Molykote(R) Thread Pastes (Asia Products)

Molykote(R) Thread Pastes (Asia Products)

Molykote(R) Thread Pastes (Asia Products)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

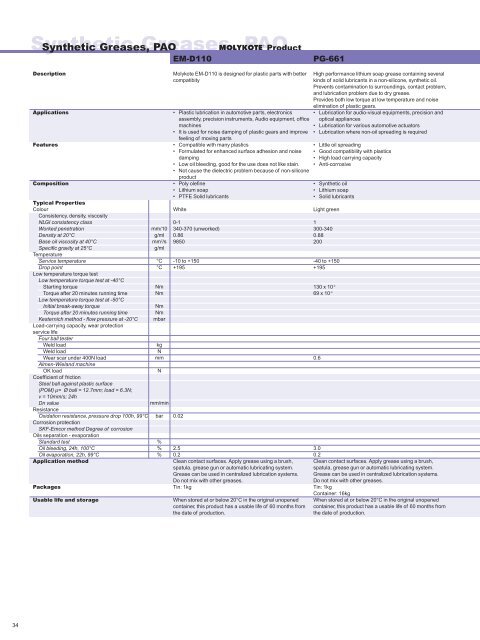

Synthetic Greases, Greases, PAO PAO<br />

EM-D110<br />

Product<br />

PG-661<br />

Description<br />

Applications<br />

Features<br />

Composition<br />

Typical Properties<br />

Colour<br />

Consistency, density, viscosity<br />

NLGI consistency class<br />

Worked penetration<br />

Density at 20°C<br />

Base oil viscosity at 40°C<br />

Specific gravity at 25°C<br />

Temperature<br />

Service temperature<br />

Drop point<br />

Low temperature torque test<br />

Low temperature torque test at -40°C<br />

Starting torque<br />

Torque after 20 minutes running time<br />

Low temperature torque test at -50°C<br />

Initial break-away torque<br />

Torque after 20 minutes running time<br />

Kesternich method - flow pressure at -20°C<br />

Load-carrying capacity, wear protection<br />

service life<br />

Four ball tester<br />

Weld load<br />

Weld load<br />

Wear scar under 400N load<br />

Almen-Wieland machine<br />

OK load<br />

Coefficient of friction<br />

Steel ball against plastic surface<br />

(POM) µ= Ø ball = 12.7mm; load = 6.3N;<br />

v = 10mm/s; 24h<br />

Dn value<br />

Resistance<br />

Oxidation resistance, pressure drop 100h, 99°C<br />

Corrosion protection<br />

SKF-Emcor method Degree of corrosion<br />

Oils separation - evaporation<br />

Standard test<br />

Oil bleeding, 24h, 100°C<br />

Oil evaporation, 22h, 99°C<br />

Application method<br />

Packages<br />

Usable life and storage<br />

mm/10<br />

g/ml<br />

mm 2 /s<br />

g/ml<br />

°C<br />

°C<br />

Nm<br />

Nm<br />

Nm<br />

Nm<br />

mbar<br />

kg<br />

N<br />

mm<br />

N<br />

mm/min<br />

bar<br />

%<br />

%<br />

%<br />

<strong>Molykote</strong> EM-D110 is designed for plastic parts with better<br />

compatibity<br />

• Plastic lubrication in automotive parts, electronics<br />

assembly, precision instruments, Audio equipment, office<br />

machines<br />

• It is used for noise damping of plastic gears and improve<br />

feeling of moving parts<br />

• Compatible with many plastics<br />

• Formulated for enhanced surface adhesion and noise<br />

damping<br />

• Low oil bleeding, good for the use does not like stain.<br />

• Not cause the dielectric problem because of non-silicone<br />

product<br />

• Poly olefine<br />

• Lithium soap<br />

• PTFE Solid lubricants<br />

White<br />

0-1<br />

340-370 (unworked)<br />

0.86<br />

9850<br />

-10 to +150<br />

+195<br />

0.02<br />

2.5<br />

0.2<br />

Clean contact surfaces. Apply grease using a brush,<br />

spatula, grease gun or automatic lubricating system.<br />

Grease can be used in centralized lubrication systems.<br />

Do not mix with other greases.<br />

Tin: 1kg<br />

When stored at or below 20°C in the original unopened<br />

container, this product has a usable life of 60 months from<br />

the date of production.<br />

High performance lithium soap grease containing several<br />

kinds of solid lubricants in a non-silicone, synthetic oil.<br />

Prevents contamination to surroundings, contact problem,<br />

and lubrication problem due to dry grease.<br />

Provides both low torque at low temperature and noise<br />

elimination of plastic gears.<br />

• Lubrication for audio-visual equipments, precision and<br />

optical appliances<br />

• Lubrication for various automotive actuators<br />

• Lubrication where non-oil spreading is required<br />

• Little oil spreading<br />

• Good compatibility with plastics<br />

• High load carrying capacity<br />

• Anti-corrosive<br />

• Synthetic oil<br />

• Lithium soap<br />

• Solid lubricants<br />

Light green<br />

1<br />

300-340<br />

0.88<br />

200<br />

-40 to +150<br />

+195<br />

130 x 10 -3<br />

69 x 10 -3<br />

0.6<br />

3.0<br />

0.2<br />

Clean contact surfaces. Apply grease using a brush,<br />

spatula, grease gun or automatic lubricating system.<br />

Grease can be used in centralized lubrication systems.<br />

Do not mix with other greases.<br />

Tin: 1kg<br />

Container: 16kg<br />

When stored at or below 20°C in the original unopened<br />

container, this product has a usable life of 60 months from<br />

the date of production.<br />

34