Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

Bamboo Incense Stick Cluster, Nalbari - Design Clinic Scheme

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

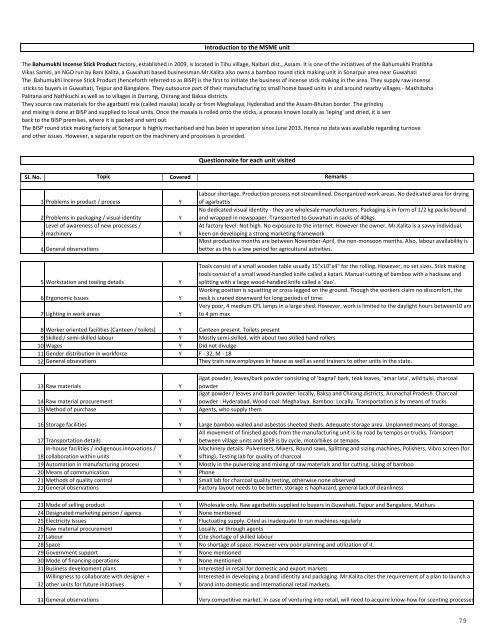

Introduction to the MSME unit<br />

The Bahumukhi <strong>Incense</strong> <strong>Stick</strong> Product factory, established in 2009, is located in Tihu village, <strong>Nalbari</strong> dist., Assam. It is one of the initiatives of the Bahumukhi Pratibha<br />

Vikas Samiti, an NGO run by Bani Kalita, a Guwahati based businessman.Mr.Kalita also owns a bamboo round stick making unit in Sonarpur area near Guwahati<br />

The Bahumukhi <strong>Incense</strong> <strong>Stick</strong> Product (henceforth referred to as BISP) is the first to initiate the business of incense stick making in the area. They supply raw incense<br />

sticks to buyers in Guwahati, Tejpur and Bangalore. They outsource part of their manufacturing to small home based units in and around nearby villages ‐ Makhibaha<br />

Palitana and Nathkuchi as well as to villages in Darrang, Chirang and Baksa districts.<br />

They source raw materials for the agarbatti mix (called masala) locally or from Meghalaya, Hyderabad and the Assam‐Bhutan border. The grinding<br />

and mixing is done at BISP and supplied to local units. Once the masala is rolled onto the sticks, a process known locally as 'leping' and dried, it is sent<br />

back to the BISP premises, where it is packed and sent out.<br />

The BISP round stick making factory at Sonarpur is highly mechanised and has been in operation since June 2013. Hence no data was available regarding turnove<br />

and other issues. However, a separate report on the machinery and processes is provided.<br />

Questionnaire for each unit visited<br />

Sl. No. Topic Covered Remarks<br />

1 Problems in product / process Y<br />

2 Problems in packaging / visual identity Y<br />

Level of awareness of new processes /<br />

3 machinery<br />

Y<br />

4 General observations<br />

5 Workstation and tooling details Y<br />

6 Ergonomic Issues Y<br />

7 Lighting in work areas Y<br />

Labour shortage. Production process not streamlined. Disorganized work areas. No dedicated area for drying<br />

of agarbattis<br />

No dedicated visual identity ‐ they are wholesale manufacturers. Packaging is in form of 1/2 kg packs bound<br />

and wrapped in newspaper. Transported to Guwahati in sacks of 40kgs.<br />

At factory level: Not high. No exposure to the internet. However the owner, Mr.Kalita is a savvy individual,<br />

keen on developing a strong marketing framework<br />

Most productive months are between November‐April, the non‐monsoon months. Also, labour availability is<br />

better as this is a low period for agricultural activities.<br />

Tools consist of a small wooden table usually 15"x10"x4" for the rolling. However, no set sizes. <strong>Stick</strong> making<br />

tools consist of a small wood‐handled knife called a katari. Manual cutting of bamboo with a hacksaw and<br />

splitting with a large wood‐handled knife called a 'dao'.<br />

Working position is squatting or cross‐legged on the ground. Though the workers claim no discomfort, the<br />

neck is craned downward for long periods of time.<br />

Very poor, 4 medium CFL lamps in a large shed. However, work is limited to the daylight hours between10 am<br />

to 4 pm max<br />

8 Worker oriented facilities (Canteen / toilets) Y Canteen present. Toilets present<br />

9 Skilled / semi‐skilled labour Y Mostly semi‐skilled, with about two skilled hand rollers<br />

10 Wages Y Did not divulge<br />

11 Gender distribution in workforce Y F ‐ 32, M ‐ 18<br />

12 General obsevations They train new employees in house as well as send trainers to other units in the state.<br />

13 Raw materials Y<br />

Jigat powder, leaves/bark powder consisting of 'bagnal' bark, teak leaves, 'amar lata', wild tulsi, charcoal<br />

powder<br />

14 Raw material procurement Y<br />

Jigat powder / leaves and bark powder: locally, Baksa and Chirang districts, Arunachal Pradesh. Charcoal<br />

powder : Hyderabad, Wood coal: Meghalaya. <strong>Bamboo</strong>: Locally. Transportation is by means of trucks<br />

15 Method of purchase Y Agents, who supply them<br />

16 Storage facilities Y Large bamboo walled and asbestos sheeted sheds. Adequate storage area. Unplanned means of storage.<br />

17 Transportation details Y<br />

All movement of finished goods from the manufacturing unit is by road by tempos or trucks. Transport<br />

between village units and BISP is by cycle, motorbikes or tempos.<br />

In‐house facilities / indigenous innovations /<br />

18 collaboration within units<br />

Y<br />

Machinery details: Pulverisers, Mixers, Round saws, Splitting and sizing machines, Polishers, Vibro screen (for<br />

sifting), Testing lab for quality of charcoal<br />

19 Automation in manufacturing process Y Mostly in the pulverizing and mixing of raw materials and for cutting, sizing of bamboo<br />

20 Means of communication Y Phone<br />

21 Methods of quality control Y Small lab for charcoal quality testing, otherwise none observed<br />

22 General observations Factory layout needs to be better, storage is haphazard, general lack of cleanliness<br />

23 Mode of selling product Y Wholesale only. Raw agarbattis supplied to buyers in Guwahati, Tejpur and Bangalore, Mathura<br />

24 <strong>Design</strong>ated marketing person / agency Y None mentioned<br />

25 Electricity Issues Y Fluctuating supply. Cited as inadequate to run machines regularly<br />

26 Raw material procurement Y Locally, or through agents<br />

27 Labour Y Cite shortage of skilled labour<br />

28 Space Y No shortage of space. However very poor planning and utilization of it.<br />

29 Government support Y None mentioned<br />

30 Mode of financing operations Y None mentioned<br />

31 Business development plans Y Interested in retail for domestic and export markets<br />

32<br />

Willingness to collaborate with designer +<br />

other units for future initiatives<br />

Y<br />

Interested in developing a brand identity and packaging. Mr.Kalita cites the requirement of a plan to launch a<br />

brand into domestic and international retail markets.<br />

33 General observations Very competitive market. In case of venturing into retail, will need to acquire know‐how for scenting processes