UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

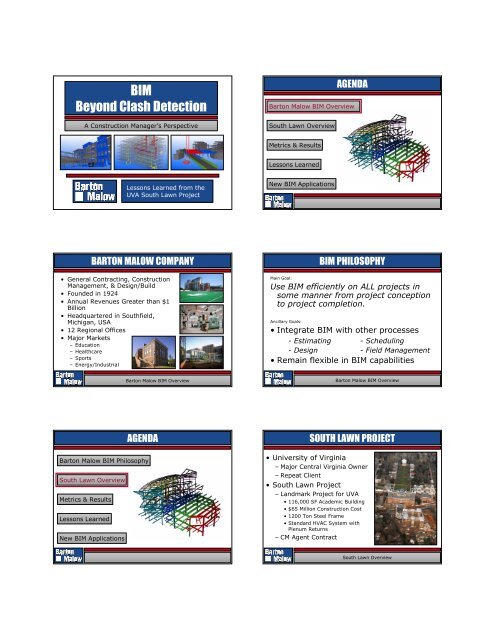

<strong>BIM</strong><br />

Beyond Clash Detection<br />

A Construction Manager’s Perspective<br />

Lessons Learned from the<br />

<strong>UVA</strong> <strong>South</strong> <strong>Lawn</strong> Project TEKLA<br />

BARTON MALOW COMPANY<br />

• General Contracting, Construction<br />

Management, & Design/Build<br />

• Founded in 1924<br />

• Annual Revenues Greater than $1<br />

Billion<br />

• Headquartered in <strong>South</strong>field,<br />

Michigan, USA<br />

• 12 Regional Offices<br />

• Major Markets<br />

– Education<br />

– Healthcare<br />

– Sports<br />

– Energy/Industrial<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Overview<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Philosophy<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

Global Business<br />

Forum<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Overview<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

<strong>BIM</strong> PHILOSOPHY<br />

Main Goal:<br />

Use <strong>BIM</strong> efficiently on ALL projects in<br />

some manner from project conception<br />

to project completion.<br />

Ancillary Goals:<br />

• Integrate <strong>BIM</strong> with other processes<br />

- Estimating - Scheduling<br />

- Design - Field Management<br />

• Remain flexible in <strong>BIM</strong> capabilities<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Overview<br />

SOUTH LAWN PROJECT<br />

• University of Virginia<br />

– Major Central Virginia Owner<br />

– Repeat Client<br />

• <strong>South</strong> <strong>Lawn</strong> Project<br />

– Landmark Project for <strong>UVA</strong><br />

• 116,000 SF Academic Building<br />

• $65 Million Construction Cost<br />

• 1200 Ton Steel Frame<br />

• Standard HVAC System with<br />

Plenum Returns<br />

– CM Agent Contract<br />

<strong>South</strong> <strong>Lawn</strong> Overview

<strong>BIM</strong> GOALS<br />

• Primary <strong>BIM</strong> Goals:<br />

– Structural and Mechanical Coordination<br />

– Greater Subcontractor Involvement<br />

• Secondary <strong>BIM</strong> Goals:<br />

– Material Status / Tracking<br />

– Scheduling and Sequencing<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

COORDINATION<br />

• Avoided Duplication<br />

• Shifted from Clash Detection to Coordination<br />

CLASH DETECTION<br />

• Find problems<br />

• Fix problems<br />

• Find more problems<br />

COORDINATION<br />

• Design & detail effectively<br />

• Communicate options clearly<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

MODEL INTELLIGENCE - nD<br />

• Visualize / Better Utilize Existing Data<br />

• Manage Jobsite Specific Risks<br />

- Steel Submittals - Connection Status - Precast Status<br />

• Input & Output Efficiently with the Model<br />

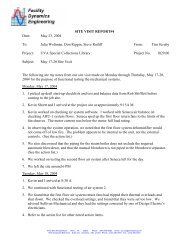

<strong>Barton</strong> <strong>Malow</strong> Company<br />

405 Valley Road<br />

Charlottesville, VA 22903<br />

Telephone: (434) 243-5335<br />

Fax: (434) 243-5394<br />

An Equal Opportunity Employer<br />

Date: 2/11/2008<br />

Submittal: 0018 - 05 12 00 - 0 Steel - Commons Building Shop Drawings<br />

File Name Assemblies Profile Status<br />

SEQUENCE C1 - Register Number 00224<br />

598-07_31001_A.pdf 31001C1 HSS10X6X3/8 1<br />

598-07_31002_A.pdf 31002C1 HSS8.625X.322 2<br />

598-07_31003_A.pdf 31003C1 HSS10X6X3/8 2<br />

598-07_31004_A.pdf 31004C1 HSS10X6X3/8 2<br />

598-07_31005_A.pdf 31005C1 HSS10X6X3/8 3<br />

598-07_31006_A.pdf 31006C1 HSS8.625X.322 3<br />

598-07_31007_A.pdf 31007C1 HSS8.625X.322 2<br />

ASSEMBLY LIST WITH PARTS (BOM)<br />

PROJECT NAME: <strong>UVA</strong> <strong>South</strong>lawn Date: 04/18/2008<br />

JOB NUMBER: 598-07 Time: 01:39:56pm<br />

-------------------------------------------------------------------------------<br />

Unit Ext. Page: 1<br />

Mark Qty. Profile Length Weight Weight Finish<br />

-------------------------------------------------------------------------------<br />

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -<br />

25001C 1 COLUMN 2399 2399<br />

m167 1 W14X90 23'-1"<br />

p37 8 PL3/4"X10 1/16" 1'-0 1/2"<br />

p63 1 FL3/8"X4" 1'-3"<br />

p69 1 FL3/8"X4" 1'-6"<br />

p517 4 PL3/8"X13 3/16" 1'-10 1/4"<br />

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -<br />

25002C 2 COLUMN 2399 4797<br />

m167 2 W14X90 23'-1"<br />

p37 16 PL3/4"X10 1/16" 1'-0 1/2"<br />

p63 2 FL3/8"X4" 1'-3"<br />

p69 2 FL3/8"X4" 1'-6"<br />

p517 8 PL3/8"X13 3/16" 1'-10 1/4"<br />

Existing Log Model Attributes Reports<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Steel Model<br />

HVAC & Plumb.<br />

Modeling<br />

Precast<br />

Modeling<br />

<strong>BIM</strong> PROCESS<br />

1. Steel Modeling 2. Other Contractor Modeling 3. Corrections 4. Drawings<br />

Electrical<br />

Modeling<br />

Fire Protection<br />

Modeling<br />

Truss<br />

Modeling<br />

MEP<br />

Corrections<br />

Structural<br />

Corrections<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

COORDINATION<br />

• Utilize Model for Meetings<br />

• Attach Models to RFI’s<br />

MEP<br />

Shop Drawings<br />

Structural<br />

Shop Drawings<br />

Textual Problem 3D Communication Tool<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

MATERIAL STATUS<br />

SUBMITTAL TRACKING<br />

THE PROBLEM<br />

•24 steel sequences<br />

• Overlap of original<br />

submittal, resubmittal,<br />

and fabrication processes<br />

• Partial approval of each<br />

sequence<br />

THE SOLUTION<br />

• Track submittal status<br />

of each piece of steel<br />

• Import submittal log<br />

into model<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

THE RESULT<br />

• Color coded model helped<br />

prioritize and focus submittal<br />

review efforts.<br />

• Submittal review and<br />

fabrication condensed.

MATERIAL STATUS<br />

CONNECTION STATUS<br />

THE PROBLEM<br />

• 174 connections had<br />

inspection problems<br />

• Additional work was<br />

needed before slab pour<br />

could occur<br />

THE SOLUTION<br />

• Create user defined<br />

attributes to track<br />

connection problems<br />

• Utilize color coded<br />

model to evaluate slab<br />

pour status<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

SCHEDULE<br />

ID Assembly EOR_STATUS Profile Moment<br />

111688 11025B3 11025 Approved 1 W24X62 1<br />

111706 11028B1 11028 Approved 3 W24X55 1<br />

121830 11038B1 11038 Approved 3 W24X62 1<br />

121812 11043B1 11043 Approved 3 W24X104 1<br />

33789 12016B2 12016 Approved 3 W21X44 2<br />

117396 12016B2 12016 Approved 3 W21X44 2<br />

112602 12019B1 12019 Approved 3 W24X55 2<br />

118622 12019B1 12019 Approved 3 W24X55 2<br />

112618 12022B1 12022 Approved 3 W24X55 2<br />

118645 12022B1 12022 Approved 3 W24X55 2<br />

112244 12027B1 12027 Approved 3 W24X55 1<br />

112262 12030B1 12030 Approved 3 W24X55 1<br />

112398 12031B1 12031 Approved 3 W24X55 1<br />

112414 12032B1 12032 Approved 3 W24X55 1<br />

117382 12037B2 12037 Approved 3 W21X44 2<br />

112973 13022B2 13022 Approved 3 W24X62 2<br />

118760 13022B2 13022 Approved 3 W24X62 2<br />

113051 13028B1 13028 Approved 3 W24X55 1<br />

THE RESULTS<br />

• Magnitude of problems<br />

were quickly understood<br />

through model and<br />

reports<br />

• Slab pours proceeded<br />

as scheduled<br />

• Communicate critical sequences better<br />

• Utilize only in select areas<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

RESULTS<br />

RESULTS<br />

• Better & quicker understanding of information is the main time &<br />

money saver<br />

• <strong>BIM</strong> can adapt to tackle new project specific problems, planned or<br />

unplanned<br />

KEYS TO RESULTS<br />

• Flexible, user-customizable technology<br />

• Ability to tackle different problems with the same basic process<br />

• Integration with multiple parties at differing abilities<br />

Metrics & Results<br />

PRECAST STATUS<br />

THE PROBLEM<br />

• 1300 pieces of precast<br />

needed to be delivered to<br />

the mason<br />

• Masonry sequence was<br />

revised during precast<br />

production<br />

MATERIAL STATUS<br />

ID CONTROLDELIVERY<br />

216491 2062 01/20/2009<br />

216508 2061 01/24/2009<br />

216525 2060 01/20/2009<br />

216542 2059 02/10/2009<br />

216566 2055 02/10/2009<br />

216583 2054 02/10/2009<br />

216608 2056 01/20/2009<br />

216658 2053 01/20/2009<br />

THE SOLUTION<br />

• Import delivery information<br />

into the model<br />

• Review if correct pieces were<br />

delivered; provide list of<br />

needed pieces<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Philosophy<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

DISCLAIMER<br />

THE RESULTS<br />

• Missed pieces were quickly<br />

delivered<br />

• Precast delivery remained<br />

flexible to changing sequence<br />

The process for defining <strong>BIM</strong> value is<br />

very subjective.<br />

Would this<br />

problem have<br />

been found<br />

without <strong>BIM</strong>?<br />

Who would have<br />

had to pay for<br />

this problem?<br />

What would have<br />

been the costs if<br />

we hadn’t found<br />

this problem?<br />

If we’re under budget or ahead<br />

of schedule is that because of<br />

<strong>BIM</strong> or something else?<br />

Metrics & Results<br />

How do we<br />

define indirect<br />

costs/savings?

METRICS<br />

1. Avoided Rework<br />

– $15,000 to rework<br />

concrete &<br />

ductwork<br />

– Schedule benefits<br />

2. Condensed Steel<br />

Schedule<br />

– $30,000 in crane<br />

costs & GC’s<br />

Submittals Fabrication<br />

Material Delay<br />

Submittals & Fabrication<br />

Design and Submittals<br />

Integrated<br />

Metrics & Results<br />

COSTS<br />

1. Minor Model Creation<br />

Costs<br />

2. ~$15,000 Software<br />

Costs<br />

3. No Additional Hardware<br />

Costs<br />

4. No Additional Process<br />

Time<br />

Metrics & Results<br />

MODEL WEAKNESSES<br />

Non-<strong>BIM</strong> Schedule<br />

Rework Issues<br />

<strong>BIM</strong> Schedule<br />

Construction<br />

Efficient Construction<br />

Operations<br />

Construction<br />

Time<br />

Savings<br />

• Not practical to model every detail<br />

• Models can contain errors<br />

• Non-model details can create problems<br />

• Updates are lacking after coordination<br />

• Contractors may not build per model<br />

New Soffits<br />

Lessons Learned<br />

Not Modeled<br />

AV Conduits<br />

3. Avoided Scaffold<br />

Costs<br />

– $10,000 Savings<br />

– Schedule Benefit<br />

METRICS<br />

4. CM Time Savings<br />

– Better & Quicker<br />

Understanding<br />

– Less End of Project<br />

Issues<br />

Metrics & Results<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Philosophy<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

CONTRACT LANGUAGE<br />

• What?<br />

– What systems should be modeled?<br />

– What level of detail is needed?<br />

– What is the purpose of the models?<br />

• When?<br />

– When should the first models be<br />

completed?<br />

– When should updated models be shared?<br />

– Is an as-built model required?<br />

• How?<br />

– Which file types are accepted?<br />

– How are models to submitted?<br />

– Who integrates and reviews files?<br />

Lessons Learned<br />

Pre-Fabricated<br />

Normal Shop Drawing<br />

Address Legal<br />

Concerns<br />

ASAP<br />

Pre-Coordination,<br />

Post-Coordination,<br />

As-Built<br />

IFC, DWG<br />

FTP Site<br />

Construction Manager

<strong>BIM</strong> PARTNERS<br />

Choose <strong>BIM</strong> Designers and Contractors<br />

• Utilize <strong>BIM</strong> for Drawing Creation<br />

• Integrate <strong>BIM</strong> with Other Processes<br />

Shop Fabrication<br />

Submittal Review<br />

Lessons Learned<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Philosophy<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

PROBLEMS<br />

Difficulty presenting &<br />

communicating<br />

schedule<br />

PROJECT<br />

EXPERIENCE:<br />

SCHEDULING<br />

<strong>BIM</strong> SOLUTION<br />

Link model objects to schedule tasks<br />

Visualize planned progress & sequence<br />

Quantify task work amounts<br />

FT. Pickett Training Facility<br />

New <strong>BIM</strong> Applications<br />

Allow for Technology Interoperability<br />

• Avoid Specifying Software<br />

• Detail Information Needed and Formats<br />

Design: Revit,<br />

Graphisoft,<br />

Bentley<br />

New Cabell Hall Renovation<br />

Charlottesville, VA<br />

Cost Model<br />

Structural<br />

Detailing:<br />

SDS/2, Tekla<br />

Description Quantity<br />

CONSTRUCTION COST<br />

DIRECT COST<br />

Demolition / Abatement 159,129 SQFT<br />

PROBLEMS<br />

Inefficient takeoffs<br />

Lengthy estimate<br />

development<br />

Difficulty<br />

communicating &<br />

reconciling estimates<br />

PROJECT<br />

EXPERIENCE:<br />

PROBLEMS<br />

Multiple uncoordinated<br />

deficiency and issue lists<br />

Inefficient information<br />

exchange between the<br />

field and the office<br />

Tracking and<br />

documentation problems<br />

PROJECT<br />

EXPERIENCE:<br />

INTEROPERABILITY<br />

Software Packages<br />

MEP/FP<br />

Detailing:<br />

Quick Pen, Cad<br />

Duct, HydraCAD<br />

Enclosure<br />

Detailing:<br />

Tekla, Other<br />

Integrated Formats: IFC, IFCZIP<br />

Lessons Learned<br />

ESTIMATING<br />

<strong>BIM</strong> SOLUTION<br />

Construction<br />

Management:<br />

Tekla Structures for<br />

CM, Vela Systems<br />

Export quantity information from <strong>BIM</strong><br />

Visualize estimate items for quick<br />

reconciliation<br />

Morgan State University - CBEIS<br />

New <strong>BIM</strong> Applications<br />

QUALITY CONTROL<br />

Tablet PC Central Database<br />

<strong>BIM</strong> SOLUTION<br />

Utilize tablet PC’s to document issues in the field<br />

Communicate issues to contractors immediately<br />

Track issues through one central database.<br />

Virginia Tech – Ambler-Johnston Renovation<br />

New <strong>BIM</strong> Applications

PROBLEMS<br />

Numerous items to<br />

commission<br />

Unclear status updates<br />

Inefficient field/office<br />

information exchange<br />

PROJECT<br />

EXPERIENCE:<br />

COMMISSIONING<br />

Data Rich <strong>BIM</strong><br />

Tablet PC<br />

<strong>BIM</strong> SOLUTION<br />

Commissioning Info<br />

VAV Status Heat Map<br />

Utilize tablet PC’s to take the model into the field<br />

Update commissioning reports using tablet PC’s<br />

Link reports to the model to communicate status<br />

Maryland General Hospital – Central Care Expansion<br />

New <strong>BIM</strong> Applications<br />

Lessons Learned from the<br />

<strong>UVA</strong> <strong>South</strong> <strong>Lawn</strong> Project<br />

TEKLA<br />

Global Business<br />

Forum<br />

PROBLEMS<br />

Incomplete, confusing<br />

paper as-builts<br />

Maintenance problems<br />

from missed schedules<br />

Misplaced and missing<br />

equipment information<br />

PROJECT<br />

EXPERIENCE:<br />

FACILITY MANAGEMENT<br />

Tablet PC<br />

<strong>BIM</strong> SOLUTION<br />

Data Rich<br />

<strong>BIM</strong><br />

Utilize <strong>BIM</strong> for 3D as-built<br />

Access equipment product data through <strong>BIM</strong><br />

Link <strong>BIM</strong> to tablet PC and facility software.<br />

Maryland General Hospital – Central Care Expansion<br />

New <strong>BIM</strong> Applications