AR 2008-04-07 Programm GBR 2008 Version 003 ... - Albert Roller

AR 2008-04-07 Programm GBR 2008 Version 003 ... - Albert Roller

AR 2008-04-07 Programm GBR 2008 Version 003 ... - Albert Roller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

T o o l s a n d M a c h i n e s f o r P i p e W o r k i n g<br />

c o m p e t e n t • r e l i a b l e • f l e x i b l e

ROLLER - Strength through innovation<br />

ROLLER - Partner to the specialist dealers<br />

German Top Quality<br />

For over 100 years <strong>Albert</strong> <strong>Roller</strong> GmbH & Co KG has developed, manufactured<br />

and sold tools and machines for pipe machining and working. ROLLER<br />

products are used by craftsmen in trade and industry. The know-how acquired<br />

over generations, the decades of experience and, most particularly, the<br />

continual and intensive exchange of experience with the user, have led to the<br />

regular introduction of innovative products offering the customer cost and<br />

application advantages. For example the following:<br />

ROLLER'S Central - hand die stock,<br />

ROLLER'S King - electic die stock,<br />

ROLLER'S Fox ANC - electric reciprocating pipe saw,<br />

ROLLER'S Multi-Press - cordless radial press.<br />

ROLLER products are well known and highly valued on the market because<br />

of their robust construction, ease of handling, universal application and long<br />

life.<br />

The technically advanced and high quality products, the innovative<br />

marketing and the year-on-year consistent sales policy are decisive<br />

factors in the great success of the ROLLER products.<br />

ROLLER products are sold exclusively through specialist dealers. This partnership<br />

with specialist dealers and the blanket coverage network of qualified<br />

service workshops guarantee the user specialist professional advice, fast<br />

access to the ROLLER products and optimum service.<br />

ROLLER supports the specialist dealers in many ways. ROLLER specialists<br />

equipped with demonstration vehicles promote the ROLLER products to the<br />

user in local visits, counter displays and presentations.<br />

ROLLER product presentation walls set up in the sales rooms of the specialist<br />

stockists also offer the user the possibility of obtaining an overview of the<br />

very extensive range of products and detailed information on the ROLLER<br />

programme.<br />

ROLLER - A pinnacle of German quality<br />

The bedrock of the renowned peak quality of ROLLER products is the ROL-<br />

LER comprehensive quality assurance system, which starts as soon as a<br />

requirement is found in the market<br />

and accompanies the product<br />

right through development<br />

and fabrication and continues<br />

with a systematic analysis of<br />

quality when the product is on<br />

the market.<br />

These "Top quality" German<br />

ROLLER products are manufactured<br />

at Waiblingen, near<br />

Stuttgart, by highly qualified<br />

employees in computer-controlled,<br />

fully automatic and high-precision<br />

production centres.<br />

The quality controls are systematically integrated in the production and<br />

assembly processes. The most modern test methods, which are carried out<br />

by specially trained employees, guarantee the consistent achievement of<br />

"Peak German quality" throughout the ROLLER product range.<br />

All ROLLER products satisfy the relevant up-to-date European standards, in<br />

accordance with the EU directives and also fulfil the safety and accident prevention<br />

requirements. The CE symbol indicates the compliance of the product<br />

with the applicable EU<br />

directives. Many of the ROL-<br />

LER products are also tested<br />

and approved by independent<br />

test centres, e.g. the technical<br />

monitoring body (TÜV). These<br />

ROLLER products carry the<br />

GS safety symbol and satisfy a<br />

particularly high standard of<br />

work, operating and functional<br />

safety.<br />

ROLLER - Online<br />

At www.albert-roller.de you will<br />

quickly find detailed information<br />

on ROLLER and its products. An<br />

online catalogue provides comprehensive<br />

coverage of the<br />

ROLLER products and applications,<br />

as well as the E-mail<br />

addresses of the appropriate<br />

ROLLER contacts. The user also<br />

has access to extensive download<br />

options, e.g. operating instructions, parts lists,<br />

catalogue extracts, etc.<br />

Promotion in<br />

the relevant<br />

specialist<br />

journals and<br />

magazines<br />

and direct<br />

mailing facilities<br />

are also<br />

much valued<br />

by the stokkists<br />

as sales promotion initiatives.<br />

Then, in addition, the ROLLER<br />

products are exhibited in modern<br />

style on the stands of many<br />

regional and national exhibitions<br />

and also abroad, where they are<br />

presented to the public by qualified<br />

specialists.<br />

We deliver exclusively on the basis of our general conditions of sale and delivery.<br />

The prices stated in this catalogue are valid for one piece respectively for one set (e.g. dies)<br />

or one pack (e.g. saw blades). Prices do not include any value added tax (VAT) and are subject<br />

to change without notice. These prices supersede all previous prices.<br />

Drawings, illustrations, dimensions, weights, standards and other data stated in this catalogue<br />

are not binding and are subject to alteration. All power data stated to be understood as<br />

the rated power input. Subject to alteration.<br />

All rights reserved, particularly for translations, reproductions, illustrations, radio transmission,<br />

photomechanic reproductions or similar and storage of data in computers, including<br />

utilization in extracts.<br />

© Copyright <strong>2008</strong> <strong>Albert</strong> ROLLER GmbH & Co KG, Waiblingen.<br />

Sale through specialist dealers.<br />

2

ROLLER’S Robot 2<br />

Robust, powerful threading machine for pipe threads 1 /16–2” (4”), 16–63 mm,<br />

bolt threads 6–60 mm. • Only 1 universal automatic die head from 1 /16–2” for all<br />

threads. • Simple and fast change of dies through lock-in positioning. • Proven<br />

quick-action hammer chuck. • Robust, maintenance-free gear. • Choice of 3<br />

powerful motors. Universal motor 230 V, 1700 W, 53 rpm; Capacitor motor 230 V,<br />

2100 W, 52/26 rpm, very quiet running; Induction motor 400 V, 2000 W, 52/26 rpm,<br />

very quiet running. • Automatic lubrication and cooling. • For work bench, stand or<br />

wheel stand.<br />

German Top Quality<br />

Stands (Accessories)<br />

ROLLER’S Robot 2 L<br />

Art.-No.<br />

Machine complete with dies BSPT 1 /2–2”.<br />

Light version with removable oil basin and chip tray.<br />

U with universal motor 340226<br />

K with capacitor motor 340227<br />

D with induction motor 340228<br />

ROLLER’S Robot 2<br />

Machine complete with dies BSPT 1 /2–2”.<br />

With integrated, very large oil basin and chip tray.<br />

U with universal motor 340220<br />

K with capacitor motor 340221<br />

D with induction motor 340222<br />

Accessories:<br />

Stand 344105<br />

Wheel stand with material support 344100<br />

ROLLER’S Robot 4<br />

German Top Quality<br />

Stands (Accessories)<br />

Robust, powerful threading machine for pipe threads 1 /4–4”, 16–63 mm, bolt<br />

threads 14–60 mm. • Only 1 universal automatic die head from 1 /4 –2” and 1 from<br />

2 1 /2–4” for all threads. • Exceptionally round and clean threads up to 4” by using 6<br />

threading dies. • Simple and fast change of dies through lock-in positioning.<br />

• Proven quick-action hammer chuck • Robust, maintenance-free gear. • Choice<br />

of 3 powerful motors: Universal motor 230 V, 1700 W, 23 rpm; Capacitor motor<br />

230 V, 2100 W, 20/10 rpm, very quiet running; Induction motor 400 V, 2000 W,<br />

20/10 rpm, very quiet running. • Automatic lubrication and cooling. • For work<br />

bench, stand or wheel stand.<br />

ROLLER’S Robot 4 L<br />

Art.-No.<br />

Machine complete with dies. Light version with<br />

removable large oil basin and chip tray.<br />

U with universal motor Equipment 1 /2 –2” 38<strong>04</strong>47<br />

Equipment 2 1 /2 –4” 38<strong>04</strong>41<br />

Equipment 1 /2 –4” 38<strong>04</strong>44<br />

K with capacitor motor Equipment 1 /2 –2” 38<strong>04</strong>48<br />

Equipment 2 1 /2 –4” 38<strong>04</strong>42<br />

Equipment 1 /2 –4” 38<strong>04</strong>45<br />

D with induction motor Equipment 2 1 /2 –4” 38<strong>04</strong>43<br />

Equipment 1 /2 –4” 38<strong>04</strong>46<br />

ROLLER’S Robot 4<br />

Machine complete with dies. With integrated, very large<br />

oil basin and chip tray.<br />

U with universal motor Equipment 2 1 /2 –4” 38<strong>04</strong>26<br />

Equipment 1 /2 –4” 38<strong>04</strong>29<br />

K with capacitor motor Equipment 2 1 /2 –4” 38<strong>04</strong>27<br />

Equipment 1 /2 –4” 38<strong>04</strong>30<br />

D with induction motor Equipment 2 1 /2 –4” 38<strong>04</strong>28<br />

Equipment 1 /2 –4” 38<strong>04</strong>31<br />

Accessories:<br />

Stand 344105<br />

Wheel stand with material support 344100<br />

ROLLER’S<br />

4” automatic die head<br />

Threading attachment for pipe threads 2 1 /2–4”. • Electric drive through<br />

ROLLER’S Robot 2, ROLLER’S Rola 2 1 /2 or others. • Excellent threads up to 4”<br />

thanks to 5 threading dies and stepless automatically opening die head. • High<br />

cutting speed, no time consuming reverse. • For automatic lubrication and cooling.<br />

ROLLER’S 4” automatic die head<br />

Art.-No.<br />

Complete with dies BSPT 2 1 /2”, 3”, 4”,<br />

chuck, gear 370002<br />

Accessories:<br />

Drive shaft fits to ROLLER’S Robot 2 846<strong>07</strong>0<br />

Drive shaft fits to ROLLER’S Rola 21/2 830<strong>07</strong>0<br />

German Top Quality<br />

Dies see page 6.<br />

3

ROLLER’S Rola 2 1 /2<br />

Robust, professional threading machine for pipe threads 1 /8–2 1 /2” (4”), bolt<br />

threads 10–39 mm. • Operating principle: stationary material - rotating die head.<br />

For secure threading also on pre-mounted resp. bent material. • Optional circular<br />

metal saw ROLLER'S Filou for right angle and rapid sawing of pipes, bars and strut.<br />

• Universal prismatic vice for secure clamping of material. • Robust, maintenancefree<br />

gear. • Choice of 3 powerful motors. Universal motor 230 V, 1700 W, 23 rpm;<br />

Capacitor motor 230 V, 2100 W, 20/10 rpm, very quiet running; Induction motor<br />

400 V, 2000 W, 20/10 rpm, very quiet running. • Automatic lubrication and cooling.<br />

• For work bench, stand or wheel stand.<br />

ROLLER’S Rola 2 1 /2 Sk<br />

Art.-No.<br />

Machine complete with quick-change die heads<br />

BSPT 1 /2–2”, integrated, very large oil basin and chip tray.<br />

U with universal motor 830320<br />

K with capacitor motor 830321<br />

D with induction motor 830322<br />

ROLLER’S Rola 2 1 /2 Sk-S<br />

Machine complete with quick-change die heads<br />

BSPT 1 /2–2”, integrated, very large oil basin and<br />

chip tray. Metal saw ROLLER’S Filou, without saw blade.<br />

U with universal motor 830310<br />

K with capacitor motor 830311<br />

D with induction motor 830312<br />

Stands (Accessories)<br />

German Top Quality<br />

Accessories:<br />

Stand 344105<br />

Wheel stand with material support 344100<br />

Circular metal saw ROLLER’S Filou with universal motor<br />

1200 W, 115 rpm, with saw bearing, without saw blade 849<strong>003</strong><br />

ROLLER’S circular saw blade HSS<br />

225x2x32, 120 teeth 849700<br />

Die heads and dies see page 6.<br />

ROLLER’S Rubinol / Smaragdol<br />

Synthetic, mineral oil free thread-cutting oil. Specially for drinking water<br />

supplies. • Completely water soluable. • Approved by DVGW, ÖVGW, SVGW.<br />

ROLLER’S Rubinol 2000<br />

Art.-No.<br />

Spray 600 ml 140115<br />

Squirt bottle 500 ml, refillable 140116<br />

Can 5 l 140110<br />

Barrel 55 l 140113<br />

High-alloyed mineral based thread-cutting oil. • Can be washed out with water.<br />

• For drinking water supplies, comply with local regulations! In AUT, CHE, DEU,<br />

DNK not permitted for drinking water supplies.<br />

ROLLER’S Rubinol 2000<br />

ROLLER’S Smaragdol<br />

Art.-No.<br />

Spray 600 ml 140105<br />

DW-0201AS2031<br />

9009-2496<br />

W 1.015<br />

German Top Quality<br />

Can 5 l 140100<br />

Barrel 55 l 140103<br />

Accessories for ROLLER’S Robot 2 and 4:<br />

ROLLER’S Spannfix<br />

Accessories for ROLLER’S Central, ROLLER’S King 1 1 /4, ROLLER’S King 2,<br />

ROLLER’S Rola 2 1 /2, ROLLER’S Robot 2 and 4:<br />

ROLLER’S Nipparo<br />

Automatic pipe nipple chuck Ø 1 /2–4”. • For nipples and double nipples.<br />

• For threading machines with opening die head. • Automatic quick-chuck..<br />

• Production of nipples possible. • For right-hand threads.<br />

Art.-No.<br />

1<br />

/2” 111000<br />

3<br />

/4” 111100<br />

1” 111200<br />

1 1 /4” 111300<br />

1 1 /2” 111400<br />

2” 111500<br />

2 1 /2” 111700<br />

3” 111800<br />

4” 111900<br />

German<br />

Top Quality<br />

Manual pipe nipple chuck Ø 3 /8–2”. • For nipples and double nipples.<br />

• To be used universally for threading machines and die stocks .<br />

• Manual internal clamping. • For right-hand and left-hand threads.<br />

Art.-Nr.<br />

3<br />

/8” 110000<br />

1<br />

/2” 110100<br />

3<br />

/4” 110200<br />

1” 110300<br />

1 1 /4” 11<strong>04</strong>00<br />

1 1 /2” 110500<br />

2” 110600<br />

Steel case ROLLER’S Nipparo 110800<br />

German<br />

Top Quality<br />

4

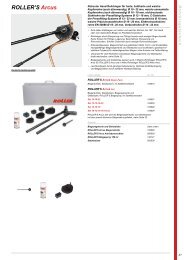

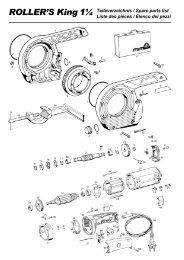

ROLLER’S King 1 1 /4<br />

only 4.5 kg<br />

Compact, powerful, handy electric die stock for pipe threads 1 /8 –1 1 /4”, 16–40 ,<br />

bolt threads 10–30 mm. • Easy, fast change of quick-change die heads.<br />

• Unique locking of quick-change die heads onto the drive unit, thus secure seating<br />

during start-cutting. • Proven, powerful universal motor 230 V, 1200 W, with 30 %<br />

power increase thanks to automatic carbon brush adjustment. • Robust, maintenance-free<br />

gear, specially designed for ideal power transmission. • Automatically<br />

opening quick-change die heads Rola Automatik (accessory) - no reverse, 50% time<br />

savings, always standard threads.<br />

ROLLER’S King 1 1 /4 Set C<br />

Art.-No.<br />

Drive unit, support bracket, quick-change die heads<br />

Central , in steel case<br />

Set BSPT 1 /2”, 3 /4”, 1”, 1 1 /4” 847301<br />

Set M 20, M 25, M 32, M 40 (Mx1,5)<br />

for threading electric conduit DIN EN 6<strong>04</strong>23 847306<br />

ROLLER’S King 1 1 /4 Set A/C<br />

Drive unit, support bracket, quick-change die heads<br />

Rola Automatik BSPT 1 /2”, 3 /4”, Central BSPT 1”, 1 1 /4”,<br />

in steel case 847313<br />

Die heads and dies see page 6.<br />

German Top Quality<br />

ROLLER’S King 2<br />

Compact, powerful, handy electric die stock for pipe threads 1 /8 –2”, 16–50<br />

mm, bolt threads 10–39 mm. • Easy, fast change of quick-change die heads and<br />

adapter. • Unique locking of quick-change die heads onto the drive unit, thus secure<br />

seating during start-cutting. • Proven, powerful universal motor 230 V, 1200 W,<br />

with 30 % power increase thanks to automatic carbon brush adjustment. • Robust,<br />

maintenance-free gear, specially designed for ideal power transmission.<br />

• Automatically opening quick-change die heads Rola Automatik (accessory) - no<br />

reverse, 50% time savings, always standard threads.<br />

ROLLER’S King 2 Set C<br />

Art.-No.<br />

Drive unit, support bracket, adapter, quick-change die heads<br />

Central, in steel case<br />

Set BSPT 1 /2”, 3 /4”, 1”, 1 1 /4” 850303<br />

Set BSPT 1 /2”, 3 /4”, 1”, 1 1 /4”, 1 1 /2”, 2”, 850301<br />

Set M 20, M 25, M 32, M 40, M 50 (M x 1,5)<br />

for threading electric conduit DIN EN 6<strong>04</strong>23 850306<br />

only 5.7 kg<br />

ROLLER’S King 2 Set A/C<br />

Drive unit, support bracket, adapter, quick-change die heads<br />

Rola Automatik BSPT 1 /2”, 3 /4”, 1”, Central<br />

BSPT 1 1 /4”, 1 1 /2”, 2”, in steel case 850312<br />

Die heads and dies see page 6.<br />

German Top Quality<br />

ROLLER’S Central<br />

Proven, robust hand die stock for pipe threads 1 /8–2”, 16–50 mm, bolt threads<br />

6–39 mm. • Extra slim design of ratchet head for working in confined areas.<br />

• Easy, fast change of quick-change die heads. • Unique locking of quick-change<br />

die heads onto the ratchet lever, thus secure seating during start-cutting. • Twopiece<br />

tubular arm for short ratchet travel and reduced lever length. • Precise, proven,<br />

robust quick-change die heads. • Proven quality dies in special-grade steel.<br />

• Manually opening quick-change die heads Rola H (accessory) - no reverse, 50%<br />

time savings.<br />

ROLLER’S Central Set<br />

Art.-No.<br />

Ratchet lever, quick-change die heads, in steel case.<br />

Set BSPT 3 /8”, 1 /2”, 3 /4”, 1”, 1 1 /4” 479012<br />

Set BSPT 1 /2”, 3 /4”, 1”, 1 1 /4” 479015<br />

Set BSPT 1 /2”, 3 /4”, 1”, 1 1 /4”, 1 1 /2”, 2” 479017<br />

Set M 20, M 25, M 32, M 40 (M x 1,5)<br />

for threading electric conduit DIN EN 6<strong>04</strong>23 479018<br />

Additional sets available.<br />

German Top Quality<br />

Accessories:<br />

Ratchet lever ROLLER’S Central 1 /8 –1 1 /4” 479092<br />

Ratchet lever ROLLER’S Central 1 1 /2 –2” 479093<br />

Die heads and dies see page 6.<br />

5

Accessories for ROLLER’S Central, ROLLER’S<br />

King 1 1 /4, ROLLER’S King 2, ROLLER’S Rola 2 1 /2:<br />

Quick-change die heads<br />

ROLLER’S Central<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

R 1 /8” 479200<br />

R 1 /4” 479201<br />

R 3 /8” 479202<br />

R 1 /2” 479203<br />

R 3 /4” 4792<strong>04</strong><br />

R 1” 479205<br />

R 1 1 /4” 479206<br />

R 1 1 /2” 4793<strong>07</strong><br />

R 2” 479308<br />

Pipe threads tapered, right-hand<br />

Taper Pipe Thread ASME B 1.20.1<br />

NPT 1 /8” 479220<br />

NPT 1 /4” 479221<br />

NPT 3 /8” 479222<br />

NPT 1 /2” 479223<br />

NPT 3 /4” 479224<br />

NPT 1” 479225<br />

NPT 1 1 /4” 479226<br />

NPT 1 1 /2” 479327<br />

NPT 2” 479328<br />

Conduit threads DIN EN 6<strong>04</strong>23<br />

M 16 x 1,5 479240<br />

M 20 x 1,5 479241<br />

M 25 x 1,5 479242<br />

M 32 x 1,5 479243<br />

M 40 x 1,5 479244<br />

M 50 x 1,5 479245<br />

Quick-change die heads<br />

ROLLER’S Rola Automatik<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

R 3 /8” 469102<br />

R 1 /2” 469103<br />

R 3 /4” 4691<strong>04</strong><br />

R 1” 469105<br />

R 1 1 /4” 469106<br />

R 1 1 /2” 4692<strong>07</strong><br />

R 2” 469208<br />

R 2 1 /2” 830350<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

in HSS for machining high strength materials<br />

R 1 /2” 469153<br />

R 3 /4” 469154<br />

R 1” 469155<br />

R 1 1 /4” 469156<br />

R 1 1 /2” 469157<br />

R 2” 469158<br />

Quick-change die heads<br />

ROLLER’S Rola H<br />

Metric bolt threads M Art.-No<br />

ISO 261 (DIN 13)<br />

M 22 459168<br />

M 24 459169<br />

M 27 459170<br />

M 30 459171<br />

M 33 459172<br />

M 36 459173<br />

M 39 459174<br />

Quick-change die heads for left-hand threads<br />

on request.<br />

Dies for ROLLER’S Central, ROLLER’S King 1 1 /4,<br />

ROLLER’S King 2, ROLLER’S Rola 2 1 /2, ROLLER’S<br />

Robot 2 and 4:<br />

Dies ROLLER’S Central<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

R 1 /8” 479400<br />

R 1 /4” 479401<br />

R 3 /8” 479402<br />

R 1 /2” 479403<br />

R 3 /4” 4794<strong>04</strong><br />

R 1” 479405<br />

R 1 1 /4” 479406<br />

R 1 1 /2” 4794<strong>07</strong><br />

R 2” 479408<br />

Pipe threads tapered, right-hand<br />

Taper Pipe Thread ASME B 1.20.1<br />

NPT 1 /8” 479420<br />

NPT 1 /4” 479421<br />

NPT 3 /8” 479422<br />

NPT 1 /2” 479423<br />

NPT 3 /4” 479424<br />

NPT 1” 479425<br />

NPT 1 1 /4” 479426<br />

NPT 1 1 /2” 479427<br />

NPT 2” 479428<br />

Conduit threads DIN EN 6<strong>04</strong>23<br />

M 16 x 1,5 521302<br />

M 20 x 1,5 521312<br />

M 25 x 1,5 521322<br />

M 32 x 1,5 521332<br />

M 40 x 1,5 521342<br />

M 50 x 1,5 521352<br />

Dies ROLLER’S Rola<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

R 3 /8” 459402<br />

R 1 /2” 459403<br />

R 3 /4” 4594<strong>04</strong><br />

R 1” 459405<br />

R 1 1 /4” 459406<br />

R 1 1 /2” 4594<strong>07</strong><br />

R 2” 459408<br />

R 2 1 /2” 83<strong>04</strong>00<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

in HSS for machining high strength materials<br />

R 1 /2” 459453<br />

R 3 /4” 459454<br />

R 1” 459455<br />

R 1 1 /4” 459456<br />

R 1 1 /2” 459457<br />

R 2” 459458<br />

Dies ROLLER’S Robot<br />

Art.-No.<br />

Pipe threads tapered, right-hand<br />

ISO 7-1, DIN EN 10226 (DIN 2999, BSPT)<br />

R 1 /16 – 1 /8” 341401<br />

R 1 /4 – 3 /8” 341402<br />

R 1 /2 – 3 /4” 341403<br />

R 1–2” 3414<strong>04</strong><br />

R 2 1 /2 –4” 381401<br />

Pipe threads tapered, right-hand<br />

Taper Pipe Thread ASME B 1.20.1<br />

NPT 1 /16 – 1 /8” 341411<br />

NPT 1 /4 – 3 /8” 341412<br />

NPT 1 /2 – 3 /4” 341413<br />

NPT 1–2” 341414<br />

NPT 2 1 /2 –4” HSS* 381410<br />

Pipe threads parallel, right-hand<br />

ISO 228-1 (DIN 259, BSPP<br />

G 1 /16 – 1 /8” 341406<br />

G 1 /4 – 3 /8” 3414<strong>07</strong><br />

G 1 /2 – 3 /4” 341408<br />

G 1–2” 341409<br />

G 2 1 /2 –4” HSS* 381405<br />

Metric bolt threads M ISO 261 (DIN 13)<br />

M 6 341426<br />

M 8 341427<br />

M 10 341428<br />

M 12 341429<br />

M 14 341430<br />

M 16 341431<br />

M 18 341432<br />

M 20 341433<br />

M 22 341434<br />

M 24 341435<br />

M 27 341436<br />

M 30 341437<br />

M 33 341438<br />

M 36 341439<br />

M 39 341440<br />

M 42 341441<br />

M 45 341442<br />

M 48 341443<br />

M 52 341444<br />

M 56 HSS* 341445<br />

M 60 HSS* 341446<br />

Conduit threads DIN EN 6<strong>04</strong>23<br />

M 16 x 1,5 341493<br />

M 20 x 1,5 341494<br />

M 25 x 1,5 341495<br />

M 32 x 1,5 341496<br />

M 40 x 1,5 341497<br />

M 50 x 1,5 341498<br />

M 63 x 1,5 341499<br />

Dies for other threads on request. Dies in HSS for<br />

machining high strength materials 50 % extra<br />

charge. * Some dies only available in HSS<br />

Metric bolt threads M Art.-No<br />

ISO 261 (DIN 13)<br />

M 10 459162<br />

M 12 459163<br />

M 14 459164<br />

M 16 459165<br />

M 18 459166<br />

M 20 459167<br />

Metric bolt threads M ISO 261 (DIN 13)<br />

M 10 459462<br />

M 12 459463<br />

M 14 459464<br />

M 16 459465<br />

M 18 459466<br />

M 20 459467<br />

M 22 459468<br />

M 24 459469<br />

M 27 459470<br />

M 30 459471<br />

M 33 459472<br />

M 36 459473<br />

M 39 459474<br />

6

ROLLER’S<br />

Robot RG/roll grooving attachment<br />

Proven, powerful roll grooving machine for steel pipes and others<br />

DN 25–200 (300), Ø 1–8” (12”), s ≤ 7 mm. • Proven, powerful drive unit with<br />

robust, compact roll grooving attachment (as described below). • Robust, maintenance-free<br />

gear. • Choice of 3 powerful motors: Universal motor 230 V, 1700 W,<br />

53 rpm; Capacitor motor 230 V, 2100 W, 52/26 rpm, very quiet running; Induction<br />

motor 400 V, 2000 W, 52/26 rpm, very quiet running. • For work bench, stand or<br />

wheel stand.<br />

ROLLER’S Robot RG<br />

Art.-No.<br />

Machine complete with roll grooving attachment<br />

(supply format as described below).<br />

U with univeral motor 340230<br />

K with capacitor motor 340231<br />

D with induction motor 340232<br />

German Top Quality<br />

Stand (Accessory)<br />

see page 3.<br />

Robust, compact roll grooving attachment for steel pipes and others<br />

DN 25–200 (300), Ø 1–8” (12”), s ≤ 7 mm. • Oil hydraulic pressure cylinder for<br />

powerful forward feed. • Built-in ring gauge for automatic groove depth stop.<br />

• Grooving rollers easily interchangeable.<br />

ROLLER’S roll grooving attachment<br />

Art.-No.<br />

Complete with hydraulic hand pump and 1 set of grooving<br />

rollers (pressure roller, counterpressure roller) 2–6”.<br />

fits to ROLLER’S Robot 347000<br />

R 300 fits to Ridgid 300 347001<br />

R 535 fits to Ridgid 535 347002<br />

N80A fits to Rothenberger/Rex N80A 347<strong>003</strong><br />

Delta 4 fits to Rex Delta 4 3470<strong>04</strong><br />

Accessories:<br />

Grooving rollers 1–1 1 /2” (set) 347030<br />

Grooving rollers 2– 6” (set) 347035<br />

Grooving rollers 8–12” (set) 347<strong>04</strong>0<br />

Grooving rollers Cu 54–159 (set)<br />

for Cu pipes 347034<br />

ROLLER’S Filou K<br />

ROLLER’S reciprocating saws<br />

Compact, powerful reciprocating pipe saw for steel pipes and others up to<br />

Ø 6”, 160 mm, metal strut, wood with nails, pallets, up to 250 mm.<br />

• Special high sliding silicone gasket protects gear against water and dust.<br />

• Ergonomically shaped front housing grip with slip resistant, heat insulating protection<br />

cover with soft grip, for forceful in-feed.<br />

German Top Quality<br />

only 2.4 kg<br />

ROLLER’S Mamba ANC VE<br />

• Compact universal electric reciprocating saw for free hand sawing. • Super<br />

handy, super light, particularly small, length only 32 cm. • Proven, powerful<br />

universal motor 500 W. • Proven, ergonomically shaped pistol grip with built-in<br />

safety tip switch. • Vario-electronic. Stepless speed control of drive unit for sensitive<br />

start-sawing and for stroke selection during sawing according to the material. Cutting<br />

speed from 0 to 2200 rpm.<br />

ROLLER’S Mamba ANC VE<br />

Art.-No.<br />

Drive unit with vario-electronic,<br />

special saw blade 150 mm, in cardboard box 560025<br />

only 3.0 kg<br />

ROLLER’S Carat ANC VE<br />

• Compact, powerful universal electric reciprocating saw for free hand sawing.<br />

• Proven, powerful universal motor 1050 W. • Proven, ergonomically D-shaped<br />

handle with built-in safety tip switch. • Vario-electronic. Stepless speed control<br />

of drive unit for sensitive start-sawing and for stroke selection during sawing<br />

according to the material. Cutting speed from 0 to 2200 rpm.<br />

ROLLER’S Carat ANC VE<br />

Art.-No.<br />

Drive unit with vario-electronic,<br />

special saw blade 150 mm, in cardboard box 56<strong>003</strong>0<br />

only 3.0 kg<br />

ROLLER’S Fox ANC<br />

• Compact, powerful electric reciprocating pipe saw for right angle cuts with unique<br />

guide support and special saw blades. Also for free hand sawing. • Proven, powerful<br />

universal motor 1050 W, with safety tip switch and thermal overload protection.<br />

• Ideal Speed. Deliberately fixed stroke. Therefore optimum cutting speed for maximum<br />

protection of motor and gear and maximum service life of saw blades. Cutting<br />

speed 2200 rpm.<br />

ROLLER’S Fox ANC Set<br />

Art.-No.<br />

Drive unit, guide support up to 2”,<br />

2 special saw blades 2”, in steel case 560020<br />

only 3.0 kg<br />

ROLLER’S Fox ANC VE<br />

• Compact, powerful electric reciprocating pipe saw for right angle cuts with unique<br />

guide support and special saw blades. Also for free hand sawing. • Proven, powerful<br />

universal motor 1050 W, with safety tip switch. • Vario-Electronic. Stepless speed<br />

control of drive unit for sensitive start-sawing and for stroke selection during sawing<br />

according to the material. Cutting speed from 0 to 2200 rpm.<br />

ROLLER’S Fox ANC VE Set<br />

Art.-No.<br />

Drive unit with vario-electronic, guide support up to 2”,<br />

2 special saw blades 2”, in steel case 560027<br />

only 3.1 kg<br />

ROLLER’S Fox ANC SR<br />

• Compact, powerful electric reciprocating pipe saw for right angle cuts with unique,<br />

patented guide support (Patent DE 3448276) and special saw blades. Also for free<br />

hand sawing. • Proven, powerful universal motor 1400 W, with safety tip switch.<br />

• Speed-regulation. The number of strokes is steplessly adjustable on the dial with 6<br />

locking positions from 700 to 2200 rpm. The electronic speed control which is being<br />

used keeps the selected speed constant, also under load, including speed generator,<br />

control electronics, residual current limitation for sensitive start-sawing, motor temperature<br />

control of field wires by PTC resistance (Positive Temperature Coefficient) and<br />

stall protection of gear and motor.<br />

ROLLER’S Fox ANC SR Set<br />

Art.-No.<br />

Drive unit with speed regulation, guide support up to 2”,<br />

2 special saw blades 2”, in steel case 560026<br />

Accessories:<br />

ROLLER’S guide support up to 4” 563100<br />

8

ROLLER’S reciprocating saws<br />

aggressive–powerful–rapid!<br />

6<br />

4<br />

7<br />

8<br />

5<br />

3<br />

2<br />

1<br />

German Top Quality<br />

1<br />

New type, super stable oscillating gear enables a simultaneous<br />

generation of saw and orbital stroke of lift rod and saw blade.<br />

Allround needle bearing mounted crank drive (ANC) reduces<br />

friction, heat generation, wear. Thus long service life also at<br />

extreme sawing.<br />

5<br />

Aggressive orbital action provides forceful, fast in-feed, excellent<br />

chip flow and long service life of saw blades. Fixed orbital action,<br />

running in needle bearings, ensures long-lasting and forceful<br />

sawing also during extreme load conditions, e.g. sawing of steel<br />

pipe.<br />

2<br />

Ergonomically shaped front housing grip with slip resistant, heat<br />

insulating protection cover with soft grip, for forceful in-feed<br />

6<br />

Universal saw blade clamp for mounting all saw blades – with<br />

universal or double tang – without changing or turning the saw<br />

blade thrust piece.<br />

3<br />

Unique guide support with 5-fold leverage for 400% additional<br />

sawing force enables effortless, super fast and right angle<br />

sawing. Easy and rapid to operate. For assembly and<br />

dismantling.<br />

7<br />

Sturdy, square lift rod in special solid steel, mounted precisely in<br />

needle bearings for distortion-free, precise cutting also during<br />

tough use and by applying multiple sawing force, e.g. using a<br />

guide support with leverage. For extremely long service life.<br />

4<br />

Special high sliding silicone gasket protects gear against water<br />

and dust.<br />

8<br />

Proven, powerful universal motor with ample reserve capacity.<br />

ROLLER’S special saw blades<br />

Special saw blade for right angle sawing with guide support. For ROLLER’S<br />

Fox ANC / VE / SR and other makes. • Extra thick, resistant to bending and distorsion,<br />

exceptionally wide clamping face. • Coarse, corrugated tooth pattern.<br />

Description Length Tooth Material Art.-No.<br />

pitch Pack of 5<br />

2” for steel pipes 140 mm 3,2 mm HSS-Bi 561001<br />

4” for steel pipes 200 mm 3,2 mm HSS-Bi 561002<br />

2,5 mm 1,8 mm<br />

Special saw blade for free hand sawing. For all ROLLER’S reciprocating saws<br />

and other makes. • With combo-toothing, flexible, exceptionally wide clamping<br />

face. • Universal, instead of many different saw blades.<br />

Combo-toothing<br />

Description Length Tooth Material Art.-No.<br />

pitch Pack of 5<br />

German Top Quality<br />

flexible<br />

150 universal 150 mm 1,8/2,5mm HSS-Bi 561005<br />

200 universal 200 mm 1,8/2,5mm HSS-Bi 561<strong>003</strong><br />

300 universal 300 mm 1,8/2,5mm HSS-Bi 5610<strong>04</strong><br />

ROLLER’S saw blades<br />

Saw blade for free hand sawing. For all ROLLER’S reciprocating saws and<br />

other makes.<br />

German Top Quality<br />

Description Length Tooth Material Art.-No.<br />

pitch Pack of 5<br />

Metals 3 mm and thicker 100 mm 1,8 mm HSS-Bi 561101<br />

Metals 3 mm and thicker 150 mm 1,8 mm HSS-Bi 561103<br />

Metals 3 mm and thicker 200 mm 1,8 mm HSS-Bi 561102<br />

Metals 1–3 mm 150 mm 1,4 mm HSS-Bi 5611<strong>04</strong><br />

Metals 1–3 mm<br />

for curved cuts 90 mm 1,4 mm HSS-Bi 5611<strong>07</strong><br />

Metals 4 mm and thicker,<br />

nail-embedded wood 150 mm 2,5 mm HSS-Bi 561110<br />

All types of woods 300 mm 4,0 mm WS 561111<br />

Plasterboards, breeze blocks 150 mm 5,0 mm WS 561115<br />

9

ROLLER’S Arco 50<br />

Patent DE 39 03 <strong>04</strong>1<br />

Patent US 5,056,347<br />

Powerful, robust electric pipe and tube bender for steel pipes DIN EN 10255<br />

(DIN 2440) Ø 1 /4 –1 1 /4”, hard, half-hard and soft copper tubes, also thin-wall,<br />

Ø 10–42 mm, stainless steel tubes of pressfitting systems Ø 12–42 mm,<br />

composite tubes 14–50 mm, coated c-steel pipes of pressfitting systems<br />

Ø 12–28 mm, soft precision steel tubes Ø 10–30 mm, conduit DIN EN 50086<br />

Ø 16–32 mm, and others. • For cold bending of hard, half-hard and soft pipes and<br />

tubes, up to 90°. • Bender cost recovered after a small number of bends. • Simple,<br />

effortless, fast working. • Fast and creep speed operation and angle scale provided<br />

on each bending former ensure precise bending. Swan-neck, U-bends possible.<br />

• With integral absorbtion of torque during bending (Patent DE 39 03 <strong>04</strong>1, Patent US<br />

5,056,347). • Robust, maintenance-free gear with safety slipping clutch. • Proven,<br />

powerful universal motor 1000 W, with 30 % power increase thanks to automatic<br />

carbon brush adjustment. With stepless electronic safety switch. • Bending formers<br />

and back formers ROLLER’S Arco 50 (Ø 35 R100 to Ø 50 R140): Form and pressure<br />

resistant bending formers in ductile iron.<br />

ROLLER’S Arco 50 Basic-Pack<br />

Art.-No.<br />

Drive unit, adaptor block 35–50, support 35–50,<br />

insert bolt, in steel case 580110<br />

German Top Quality<br />

Accessories:<br />

Bending former and back former Ø 35 R 100 581500<br />

Ø 42 R 140 581510<br />

Ø 50 R 140 581540<br />

Ø 1” R 100 581520<br />

Ø 1 1 /4” R 140 581530<br />

Adaptor block 10–40, Support 10–40,<br />

for bending formers and back formers ROLLER’S Arco 582120<br />

Steel case with insert<br />

for bending former and back former 586012<br />

ROLLER’S bending spray, 150 ml 140121<br />

ROLLER’S Arco<br />

German Top Quality<br />

Patent DE 39 03 <strong>04</strong>1<br />

Patent US 5,056,347<br />

Powerful, robust electric pipe and tube bender for hard, half-hard and soft<br />

copper tubes, also thin-wall, Ø 10–35 mm, 3 /8–1 1 /8”, coated soft<br />

copper tubes, also thin-wall, Ø 10–18 mm, stainless steel tubes of pressfitting<br />

systems Ø 12–28 mm, coated c-steel pipes of pressfitting systems<br />

Ø 12–28 mm, soft precision steel tubes Ø 10–30 mm, steel pipes DIN EN<br />

10255 (DIN 2440) Ø 1 /4– 3 /4”, conduit DIN EN 50086 Ø 16–32 mm, composite<br />

tubes Ø 14–40 mm, and others. • For cold bending of hard, half-hard and soft<br />

pipes and tubes, up to 180°. • Universal for many pipes and tubes. • Bender cost<br />

recovered after a small number of bends. • Simple, effortless, fast working.<br />

• Compact, handy, super light, drive unit only 8 kg (17.6 lbs). • Angle scale 0 to<br />

180°. • Fast and creep speed operation and angle scale provided on each bending<br />

former ensure precise bending. Swan-neck, U-bends possible. • With integral<br />

absorbtion of torque during bending (Patent DE 39 03 <strong>04</strong>1, Patent US 5,056,347).<br />

• Robust, maintenance-free gear with safety slipping clutch. • Proven, powerful<br />

universal motor 1000 W, with 30 % power increase thanks to automatic carbon<br />

brush adjustment. With stepless electronic safety switch.<br />

ROLLER’S Arco Basic-Pack<br />

Art.-No.<br />

Drive unit, insert bolt, in steel case 580010<br />

ROLLER’S Arco Set<br />

Drive unit, insert bolt, bending formers and back<br />

formers, in steel case.<br />

Set 15-18-22 580026<br />

Set 15-18-22-28 580027<br />

Set 15-22-28 580022<br />

Set 17-20-24 580023<br />

Set 12-14-16-18-22 580021<br />

Set 14-16-18-22-28 580028<br />

Set 3 /8- 1 /2- 5 /8- 3 /4- 7 /8” 580024<br />

Set 16-20-26-32 580025<br />

Set 20-25-32 580029<br />

Set 32-40 58<strong>003</strong>0<br />

ROLLER’S Arco Set is delivered with the smaller radius bending and back<br />

former (except 580029 and 58<strong>003</strong>0), see table page 11.<br />

3 B<br />

Accessories:<br />

Arco drive unit 580000<br />

ROLLER’S bending spray, 150 ml 140121<br />

Machine support 3 B, height adjustable on tripod 586100<br />

Machine support WB<br />

height adjustable, for mounting on work bench 586150<br />

Bending and back former see page 11.<br />

10

ROLLER’S Arcus<br />

German Top Quality<br />

Robust hand tube bender for hard, half-hard and soft copper tubes, also thinwall,<br />

Ø 10–22 mm, 3 /8– 7 /8”, coated soft copper tubes, also thin-wall, Ø 10–18<br />

mm, stainless steel tubes of pressfitting systems Ø 12–18 mm, coated c-steel<br />

pipes of pressfitting systems Ø 12–28 mm, soft precision steel tubes<br />

Ø 10–20 mm, conduit DIN EN 6<strong>04</strong>23 Ø 16–20 mm, composite tubes<br />

Ø 14–32 mm, and others. Up to 180°. • For cold bending of hard, half-hard and<br />

soft pipes and tubes, up to 180°. • Universal use, in parallel vice or free-hand as<br />

double-hand-bender. • Bender recovered after a few bends through savings on fittings.<br />

• Only one type of bending formers for ROLLER’S Arcus and ROLLER’S<br />

Arco. • Easy bending through long levers.<br />

ROLLER’S Arcus Set<br />

Art.-No.<br />

Bender drive, insert bolt, bending formers and back<br />

formers, ROLLER’S bending spray, in steel case.<br />

Set 15-18-22 154001<br />

Set 14-16-18 154002<br />

Set 10-12-14-16-18-22 1540<strong>04</strong><br />

ROLLER’S Polo<br />

German Top Quality<br />

Patent DE 38 03 128<br />

Robust, compact single-hand tube bender for soft copper tubes Ø 10–22 mm,<br />

3<br />

/8– 7 /8”, s ≤ 1 mm, coated soft copper tubes Ø 10–18 mm, 3 /8– 5 /8”, s ≤ 1 mm,<br />

coated c-steel pipes of pressfitting systems Ø 12–18 mm, soft precision steel<br />

tubes Ø 10–18 mm, s ≤ 1 mm, multi-layer composite tubes Ø 14–32 mm.<br />

• Only 1 bender drive for the complete work range up to Ø 32 mm. • Handy and<br />

light, only 1.3 kg (2.9 lbs). • Bender recovered after a few bends through savings<br />

on fittings. • Marked bending formers for exact bending • Fast operation through<br />

patented quick-acting feed forward and release (Patent DE 38 03 128).<br />

ROLLER’S Polo Set<br />

Art.-No.<br />

Up to Ø 26 mm with bender drive, bending formers,<br />

universal crossbar with sliding pieces, in steel case.<br />

Up to Ø 32 mm with bender drive, bending formers,<br />

2 universal crossbars with sliding pieces, in sturdy case.<br />

Set 12-15-18-22 ( 1 /2- 5 /8- 3 /4- 7 /8”) 153025<br />

Set 12-14-16-18-22 153020<br />

Set 14-16-18-20-25/26 153022<br />

Set Allround 10-12-14-15-16-17-18-20-22 ( 3 /8- 1 /2- 5 /8- 3 /4- 7 /8”) 153027<br />

Set 16-18-20-25/26-32 153023<br />

Set Allround 10-12-14-15-16-17-18-20-22-25/26-32 153028<br />

Crossbar for bending formers Ø 32 mm 153115<br />

Accessories for ROLLER’S Arco 50, ROLLER’S Arco and ROLLER’S Arcus:<br />

Bending and<br />

back former<br />

Suitable for<br />

Bending<br />

for tubes<br />

radius<br />

Ø mm /inch mm Art.-No.<br />

Cu<br />

Cu-U soft<br />

St 2463<br />

St 2394-U<br />

St 2391-2394<br />

St 10255<br />

St 50086<br />

V<br />

10 40 • • 581400<br />

12 45 • • • 581410<br />

14, 10 U, 1 /4 (DN 6) 50 • • • • • 581420<br />

15, 12 U 55 • • • • 581430<br />

16, 12 U 60 • • • • • 581440<br />

17, 15 U 56 • • 581110<br />

18, 14 U, 15 U, 3 /8 (DN 10) 70 • • • • • 581450<br />

20, 16 U, 18 U 75 • • • • • 581080<br />

22, 18 U, 1 /2 (DN 15) 77 • • • • • 581460<br />

22, 18 U, 1 /2 (DN 15) 88 • • • • 581470<br />

24, 22 U 75 • • 581130<br />

25 98 • • • • 581180<br />

26 98 • • 581270<br />

28, 3 /4 (DN 20) 102 1) • • • • 581<strong>07</strong>0<br />

28, 3 /4 (DN 20) 114 • • • • 581310<br />

30, 28 U 98 1) • • 581150<br />

32 98 • 581280<br />

32 114 • • 581320<br />

35 140 • 581350<br />

40 140 • 581330<br />

1) According to DVGW work sheet GW 392 minimum bending radius<br />

of 114 mm required for copper tubes Ø 28 mm.<br />

Cu:<br />

hard, half-hard, soft copper tubes, also thin-wall<br />

St 2463: stainless steel tubes of pressfitting systems DIN 2463<br />

St 2394-U: coated c-steel pipes of pressfitting systems DIN 2394<br />

St 2440: steel pipes (thread pipes) DIN 2440<br />

St 2391-2394: soft precision steel tubes DIN 2391–2394<br />

St 50086: conduit DIN EN 50086<br />

U: coated<br />

V: multi-layer composite tubes of pressfitting systems<br />

Accessories for ROLLER’S Polo:<br />

Bending formers<br />

Suitable for<br />

Bending<br />

for tubes<br />

radius<br />

Ø mm /inch mm Art.-No.<br />

10, 3 /8 30 • • 153155<br />

12, 10 U, 1 /2 36 • • • 153160<br />

14, 12 U 50 • • • • 153170<br />

15, 12 U, 5 /8 55 • • • 153175<br />

16, 14 U 55 • • • • 153180<br />

17, 15 U 60 • • 153185<br />

18, 14 U, 15 U, 16 U, 3 /4 72 • • • • 153190<br />

20, 18 U 79 • • • • 153195<br />

22, 18 U, 7 /8 86 • • 153200<br />

25, 26 88 • 153205<br />

32 128 • 153210<br />

Cu:<br />

soft copper tubes, also thin-wall<br />

St 2394 -U: coated c-steel pipes of pressfitting systems C-STAHL<br />

St 2391–2394: soft precision steel tubes DIN 2391–2394<br />

U: coated tubes<br />

V: multi-layer composite tubes of pressfitting systems<br />

Cu<br />

Cu-U<br />

St 2394-U<br />

St 2391-2394<br />

V<br />

Bending and backformer for other sizes on request.<br />

11

ROLLER’S crimping tools<br />

ROLLER’S radial presses<br />

Universal for pressfitting systems!<br />

The ROLLER radial presses are universal for all common pressfitting systems and<br />

meet all requirements in respect of work, functional and operational safety for perfect,<br />

system-conformity, secure crimping.<br />

ROLLER manufactures<br />

• manual radial press with final-lock positioning,<br />

• electric radial presses with or without acoustic switch-off signal, as well as with<br />

automatic retraction (automatic circuit control),<br />

• hybrid (cordless) radial presses (for battery and corded operation) with acoustic<br />

switch-off signal or with automatic retraction (automatic circuit control) and electronic<br />

service call,<br />

• hybrid (cordless) radial presses mini (for battery and corded operation) with automatic<br />

retraction (automatic circuit control).<br />

For any requirement the right solution.<br />

A comprehensive quality assurance system and extensive fatigue tests with some of<br />

our own crimping tools and tools of other makes confirm the high quality and reliability<br />

of ROLLER’S crimping tools. The consistent thrust of ROLLER’S radial presses<br />

enables constant, secure crimping.<br />

German Top Quality<br />

ROLLER’S pressing tongs<br />

For highest quality demands!<br />

During the crimping operation pressing forces of up to 100 kN (10 t) may apply at<br />

the pressing jaws which have to be safely absorbed. Therefore ROLLER’S pressing<br />

tongs / ROLLER’S pressing tongs mini are made in forged and specially hardened,<br />

high-strength steel. The specific pressing contour is precisely machined and shaped<br />

together with the required outer machining of the pressing jaws and the denomination<br />

of the pressing contour and pipe size - in one operation on CNC production centres.<br />

Thus perfect, system-conformity secure pressing joints and long service life.<br />

ROLLER’S pressing tongs drives through ROLLER’S radial press and suitable drive<br />

units of other makes.<br />

Exceptionally high safety standard!<br />

All ROLLER’S crimping tools are tested and approved by independent testing institutes,<br />

e.g. TÜV. Therefore all ROLLER’S crimping tools fulfill a very high standard of<br />

functional and operational safety<br />

Hold-harmless and indemnification agreement !<br />

ZVSHK<br />

The Central Organization for the Sanitary-, Heating- and Climatization Industries<br />

(ZVSHK), the German Association for Heating, Air Conditioning, Sanitary<br />

Systems/Technical Building Systems (BHKS), the Austrian Association for Sanitary-,<br />

Heating- and Climatization Technology (B.S.H.L.) and <strong>Albert</strong> ROLLER GmbH & Co<br />

KG (ROLLER) have concluded a hold-harmless and indemnification agreement for<br />

radial pressing tools. The hold-harmless and indemnification agreement shall be<br />

independently valid, regardless of which pressfitting system is pressed with the<br />

ROLLER’S pressing tools. The suitability of the ROLLER’S pressing tools for the<br />

pressfitting systems shall be gathered from the respective current sales documentation.<br />

12

ROLLER’S crimping tools<br />

Suitability of<br />

ROLLER’S crimping tools!<br />

The suitability of crimping tools is determined basically by the manufacturer of crimping<br />

tools. Moreover the suitability of ROLLER’S crimping tools has been<br />

confirmed by the system manufacturer/supplier himself or approved through<br />

independent testing institutes.<br />

Confirmation of suitability through the system manufacturer/supplier<br />

More than 90 % of the manufacturers/suppliers of the pressfitting systems listed herein<br />

have tested ROLLER’S pressing tongs and confirmed the suitability for their<br />

pressfitting system.<br />

Confirmation of suitability through independent testing institutes<br />

The suitability of ROLLER’S pressing tongs for additional pressfitting systems have<br />

been confirmed through independent technical institutes:<br />

Eignungsprüfung<br />

n a c h<br />

T Ü V<br />

Eignungsprüfung<br />

W<br />

D V G W<br />

drinking water<br />

5 3 4<br />

TÜV-Certificates<br />

Available for biroduct P, Geberit Mepla, Geberit Mapress C-STAHL, Geberit Mapress<br />

EDELSTAHL, Geberit Mapress Kupfer, Nussbaum Cupress, Nussbaum Optipress,<br />

Unicor Unipipe, Velta Fußbodenheizung, Velta rapex P, Viega-‘profipress’, Viega-<br />

‘profipress G’, Viega-‘sanfix P’, Viega-‘sanpress’, Viega-‘Viegatherm P’, Wavin Tigris.<br />

The TÜV-certificates confirm that ROLLER’S crimping tools are suitable for producing<br />

perfect and system-conformity pressing joints corresponding to these systems,<br />

both in conjunction with ROLLER’S pressing tongs and the pressing tongs of system<br />

manufacturers/suppliers.<br />

Suitability test according to DVGW W 534 (potable water)<br />

Pressing joints produced with ROLLER’S crimping tools were tested by the stateoperated<br />

material testing institute (MPA) in Darmstadt/Germany according to DVGW<br />

work sheet W 534. The institute is certified to perform these tests by the DVGW. A<br />

representative cross-section of pressing joints of pressfitting systems biroduct P<br />

(Velta), Geberit Mapress EDELSTAHL, Unicor Unipipe and Viega-‘profipress’ had<br />

been tested. The tests lead to the result that all ROLLER’S press tools are suitable<br />

for producing perfect and system-conformity pressing joints in accordance with these<br />

systems.<br />

Suitability test according to DVGW VP 614 (gas)<br />

TÜV-Eignungsprüfung<br />

nach<br />

D V GW<br />

gas<br />

V P<br />

614<br />

Pressing joints produced with ROLLER’S press tools have been tested by the TÜV<br />

according to DVGW VP 614. A representative selection of press joints of press fitting<br />

systems Geberit Mapress EDELSTAHL GAS, Geberit Mapress KUPFER GAS, IBP<br />

>B

ROLLER’S radial presses<br />

Choose pressing tongs yourself, see page 15–18.<br />

Hold-harmless and indemnification agreement, see page 12!<br />

German Top Quality<br />

Patent EP 1 223 008<br />

Patent US 6,739,172<br />

Robust, compact electric / cordless radial presses for producing pressing<br />

joints Ø 10–108 mm. • Only one universal drive unit for operating with ROLLER’S<br />

pressing tongs (except ROLLER’S Multi-Press Mini) and pressing tongs/pressing<br />

chains of numerous other manufacturers/suppliers. • Secure seating of pressing<br />

tongs by auto matic locking. • System-specific pressing tongs for all common pressfitting<br />

systems, quickly interchangeable. • Only one type of pressing tongs (except<br />

ROLLER’S pressing tongs Mini) for all ROLLER’S radial presses and suitable drive<br />

units of other makes. All pressing tongs marked with * have an optional connection<br />

(Patent EP 1 223 008, patent US 6,739,172) for manual drive through the manual<br />

radial press ROLLER’S Easy-Press. • Confirmation of suitability see page 13.<br />

only 4.4 kg<br />

ROLLER’S Uni-Press E<br />

• Electric radial press. • The pressing jaws remain closed until switched into reverse.<br />

Visual confirmation of a perfectly pressed joint (completely closed pressing tong)<br />

possible. • Electro-mechanic drive unit with maintenance-free reduction gear with<br />

safety slipping clutch. • Proven, powerful universal motor 450 W, with safety tip<br />

switch.<br />

ROLLER’S Uni-Press E Basic-Pack<br />

Art.-No.<br />

Drive unit, in steel case 572110<br />

Accessories<br />

ROLLER’S Uni-Press E drive unit 572100<br />

only 4.8 kg<br />

ROLLER’S Uni-Press<br />

• Electric radial press with switch-off signal. • Acoustic signal after successful completion<br />

of pressing operation enables confirmation of a perfectly pressed joint (completely<br />

closed pressing tong). • Electro-hydraulic drive unit with eccentric reciprocating<br />

pump with robust planetary gear. • Proven, powerful universal motor 450 W,<br />

with safety tip switch. • Swivelling pressing tongs seat<br />

ROLLER’S Uni-Press Basic-Pack<br />

Art.-Nr.<br />

Drive unit, in steel case 577011<br />

with automatic<br />

circuit control<br />

only 4.8 kg<br />

Accessories<br />

ROLLER’S Uni-Press drive unit 577001<br />

ROLLER’S Uni-Press ACC<br />

• Electric radial press with automatic circuit control. • Automatic retraction after<br />

completion of pressing operation (Automatic Circuit Control). For crimping within<br />

seconds. • Electro-hydraulic drive unit with eccentric reciprocating pump with<br />

robust planetary gear. • Proven, powerful universal motor 450 W, with safety tip<br />

switch. • Swivelling pressing tongs seat.<br />

Automatic Circuit Control<br />

ROLLER’S Uni-Press ACC Basic-Pack<br />

Art.-No.<br />

Drive unit, in steel case 577010<br />

Accessories<br />

ROLLER’S Uni-Press ACC drive unit 577000<br />

International<br />

Design Award<br />

only 4.5 kg<br />

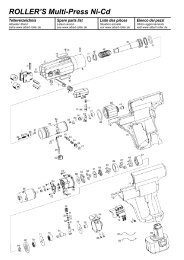

ROLLER’S Multi-Press<br />

• Hybrid (cordless) radial press (for battery and corded operation) with switch-off<br />

signal. • Acoustic signal after successful completion of pressing operation enables<br />

confirmation of a perfectly pressed joint (completely closed pressing tong).<br />

• Electro-hydraulic drive unit with eccentric reciprocating pump with robust planetary<br />

gear • Powerful battery motor 12 V, 270 W, with safety tip switch. Battery 12 V,<br />

2.0 Ah. • Swivelling pressing tongs seat.<br />

ROLLER’S Multi-Press Basic-Pack<br />

Art.-No.<br />

Drive unit, battery 12 V, rapid charger,<br />

in steel case 571010<br />

with automatic circuit control<br />

with electronic service control<br />

Accessories<br />

Battery 12 V, 2.0 Ah 571510<br />

Voltage supply 230 V 571535<br />

only 4.5 kg<br />

Automatic Circuit Control<br />

ROLLER’S Multi-Press ACC<br />

• Hybrid (cordless) radial press (for battery and corded operation) with automatic<br />

circuit control and electronic service control. • Automatic retraction after completion<br />

of pressing operation (Automatic Circuit Control). • Electronic service control with<br />

visual maintenance call after approx. 10,000 crimps. • Electro-hydraulic drive unit<br />

with eccentric reciprocating pump with robust planetary gear • Powerful battery<br />

motor 12 V, 270 W, with safety tip switch. Battery 12 V, 2.0 Ah. • Swivelling pressing<br />

tongs seat.<br />

ROLLER’S Multi-Press ACC Basic-Pack<br />

Art.-No.<br />

Drive unit, battery 12 V, rapid charger,<br />

in steel case 571011<br />

14<br />

Further accessories:<br />

ROLLER’S cable shear,<br />

ROLLER’S cropping tongs M, see page 28/29.<br />

Accessories<br />

Battery 12 V, 2.0 Ah 571510<br />

Voltage supply 230 V 571535

Accessories for ROLLER’S radial presses (except ROLLER’S Multi-Press<br />

Mini ACC)<br />

ROLLER’S pressing tongs<br />

German Top Quality<br />

Hold-harmless and indemnification agreement, see page 12!<br />

System-specific pressing tongs for all common pressfitting systems.<br />

• Only one type of pressing tongs (except ROLLER’S pressing tongs Mini) for all<br />

ROLLER’S radial presses and suitable drive units of other makes. All pressing tongs<br />

marked with * have an optional connection (Patent EP 1 223 008, patent US<br />

6,739,172) for manual drive through the manual radial press<br />

ROLLER’S Easy-Press. • Pressing contours of pressing tongs are system-specific<br />

and correspond to the respective pressfitting system. Thus perfect system-conformity,<br />

safe crimping. • High-compression pressing tongs in forged and specially hardened<br />

steel.<br />

B<br />

CO<br />

F<br />

G<br />

H<br />

HA<br />

HRA<br />

KI<br />

M<br />

MT<br />

RFz<br />

SA<br />

TH<br />

U<br />

US<br />

V<br />

VP<br />

VX<br />

VUS<br />

* These ROLLER’S pressing tongs fit into the ROLLER’S Easy-Press drive unit.<br />

1)<br />

ROLLER’S pressing tongs U are also suitable for the new Uponor Unipipe/Vescal<br />

Metalplast metal fitting generation, however ROLLER’S pressing tongs U 16 only<br />

from production date 4 th quarter 2001 and later. The marking is stamped on each<br />

pressing jaw.<br />

2)<br />

For these pressfitting systems the ROLLER’S pressing tongs marked "77", "87" or<br />

from production date <strong>2008</strong> onwards marked "108" (1 st quarter <strong>2008</strong>), "208"<br />

(2 nd quarter <strong>2008</strong>) etc are suitable. The marking is stamped on each pressing jaw.<br />

Application ROLLER’S pressing tools for pressfitting systems: Date 01.01.<strong>2008</strong>.<br />

ROLLER’S pressing tongs for additional pressfitting systems on request.<br />

System Pressing tongs Art.-No.<br />

AC-FIX PRESS RFz 12* 571320<br />

(Global Piping RFz 16* 571325<br />

Systems) RFz 20* 571330<br />

RFz 25* 571335<br />

RFz 32 571340<br />

H 12* 570300<br />

H 16* 570320<br />

H 20* 570350<br />

H 25* 570360<br />

H 32 570380<br />

AC-FIX H 16* 570320<br />

PRESS-MULTI H 18* 570340<br />

(Global Piping H 20* 570350<br />

Systems) H 25* 570360<br />

H 32 570380<br />

U 16* 57<strong>07</strong>65<br />

U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

AHLSELL M 12 570100<br />

A-press M 15 570110<br />

elgalvaniserat M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

M 42 (4G) 570160<br />

M 54 (4G) 570170<br />

AHLSELL V 12 5701<strong>07</strong><br />

A-press koppar V 15 570115<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

AHLSELL M 15 570110<br />

A-press rostfritt M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

M 42 (4G) 570160<br />

M 54 (4G) 570170<br />

AIRBEL M 12 570100<br />

SERTINOX M 15 570110<br />

M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

ALB TH 16* 57<strong>04</strong>60<br />

Sistema Multicapa TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

H 16* 570320<br />

H 18* 570340<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

H 40 (4G) 570390<br />

U 16* 57<strong>07</strong>65<br />

U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

C 26* 57<strong>07</strong>50<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

U 50 57<strong>07</strong>95<br />

U 63 (S) 572365<br />

APE Raccordi TH 14* 57<strong>04</strong>55<br />

a pressare TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

AP-Presssystem U 14* 57<strong>07</strong>60<br />

U 16* 57<strong>07</strong>65<br />

U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

U 50 57<strong>07</strong>95<br />

U 63 (S) 572365<br />

ASTM F 18<strong>07</strong> US 3 /8”* 571450<br />

(Fittings with US 1 /2”* 571455<br />

Copper Crimp Ring US 3 /4”* 571460<br />

for PEX tubing) US 1”* 571465<br />

US 1 1 /4” 571470<br />

BAMPI BALPED, TH 14* 57<strong>04</strong>55<br />

BAMPI BALPEX TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

B<strong>AR</strong>BI RFz 12* 571320<br />

EASYPRESS RFz 16* 571325<br />

(Industrial Blansol) RFz 20* 571330<br />

RFz 25* 571335<br />

RFz 32 571340<br />

B<strong>AR</strong>BI MULTIPEX H 11,5* 570315<br />

(Industrial Blansol) H 14* 570310<br />

H 16* 570320<br />

H 17* 570330<br />

H 18* 570340<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

H 40 (4G) 570390<br />

U 40 57<strong>07</strong>90<br />

System Pressing tongs Art.-No.<br />

BEGETUBE/IV<strong>AR</strong> B 14* 570845<br />

B 16* 570850<br />

B 18* 570855<br />

B 20* 570860<br />

B 26 570870<br />

B 32 570880<br />

F 40 57<strong>07</strong>40<br />

F 50 57<strong>07</strong>45<br />

F 63 (S) 572385<br />

BRASELI RFz 16* 571325<br />

Pressfitting Pex RFz 20* 571330<br />

RFz 25* 571335<br />

RFz 32 571340<br />

BRASELI U 16* 57<strong>07</strong>65<br />

Pressfitting U 18* 57<strong>07</strong>70<br />

Multicapa U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

U 50 57<strong>07</strong>95<br />

Brasstech TH 14* 57<strong>04</strong>55<br />

Brasspress Aluplast TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

BROEN M 15 570110<br />

BALLOFIX PRES M 18 570120<br />

M 22 570130<br />

V 15 570115<br />

V 18 570125<br />

V 22 570135<br />

BUCCHI tech MP TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

CHIBRO pressfitting M 12 570100<br />

M 15 570110<br />

M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

chronimo SA 12 570930<br />

SANHA-NiroSan- SA 14 570932<br />

Presssystem SA 15 570935<br />

SA 16 570937<br />

SA 18 570940<br />

SA 22 570945<br />

SA 28 570950<br />

SA 35 570955<br />

M 12 570100<br />

M 15 570110<br />

M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

V 12 5701<strong>07</strong><br />

V 14 570112<br />

V 15 570115<br />

V 16 570117<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

ClouSet Press TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

CO.E.S. U 14* 57<strong>07</strong>60<br />

Coesklima U 16* 57<strong>07</strong>65<br />

U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

U 50 57<strong>07</strong>95<br />

U 63 (S) 572365<br />

Comap V 12 5701<strong>07</strong><br />

Sudopress Cu V 14 570112<br />

V 15 570115<br />

V 16 570117<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

Comap CO 12* 571600<br />

Sudopress PEX CO 16* 571605<br />

(PER) CO 20* 571610<br />

CO 25* 571615<br />

Comap TH 16* 57<strong>04</strong>60<br />

Multiskin Gas TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

THL 32 57<strong>04</strong>87<br />

Comap Sudopress TH 14* 57<strong>04</strong>55<br />

Skin Visu-control TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

THL 32 57<strong>04</strong>87<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

Comap Sudopress TH 16* 57<strong>04</strong>60<br />

Skin Gaz TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

THL 32 57<strong>04</strong>87<br />

Comap Sudopress TH 16* 57<strong>04</strong>60<br />

Skin Plastic TH 20* 57<strong>04</strong>70<br />

15

Accessories for ROLLER’S radial presses (except ROLLER’S Multi-Press<br />

Mini ACC)<br />

ROLLER’S pressing tongs<br />

German Top Quality<br />

System Pressing tongs Art.-No.<br />

COMISA TH 16* 57<strong>04</strong>60<br />

COMISA-PRESS TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

U 63 (S) 572365<br />

CosmoCONNECT F 16* 57<strong>07</strong>15<br />

F 20* 57<strong>07</strong>25<br />

F 26* 57<strong>07</strong>30<br />

F 32 57<strong>07</strong>35<br />

H 16* 570320<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

U 16* 57<strong>07</strong>65<br />

U 20* 57<strong>07</strong>75<br />

(NW 26) U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

VP 16* 570910<br />

VP 20* 570915<br />

(NW 26) VP 25* 570920<br />

VP 32 570925<br />

cusmart TH 14* 57<strong>04</strong>55<br />

TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

Dalpex TH 14* 57<strong>04</strong>55<br />

LaserMultiDalpex TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

DiaNorm TH 14* 57<strong>04</strong>55<br />

HKS Sitec Press TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

DIWAflex systems TH 14* 57<strong>04</strong>55<br />

TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

DUOFIL U 16* 57<strong>07</strong>65<br />

MKSYSTEM U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

DW Verbundrohr U 16* 57<strong>07</strong>65<br />

multitubo systems U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

U 50 57<strong>07</strong>95<br />

U 63 (S) 572365<br />

egeda Comisa TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

egeda Baronio V 12 5701<strong>07</strong><br />

V 15 570115<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

Elkhart XPRESS VUS 1 /2” 571770<br />

VUS 3 /4” 571775<br />

VUS 1” 571780<br />

VUS 1 1 /4” 571785<br />

VUS 1 1 /2” 571790<br />

VUS 2” 571795<br />

EMPUR TH 14* 57<strong>04</strong>55<br />

PEXPRESS TH 16* 57<strong>04</strong>60<br />

TH 17* 57<strong>04</strong>62<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

eurotherm TH 16* 57<strong>04</strong>60<br />

Multistrato TH 20* 57<strong>04</strong>70<br />

Euro2000 TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

EUROTUBI INOX M 15 570110<br />

PRESSFITTING M 18 570120<br />

SISTEM M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

M 42 (4G) 570160<br />

M 54 (4G) 570170<br />

System Pressing tongs Art.-No.<br />

F<strong>AR</strong> Rubinetterie TH 14* 57<strong>04</strong>55<br />

PRESSF<strong>AR</strong> TH 16* 57<strong>04</strong>60<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 25* 57<strong>04</strong>95<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

H 14* 570310<br />

H 16* 570320<br />

H 18* 570340<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

H 40 (4G) 570390<br />

U 14* 57<strong>07</strong>60<br />

U 16* 57<strong>07</strong>65<br />

U 18* 57<strong>07</strong>70<br />

U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

U 40 57<strong>07</strong>90<br />

F.B.Q. B<strong>AR</strong>ONIO V 14 570112<br />

BQ press V 15 570115<br />

V 16 570117<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

FILTUBE M 15 570110<br />

Instalpress M 18 570120<br />

M 22 570130<br />

M 28 570140<br />

M 35 570150<br />

M 42 (4G) 570160<br />

M 54 (4G) 570170<br />

FILTUBE M 42 (4G) 570160<br />

Filpress M 54 (4G) 570170<br />

Fimisol H 14* 570310<br />

HAKAPRESS H 16* 570320<br />

H 17* 570330<br />

H 18* 570340<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

H 40 (4G) 570390<br />

U 40 57<strong>07</strong>90<br />

FittingsEstándar,S.L. U 16* 57<strong>07</strong>65<br />

Fittings Estándar U 18* 57<strong>07</strong>70<br />

Multicapa U 20* 57<strong>07</strong>75<br />

U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

FittingsEstándar,S.L. RFz 16* 571325<br />

Fittings Estándar RFz 20* 571330<br />

PE-X/Ecopress RFz 25* 571335<br />

RFz 32 571340<br />

FRA-BO V 12 5701<strong>07</strong><br />

FRABOPRESS V 15 570115<br />

V 18 570125<br />

V 22 570135<br />

V 28 570145<br />

V 35 570155<br />

V 42 570165<br />

V 54 570175<br />

Fränkische F 16* 57<strong>07</strong>15<br />

alpex-duo F 18* 57<strong>07</strong>20<br />

F 20* 57<strong>07</strong>25<br />

F 26* 57<strong>07</strong>30<br />

F 32 57<strong>07</strong>35<br />

F 40 57<strong>07</strong>40<br />

F 50 57<strong>07</strong>45<br />

F 63 (S) 572385<br />

Fränkische F 16* 57<strong>07</strong>15<br />

alpex F50 PROFI F 20* 57<strong>07</strong>25<br />

F 26* 57<strong>07</strong>30<br />

F 32 57<strong>07</strong>35<br />

H 16* 570320<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

U 16* 57<strong>07</strong>65<br />

U 20* 57<strong>07</strong>75<br />

(NW 26) U 25* 57<strong>07</strong>80<br />

U 32 57<strong>07</strong>85<br />

VP 16* 570910<br />

VP 20* 570915<br />

(NW 26) VP 25* 570920<br />

VP 32 570925<br />

FRIATHERM uni H 16* 570320<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

H 40 (4G) 570390<br />

U 40 57<strong>07</strong>90<br />

gabo TH 10* 57<strong>04</strong>67<br />

Systemtechnik TH 12* 57<strong>04</strong>52<br />

TH 14* 57<strong>04</strong>55<br />

TH 15* 57<strong>04</strong>57<br />

TH 16* 57<strong>04</strong>60<br />

TH 17* 57<strong>04</strong>62<br />

TH 18* 57<strong>04</strong>65<br />

TH 20* 57<strong>04</strong>70<br />

TH 25* 57<strong>04</strong>95<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

System Pressing tongs Art.-No.<br />

G<strong>AR</strong>OS TH 14* 57<strong>04</strong>55<br />

TH 16* 57<strong>04</strong>60<br />

TH 20* 57<strong>04</strong>70<br />

TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

Geberit Mapress M 12 570100<br />

C-STAHL/ M 15 570110<br />

EDELSTAHL/ M 18 570120<br />

EDELSTAHL Gas M 22 570130<br />

(15–35 mm)/ M 28 570140<br />

KUPFER/ M 35 570150<br />

KUPFER Gas M 42 (4G) 570160<br />

(15–35 mm) M 54 (4G) 570170<br />

Geberit Mepla G 16* 57<strong>04</strong>00<br />

G 20* 57<strong>04</strong>10<br />

G 26* 57<strong>04</strong>20<br />

G 32 57<strong>04</strong>30<br />

G 40 57<strong>04</strong>40<br />

G 50 57<strong>04</strong>50<br />

G 63 (S) 572470<br />

General Fittings TH 16* 57<strong>04</strong>60<br />

General-Flex-Press TH 20* 57<strong>04</strong>70<br />

5900 TH 26* 57<strong>04</strong>75<br />

TH 32 57<strong>04</strong>80<br />

TH 40 57<strong>04</strong>85<br />

TH 50 (S) 572400<br />

TH 63 (S) 572405<br />

H 16* 570320<br />

H 20* 570350<br />

H 26* 570370<br />

H 32 570380<br />

U 16* 57<strong>07</strong>65<br />