Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

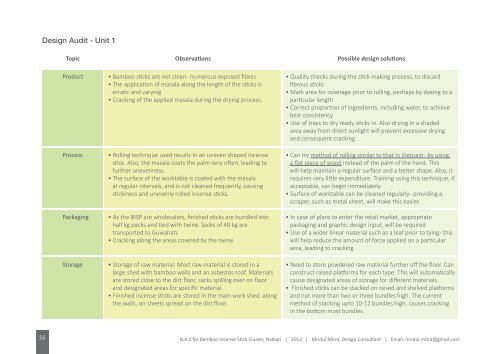

<strong>Design</strong> Audit - Unit 1<br />

Topic<br />

Observations<br />

Possible design solutions<br />

Product<br />

Process<br />

Packaging<br />

Storage<br />

• <strong>Bamboo</strong> sticks are not clean - numerous exposed fibres<br />

• The application of masala along the length of the sticks is<br />

erratic and varying<br />

• Cracking of the applied masala during the drying process.<br />

• Rolling technique used results in an uneven shaped incense<br />

stick. Also, the masala coats the palm very often, leading to<br />

further unevenness.<br />

• The surface of the worktable is coated with the masala<br />

at regular intervals, and is not cleaned frequently, causing<br />

stickiness and unevenly rolled incense sticks.<br />

• As the BISP are wholesalers, finished sticks are bundled into<br />

half kg packs and tied with twine. Sacks of 40 kg are<br />

transported to Guwahati.<br />

• Cracking along the areas covered by the twine<br />

• Storage of raw material: Most raw material is stored in a<br />

large shed with bamboo walls and an asbestos roof. Materials<br />

are stored close to the dirt floor, sacks spilling over on floor<br />

and designated areas for specific material.<br />

• Finished incense sticks are stored in the main work shed, along<br />

the walls, on sheets spread on the dirt floor.<br />

• Quality checks during the stick making process, to discard<br />

fibrous sticks<br />

• Mark area for coverage prior to rolling, perhaps by dyeing to a<br />

particular length<br />

• Correct proportion of ingredients, including water, to achieve<br />

best consistency<br />

• Use of trays to dry ready sticks in. Also drying in a shaded<br />

area away from direct sunlight will prevent excessive drying<br />

and consequent cracking<br />

• Can try method of rolling similar to that in Vietnam - by using<br />

a flat piece of wood instead of the palm of the hand. This<br />

will help maintain a regular surface and a better shape. Also, it<br />

requires very little expenditure. Training using this technique, if<br />

acceptable, can begin immediately.<br />

• Surface of worktable can be cleaned regularly - providing a<br />

scraper, such as metal sheet, will make this easier.<br />

• In case of plans to enter the retail market, appropriate<br />

packaging and graphic design input, will be required<br />

• Use of a wider linear material such as a leaf prior to tying - this<br />

will help reduce the amount of force applied on a particular<br />

area, leading to cracking<br />

• Need to store powdered raw material further off the floor. Can<br />

construct raised platforms for each type. This will automatically<br />

cause designated areas of storage for different materials.<br />

• Finished sticks can be stacked on raised and shelved platforms<br />

and not more than two or three bundles high. The current<br />

method of stacking upto 10-12 bundles high, causes cracking<br />

in the bottom most bundles.<br />

16<br />

N.A.S for <strong>Bamboo</strong> <strong>Incense</strong> <strong>Stick</strong> <strong>Cluster</strong>, <strong>Nalbari</strong> | 2013 | Mridul Mitra, <strong>Design</strong> Consultant | Email: mridul.mitra@gmail.com