PET Compressed Air Solutions - Ingersoll Rand

PET Compressed Air Solutions - Ingersoll Rand

PET Compressed Air Solutions - Ingersoll Rand

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

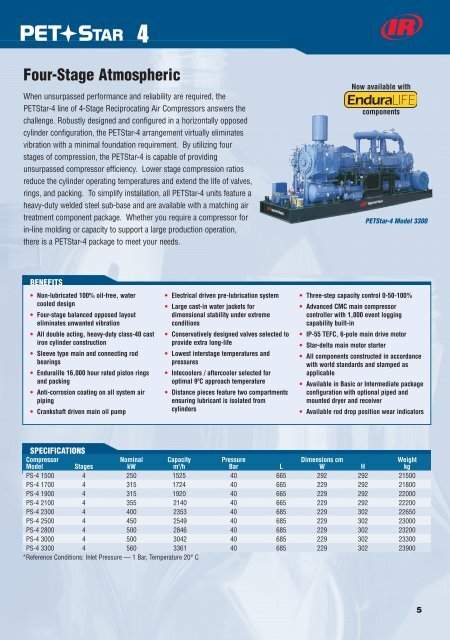

Four-Stage Atmospheric<br />

When unsurpassed performance and reliability are required, the<br />

<strong>PET</strong>Star-4 line of 4-Stage Reciprocating <strong>Air</strong> Compressors answers the<br />

challenge. Robustly designed and configured in a horizontally opposed<br />

cylinder configuration, the <strong>PET</strong>Star-4 arrangement virtually eliminates<br />

vibration with a minimal foundation requirement. By utilizing four<br />

stages of compression, the <strong>PET</strong>Star-4 is capable of providing<br />

unsurpassed compressor efficiency. Lower stage compression ratios<br />

reduce the cylinder operating temperatures and extend the life of valves,<br />

rings, and packing. To simplify installation, all <strong>PET</strong>Star-4 units feature a<br />

heavy-duty welded steel sub-base and are available with a matching air<br />

treatment component package. Whether you require a compressor for<br />

in-line molding or capacity to support a large production operation,<br />

there is a <strong>PET</strong>Star-4 package to meet your needs.<br />

Now available with<br />

EnduraLIFE<br />

components<br />

<strong>PET</strong>Star-4 Model 3300<br />

BENEFITS<br />

• Non-lubricated 100% oil-free, water<br />

cooled design<br />

• Four-stage balanced opposed layout<br />

eliminates unwanted vibration<br />

• All double acting, heavy-duty class-40 cast<br />

iron cylinder construction<br />

• Sleeve type main and connecting rod<br />

bearings<br />

• Enduralife 16,000 hour rated piston rings<br />

and packing<br />

• Anti-corrosion coating on all system air<br />

piping<br />

• Crankshaft driven main oil pump<br />

• Electrical driven pre-lubrication system<br />

• Large cast-in water jackets for<br />

dimensional stability under extreme<br />

conditions<br />

• Conservatively designed valves selected to<br />

provide extra long-life<br />

• Lowest interstage temperatures and<br />

pressures<br />

• Intecoolers / aftercooler selected for<br />

optimal 9ºC approach temperature<br />

• Distance pieces feature two compartments<br />

ensuring lubricant is isolated from<br />

cylinders<br />

• Three-step capacity control 0-50-100%<br />

• Advanced CMC main compressor<br />

controller with 1,000 event logging<br />

capability built-in<br />

• IP-55 TEFC, 6-pole main drive motor<br />

• Star-delta main motor starter<br />

• All components constructed in accordance<br />

with world standards and stamped as<br />

applicable<br />

• Available in Basic or Intermediate package<br />

configuration with optional piped and<br />

mounted dryer and receiver<br />

• Available rod drop position wear indicators<br />

SPECIFICATIONS<br />

Compressor Nominal Capacity Pressure Dimensions cm Weight<br />

Model Stages kW m 3 /h Bar L W H kg<br />

PS-4 1500 4 250 1525 40 665 292 292 21500<br />

PS-4 1700 4 315 1724 40 665 229 292 21800<br />

PS-4 1900 4 315 1920 40 665 229 292 22000<br />

PS-4 2100 4 355 2140 40 665 229 292 22200<br />

PS-4 2300 4 400 2353 40 685 229 302 22650<br />

PS-4 2500 4 450 2549 40 685 229 302 23000<br />

PS-4 2800 4 500 2846 40 685 229 302 23200<br />

PS-4 3000 4 500 3042 40 685 229 302 23300<br />

PS-4 3300 4 560 3361 40 685 229 302 23900<br />

*Reference Conditions: Inlet Pressure — 1 Bar, Temperature 20° C<br />

5