Drive Solutions for the Global Oil and Gas Industry ... - GE Energy

Drive Solutions for the Global Oil and Gas Industry ... - GE Energy

Drive Solutions for the Global Oil and Gas Industry ... - GE Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Three-<br />

Phase Electric<br />

Electric Supply<br />

Supply<br />

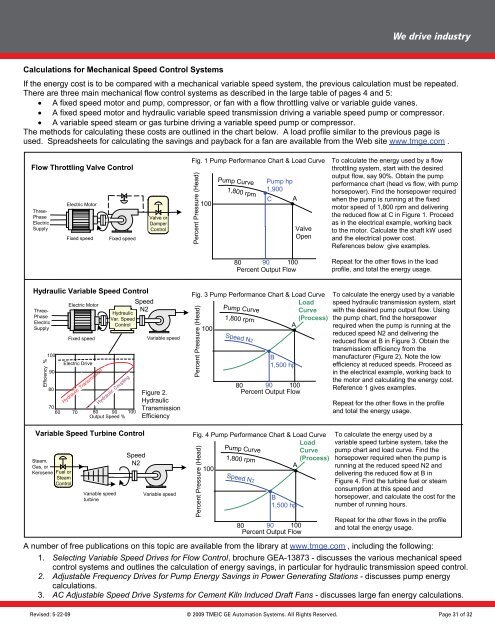

Calculations <strong>for</strong> Mechanical Speed Control Systems<br />

Calculations <strong>for</strong> Mechanical Speed Control Systems<br />

If <strong>the</strong> energy cost is to be compared with a mechanical variable speed system, <strong>the</strong> previous calculation must be repeated.<br />

There If <strong>the</strong> energy are three cost main is to mechanical be compared flow with control mechanical systems as variable described speed in system, <strong>the</strong> large <strong>the</strong> table previous of pages calculation 4 <strong>and</strong> 5: must be repeated.<br />

There<br />

•<br />

are<br />

A fixed<br />

three<br />

speed<br />

main mechanical<br />

motor <strong>and</strong> pump,<br />

flow control<br />

compressor,<br />

systems<br />

or<br />

as<br />

fan<br />

described<br />

with a flow<br />

in <strong>the</strong><br />

throttling<br />

large table<br />

valve<br />

of<br />

or<br />

pages<br />

variable <strong>and</strong><br />

guide<br />

5:<br />

vanes.<br />

• A fixed<br />

fixed<br />

speed<br />

speed<br />

motor<br />

motor<br />

<strong>and</strong><br />

<strong>and</strong><br />

hydraulic<br />

pump, compressor,<br />

variable speed<br />

or fan<br />

transmission<br />

with flow throttling<br />

driving a<br />

valve<br />

variable<br />

or variable<br />

speed pump<br />

guide<br />

or<br />

vanes.<br />

compressor.<br />

• A variable<br />

fixed speed<br />

speed<br />

motor<br />

steam<br />

<strong>and</strong><br />

or<br />

hydraulic<br />

gas turbine<br />

variable<br />

driving<br />

speed<br />

a variable<br />

transmission<br />

speed pump<br />

driving<br />

or compressor.<br />

variable speed pump or compressor.<br />

The methods variable <strong>for</strong> calculating speed steam <strong>the</strong>se or costs gas turbine are outlined driving in <strong>the</strong> variable chart speed below. pump A load or profile compressor. similar to <strong>the</strong> previous page is<br />

used. The methods Spreadsheets <strong>for</strong> calculating <strong>for</strong> calculating <strong>the</strong>se costs <strong>the</strong> savings are outlined <strong>and</strong> payback in <strong>the</strong> chart <strong>for</strong> below. a fan are available load profile from similar <strong>the</strong> Web to <strong>the</strong> site previous www.tmge.com page is .<br />

used. Spreadsheets <strong>for</strong> calculating <strong>the</strong> savings <strong>and</strong> payback <strong>for</strong> fan are available from <strong>the</strong> Web site www.tmge.com Fig. 1 Pump Per<strong>for</strong>mance Chart & Load Curve To calculate <strong>the</strong> energy used by a flow<br />

Flow Throttling Valve Control<br />

Fig. 1 Pump Per<strong>for</strong>mance Chart & Load Curve To throttling calculate system, <strong>the</strong> energy start with used <strong>the</strong> by desired a flow<br />

Flow Throttling Valve Control<br />

throttling output flow, system, say 90%. start Obtain with <strong>the</strong> <strong>the</strong> desired pump<br />

Pump hp<br />

output per<strong>for</strong>mance flow, say chart 90%. (head Obtain vs flow, <strong>the</strong> pump with pump<br />

Pump 1,900 hp<br />

per<strong>for</strong>mance horsepower). chart Find <strong>the</strong> (head horsepower vs flow, with required pump<br />

1,900<br />

C A<br />

horsepower). when <strong>the</strong> pump Find is running <strong>the</strong> horsepower at <strong>the</strong> fixed required<br />

Electric Motor<br />

100<br />

C A<br />

when <strong>the</strong> pump is running at <strong>the</strong> fixed<br />

Electric Motor<br />

100<br />

motor speed of 1,800 rpm <strong>and</strong> delivering<br />

Threemotor<br />

speed of 1,800 rpm <strong>and</strong> delivering<br />

Three- Phase<br />

Valve or<br />

<strong>the</strong> reduced flow at C in Figure 1. Proceed<br />

Phase Electric<br />

Valve Damper or<br />

<strong>the</strong> as in reduced <strong>the</strong> electrical flow at example, C in Figure working 1. Proceed back<br />

Electric Supply<br />

Damper Control<br />

Valve as to <strong>the</strong> in <strong>the</strong> motor. electrical Calculate example, <strong>the</strong> shaft working kW used back<br />

Supply<br />

Control<br />

Valve<br />

Fixed speed Fixed speed<br />

Open to <strong>and</strong> <strong>the</strong> <strong>the</strong> motor. electrical Calculate power <strong>the</strong> cost. shaft kW used<br />

Fixed speed Fixed speed<br />

Open <strong>and</strong> References <strong>the</strong> electrical below power give examples. cost.<br />

References below give examples.<br />

80 90 100<br />

Repeat <strong>for</strong> <strong>the</strong> o<strong>the</strong>r flows in <strong>the</strong> load<br />

80 Percent Output 90 Flow 100<br />

Repeat profile, <strong>and</strong> <strong>for</strong> <strong>the</strong> total o<strong>the</strong>r energy flows in usage. <strong>the</strong> load<br />

Percent Output Flow<br />

profile, <strong>and</strong> total <strong>the</strong> energy usage.<br />

Hydraulic Variable Speed Control<br />

Hydraulic Variable Speed Control<br />

Speed<br />

Electric Motor<br />

Three-<br />

Speed<br />

Electric Motor<br />

N2<br />

Hydraulic<br />

Phase<br />

N2<br />

Efficiency % %<br />

100<br />

100<br />

90<br />

90<br />

80<br />

80<br />

Fixed speed<br />

Fixed speed<br />

Var. Hydraulic Speed<br />

Var. Control Speed<br />

Control<br />

70<br />

70 60 70 *<br />

*<br />

60 70<br />

Output 80 80 Speed 90 90<br />

%<br />

100<br />

100<br />

Output Speed %<br />

Variable Speed Turbine Control<br />

Variable Speed Turbine Control<br />

Steam,<br />

Steam, <strong>Gas</strong>, or<br />

<strong>Gas</strong>, Kerosene or Fuel or<br />

Kerosene Fuel Steamor<br />

Control Steam<br />

Control<br />

Electric <strong>Drive</strong><br />

Electric <strong>Drive</strong><br />

Hydraulic Transmission<br />

Hydraulic Transmission<br />

Hydraulic Coupling<br />

Hydraulic Coupling<br />

Variable speed<br />

Variable turbine speed<br />

turbine<br />

Speed<br />

Speed N2<br />

N2<br />

Variable speed<br />

Variable speed<br />

Figure 2.<br />

Figure Hydraulic 2.<br />

Hydraulic Transmission<br />

Transmission<br />

Efficiency<br />

Efficiency<br />

Variable speed<br />

Variable speed<br />

Percent Pressure (Head)<br />

Pump Curve<br />

Pump Curve<br />

1,800 rpm<br />

1,800 rpm<br />

Fig. 3 Pump Per<strong>for</strong>mance Chart & Load Curve<br />

Fig. 3 Pump Per<strong>for</strong>mance Chart & Load Load Curve<br />

Load Curve<br />

Curve (Process)<br />

A (Process)<br />

100<br />

A<br />

100<br />

Percent Pressure (Head)<br />

Fig. 4 Pump Per<strong>for</strong>mance Chart & Load Curve<br />

Fig. 4 Pump Per<strong>for</strong>mance Chart & Load Load Curve<br />

Load Curve<br />

Curve (Process)<br />

A (Process)<br />

100<br />

A<br />

100<br />

Percent Pressure (Head)<br />

Pump Curve<br />

Pump Curve<br />

1,800 rpm<br />

1,800 rpm<br />

Speed N2<br />

Speed N2<br />

80 90 100<br />

80Percent Output 90 Flow 100<br />

Percent Output Flow<br />

Pump Curve<br />

Pump Curve<br />

1,800 rpm<br />

1,800 rpm<br />

Speed N2<br />

Speed N2<br />

B<br />

B1,500 hp<br />

1,500 hp<br />

B<br />

B1,500 hp<br />

1,500 hp<br />

80 90 100<br />

80Percent Output 90 Flow 100<br />

Percent Output Flow<br />

To calculate <strong>the</strong> energy used by a variable<br />

To speed calculate hydraulic <strong>the</strong> transmission energy used by system, a variable start<br />

speed with <strong>the</strong> hydraulic desired pump transmission output flow. system, Using start<br />

with <strong>the</strong> pump <strong>the</strong> desired chart, find pump <strong>the</strong> output horsepower flow. Using<br />

<strong>the</strong> required pump when chart, <strong>the</strong> find pump <strong>the</strong> horsepower is running at <strong>the</strong><br />

required reduced speed when <strong>the</strong> N2 pump <strong>and</strong> delivering is running <strong>the</strong> at <strong>the</strong><br />

reduced speed flow at N2 B in <strong>and</strong> Figure delivering 3. Obtain <strong>the</strong> <strong>the</strong><br />

reduced transmissiom flow at efficiency B in Figure from 3. <strong>the</strong> Obtain <strong>the</strong><br />

transmissiom manufacturer (Figure efficiency 2). from Note <strong>the</strong> <strong>the</strong> low<br />

manufacturer efficiency at reduced (Figure speeds. 2). Note Proceed <strong>the</strong> low as<br />

efficiency in <strong>the</strong> electrical at reduced example, speeds. working Proceed back as to<br />

in <strong>the</strong> <strong>the</strong> motor electrical <strong>and</strong> calculating example, working <strong>the</strong> energy back cost. to<br />

<strong>the</strong> Reference motor <strong>and</strong> 1 gives calculating examples. <strong>the</strong> energy cost.<br />

Reference 1 gives examples.<br />

Repeat <strong>for</strong> <strong>the</strong> o<strong>the</strong>r flows in <strong>the</strong> profile<br />

Repeat <strong>and</strong> total <strong>for</strong> <strong>the</strong> <strong>the</strong> energy o<strong>the</strong>r usage. flows in <strong>the</strong> profile<br />

<strong>and</strong> total <strong>the</strong> energy usage.<br />

To calculate <strong>the</strong> energy used by a<br />

To variable calculate speed <strong>the</strong> turbine energy system, used by take a <strong>the</strong><br />

variable pump chart speed <strong>and</strong> turbine load curve. system, Find take <strong>the</strong> <strong>the</strong><br />

pump horsepower chart <strong>and</strong> required load when curve. <strong>the</strong> Find pump <strong>the</strong> is<br />

horsepower running at <strong>the</strong> required reduced when speed <strong>the</strong> N2 pump <strong>and</strong>is<br />

running delivering at <strong>the</strong> reduced flow speed at B N2 in<strong>and</strong><br />

delivering Figure 4. Find <strong>the</strong> reduced <strong>the</strong> turbine flow fuel at B or insteam<br />

Figure consumption 4. Find at <strong>the</strong> this turbine speed fuel <strong>and</strong>or steam<br />

consumption horsepower, <strong>and</strong> at this calculate speed <strong>the</strong> <strong>and</strong>cost <strong>for</strong> <strong>the</strong><br />

horsepower, number of running <strong>and</strong> calculate hours. <strong>the</strong> cost <strong>for</strong> <strong>the</strong><br />

number of running hours.<br />

Repeat <strong>for</strong> <strong>the</strong> o<strong>the</strong>r flows in <strong>the</strong> profile<br />

Repeat <strong>and</strong> total <strong>for</strong> <strong>the</strong> <strong>the</strong> energy o<strong>the</strong>r usage. flows in <strong>the</strong> profile<br />

<strong>and</strong> total <strong>the</strong> energy usage.<br />

A number of free publications on this topic are available from <strong>the</strong> library at www.tmge.com , including <strong>the</strong> following:<br />

number of free publications on this topic are available from <strong>the</strong> library at www.tmge.com , including <strong>the</strong> following:<br />

1. Selecting Variable Speed <strong>Drive</strong>s <strong>for</strong> Flow Control, brochure <strong>GE</strong>A-13873 - discusses <strong>the</strong> various mechanical speed<br />

1. control Selecting systems Variable <strong>and</strong> Speed outlines <strong>Drive</strong>s <strong>the</strong> calculation <strong>for</strong> Flow Control, of energy brochure savings, <strong>GE</strong>A-13873 in particular discusses <strong>for</strong> hydraulic <strong>the</strong> various transmission mechanical speed speed control.<br />

2. control Adjustable systems Frequency <strong>and</strong> outlines <strong>Drive</strong>s <strong>the</strong> <strong>for</strong> Pump calculation <strong>Energy</strong> of energy Savings savings, Power in Generating particular <strong>for</strong> Stations hydraulic - discusses transmission pump speed energy control.<br />

2. calculations.<br />

Adjustable Frequency <strong>Drive</strong>s <strong>for</strong> Pump <strong>Energy</strong> Savings in Power Generating Stations discusses pump energy<br />

3. AC calculations. Adjustable Speed <strong>Drive</strong> Systems <strong>for</strong> Cement Kiln Induced Draft Fans - discusses large fan energy calculations.<br />

3. AC Adjustable Speed <strong>Drive</strong> Systems <strong>for</strong> Cement Kiln Induced Draft Fans discusses large fan energy calculations.<br />

Revised: 5-22-09 © 2009 TMEIC <strong>GE</strong> Automation Systems. All Rights Reserved.<br />

Page 31 of 32