Resconcept PGF Green - Kinetik

Resconcept PGF Green - Kinetik

Resconcept PGF Green - Kinetik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RESCONCEPT ® <strong>PGF</strong> GREEN:<br />

a natural way to formulate<br />

RESCONCEPT ® is a new way of<br />

approaching the manufacturing process<br />

of cosmetic emulsions.<br />

RESCONCEPT ® products are extremely<br />

stable concentrated cosmetic emulsions<br />

that can be used as frame emulsions for<br />

the production of any type of cosmetic<br />

product. RESCONCEPT ® products are,<br />

in fact, the result of our experience with<br />

Wet Wipe concentrated emulsions.<br />

Further studies show how they can be<br />

used to make excellent quality cosmetic<br />

emulsions of any viscosity through the<br />

simple use of rheological agents.<br />

NEW<br />

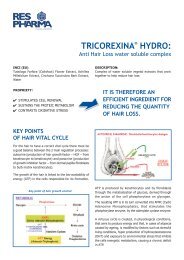

INCI:<br />

OCTYLDODECANOL,<br />

CAPRYLYL/CAPRYL GLUCOSIDE,<br />

SORBITAN OLEATE, OLIVE OIL<br />

POLYGLYCERYL-4 ESTERS,<br />

DICAPRYLYL ETHER, GLYCERIN,<br />

POLYGLYCERYL 4 CAPRYLATE<br />

RESCONCEPT ® <strong>PGF</strong> GREEN<br />

RESCONCEPT ® <strong>PGF</strong> GREEN is a preservative free and PEG-free concentrated<br />

emulsion with low water content. It was designed to be used diluted, in cold<br />

process, and personalized through the addition of actives for the production of a<br />

wide range of modern and green skin products.<br />

Application studies performed by Res Pharma Industriale laboratories result in several<br />

formulations based on RESCONCEPT ® <strong>PGF</strong> GREEN that show versatility and performance<br />

of the product.<br />

GOOD COMPATIBILITY with:<br />

4<br />

4 SLES FREE SURFACTANT SYSTEMS<br />

4 HYDROPHILIC AND LIPOPHILIC COMPONENTS<br />

4 DIFFERENT PRESERVATIVE SYSTEMS<br />

NATURAL AND SYNTHETIC RHEOLOGICAL ADDITIVES

THE ADVANTAGES OF THE “RESCONCEPT” CONCEPT<br />

COLD EASY FAST PROCESS<br />

RES CONCEPT ® products do not require heating during<br />

the manufacturing process.<br />

Both liposoluble and hydrosoluble ingredients or phases can<br />

also be added cold.<br />

FASTER LAB DEVELOPMENT TIME<br />

Thanks to their ease of use, the development time required<br />

to produce a lab formula is drastically reduced.<br />

The formulator can therefore offer a wider choice of<br />

formulations to the customer/marketing department.<br />

INCREASED PRODUCTION CAPACITY<br />

A cold production process requires less time than a traditional<br />

emulsion manufacturing process, allowing to produce multiple<br />

batches per day.<br />

ECONOMICAL FORMULATION<br />

The efficacy of these ingredients means they can be used in<br />

quantities ranging between 5 and 30% to produce quality<br />

cosmetic emulsions and consequently lower total formula costs.<br />

VERSATILITY<br />

The same RES CONCEPT ® ingredient can be used to<br />

manufacture cosmetic emulsions of any viscosity: from spray<br />

emulsions, such as deodorants or sunscreen products, to<br />

thick creams, such as day or night creams or moisturizing<br />

creams.<br />

LOGISTICAL SAVINGS<br />

As the same emulsion concentrate can be used to manufacture<br />

a whole range of finished products, the number of raw<br />

materials purchased, transported and stocked can be reduced.<br />

PLUS<br />

4<br />

4<br />

4<br />

CLEAR LIQUID<br />

LOW WATER CONTENT<br />

PRESERVATIVE FREE<br />

4<br />

4<br />

HIGH CONTENT OF ACTIVE<br />

LOW % OF USE (1-6%)<br />

Formulators can personalise the finish products, diversifying the<br />

final structure, the activities and the preservative system.

The product is presented together with a rheological study<br />

based on RESCONCEPT ® <strong>PGF</strong> GREEN and RESIL ® GX, a complex<br />

of natural rheological agents<br />

ResConcept <strong>PGF</strong> <strong>Green</strong>:<br />

rhelogical approch to a natural formulation<br />

Monica Bufo 1 , Maria Ferrero 2 , Silvia Pozzoni 1<br />

1 Res Pharma Industriale srl, Trezzo sull’Adda (MI), Italy; 2 Consultant<br />

Rheology<br />

Res Pharma Industriale’s laboratories perform a study<br />

on natural thickening agents (or from natural sources)<br />

concluding that the possibilities are very few and<br />

chose the “green way” often means to achieve weak<br />

rheological and sensorial performances.<br />

Starting from studies performed in food field (1) , we<br />

decided to test the properties of mixture Guar/Xanthan<br />

gum: rheologists know very well that they have a<br />

sinergic effect in thickening acqueous solutions in<br />

cold processing.<br />

From the two polymer Idrossipropilguar (G) and<br />

Xanthan gum (X) we prepared different mixture<br />

changing the relative amount. Viscosity of the different<br />

mix has been tested with viscosimeter increasing<br />

shear rate from 1 a 1000 s -1 (Flow Curve Analysis).<br />

For all products viscosity decrease with the increasing<br />

of the flow in logarithmic way (shear thinning<br />

behavior), as reported in Picture 1:<br />

Formulation<br />

Concentrated emulsion ResConcept <strong>PGF</strong> <strong>Green</strong>,<br />

diluted in water, has been added with Resil GX<br />

mixture already optimized with cold processing.<br />

The emulsions obtained this way, analyzed with<br />

viscosimeter, showed the same behavior as to the<br />

one in Picture 1, proving a good structure of polymeric<br />

network, able to stabilize the small drops in the<br />

dispersed phase.<br />

Besides the viscosity those emulsions has been<br />

evaluated regarding their stability (oven 45°C, fridge<br />

4°C, RT) and the sensorial characteristic (in use, pre<br />

and post application). Three combination areas have<br />

been underlined, as shown in Picture 2:<br />

A: <strong>Resconcept</strong> <strong>PGF</strong> <strong>Green</strong> 3% / Resil GX 0.8%<br />

B: <strong>Resconcept</strong> <strong>PGF</strong> <strong>Green</strong> 4%/ Resil GX 1.3%<br />

C: <strong>Resconcept</strong> <strong>PGF</strong> <strong>Green</strong> 5%/ Resil GX 1.5%<br />

High viscosity at low shear rate assure resistance to<br />

sedimentation and long shelf life stability. At the<br />

same time a low viscosity at high shear rate means<br />

good application and pleasant sensorial effect.<br />

All the Flow Curves has been fitted with a Ostwald<br />

Model (y = k x n ) allowing the confront between the<br />

different formulation through the values of parameters<br />

k (consistency factor) and n (flow behaviour index).<br />

This way has been possible to reach the “optimum”<br />

in mixture Resil GX formulation.<br />

Starting from each standard formulation several<br />

products have been prepared, adding oils, moisturizing,<br />

actives, powders and preservatives. So we are able<br />

to propose a wide set of complete formulations that<br />

have successfully passed the stability and sensorial<br />

tests.<br />

Using ResConcept <strong>PGF</strong> <strong>Green</strong> and Resil GX in<br />

the ratio closed to the proposed ones it’s possible to<br />

achieve the best compromise between “green”<br />

rheological additive, a good texture and great skin<br />

feel. The products, in fact, appears to have increasing<br />

and appropriate viscosity and with good capability of<br />

absorption and use.<br />

1) Viscosity of guar gum and xanthan/guar gum<br />

mixture solutions, Journal of the Science of Food and<br />

Agriculture, (2000) 80: 1722-1727<br />

Please ask for complete scientific documentation<br />

at info@respharma.com

MOISTURIZING EYE SERUM_11R29S06<br />

SILK HAIR TREATMENT_ 11R29B14.5 PROTECTIVE<br />

BABY CREAM_11R29ML1<br />

Radar graphs shows the result of sensory evaluation obtained<br />

from 10 volunteers on the three final formulations.<br />

TOXICOLOGICAL DATA<br />

Test in Vitro Ocular Irritection ® : “Minimal irritant”<br />

Test in Vitro Dermal Irritection ® : “Not irritant”<br />

The data provided in this publication is based on our current<br />

knowledge and experience and is offered free of charge and<br />

in good faith for guidance only. It does not constitute a<br />

guarantee in the legal sense of the term and in view of the<br />

multiple factors that may affect processing and applications,<br />

it does not relieve those to whom we supply our products<br />

from the responsibility of carrying out their own tests and<br />

experiments. All express and implied warranties are disclaimed.<br />

Any relevant patent rights and existing legislations and<br />

regulations must be observed.<br />

www.respharma.com<br />

70325_2<br />

Res Pharma s.r.l.<br />

Via Giulio Pastore, 3 - Trezzo sull'Adda (MI) Italia<br />

Tel. 02.909941 - Fax. 02.90963944<br />

E-mail: info@respharma.com<br />

Register to get access to complete<br />

technical documentation and formula<br />

examples by Centro Tecnico Res Pharma