UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

UVA South Lawn BIM Case Study by Barton Malow - Facilities ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

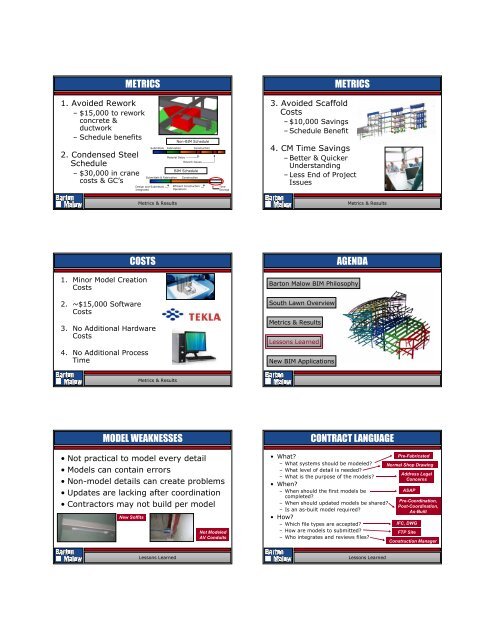

METRICS<br />

1. Avoided Rework<br />

– $15,000 to rework<br />

concrete &<br />

ductwork<br />

– Schedule benefits<br />

2. Condensed Steel<br />

Schedule<br />

– $30,000 in crane<br />

costs & GC’s<br />

Submittals Fabrication<br />

Material Delay<br />

Submittals & Fabrication<br />

Design and Submittals<br />

Integrated<br />

Metrics & Results<br />

COSTS<br />

1. Minor Model Creation<br />

Costs<br />

2. ~$15,000 Software<br />

Costs<br />

3. No Additional Hardware<br />

Costs<br />

4. No Additional Process<br />

Time<br />

Metrics & Results<br />

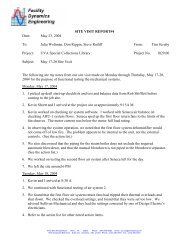

MODEL WEAKNESSES<br />

Non-<strong>BIM</strong> Schedule<br />

Rework Issues<br />

<strong>BIM</strong> Schedule<br />

Construction<br />

Efficient Construction<br />

Operations<br />

Construction<br />

Time<br />

Savings<br />

• Not practical to model every detail<br />

• Models can contain errors<br />

• Non-model details can create problems<br />

• Updates are lacking after coordination<br />

• Contractors may not build per model<br />

New Soffits<br />

Lessons Learned<br />

Not Modeled<br />

AV Conduits<br />

3. Avoided Scaffold<br />

Costs<br />

– $10,000 Savings<br />

– Schedule Benefit<br />

METRICS<br />

4. CM Time Savings<br />

– Better & Quicker<br />

Understanding<br />

– Less End of Project<br />

Issues<br />

Metrics & Results<br />

AGENDA<br />

<strong>Barton</strong> <strong>Malow</strong> <strong>BIM</strong> Philosophy<br />

<strong>South</strong> <strong>Lawn</strong> Overview<br />

Metrics & Results<br />

Lessons Learned<br />

New <strong>BIM</strong> Applications<br />

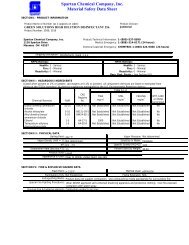

CONTRACT LANGUAGE<br />

• What?<br />

– What systems should be modeled?<br />

– What level of detail is needed?<br />

– What is the purpose of the models?<br />

• When?<br />

– When should the first models be<br />

completed?<br />

– When should updated models be shared?<br />

– Is an as-built model required?<br />

• How?<br />

– Which file types are accepted?<br />

– How are models to submitted?<br />

– Who integrates and reviews files?<br />

Lessons Learned<br />

Pre-Fabricated<br />

Normal Shop Drawing<br />

Address Legal<br />

Concerns<br />

ASAP<br />

Pre-Coordination,<br />

Post-Coordination,<br />

As-Built<br />

IFC, DWG<br />

FTP Site<br />

Construction Manager