Metric thread repair Kit - Harbor Freight Tools

Metric thread repair Kit - Harbor Freight Tools

Metric thread repair Kit - Harbor Freight Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Metric</strong> Thread Repair <strong>Kit</strong><br />

Model 98873<br />

Instruction Sheet<br />

Due to continuing improvements, actual product may differ slightly from the product described herein.<br />

Distributed exclusively by <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> ® .<br />

3491 Mission Oaks Blvd., Camarillo, CA 93011<br />

Visit our website at: http://www.harborfreight.com<br />

Read this material before using this product. Failure to do so can<br />

result in serious injury.<br />

Save this instruction sheet.<br />

Copyright © 2008 by <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> ® . All rights reserved. No portion of this instruction sheet<br />

or any artwork contained herein may be reproduced in any shape or form without the express written<br />

consent of <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong>.<br />

For technical questions or replacement parts, please call 1-800-444-3353.<br />

Safety Rules<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

WARNING! Read all instructions<br />

Failure to follow all instructions<br />

listed below may result in electric<br />

shock, fire, and/or serious injury.<br />

This product is not a toy. Keep it out of reach of children.<br />

Wear ANSI approved safety goggles and heavy work<br />

gloves when using this product.<br />

Handle with care. <strong>Tools</strong> are sharp.<br />

When cutting <strong>thread</strong>s, use only with Tap Handle, Tapping<br />

Machine and Die Handle (not included). Do not<br />

use high speed drill or powered tool to cut <strong>thread</strong>s or<br />

install the <strong>thread</strong> inserts.<br />

Firmly secure work piece to work bench before working.<br />

Do not attempt to hold work piece by hand during<br />

operation.<br />

The warnings, precautions, and instructions discussed<br />

in this instruction sheet cannot cover all possible<br />

conditions and situations that may occur. It must be<br />

understood by the operator that common sense and<br />

caution are factors which cannot be built into this product,<br />

but must be supplied by the operator.<br />

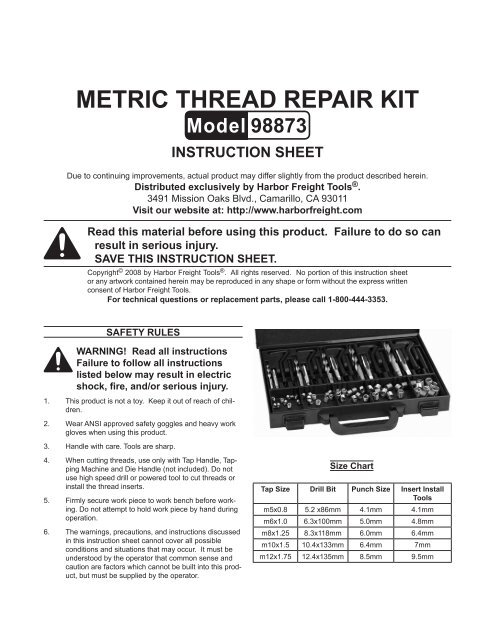

Size Chart<br />

Tap Size Drill Bit Punch Size Insert Install<br />

<strong>Tools</strong><br />

m5x0.8 5.2 x86mm 4.1mm 4.1mm<br />

m6x1.0 6.3x100mm 5.0mm 4.8mm<br />

m8x1.25 8.3x118mm 6.0mm 6.4mm<br />

m10x1.5 10.4x133mm 6.4mm 7mm<br />

m12x1.75 12.4x135mm 8.5mm 9.5mm

Thread Insert Material<br />

Drill Bits and Taps Material<br />

Specifications<br />

Unpacking<br />

Stainless Steel<br />

High Speed Steel<br />

When unpacking, check to make sure that the item is<br />

intact and undamaged. If any parts are missing or broken,<br />

please call <strong>Harbor</strong> <strong>Freight</strong> <strong>Tools</strong> at the number shown on the<br />

cover of this instruction sheet as soon as possible.<br />

1.<br />

2.<br />

3.<br />

Item Description QTY.<br />

1 Drill Bits (see Size Chart) 5<br />

2 Thread Cutting Taps (see Size Chart) 5<br />

3 Insert Tool 1<br />

4 Insert Collars (see Size Chart) 5<br />

5 10 Thread Inserts in each size 50<br />

6 Punch <strong>Tools</strong> (see Size Chart) 5<br />

7 2.5 mm Hex Wrench 1<br />

Instructions<br />

Read the entire Safety Rules section<br />

at the beginning of this instruction sheet<br />

including all text under subheadings therein<br />

before set up or use of this product.<br />

Set up<br />

This kit is used to replace damaged <strong>thread</strong>s in metal or<br />

hard plastic.<br />

Secure your work piece firmly in a vise, with clamps, or<br />

some other means to prevent it from moving during the<br />

<strong>repair</strong> operation.<br />

Have cutting oil and a rag ready.<br />

5.<br />

6.<br />

7.<br />

Using the 2.5 mm Hex Wrench, adjust the col-<br />

lar on the Insert Tool so that the tang of<br />

the insert is about midway in the slot with<br />

the <strong>thread</strong>s compressed. See Figure 1.<br />

Figure 1.<br />

Collar Adjusted<br />

too Low.<br />

Collar Adjusted<br />

Correctly.<br />

Collar Adjusted<br />

too High.<br />

Using the Correct Size Insert Tool, screw the insert<br />

clockwise into the hole. The insert will compress to fit<br />

the hole as it is inserted. See Figure 2.<br />

Figure 2.<br />

After the insert<br />

is in the hole,<br />

remove the<br />

Tang by placing<br />

the Punch<br />

Tool on it and<br />

striking the<br />

Punch Tool<br />

with a hammer<br />

(not included).<br />

See Figure 3.<br />

Figure 3.<br />

Tang<br />

Insert Tool<br />

Collar<br />

1.<br />

2.<br />

3.<br />

Operation<br />

Determine the size of the <strong>thread</strong>ed hole that you want.<br />

Drill out the hole, using the included drill bit to the<br />

proper size. Refer to the Size Chart on page 1 of this<br />

manual. When drilling metal parts, use a little cutting<br />

oil to lubricate and cool the drill bit.<br />

If you are going to make the <strong>thread</strong>ed hole larger<br />

than the original, drill it out in steps, using a series of<br />

increasingly larger drill bits until the desired size is<br />

reached.<br />

8.<br />

To prevent accidents,<br />

clean,<br />

then store<br />

the product<br />

indoors out of<br />

children’s reach.<br />

Steel Insert<br />

Note: Replacement parts are not available for this item.<br />

4.<br />

Clamp the Tap in a Tap Handle (not included). Us the<br />

same size tap as the <strong>thread</strong> size desired.<br />

SKU 98873 For technical questions, please call 1-800-444-3353.