TECHNICAL PARTICULARS FOR PRESSED STEEL SHUTTERS ...

TECHNICAL PARTICULARS FOR PRESSED STEEL SHUTTERS ...

TECHNICAL PARTICULARS FOR PRESSED STEEL SHUTTERS ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

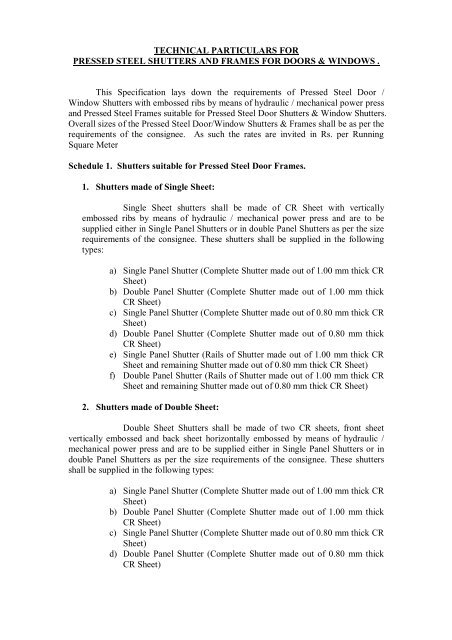

<strong>TECHNICAL</strong> <strong>PARTICULARS</strong> <strong>FOR</strong><br />

<strong>PRESSED</strong> <strong>STEEL</strong> <strong>SHUTTERS</strong> AND FRAMES <strong>FOR</strong> DOORS & WINDOWS .<br />

This Specification lays down the requirements of Pressed Steel Door /<br />

Window Shutters with embossed ribs by means of hydraulic / mechanical power press<br />

and Pressed Steel Frames suitable for Pressed Steel Door Shutters & Window Shutters.<br />

Overall sizes of the Pressed Steel Door/Window Shutters & Frames shall be as per the<br />

requirements of the consignee. As such the rates are invited in Rs. per Running<br />

Square Meter<br />

Schedule 1. Shutters suitable for Pressed Steel Door Frames.<br />

1. Shutters made of Single Sheet:<br />

Single Sheet shutters shall be made of CR Sheet with vertically<br />

embossed ribs by means of hydraulic / mechanical power press and are to be<br />

supplied either in Single Panel Shutters or in double Panel Shutters as per the size<br />

requirements of the consignee. These shutters shall be supplied in the following<br />

types:<br />

a) Single Panel Shutter (Complete Shutter made out of 1.00 mm thick CR<br />

Sheet)<br />

b) Double Panel Shutter (Complete Shutter made out of 1.00 mm thick<br />

CR Sheet)<br />

c) Single Panel Shutter (Complete Shutter made out of 0.80 mm thick CR<br />

Sheet)<br />

d) Double Panel Shutter (Complete Shutter made out of 0.80 mm thick<br />

CR Sheet)<br />

e) Single Panel Shutter (Rails of Shutter made out of 1.00 mm thick CR<br />

Sheet and remaining Shutter made out of 0.80 mm thick CR Sheet)<br />

f) Double Panel Shutter (Rails of Shutter made out of 1.00 mm thick CR<br />

Sheet and remaining Shutter made out of 0.80 mm thick CR Sheet)<br />

2. Shutters made of Double Sheet:<br />

Double Sheet Shutters shall be made of two CR sheets, front sheet<br />

vertically embossed and back sheet horizontally embossed by means of hydraulic /<br />

mechanical power press and are to be supplied either in Single Panel Shutters or in<br />

double Panel Shutters as per the size requirements of the consignee. These shutters<br />

shall be supplied in the following types:<br />

a) Single Panel Shutter (Complete Shutter made out of 1.00 mm thick CR<br />

Sheet)<br />

b) Double Panel Shutter (Complete Shutter made out of 1.00 mm thick<br />

CR Sheet)<br />

c) Single Panel Shutter (Complete Shutter made out of 0.80 mm thick CR<br />

Sheet)<br />

d) Double Panel Shutter (Complete Shutter made out of 0.80 mm thick<br />

CR Sheet)

General requirements and details of profile & accessories for Shutters made of<br />

Single Sheet / Double Sheet are given in Annexure – I.<br />

Schedule 2. Frames for Pressed Steel Door Shutters.<br />

Pressed Steel Door Frames shall be manufactured from Cold Rolled Steel<br />

Sheet of 1.25 mm thickness and shall be of the following profiles as per the size<br />

requirements of the consignee:<br />

a) Profile ‘A’ - 115 X 50 mm<br />

b) Profile ‘B’ - 100 X 50 mm<br />

c) Profile ‘C’ - 80 X 50 mm<br />

d) Profile ‘D’ - 65 X 40 mm<br />

General requirements and details of profiles & accessories for Pressed Steel<br />

Frames are given in Annexure – II.<br />

Note: Door Frames can also be supplied with Mullion Sections/Fan light as per the<br />

requirements of the consignee. Tenderers may also quote rates for Door Frames with<br />

Mullion Sections/Fanlight. Tenderers shall obtain an approved drawing from the<br />

Indentor before commencing bulk production.<br />

Schedule 3. Frames for Pressed Steel Window Shutters / Ventilators:<br />

Pressed Steel Window Frames shall be manufactured from Cold Rolled Steel<br />

Sheet of 1.25 mm thickness and shall be of the following profiles as per the size<br />

requirements of the consignee:<br />

General Requirements:<br />

a) Profile ‘D’ - 65 X 40 mm<br />

b) Profile ‘E’ - 115 X 40 mm<br />

1. The corners of doorframes shall be welded to form a solid fused welded joint.<br />

2. The process of welding adopted may be flash butt welding or any other<br />

suitable method, which gives desired requirements.<br />

3. The outer frame shall be made from Profile ‘D’ and Profile ‘E’ shall be used<br />

between the two panels.<br />

4. Proper provision shall be made for Tower Bolt.<br />

5. Two Nos. of ISI marked hinges of size 75 mm long shall be fixed on each<br />

vertical side.<br />

6. Three Nos. of fixing lugs made from 18 X 3 X 150 mm M.S. Sheet shall be<br />

welded on each vertical side of the doorframe at equidistance. The lugs shall<br />

be split for 100 mm at the end.<br />

7. Window Frames with Mullion Sections/Fan light as per the requirements of<br />

the consignee can also be supplied. Tenderers may also quote rates for<br />

Window Frames with Mullion Sections/Fanlight. Tenderers shall obtain an<br />

approved drawing from the Indentor before commencing bulk production.<br />

8. Window Frames may also be supplied with window safety bars as desired by<br />

the consignee. The safety bars shall be of 12 mm dia M.S. Round Bars or of<br />

10 mm M.S. Square bars and they shall be fixed horizontally or vertically with<br />

centre to centre distance not more than 100 mm, as per the requirements of the<br />

consignee. Tenderers may quote rates separately for Window Frames with<br />

safety bars / without safety bars

Schedule 4. Pressed Steel Shutters for Windows / Ventilators.<br />

Shutters shall be made of CR Sheet of 0.8 mm thickness. The shutters may be<br />

in two panels / three panels as per the size requirements of the consignee.<br />

1. Maximum distance between two vertical ribs shall be 150<br />

mm centre to centre.<br />

2. Minimum depth of ribs shall be 10 mm and width of rib<br />

between 10 to 15 mm.<br />

3. Width of styles and rails shall be 75 mm.<br />

4. One Tower Bolt of 8 X 100 mm shall be provided.<br />

5. Chrome Plated Steel handles of 100 mm size shall be<br />

riveted / bolted on each shutter.<br />

SCHEDULE – 5<br />

<strong>STEEL</strong> FLUSH DOOR<br />

Providing and fixing in position factory made (on precision machines) Steel Flush<br />

Doors, with brand name duty marked on it or equivalent, complete with frame, shutter<br />

and required hard wares. The frame and shutter are made out of Galvanized Steel<br />

Sheets. The frame is hallow metal pressed profile as per IS: 4351/2003 with up-todate<br />

amendments - size - 80 x 50 mm - 1.25 mm thickness. The Door Shutter, 35 mm<br />

thick, is fabricated from 1.0 mm thick Galvanized Steel Sheets. It is fully flush,<br />

double skin door with lock seam joints at the style edges. Internal reinforcements are<br />

provided at the top, bottom and style edges. A specially designed resin bonded Craft<br />

paper Honey Comb structure is provided as an infill for the door shutter to give<br />

additional rigidity and effective acoustic and thermal insulation.<br />

Providing 6 no. free hanging holdfast 25 x 3 mm - 150 mm long embedded in cement<br />

concrete blocks - 15 x 10 x 10 cm - size of 1:3:6 cement concrete with 20 mm graded<br />

metal of nominal size. The door frame bottom is tied with 2 nos. 25 x 25x 2 mm<br />

angles. The door is to be fitted with 2 nos. Aldrops steel chrome plated - 16 x 250 mm,<br />

2 nos. heavy designs steel handles - 150 mm long, 1 no. tower bolt steel chrome<br />

plated - 10 x 200 mm, 3 nos. ISI marked steel anodized hinges - 125 mm. The door is<br />

to cleaned with suitable three-in-one chemical for degreasing, derusting and<br />

phosphating and applied with special coat of PU rust preventive by dip process in the<br />

lower one fit height (to save door from in long run) and than 2 coats of Zinc Chromate<br />

primer on the complete door.

SCHEDULE – 6 Pressed Steel Doors<br />

Providing and fixing in position factory made (on precision machines) Pressed Steel<br />

Doors, with brand name duty marked on it or equivalent, complete with frame, shutter<br />

and required hard wares. The frame and shutter are made out of CRCA Steel Sheets<br />

confirming to IS: 513/2008 with up-to-date amendments. The frame is hallow metal<br />

pressed profile as per IS: 4351/2003 with up-to-date amendments, size - 80 x 50 mm -<br />

1.25 mm/ 18 gauge thickness. The Shutter is 32 mm thick, fabricated using 2 sheets of<br />

1.00 mm/ 20 gauge. The front sheet with vertical embossing of size 14 x 14 mm: Pitch<br />

800 mm and back sheet with horizontal embossing of size 14 x 14 mm: Pitch 125 mm,<br />

the complete shutter is to be spot welded in embossed grooves to make it a single<br />

piece strong unit.<br />

Providing 6 no. free hanging holdfast 25 x 3 mm - 150 mm long embedded in cement<br />

concrete blocks - 15 x 10 x 10 cms. - size of 1:3:6 cement concrete with 20 mm<br />

graded metal of nominal size. The door frame bottom is tied with 2 nos. 25 x 25x 3<br />

mm angles. The door is to be fitted with 2 nos. Aldrops steel chrome plated - 14 x 250<br />

mm, 2 nos. heavy designs steel handles - 150 mm long, 1 no. tower bolt steel chrome<br />

plated - 10 x 200 mm, 3 nos. ISI marked steel anodized hinges - 125 mm. The door is<br />

to cleaned with suitable three-in-one chemical for degreasing, derusting and<br />

phosphating and applied with special coat of rust preventive by dip process in the<br />

lower 0.5 meter height and than 2 coats of Zinc Chromate primer on the complete<br />

door.

Schedule - 7 Pressed Steel Doors<br />

Providing and fixing in position factory made (on precision machines) Pressed Steel<br />

Doors, with brand name duty marked on it or equivalent, complete with frame, shutter<br />

and required hard wares. The frame and shutter are made out of CRCA Steel Sheets<br />

confirming to IS: 513/2008 with up-to-date amendments. The frame is hallow metal<br />

pressed profile as per IS: 4351/2003 with up-to-date amendments - size - 80 x 50 mm<br />

- 1.25 mm/ 18 gauge thickness. The Shutter is 32 mm thick Pressed steel shutter made<br />

out of CCRCA Steel sheets 1.00 mm/20 gauge having 100 mm wide vertical styles<br />

and strengthening ribs embossing of size 14 x 14 mm at 80 mm C/C Pitch in between<br />

the vertical style (Full width for the shutter including vertical style must be formed<br />

out of single sheet only). Top and bottom rail of 100 mm width and lock rail of 150<br />

mm with to be welded system between the vertical style to make the shutter thickness<br />

of 32 mm.<br />

Providing 6 no. free hanging holdfast 25 x 3 mm - 150 mm long embedded in cement<br />

concrete blocks - 15 x 10 x 10 cm. - size of 1:3:6 cement concrete with 20 mm graded<br />

metal of nominal size. The door frame bottom is tied with 2 nos. 25 x 25x 3 mm<br />

angles. The door is to be fitted with 2 nos. Aldrops steel chrome plated - 14 x 250 mm,<br />

2 nos. heavy designs steel handles - 150 mm long, 1 no. tower bolt steel chrome<br />

plated - 10 x 200 mm, 3 nos. ISI marked steel anodized hinges - 125 mm. The

complete door is to cleaned with suitable three-in-one chemical for degreasing,<br />

derusting and phosphating and applied with special coat of rust preventive by dip<br />

process in the lower 0.5 meter height and then 2 coats of Zinc Chromate primer on the<br />

complete door.<br />

Schedule - 8 PVC Flush Door complete<br />

Providing and fixing in position equivalent PVC Flush Door complete with steel<br />

frame and required hard wares. The frame is made out of prime quality CRCA Steel<br />

Sheets confirming to IS: 513/2008 with up-to-date amendments. The frame is hallow<br />

metal pressed profile as per general specification of IS: 4351/2003 with up-to-date<br />

amendments - size – 65 x 40 mm - 1.25 mm/ 18 gauge thickness. The Shutter is a<br />

single piece PVC panel 22 mm thick with border “A” section 25 mm thickness.<br />

Providing 6 no. free hanging holdfast 25 x 3 mm - 150 mm long embedded in cement<br />

concrete blocks - 15 x 10x10 cm. - size of 1:3:6 cement concrete with 20 mm graded<br />

metal of nominal size. The door frame is also to filled with cement concrete. The door<br />

frame bottom is also to be tied with 2 nos. 25 x 3 mm angles. The door is to be fitted<br />

with 2 nos. Aldrops steel chrome plated - 12 x 250 mm, 2 handles steel CP 150 mm, 3<br />

hinges ISI marked steel anodized 100 mm. The door frame is chemically cleaned with<br />

suitable three-in-one chemical for degreasing, derusting and phosphoting and applied<br />

with a special coat of rust preventive by dip process the lower 0.5 meter height and<br />

than 2 coats of Zinc Chromate primer on the complete frame.

Schedule – 9 Premium Glazed Pressed Steel Window<br />

Providing and fixing in position window complete with shutter and square bar grills.<br />

The frame is to be hallow metal pressed profile as per general specification of IS:<br />

4351/2003 with up-to-date amendments - size - 65 x 40 mm - 1.25 mm/ 18 SWG<br />

thickness. The Shutter is made of tubular profile of size23 x 50 x 1.3 mm having 15<br />

mm vide lips. Steel beading of size 10 x 10 mm with necessary screws to be provided<br />

to hold the glass in position. The safety gill is to be fabricated using 10 mm square<br />

bars - 10 mm centre to centre. The window frame is to be punched - square holes - to<br />

accommodate bars and they are welded at inside of the frame for further strengthening.<br />

Providing minimum 4 nos. free hanging holds fasts - 25 x 3 mm - 150 long embedded<br />

in cement concrete blocks - 15 x 10 x 10 mm size of 1:3:6 cement concrete with 20<br />

mm graded metal of nominal size. The window frame is also to be filled with cement<br />

concrete. The window shutter is to be fitted with 2 heavy box hinges 70 mm on each<br />

shutter and 250 mm long 12 SWG Oxidized steel stay rods on each shutter and also<br />

the steel chrome plated handles 125 mm and tower bolts 10 x 100 mm to be fitted on<br />

it.<br />

The complete window is chemically treated with 3-in-1 chemical and the applied 2<br />

coats of Zinc chromate primer and oven baked.

Schedule – 10 Standard Pressed Steel Window<br />

Providing and fixing in position complete with frame, shutter and square bar grills.<br />

The frame and shutter panels are made of prime quality CRCA steel sheets<br />

confirming to IS: 513/2008 with up-to-date amendments. The frame is to be hallow<br />

metal pressed profile as per general specification of IS: 4351/2003 with up-to-date<br />

amendments, size 65 x 40 mm - 1.25 mm/ 18 gauge thickness. The shutter is to be<br />

fabricated using 7FD and T2 hot rolled section as per IS: 7452/1990 with up-to-date<br />

amendments with spot-welded 0.8 mm thick CRCA steel panels having vertical<br />

embossed ribs of size 30 x 6 mm for strengthening safety grill is to be fabricated using<br />

10 mm square bars - 100 mm C/C in brick design, with vertical pieces at 200 mm<br />

spacing. The window frame is to be punched - square holes - to accommodate<br />

horizontal bars and they should be welded at inside of the frame for strength purpose.<br />

Provide minimum 4 nos free hanging holdfast - 25 x 3 mm - 150 mm long embedded<br />

in cement concrete blocks - 15 x 10 x 10 cm - size of 1:3:6 cement concrete with 20<br />

mm graded metal of nominal size. The window frame is also to be fitted with cement<br />

concrete. The window is to be fitted with 2 boxes hinges - 70 mm on each shutter, and<br />

250 mm long - 12 long oxidized steel stay rods on each shutter and also the standard<br />

design handles to be fitted. The complete window is treated with three-in-one<br />

chemical and than applied 2 coats of Zinc Chromate primer and oven backed.

SCHEDULE – 11<br />

Standard Glazed Shutter Windows<br />

Providing and fixing in position equivalent pressed steel windows, complete with<br />

frame, shutter and square bar grills. The frame is made of CRCA steel sheets<br />

confirming to IS: 513/2008 with up-to-date amendments. The frame is to be hallow<br />

metal pressed profile as per general specification of IS: 4351/2003 with up-to-date<br />

amendments, size 65 x 40 mm - 1.25 mm/ 18 gauge thickness. The shutter frame is to<br />

be fabricated using 7FD and T2 hot rolled sections as per IS: 7452/1990. Safety grill<br />

is to be fabricated using 10 mm square bars - 100 mm C/C in brick design, with<br />

vertical pieces at 200 mm spacing. The window frame is to be punched - square holes<br />

- to accommodate horizontal bars and they should be welded at inside of the frame for<br />

strength purpose. Provide minimum 4 nos. free hanging holdfast - 25 x 3 mm - 150<br />

mm long embedded in cement concrete blocks - 15 x 10 x 10 cm - size of 1:3:6<br />

cement concrete with 20 mm graded metal of nominal size. The window frame is also<br />

to be fitted with cement concrete. The window is to be fitted with 2 boxes hinges - 70<br />

mm on each shutter, and 250 mm long - 12 long oxidized steel stay rods on each<br />

shutter and also the standard design handles to be fitted. The complete window is<br />

treated with three-in-one chemical and than applied 2 coats of Zinc Chromate primer.

SCHEDULE – 12<br />

Pressed Steel Ventilators<br />

Providing and fixing in position equivalent - complete with frame, luvers and 10 mm<br />

square bars in case of glass luyered ventilators. The frame is to be made up of 50 x 30<br />

mm pressed box - section 1.25 mm/ 18 SWG steel sheets. The Luvers of pressed<br />

design made up of 1.00 mm/ 20 SWG CRCA steel sheets. In case of glass luvers<br />

ventilators 10 mm square bar - 100 mm centre to centre to be provided. The complete<br />

ventilator is chemically treated with 3-in-1 chemical and then applied 2 coats of Zinc<br />

Chromate primer and oven backed.<br />

Schedule – 13 Cub Board Shutter<br />

Providing and fixing in position shutter with frame made prime quality CRCA steel<br />

sheets. Frame out of 1.25 mm thick sheets, size 40 x 40 mm, shutter out of 0.90 mm<br />

thick sheets, with two hinges on each shutter - IS marked - 75 mm in case of frame<br />

height upto 1.5 meters and 3 hinges for bigger sizes. The hinges are screwed on 2 mm<br />

thick plate channel base welded to the frame. The door is with three way looking<br />

system includes locking bar of 10 mm diameter of required length and the middle<br />

locking pad operated by the chrome plate handle, provided with 6 lever GODREJ<br />

make cup-board lock provided with 25 x 3 mm - 200 mm long - 6 nos. hold fasts. The

complete cup-board shutter with frame is chemically treated with 3-in-1 chemical and<br />

then applied 2 coats of Zinc Chromate primer and the 1 coats of “GOODLASS<br />

NEROLAC - TA Grey” oil paint duty oven backed.<br />

Schedule – 14 Steel Door Frame<br />

Providing and fixing in position factory made (on precision machines) with brand<br />

name duty marked on it. The profile is made from prime quality CRCA steel sheets<br />

confirming to IS: 513/2008 with up-to-date amendments and as per general<br />

specifications of IS: 4351/2003 with up-to-date amendments. The frame is to be<br />

provided with 6 numbers free handing hold fasts 25 x 3 mm - 150 mm long embedded<br />

in cement concrete blocks - 15 x 10 x 10 cm - size of 1:3:6 cement concrete with 20<br />

mm graded metal of nominal size. The door frame is also to be fitted with cement<br />

concrete. The door frame bottom is tied with 2 numbers - 25 x 25 x 3 mm steel angles,<br />

provided with 3 nos. IS marked steel anodized hinges - 125 mm long, having suitable<br />

position for aldrops and tower bolts. The complete door frame is chemically treated<br />

with 3-in-1 chemical and then 2 coats of zinc chromate primer are applied followed<br />

by oven backing. The two ft. lower height of the frame duly painted with anti<br />

corrosive paint.

Schedule – 15<br />

PREMIUM <strong>STEEL</strong> SHUTTER WINDOW<br />

Complete with frame, shutters and square bar grill. The frame and shutters are made<br />

of prime quality of CRCA steel sheets conforming to IS: 513/2008 with up-to-date<br />

amendments. The frame is to be hollow metal pressed profile as per general<br />

specifications of IS: 4351/2003 with up-to-date amendments, size: 80x50 mm, 1.25<br />

mm/ 18 gauge thickness.<br />

The shutters are fabricated like door shutters, 32mm thick. Pressed steel window<br />

shutters having 80 mm wide vertical styles and strengthening ribs embossed of<br />

14x14mm at 60 mm C/C pitch in between the vertical styles (full width of the shutter<br />

including vertical styles must be formed out of single sheet only). Top and bottom rail<br />

of 80 mm width. Welded to the shutter between the vertical styles (using MIG<br />

welding only).<br />

The safety grill is to be fabricated using 10mm square bars- 100 mm center to center.<br />

The window frame is to be punched square holes to accommodate bars and they are<br />

welded at inside of the frame for strength purpose. Provide minimum 4 Nos free<br />

hanging hold fasts – 25x3 mm-150 mm long embedded in cement concrete blocks –<br />

15x10x10 mm size of 1:3:6 cement concrete with 20mm graded metal of nominal size.<br />

The window frame is also to be filled with cement concrete. The window shutter is to<br />

be fitted with 2 Nos. IS marked hinges 100 mm on each shutter and 250 mm long 12<br />

SWG oxidized steel stay rods on each shutter and also the steel chrome plated handles<br />

125 mm and Tower bolts 10x100 mm to be fitted on it.<br />

Technical requirements for Pressed Steel Doors & Windows<br />

1. Mild Steel Sheet, Round Bars, Square Bars and other sections used in the<br />

fabrication shall conform to Grade Fe 410W A of IS: 2062 / 2006 with up-todate<br />

amendments.<br />

2. CR-sheet used in the fabrication shall conform to IS: 513 /2008 with up-todate<br />

amendments.<br />

3. Pressed Steel Shutters / Frames for Door / Windows shall be de-rusted, degreased<br />

& painted with one coat of metal primer.<br />

4. Tolerances: Rolling and Cutting Tolerances shall conform to IS: 1852 / 1985<br />

with up-to-date amendments.<br />

5. Visual Examination: The finished products shall be reasonably free from<br />

surface flaws, laminations, rough / jiggered and imperfect edges and other<br />

harmful defects.<br />

6. Marking: The stores shall be marked for the identity of the manufacturer.<br />

7. Test Certificate: At the time of Inspection, the manufacturer shall produce<br />

Test Certificate for the steel used.

BOTTOM<br />

BOTTOM RAIL<br />

STYLES<br />

CR SHEET WITH<br />

VERTICALLY<br />

EMBOSSED RIBS<br />

<strong>STEEL</strong> DOOR SHUTTER<br />

10 10 Y<br />

TOP RAIL<br />

LOCK RAIL<br />

BOTTOM RAIL<br />

ANNEXURE – I<br />

STYLES<br />

GENERAL REQUIREMENTS:<br />

1. Maximum distance between<br />

two vertically embossed ribs<br />

shall be 95 mm centre to centre<br />

2. Minimum depth of ribs shall<br />

be10 mm & width of ribs shall<br />

be between 10 to 15 mm.<br />

3. Minimum width of Styles shall<br />

be 75 mm.<br />

4. Minimum width of Top &<br />

Bottom Rails shall be 90 mm.<br />

5. Minimum width of Lock Rail<br />

shall be 150 mm.<br />

6. Bottom Rail shall be fabricated<br />

in such a manner that water<br />

could not get accumulated in it.<br />

Straight front face width of<br />

Bottom Rail shall be same as<br />

mentioned above, i.e., 90 mm<br />

minimum. Holes shall be<br />

provided at bottom of shutter to<br />

drain out water.<br />

ACCESSORIES:<br />

1. One chrome-plated aldrop of<br />

16x300 mm shall be<br />

riveted/bolted on one side and<br />

one chrome-plated latch shall<br />

be fitted on another side.<br />

2. One tower bolt of 8 x 200 mm<br />

shall be provided at upper side.<br />

3. Chrome plated steel handles of<br />

150 mm size shall be<br />

riveted/bolted on both sides of<br />

shutter.<br />

X<br />

PROFILE OF STYLES,<br />

TOP RAIL, BOTTOM<br />

RAIL & LOCK RAIL.<br />

DETAILS OF <strong>SHUTTERS</strong> <strong>FOR</strong> <strong>PRESSED</strong><br />

<strong>STEEL</strong> DOOR FRAMES & ITS PROFILES<br />

CHHATTISGARH STATE INDUSTRIAL<br />

DEVELOPMENT CORPORATION LTD.<br />

PROFILE X<br />

(MIN)<br />

Y<br />

(MIN)<br />

STYLES 75 25<br />

TOP RAIL 90 25<br />

BOTTOM RAIL 90 25<br />

LOCK RAIL 150 25<br />

ALL DIMENSIONS IN MILLIMETERS<br />

NOT TO SCALE

ANNEXURE – II.<br />

<strong>PRESSED</strong> <strong>STEEL</strong> DOOR FRAME<br />

GENERAL REQUIREMENTS:<br />

1. The corners of door frames shall be<br />

welded to form a solid fused<br />

welded joint.<br />

2. The process of welding adopted<br />

may be flash butt welding or any<br />

other suitable method which gives<br />

desired requirements.<br />

3. All door frames shall be made of<br />

three sides (two vertical sides and<br />

one horizontal at top.) One 10 mm<br />

dia round bar shall be welded at<br />

bottom to tie up vertical sides to<br />

keep in exact rectangular shapes.<br />

4. Proper provision for bolting/locking<br />

the shutters shall be provided in top<br />

side of door frame.<br />

5. Proper provision shall be made for<br />

tower bolt and aldrop in the frame.<br />

6. 4 Nos. of ISI marked hinges of size<br />

125x65x2.12 mm shall be fixed for<br />

single panel door on right side or<br />

left side as per the consignee’s<br />

requirement and 8 Nos. of ISI<br />

marked hinges shall be provided for<br />

double panel door shutter.<br />

7. Three Nos. of fixing lugs shall be<br />

welded on each vertical side of the<br />

door frame at equidistance. The<br />

lugs shall be made from 3.0 mm<br />

thick M.S.Sheet of 18 mm width &<br />

175 mm long, bent for 25 mm at<br />

one end and split for 100 mm at the<br />

other end.<br />

PROFILE ‘A’<br />

PROFILE X Y<br />

A 115+/-2 50+-2<br />

B 100+/-2 50+/-2<br />

C 80+/-2 50+/-2<br />

D 65+/-2 40+/-2<br />

PROFIE ‘B’/‘C’/‘D’<br />

ALL DIMENSIONS IN MILLIMETERS<br />

NOT TO SCALE<br />

DETAILS OF <strong>PRESSED</strong> <strong>STEEL</strong> DOOR<br />

FRAMES & ITS PROFILES<br />

CHHATTISGARH STATE INDUSTRIAL<br />

DEVELOPMENT CORPORATION LTD.

RATE ANNEXURE <strong>FOR</strong><br />

<strong>PRESSED</strong> <strong>STEEL</strong> <strong>SHUTTERS</strong> AND FRAMES <strong>FOR</strong> DOORS & WINDOWS .<br />

1. Rate of excise duty ……………………………..% extra<br />

2. Rate of S.T. ……………………………...% extra<br />

4. Delivery Period (for supply order) ……………………………..<br />

5 Whether registered with DGS&D / NSIC / DTIC<br />

6. Whether holding BIS / ISO Certificate (as per specification) ………………<br />

7. Whether holding T.T.C. (Yes / No)<br />

a). Name of Laboratory<br />

b). Date of Issue<br />

c). Validity<br />

8. Rates shall be quoted on F.O.R. Destination basis, excluding Duties & Taxes.<br />

Sub<br />

Item Description<br />

Item .<br />

Code<br />

Schedule 1<br />

1 Single Panel Shutter (1.0 mm ) Single Sheet<br />

2 Double Panel Shutter (1.0 mm ) Single Sheet<br />

3 Single Panel Shutter (0.8 mm) Single Sheet<br />

4 Double Panel Shutter (0.8 mm) Single Sheet<br />

5 Single Panel Shutter (Rails 1mm, Shutter 0.8 mm ) Single Sheet<br />

6 Double Panel Shutter (Rails 1mm, Shutter 0.8 mm ) Single Sheet<br />

7 Single Panel Shutter (1.0mm ) Double Sheet<br />

8 Double Panel Shutter (1.0mm ) Double Sheet<br />

9 Single Panel Shutter (0.8 mm) Double Sheet<br />

10 Double Panel Shutter (0.8 mm) Double Sheet<br />

Schedule 2.<br />

11 Profile ‘A’ - 115 X 50 mm<br />

12 Profile ‘B’ - 100 X 50 mm<br />

13 Profile ‘C’ - 80 X 50 mm<br />

14 Profile ‘D’ - 65 X 40 mm<br />

15 Profile ‘A’ - 115 X 50 mm (With Mullion Section )<br />

16 Profile ‘B’ - 100 X 50 mm (With Mullion Section )<br />

17 Profile ‘C’ - 80 X 50 mm (With Mullion Section )<br />

18 Profile ‘D’ - 65 X 40 mm (With Mullion Section )<br />

Schedule 3.<br />

19 Frames for Window Shutters -Single<br />

20 Frames for Window Shutters - Double<br />

21 Frames for Window Shutters - Triple<br />

22 Frames for Window Shutters -Single (With Mullion Section )<br />

23 Frames for Window Shutters - Double (With Mullion Section )<br />

24 Frames for Window Shutters - Triple (With Mullion Section )<br />

25 Frames for Window Shutters -Single (With Safety bars )<br />

26 Frames for Window Shutters - Double (With Safety bars )<br />

27 Frames for Window Shutters - Triple (With Safety bars )<br />

28 Frames for Window Shutters -Single (With Mullion Section ) (With<br />

Safety bars )<br />

29 Frames for Window Shutters - Double (With Mullion Section ) (With<br />

Safety bars )<br />

30 Frames for Window Shutters - Triple (With Mullion Section ) (With<br />

Safety bars )<br />

Schedule 4<br />

31 Pressed Steel Shutters for window - Double<br />

32 Pressed Steel Shutters for window - Triple<br />

Rates on <strong>FOR</strong> Destination<br />

Basis Excluding ED & ST<br />

in Rs.

Schedule 5<br />

33 Steel Flush Door<br />

Schedule 6<br />

34 Pressed Steel Doors<br />

Schedule 7<br />

35 Pressed Steel Doors<br />

Schedule 8<br />

36 PVC Flush Door Complete<br />

Schedule 9<br />

37 Premium Glazed Pressed Steel Window<br />

Schedule 10<br />

38 Standard Pressed Steel Window<br />

Schedule 11<br />

39 Standard Glazed Shutter Windows<br />

Schedule 12<br />

40 Pressed Steel Ventilators<br />

Schedule 13<br />

41 Cub Board Shutter<br />

Schedule 14<br />

42 Steel Door Frame<br />

Schedule 15<br />

43 Premium Steel Shutter Window