Wärtsilä Medium-Speed Marine Diesel Engines

Wärtsilä Medium-Speed Marine Diesel Engines

Wärtsilä Medium-Speed Marine Diesel Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

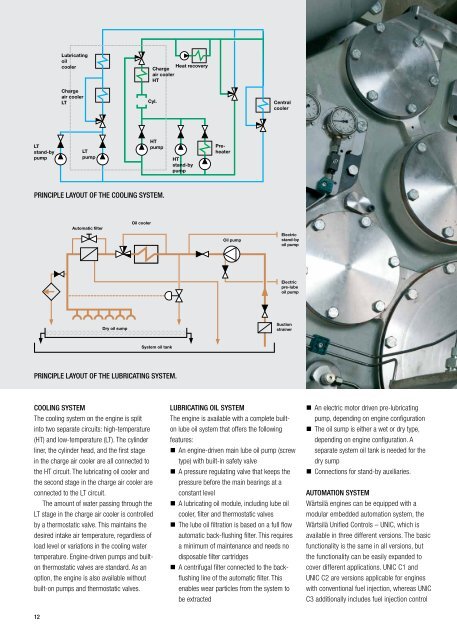

Lubricating<br />

oil<br />

cooler<br />

Charge<br />

air cooler<br />

LT<br />

Heat recovery<br />

Charge<br />

air cooler<br />

HT<br />

Cyl.<br />

Central<br />

cooler<br />

LT<br />

standby<br />

pump<br />

LT<br />

pump<br />

HT<br />

pump<br />

HT<br />

standby<br />

pump<br />

Preheater<br />

PRINCIPLE LAYOUT OF THE COOLING SYSTEM.<br />

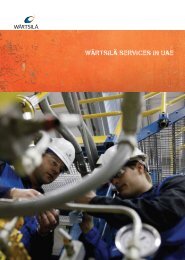

Automatic filter<br />

Oil cooler<br />

Oil pump<br />

Electric<br />

standby<br />

oil pump<br />

Centrifugal filter<br />

Electric<br />

prelube<br />

oil pump<br />

Dry oil sump<br />

Suction<br />

strainer<br />

System oil tank<br />

PRINCIPLE LAYOUT OF THE LUBRICATING SYSTEM.<br />

COOLING SYSTEM<br />

The cooling system on the engine is split<br />

into two separate circuits: high-temperature<br />

(HT) and low-temperature (LT). The cylinder<br />

liner, the cylinder head, and the first stage<br />

in the charge air cooler are all connected to<br />

the HT circuit. The lubricating oil cooler and<br />

the second stage in the charge air cooler are<br />

connected to the LT circuit.<br />

The amount of water passing through the<br />

LT stage in the charge air cooler is controlled<br />

by a thermostatic valve. This maintains the<br />

desired intake air temperature, regardless of<br />

load level or variations in the cooling water<br />

temperature. Engine-driven pumps and builton<br />

thermostatic valves are standard. As an<br />

option, the engine is also available without<br />

built-on pumps and thermostatic valves.<br />

LUBRICATING OIL SYSTEM<br />

The engine is available with a complete builton<br />

lube oil system that offers the following<br />

features:<br />

•An engine-driven main lube oil pump (screw<br />

type) with built-in safety valve<br />

•A pressure regulating valve that keeps the<br />

pressure before the main bearings at a<br />

constant level<br />

•A lubricating oil module, including lube oil<br />

cooler, filter and thermostatic valves<br />

•The lube oil filtration is based on a full flow<br />

automatic back-flushing filter. This requires<br />

a minimum of maintenance and needs no<br />

disposable filter cartridges<br />

•A centrifugal filter connected to the backflushing<br />

line of the automatic filter. This<br />

enables wear particles from the system to<br />

be extracted<br />

•An electric motor driven pre-lubricating<br />

pump, depending on engine configuration<br />

•The oil sump is either a wet or dry type,<br />

depending on engine configuration. A<br />

separate system oil tank is needed for the<br />

dry sump<br />

•Connections for stand-by auxiliaries.<br />

AUTOMATION SYSTEM<br />

Wärtsilä engines can be equipped with a<br />

modular embedded automation system, the<br />

Wärtsilä Unified Controls – UNIC, which is<br />

available in three different versions. The basic<br />

functionality is the same in all versions, but<br />

the functionality can be easily expanded to<br />

cover different applications. UNIC C1 and<br />

UNIC C2 are versions applicable for engines<br />

with conventional fuel injection, whereas UNIC<br />

C3 additionally includes fuel injection control<br />

12