PET Compressed Air Solutions - Ingersoll Rand

PET Compressed Air Solutions - Ingersoll Rand

PET Compressed Air Solutions - Ingersoll Rand

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3<br />

Three-Stage Atmospheric<br />

<strong>PET</strong>Star-3 reciprocating compressors are designed to meet the<br />

needs of customers with small rotary or inline blow molding<br />

equipment. These customers require an economical and<br />

efficient solution to maximize productivity. Arranged in a<br />

space-saving package, the <strong>PET</strong>Star-3 has single point air,<br />

water and electrical connections for easy installation. The<br />

machine base is also designed with forklift access for<br />

convenient transport. By utilizing a W configuration, access to<br />

all areas is made unobtrusive during maintenance operations.<br />

Equally robust in design and construction, the <strong>PET</strong>Star-3 is<br />

truly a cost effective solution.<br />

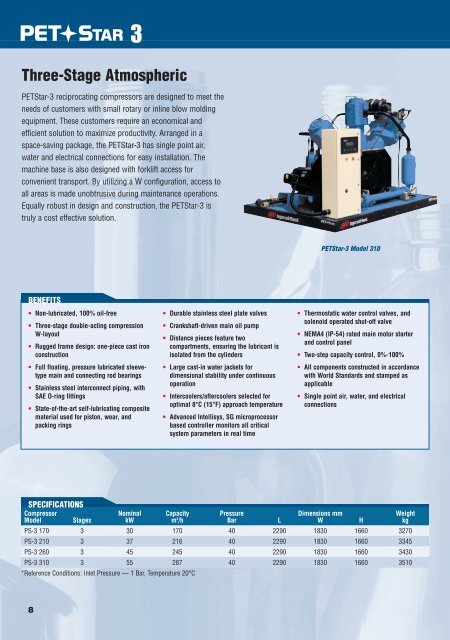

<strong>PET</strong>Star-3 Model 310<br />

BENEFITS<br />

• Non-lubricated, 100% oil-free<br />

• Three-stage double-acting compression<br />

W-layout<br />

• Rugged frame design: one-piece cast iron<br />

construction<br />

• Full floating, pressure lubricated sleevetype<br />

main and connecting rod bearings<br />

• Stainless steel interconnect piping, with<br />

SAE O-ring fittings<br />

• State-of-the-art self-lubricating composite<br />

material used for piston, wear, and<br />

packing rings<br />

• Durable stainless steel plate valves<br />

• Crankshaft-driven main oil pump<br />

• Distance pieces feature two<br />

compartments, ensuring the lubricant is<br />

isolated from the cylinders<br />

• Large cast-in water jackets for<br />

dimensional stability under continuous<br />

operation<br />

• Intercoolers/aftercoolers selected for<br />

optimal 8°C (15°F) approach temperature<br />

• Advanced Intellisys‚ SG microprocessor<br />

based controller monitors all critical<br />

system parameters in real time<br />

• Thermostatic water control valves, and<br />

solenoid operated shut-off valve<br />

• NEMA4 (IP-54) rated main motor starter<br />

and control panel<br />

• Two-step capacity control, 0%-100%<br />

• All components constructed in accordance<br />

with World Standards and stamped as<br />

applicable<br />

• Single point air, water, and electrical<br />

connections<br />

SPECIFICATIONS<br />

Compressor Nominal Capacity Pressure Dimensions mm Weight<br />

Model Stages kW m 3 /h Bar L W H kg<br />

PS-3 170 3 30 170 40 2290 1830 1660 3270<br />

PS-3 210 3 37 216 40 2290 1830 1660 3345<br />

PS-3 260 3 45 245 40 2290 1830 1660 3430<br />

PS-3 310 3 55 287 40 2290 1830 1660 3510<br />

*Reference Conditions: Inlet Pressure — 1 Bar, Temperature 20°C<br />

8