br />

0.0035<br />

0.0030<br />

0.0025<br />

0.0020<br />

0.0015<br />

0.0010<br />

0.0005<br />

0.0000<br />

10 mm Pathlength<br />

500 nL Volume<br />

Analytical High Sensitivity Ratio<br />

Area 2995 6845 2.29<br />

Height 2368 5123 2.16<br />

Peak Width at 13.4% 2.02 sec 2.14 sec 1.059<br />

Noise:<br />

High Sensitivity Flow Cell = 0.000015 AU<br />

Analytical Flow Cell = 0.000012 AU<br />

0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00<br />

Minutes<br />

1.10 1.20 1.30 1.40 1.50 1.60 1.70<br />

Dr. Shula Levin, Medtechnica<br />

Flow Cell Comparison<br />

<strong>UPLC</strong> Conditions<br />

System: ACQUITY <strong>UPLC</strong> with TUV<br />

Column: 2.1 X 50 mm ACQUITY <strong>UPLC</strong> BEH C18, 1.7 µm<br />

Mobile Phase 7:3 Water/ACN + 0.1% Formic<br />

Flow Rate: 0.65 mL/min<br />

Injection Volume: 2 µL<br />

Strong Wash = 75% ACN/25% Water (250 uL)<br />

Weak Wash = 5% ACN/95%Water (1000 uL)<br />

Sample Temperature: 10 °C<br />

Column Temperature: 35 °C<br />

Detection: ACQUITY TUV @ 231nm (0-1.7 min)<br />

280 nm (1.7 – 3.0 min) 20 pps, FTC=0.30<br />

Sample = 080 mg/mL2,4-D in 50% ACN/50% Water<br />

Data: Empower 2<br />

2,4-D and Impurities<br />

AU<br />

0.20<br />

0.18<br />

0.16<br />

0.14<br />

0.12<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

0.00<br />

Analytical Flow Cell<br />

Flow Cell Comparison – Sensitivity<br />

Area<br />

Height<br />

Peak Width at 13.4%<br />

Analytical<br />

140955<br />

93942<br />

0.040497<br />

High Sensitivity<br />

326881<br />

211138<br />

0.042033<br />

Delta<br />

2.319<br />

2.248<br />

1.038<br />

High Sensitivity Flow Cell<br />

4.40 4.45 4.50 4.55 4.60 4.65<br />

Minutes<br />

4.70 4.75 4.80 4.85 4.90<br />

AU<br />

0.24<br />

0.22<br />

0.20<br />

0.18<br />

0.16<br />

0.14<br />

0.12<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

0.00<br />

-0.02<br />

-0.04<br />

-0.06<br />

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9 .00<br />

Minutes

23<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Flow Cell Recommendations<br />

Analytical Flow Cell<br />

— Better chromatographic resolution<br />

High Sensitivity Flow Cell<br />

— For the highest sensitivity<br />

— Higher peak height (Beer’s law)<br />

— In general, better signal to noise<br />

Both Cells<br />

o Slightly higher noise because more flow perturbations to contribute to<br />

the noise, especially with absorbing mobile phases<br />

— Same linearity<br />

— Cover the full flow rate range<br />

Back Pressure Regulator<br />

Maintains a constant 250 psi<br />

back pressure on the flow cell<br />

Not used with a mass<br />

spectrometer<br />

Used with both TUV and PDA<br />

Dr. Shula Levin, Medtechnica<br />

ACQUITY <strong>UPLC</strong><br />

High Brightness Lamp<br />

High brightness deuterium lamp<br />

—Low noise characteristics<br />

—Nearly twice the brightness (energy) of ordinary deuterium<br />

lamps<br />

Benefits<br />

—Less Noise<br />

—Higher sensitivity<br />

Lamp Warranty<br />

— 2000 hours<br />

Lamp Firmware through Console<br />

—Hours of operation<br />

—Ignitions<br />

—Serial Number<br />

Recommendations

24<br />

Data acquisition<br />

Preparing to Run <strong>UPLC</strong>; Injection and Detection Paramters<br />

Recommendations<br />

— Sampling rate<br />

— Filtering<br />

Tubing<br />

Vial Storage<br />

o Time constant<br />

— Use only the internal diameters for the<br />

ACQUITY <strong>UPLC</strong> system<br />

— Use connections with features designed for<br />

the ACQUITY <strong>UPLC</strong> system<br />

Bad storage could induce possible<br />

contamination<br />

—Ghost peaks<br />

—Unpredictable phenomena<br />

Storage condition<br />

—With cap<br />

—Away from dust<br />

Dr. Shula Levin, Medtechnica<br />

Sources of Potential Contaminants<br />

Incompletely flushed samples, in stagnant condition<br />

—Formation of particulates<br />

—Formation of “thin film” layer<br />

—Photodegradation<br />

Column bleed, connection, tubing…<br />

Observations/Results<br />

—Progressive increase in gradient baseline curvature<br />

—Decrease in absolute energy (increased exposure time)<br />

Injections Recommendations<br />

Wash Process<br />

— Dedicated to sample to decrease carry over<br />

Full loop injection<br />

— Use overfill factor<br />

Partial loop injection<br />

— Use air gaps<br />

Air gap and Draw speed<br />

— Use automatic settings<br />

Sample loop volume determination<br />

— Best way to load the sample correctly in the loop